PE pipe and preparation method thereof

A pipe and pipe layer technology, applied in the field of PE pipe and its preparation, can solve the problems of unsatisfactory mechanical strength and performance, and achieve the effects of improving stiffness, improving product quality, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

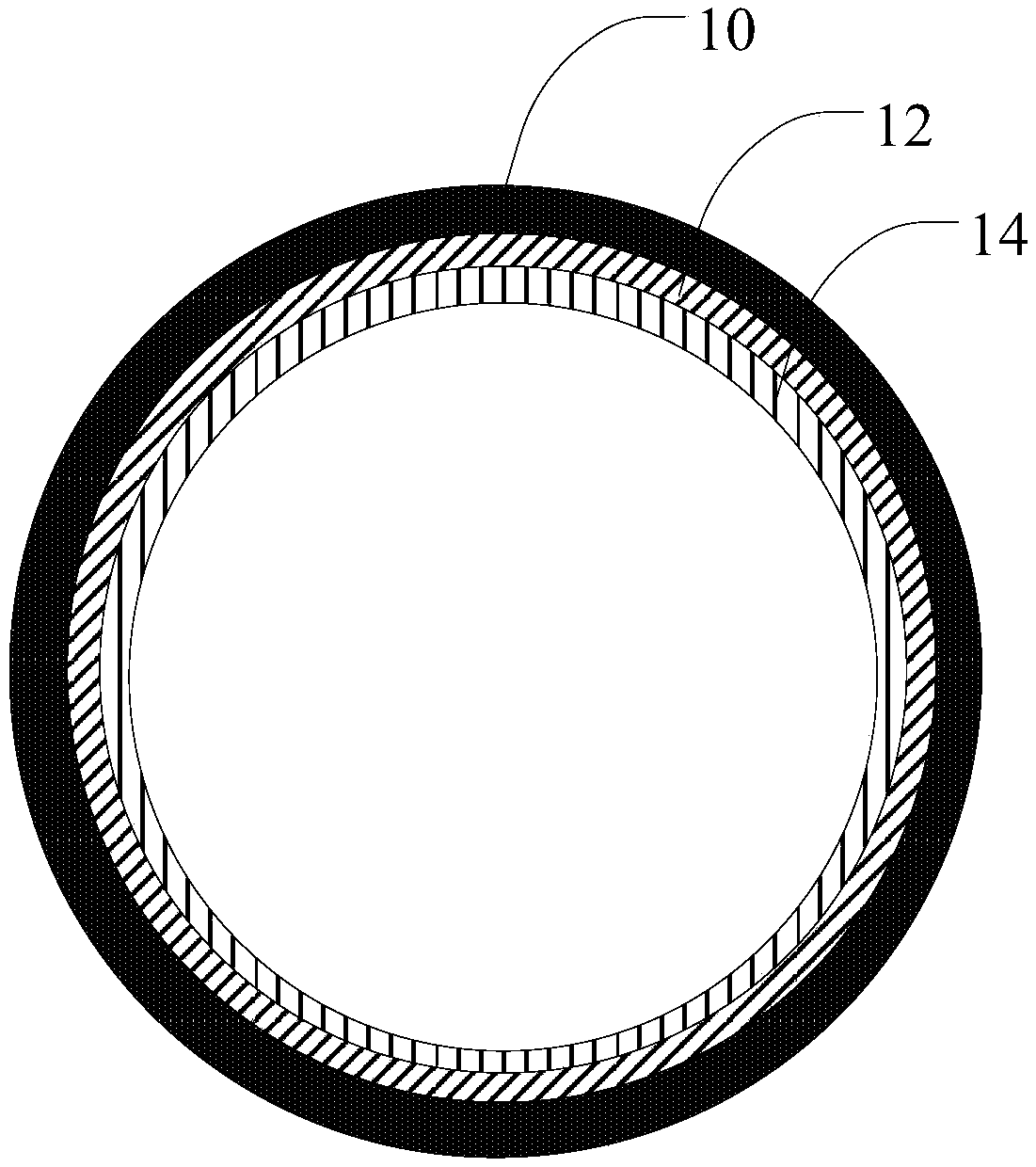

[0062] In some implementations of the embodiments of the present invention, the preparation method of the PE pipe includes the following steps:

