Electromagnetic induction heating type steel-plastic composite pipeline full fusion welding structure

An electromagnetic induction heating, steel-plastic composite pipe technology, applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc., can solve the problems of large welding gap and leakage, achieve good fluid tightness, ensure electromagnetic The effect of weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

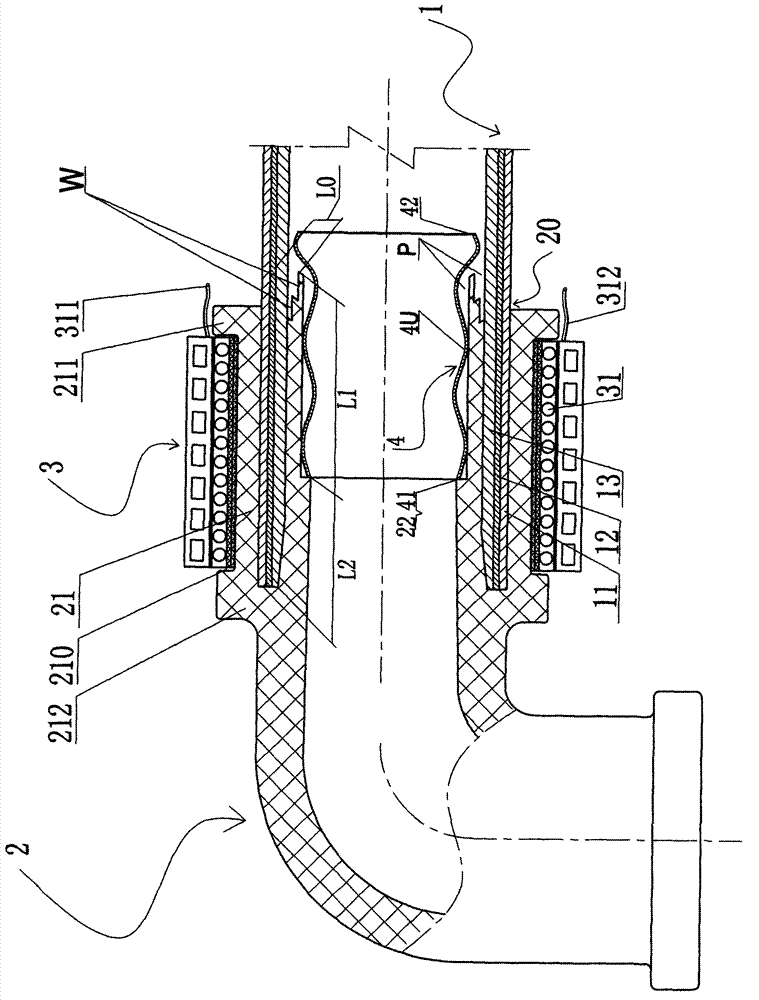

[0014] Such as figure 1 As shown, the electromagnetic induction heating type steel-plastic composite pipe has a fully welded structure, including a liner 4 arranged on the inner ring, a pure plastic pipe fitting 2, and a steel-plastic pipe with an outer plastic pipe layer 11, a middle steel pipe layer 12, and an inner plastic pipe layer 13. Composite pipe 1.

[0015] The pure plastic pipe fitting 2 has at least one inner ring portion, an outer ring portion 21 and an annular socket cavity 20 formed between the inner ring portion and the outer ring portion 21 (shown in the figure is that the pure plastic pipe fitting 2 is a two-way Pure plastic pipe fittings, of course also can be three-way pure plastic pipe fittings, four-way pure plastic pipe fittings, etc.), the steel-plastic composite pipe 1 is inserted in the annular socket cavity 20, the inner ring part has the inner ring body section L2, the inner ring expansion The diameter section L1 and the transition step 22 formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com