Erecting structure and erecting method for top ring beam construction platform of concrete silo

A construction platform and concrete technology, which is applied in the direction of house structure support, house structure support, house structure support scaffolding, etc., can solve the problems of time-consuming scaffold erection, long silo construction period, and many scaffold materials, etc., and achieve good stability, The effect of shortening the construction period and using less materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

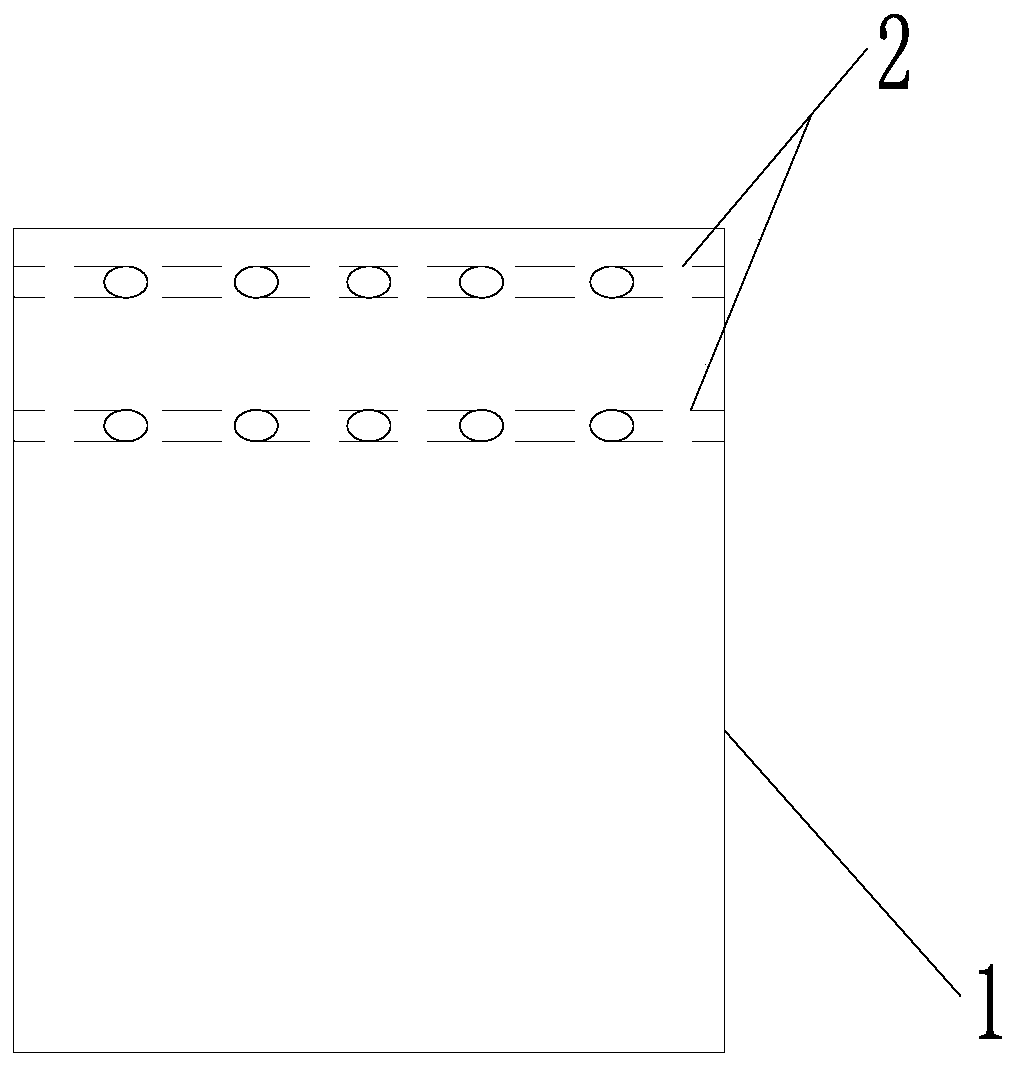

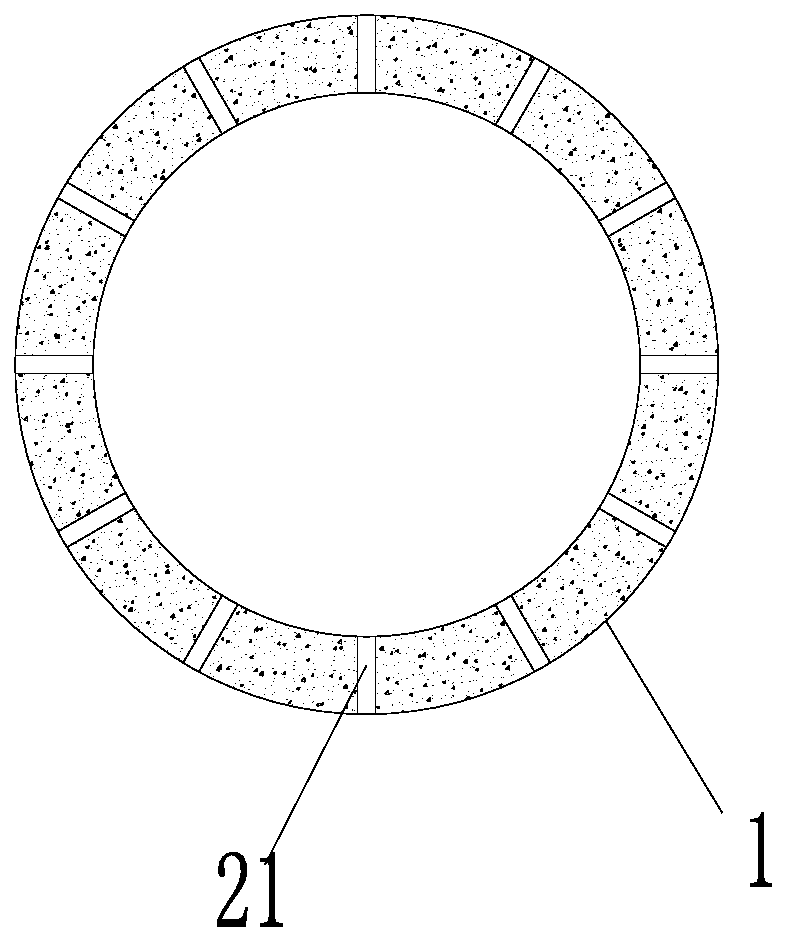

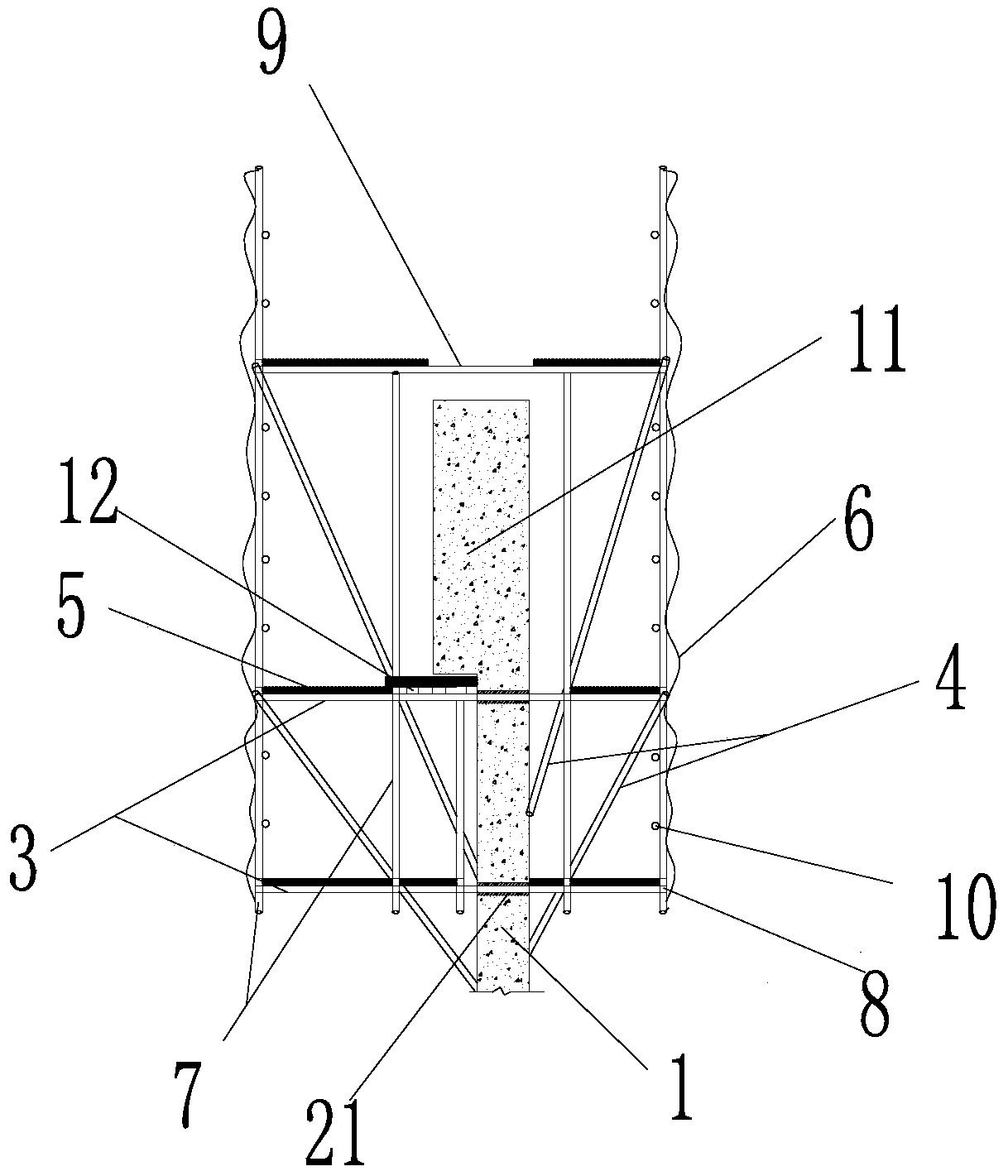

[0026] Such as Figure 1 to Figure 3 As shown, the erection structure of the ring beam construction platform at the top of the concrete silo of the present invention includes: a cantilevered scaffold pipe 3 and a steel pipe layer 2 composed of a plurality of horizontally arranged steel pipes 21 embedded in the upper end of the cylinder wall 1; the steel pipe layer 2 There are two layers, and there is a space between the two layers. The steel pipes 21 of the steel pipe layer 2 in each layer pass through the cylinder wall 1 and are distributed along the circumference of the cylinder wall 1, and the steel pipes 21 of the steel pipe layer 2 in each layer Set at intervals; the cantilevered scaffold pipe 3 is inserted into the steel pipe 21 of the steel pipe layer 2 and both ends are suspended in the air; the erection structure also includes a vertical pole s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Board width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com