Sewing machine

A technology for sewing machines and sewing needles, which is applied to sewing machine components, needle holders for sewing machines, sewing equipment, etc., can solve problems such as troublesome work and inability to improve sewing efficiency, and achieves the improvement of sewing efficiency and sewing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

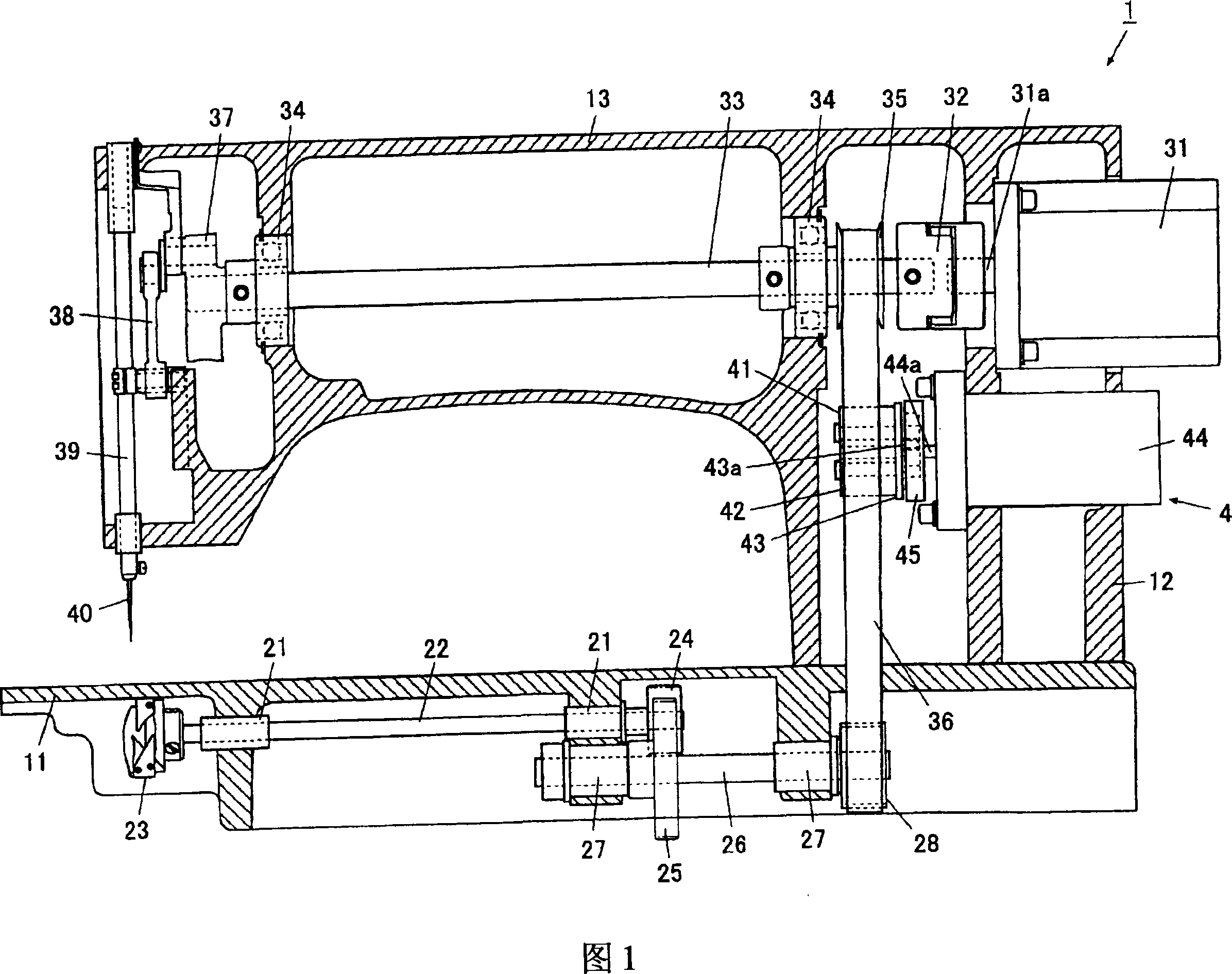

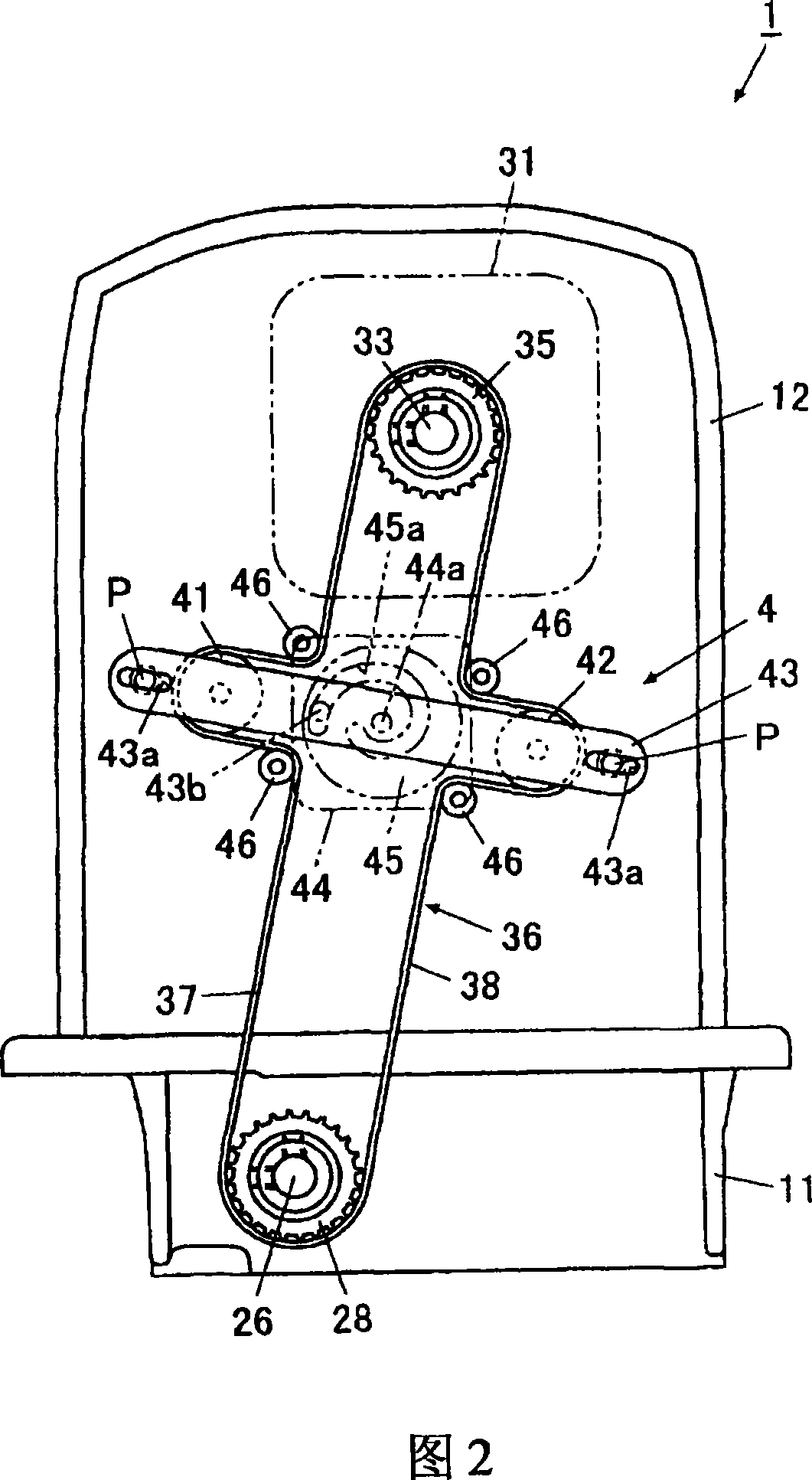

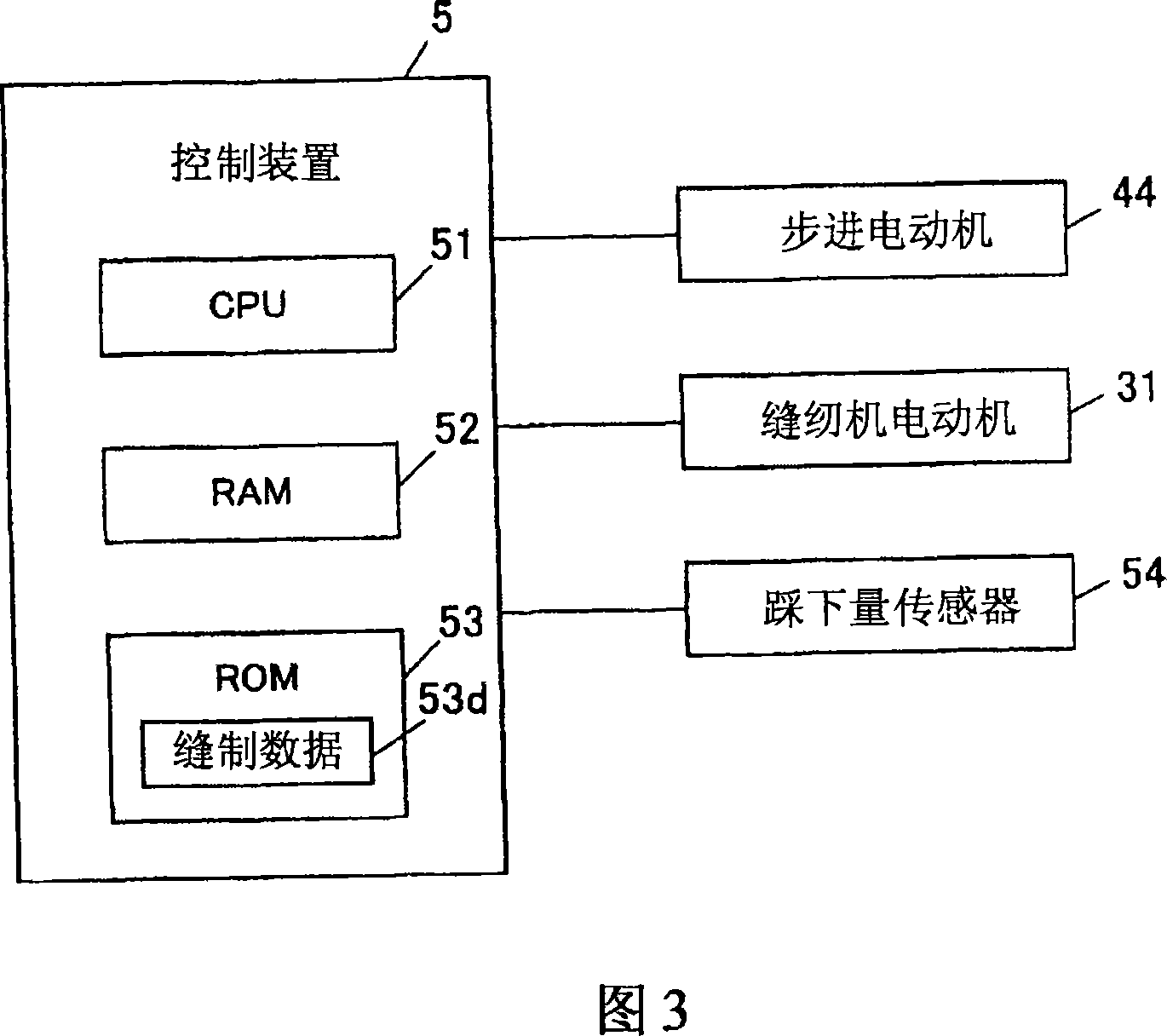

[0086] (Structure of Sewing Machine)

[0087] As shown in Fig. 5 and Fig. 6, the sewing machine 10 is provided with a looping device to replace the kettle for winding the lower thread on the upper thread. The sewing machine 10 has a base portion 15 , a body portion 16 standing upward from the rear end of the base portion 15 , and an arm portion 17 extending forward from an upper portion of the body portion 16 .