[0063] Step S100. Prepare the first raw material for preparing the antibacterial inner tube layer 10, the second raw material for preparing the fiber reinforced layer 12 and the third raw material for preparing the fire-resistant outer tube layer 14;

[0064] Step S200. Sending the first raw material, the second raw material and the third raw material obtained through the step S100 into extrusion equipment for melt kneading and extrusion;

[0065] Step S300. Guide the first raw material, the second raw material and the third raw material in the molten state obtained through the step S200 into a multi-layer co-extrusion die through a split feeding device, and the Co-compression extrusion in a multi-layer co-extrusion die;

[0066] Step S400. The compressed extruded material obtained through the step S300 is first subjected to primary...

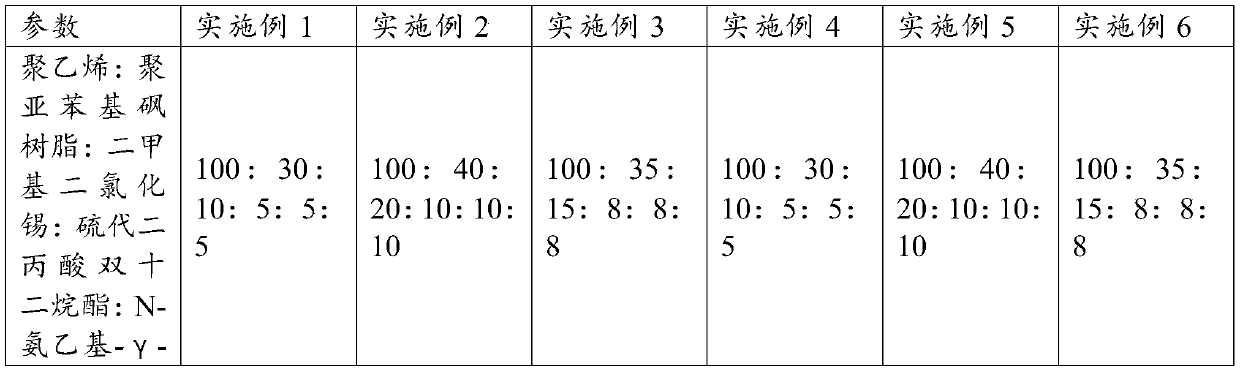

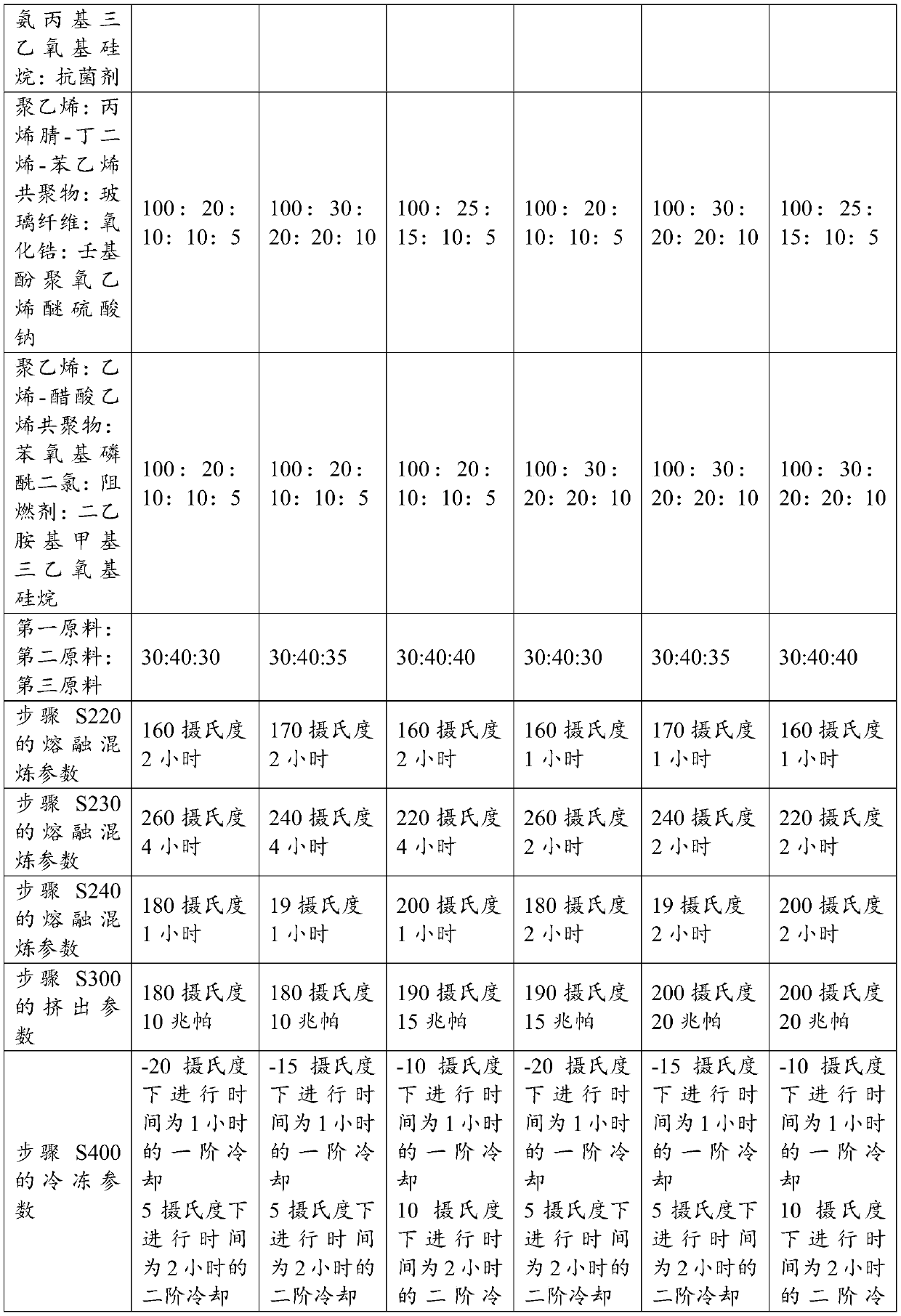

Embodiment 1 to Embodiment 6

[0105] This embodiment provides some PE pipes. The raw material composition and process parameters of the PE pipe in this embodiment are shown in Table 1. The PE pipe material of the present embodiment is prepared through the following steps:

[0106] Step S110. Polyethylene, polyphenylene sulfone resin, dimethyl tin dichloride, didodecyl thiodipropionate, N-aminoethyl-γ-aminopropyltriethoxysilane and The antibacterial agent is mixed evenly to obtain the first raw material;

