Cold-resistant high impact strength unplasticized polyvinyl chloride (PVC-U) composite pipe and preparation method thereof

A technology of PVC-U and composite pipes, applied in the direction of hoses, pipes, rigid pipes, etc., can solve the problems of low temperature toughness, cold resistance and poor thermal insulation, and achieve the effect of improving cold resistance, reducing damage, and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

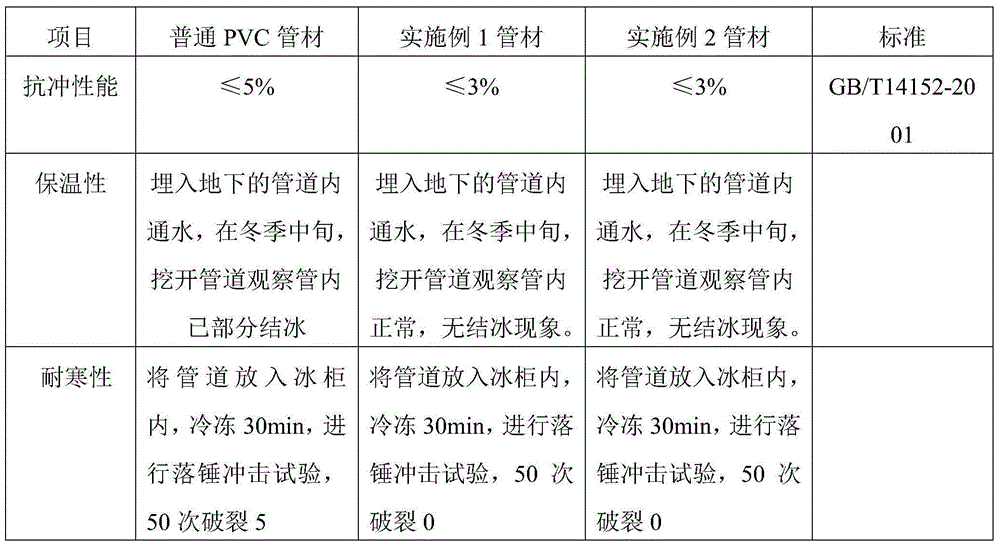

Examples

Embodiment 1

[0025] A cold-resistant and high-impact PVC-U composite pipe, comprising a three-layer structure, a PVC inner layer, a foamed PE middle layer and a PE outer layer, wherein the PVC inner layer is prepared from the following components in parts by weight:

[0026] 100 parts of PVC resin; 3.1 parts of calcium zinc stabilizer; 9 parts of light calcium carbonate filler; 0.4 parts of stearic acid and / or PE wax; 1.35 parts of processing aid ACR; 2.3 parts of toughening agent CPE; 0.1 parts of carbon black share.

[0027] The preparation method of the pipe is:

[0028] First, weigh the components for preparing the PVC inner layer, and then add them into the mixing pot in sequence, first perform hot mixing, the hot mixing temperature is 125°C, mix for 20-25min, and then cold mix, the cold mixing temperature 45°C, mix for 10-15min.

[0029] Secondly, the uniformly mixed material is added to the PVC pipe production line through an automatic feeding machine, and the inner layer of the p...

Embodiment 2

[0032] In this embodiment, the PVC layer is prepared from the following components in parts by weight:

[0033] 100 parts of PVC resin; 3.1 parts of calcium zinc stabilizer; 11 parts of light calcium carbonate filler; 0.5 parts of PE wax; 1.35 parts of processing aid ACR; 2.3 parts of toughening agent CPE; 0.1 part of carbon black.

[0034] Others are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com