[0088] A sewing machine motor 61 is provided in the base portion 15 , and a lower shaft 62 is connected to an output shaft of the sewing machine motor 61 . The lower shaft 62 is provided with a spreader drive cam 63 close to the needle thread and a looper drive cam 64 for driving the looper. Near one end of the lower shaft 62 , the lower shaft 62 is rotatably supported by the bearing 60 , and a lower pulley 65 is provided at one end of the lower shaft 62 .

[0089] A spreader drive lever 80 is provided on the spreader drive cam 63 so that power can be transmitted. ...

Embodiment approach 3

[0123] A sewing machine 20 in Embodiment 3 is a sewing machine in which the length ratio variable mechanism 4 of the sewing machine 1 in Embodiment 1 is changed to a length ratio variable mechanism 8 . Therefore, in Embodiment 3, the length ratio variable mechanism 8 having a different structure will be described, and other common structures will be given the same reference numerals, and description will be omitted.

[0124] (Structure of Sewing Machine)

[0125] As shown in Figure 9, the length ratio variable mechanism 8 provided on the sewing machine 20 is arranged below the sewing machine motor 31, between the upper pulley 35 and the lower pulley 28, and changes the connection between the upper pulley 35 and the lower pulley 28. The length ratio of the bridging parts 37, 38.

[0126] As shown in Fig. 9 and Fig. 10, the length ratio variable mechanism 8 has: abutment parts 121, 122, which are in the position of pre-tensioning the two erection parts 37, 38, and the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com