[0107] Step S120. uniformly mixing polyethylene, acrylonitrile-butadiene-styrene copolymer, glass fiber, zirconia and sodium nonylphenol polyoxyethylene ether sulfate to obtain a second raw material;

[0108] Step S130. Mix polyethylene, ethylene-vinyl acetate copolymer, phenoxyphosphoryl dichloride, flame retardant and diethylaminomethyltriethoxysilane evenly to obtain a third raw material.

[0109] Step S210. Weighing the first raw material, the second raw material and the third raw material respecti...

Embodiment 7

[0120] This embodiment provides a preparation method for the antibacterial agent used to prepare the PE pipes of Embodiment 1 to Embodiment 6, specifically including:

[0121] Step S1102. According to the mass ratio of strontium oxide: zinc oxide: sodium nonylphenol polyoxyethylene ether sulfate: water = 2:5:0.2:100, add strontium oxide, zinc oxide and nonylphenol polyoxyethylene ether sulfuric acid to the water Sodium, and ultrasonically dispersed for 20 minutes at a temperature of 60 degrees Celsius to obtain the first slurry;

[0122] Step S1104. Add phosphoric acid solution dropwise to the first slurry obtained in step S1102 to adjust the pH value to 3 to 4, then add phosphoric acid solution and potassium metaaluminate solution dropwise to the first slurry at the same time Until the pH value is 5 to 6, stir for 20 minutes, age for 1 hour, and then dropwise add acetic acid solution and potassium metaaluminate solution to the first slurry until the pH value is 8 to 9, stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com