Impedance sensor of split phase ratio of two phase flows, and method for optimizing structural parameter

A sensor and phase separation technology, applied in the fields of instruments, material resistance, electrical digital data processing, etc., can solve the problems of limiting the measurement range and accuracy, poor uniformity of the sensitive field in the measurement area, saturation of the resistance/conductance measurement circuit, etc. Low cost, widened measuring range, fast optimization of structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

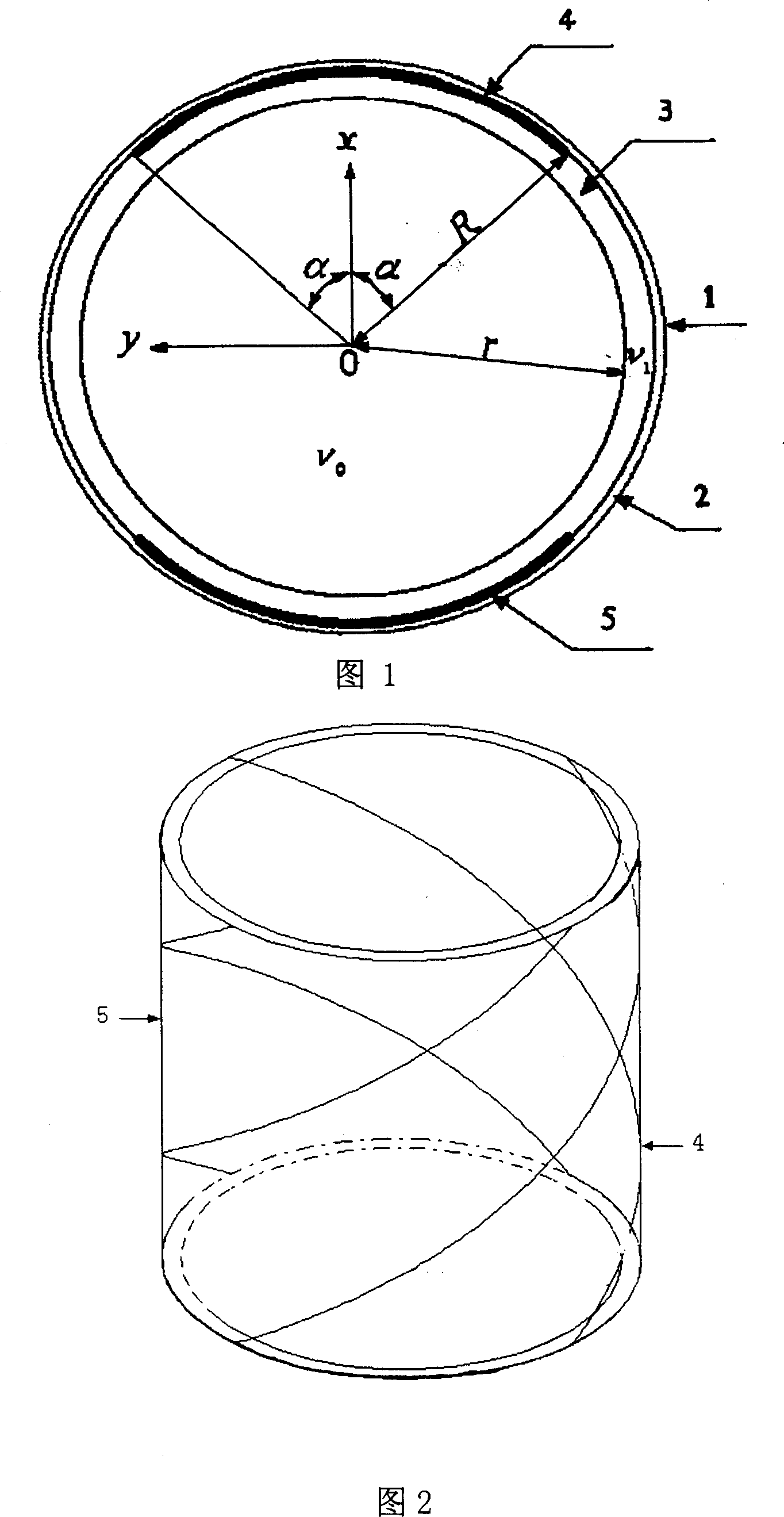

[0021] The two-phase flow split-phase holdup impedance sensor and its structural parameter optimization method of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0022] As shown in Figures 1 and 2, in the cross-section of the two-phase flow split-phase holdup impedance sensor, its structure is composed of three layers. The outer structural layer is a metal shielding layer 1, which plays a shielding role. When the inner structural strength is not enough , the thickness can be adjusted to play the role of structural support, pressure resistance, etc., the middle layer structure layer is the insulating material layer 2, which isolates the excitation electrode 4 and the measurement electrode 5 from the metal shielding layer 1, and the inner layer structure layer is the insulating tube layer 3 And the excitation electrode 4 and the measurement electrode 5 attached to its outer wall, in the axial direction, when the excitation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com