Needle-bar-rotating pattern sewing machine

A pattern sewing machine and needle bar rotation technology, applied in the field of sewing machines, can solve the problems of affecting the service life of the product, high motor power, occupying space resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

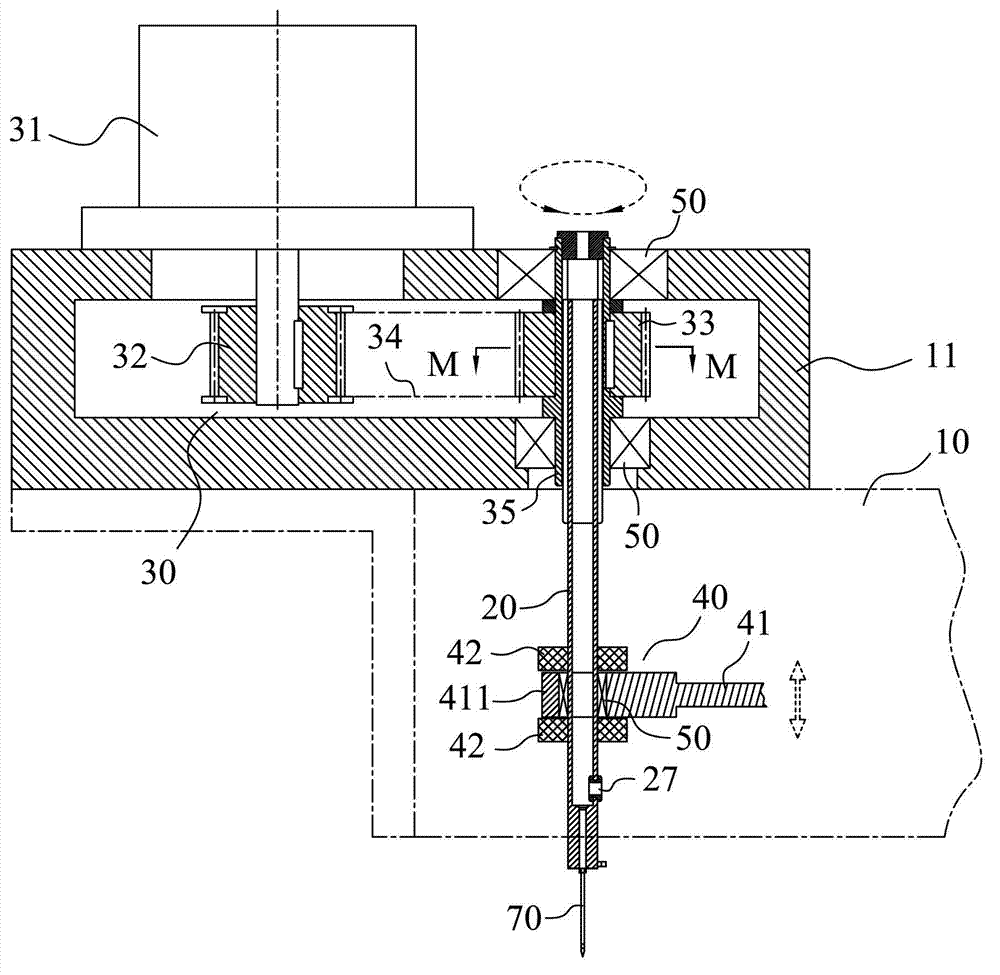

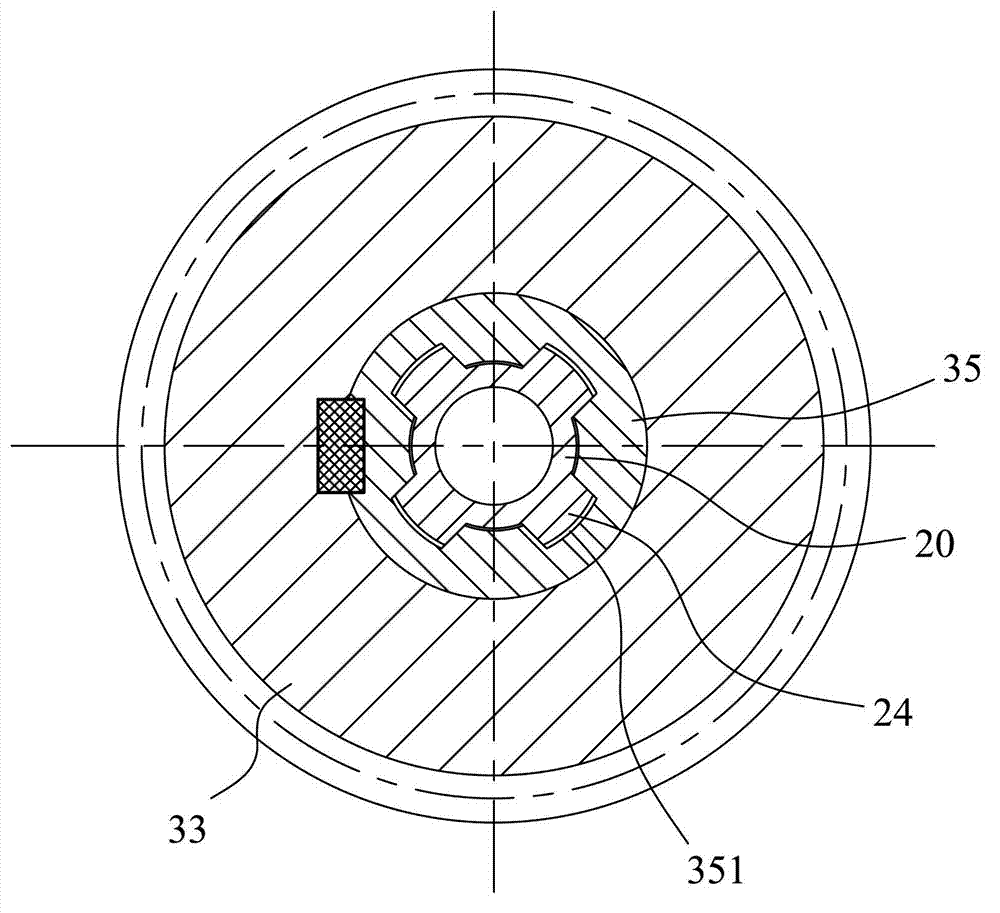

[0041] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of one of the preferred embodiments of the present invention, including machine head housing 10, a fixed seat 11 is installed on the machine head housing, needle bar 20, needle bar rotating mechanism 30 are installed in the fixed seat 11 And needle bar up and down movement