Auxiliary lifting mechanism of presser foot of computerized embroidery machine

An embroidery machine and presser foot technology, which is applied to the embroidery machine mechanism, embroidery machine, cloth press mechanism and other directions, can solve the problems of large rotation noise of the cam mechanism, poor synchronization of movement coordination, inconvenient assembly and maintenance, etc., and achieves low production cost. , good stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

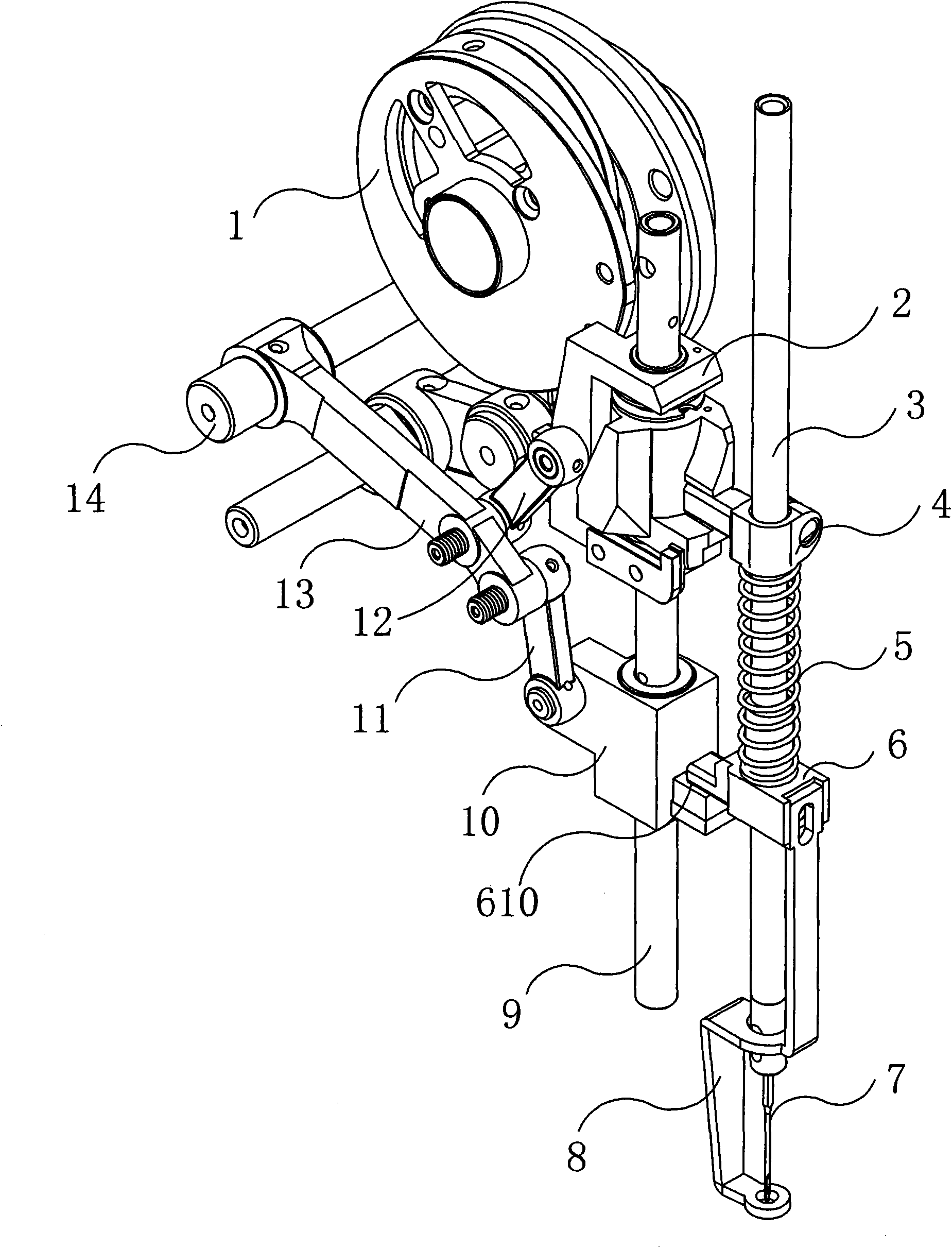

