Nano antibacterial PP-R composite pipe and manufacturing method thereof

A PP-R, manufacturing method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems that bacteria cannot inhibit growth, large linear expansion coefficient, insufficient strength, etc., and achieve self-cleaning and anti-fouling performance. Good, small coefficient of linear expansion, the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0016] Its implementation method includes the following steps:

[0017] A. Select the corresponding three-layer composite mold according to the pipe specifications, connect with three plastic extruders, and preheat;

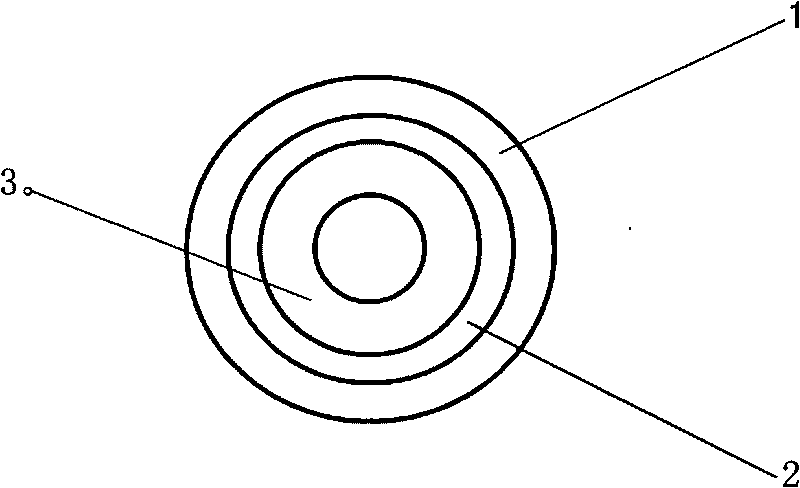

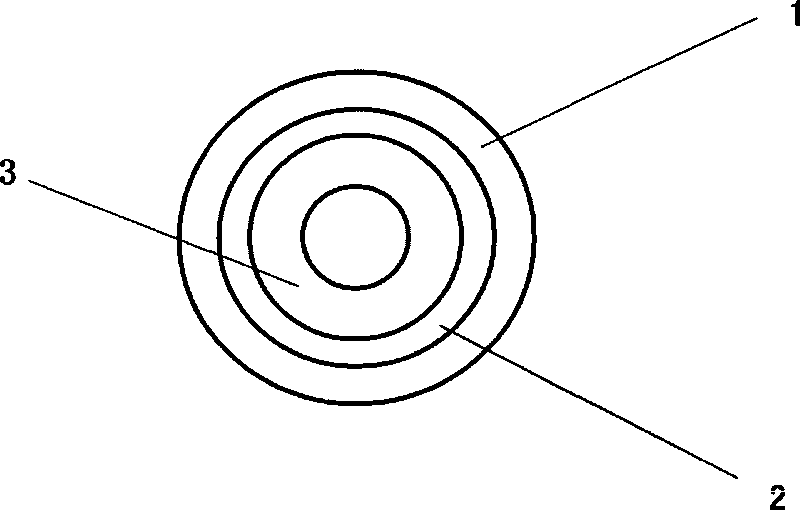

[0018] B. Start the feeding equipment, which will correspond to the ordinary PP-R outer tube layer (1), the composite reinforcement layer (2) blended with glass fiber and PP-R, and the inner tube loaded with silver ion antibacterial agent PP-R The raw materials of layer (3) are respectively sucked into the hopper of the extruder for drying and preheating;

[0019] C. After the extruder and the mold are preheated to the corresponding temperature, start the three extruders in sequence, and form a nano-antibacterial PP-R composite tube blank through three-layer co-extrusion;

[0020] D. After vacuum sizing, spray cooling, surface drying, laser coding, cut-to-length cutting, end milling and inspection, the tube blank can get the finished nano antibacterial PP-R comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com