mechanism 40. Other mechanisms of the sewing machine can adopt existing known technologies, so details are not repeated here.

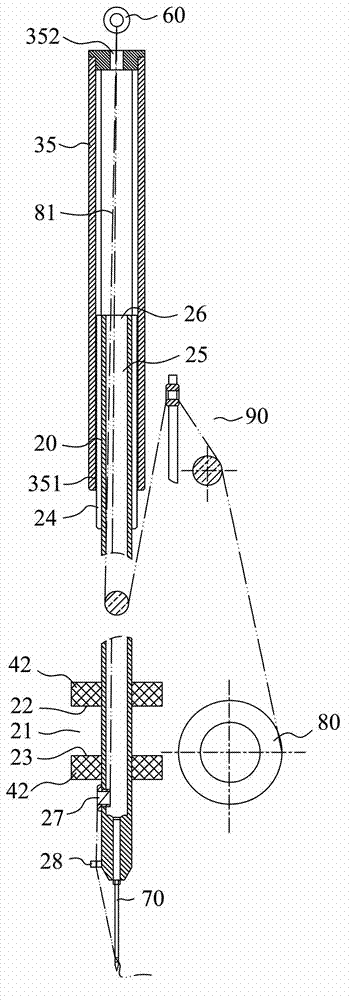

[0042] Wherein, needle bar 20, this needle bar 20 is hollowly formed with axial thread hole 25, and the top end of this axial thread hole 25 is provided with axial line inlet 26, and the top of thread inlet 26 is provided with wire eye 60, and axial The lower end of the thread hole 25 is provided with a laterally open wire outlet 27 and a wire eye 28, the wire eye 28 is located below the lateral wire outlet 27, and the sewing needle 70 is also installed on the lower end of the needle bar 20, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com