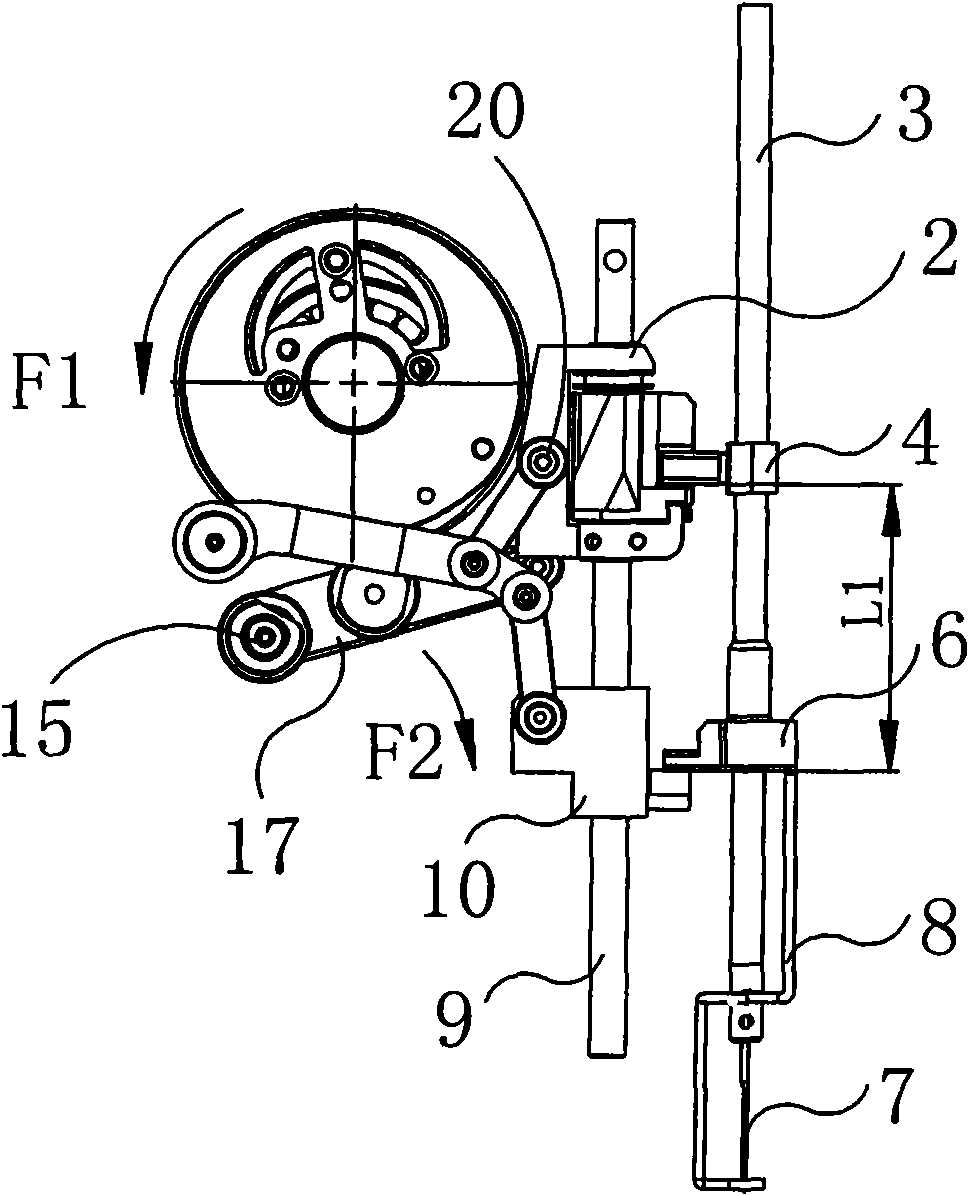

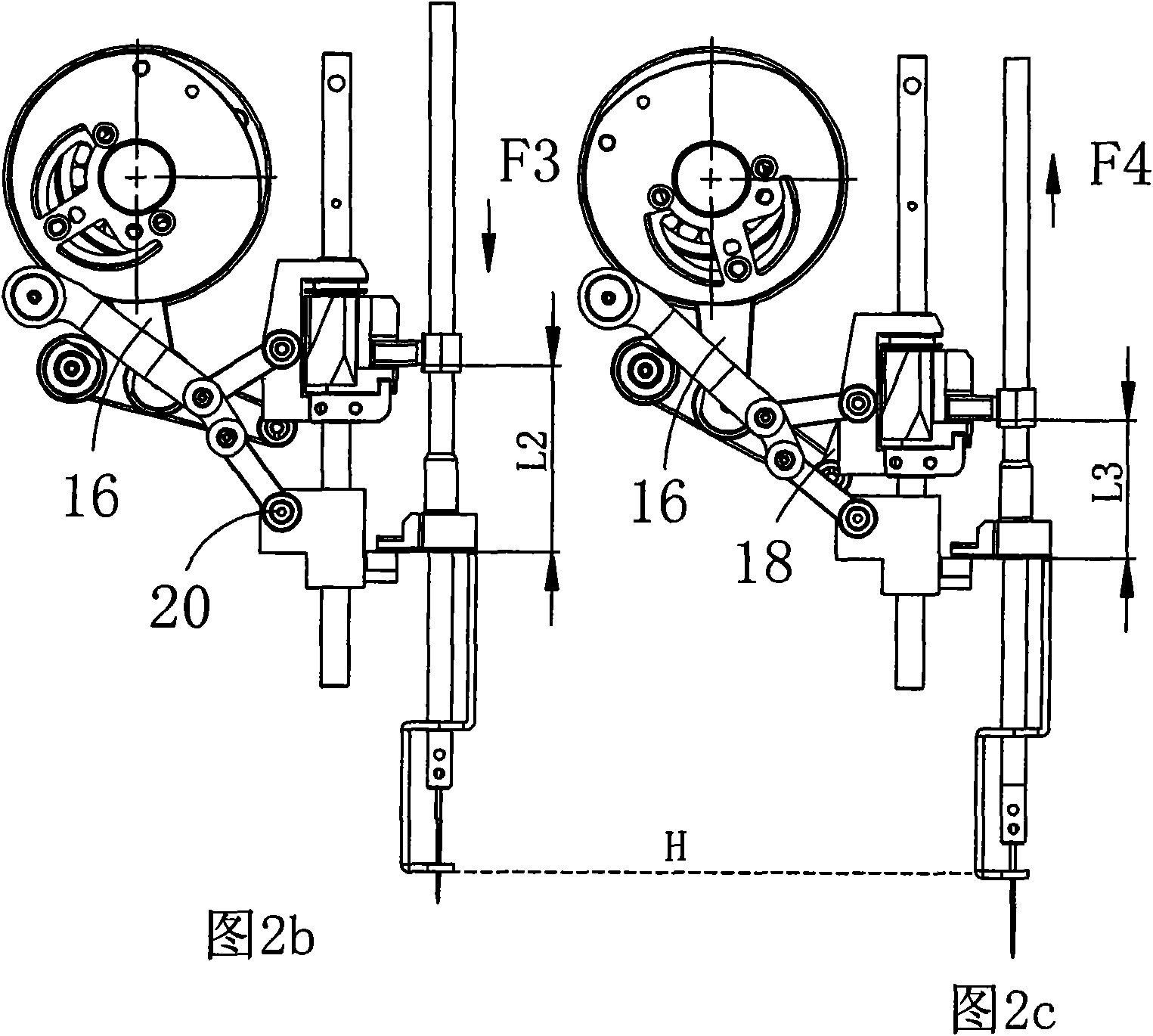

[0023] Now in conjunction with accompanying drawing, structure of the present invention, motion principle and use are further described. Such as Figure 1~6 As shown, the presser foot auxiliary lifting mechanism (or E mechanism) is mainly composed of three-hole connecting rod A13, two-hole connecting rod B12, two-hole connecting rod C11 and related pin shaft 19 to form a "Y"-shaped connecting rod mechanism. The other parts belong to the relevant parts of the computerized embroidery machine. Such as figure 1 As shown, the relevant component structures are as follows:

[0024] One end of the needle bar 3 is provided with a needle 7 and a presser foot 8, as well as a driving block 4 and a transmission block 6. The guide bar 9 is provided with a slider A2 and a slider B10. A spring 5 is arranged between the driving block and the transmission block, and the driving block is fixed. on the needle bar. The slider A is connected to one side of the driving block through a groove, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com