Metal mesh plastic composite pipe winded with reinforced structure and preparation method thereof

A technology of reinforcing structure and winding tape, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of the overall structure of the composite pipe being integrated, the composite pipe is not formed, the overall failure of the steel wire wound composite pipe, etc., to improve safety. , the effect of improving the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

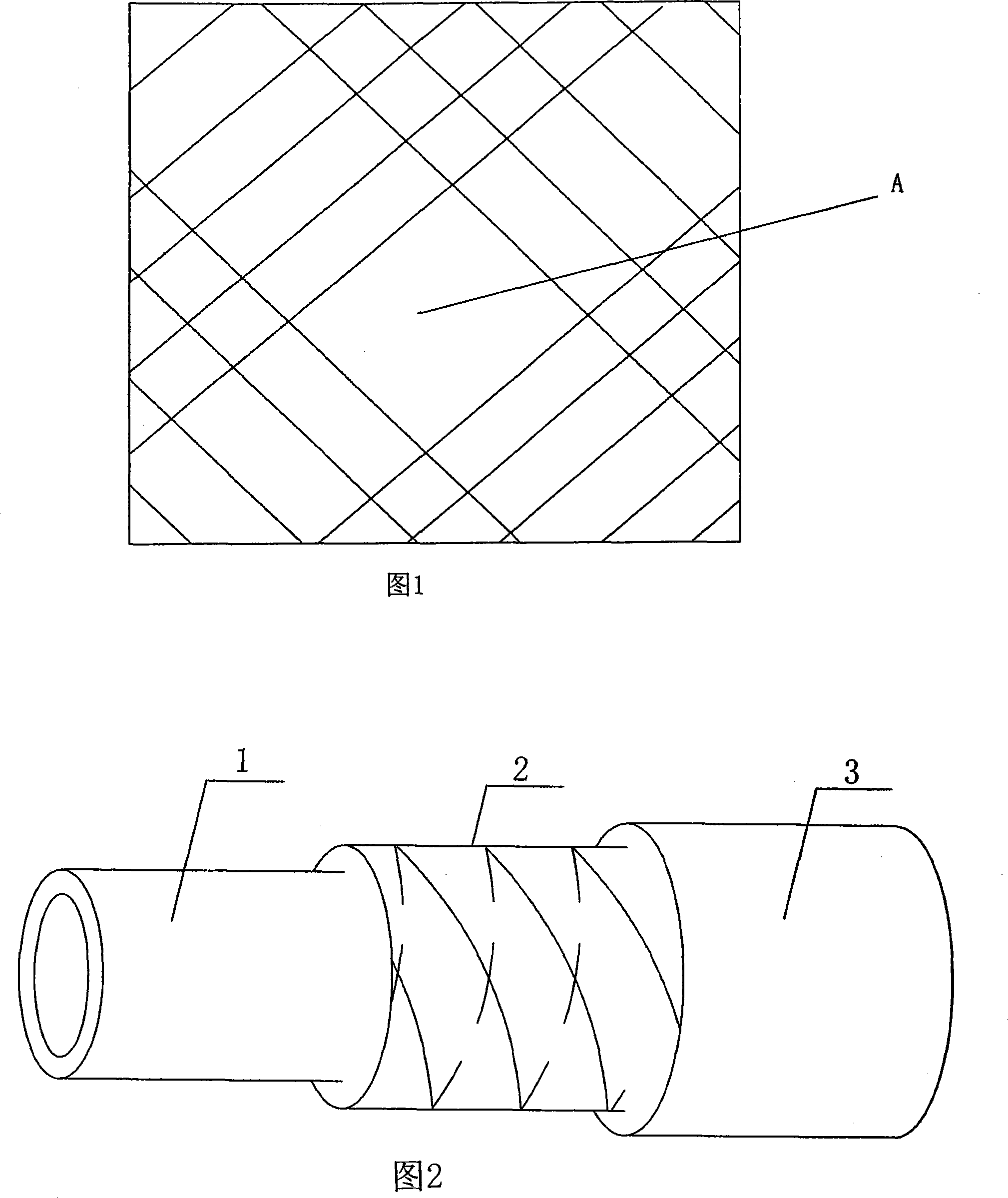

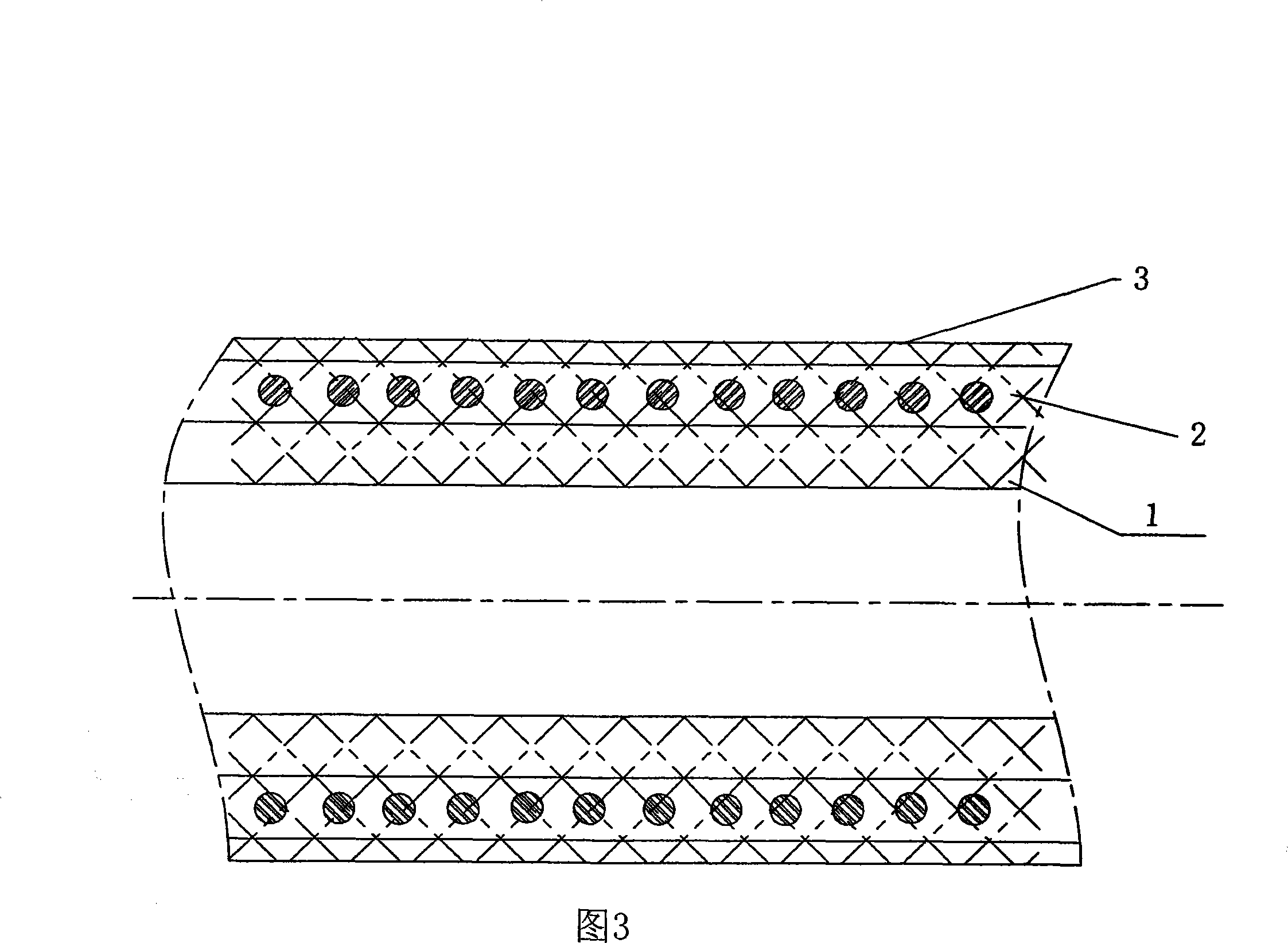

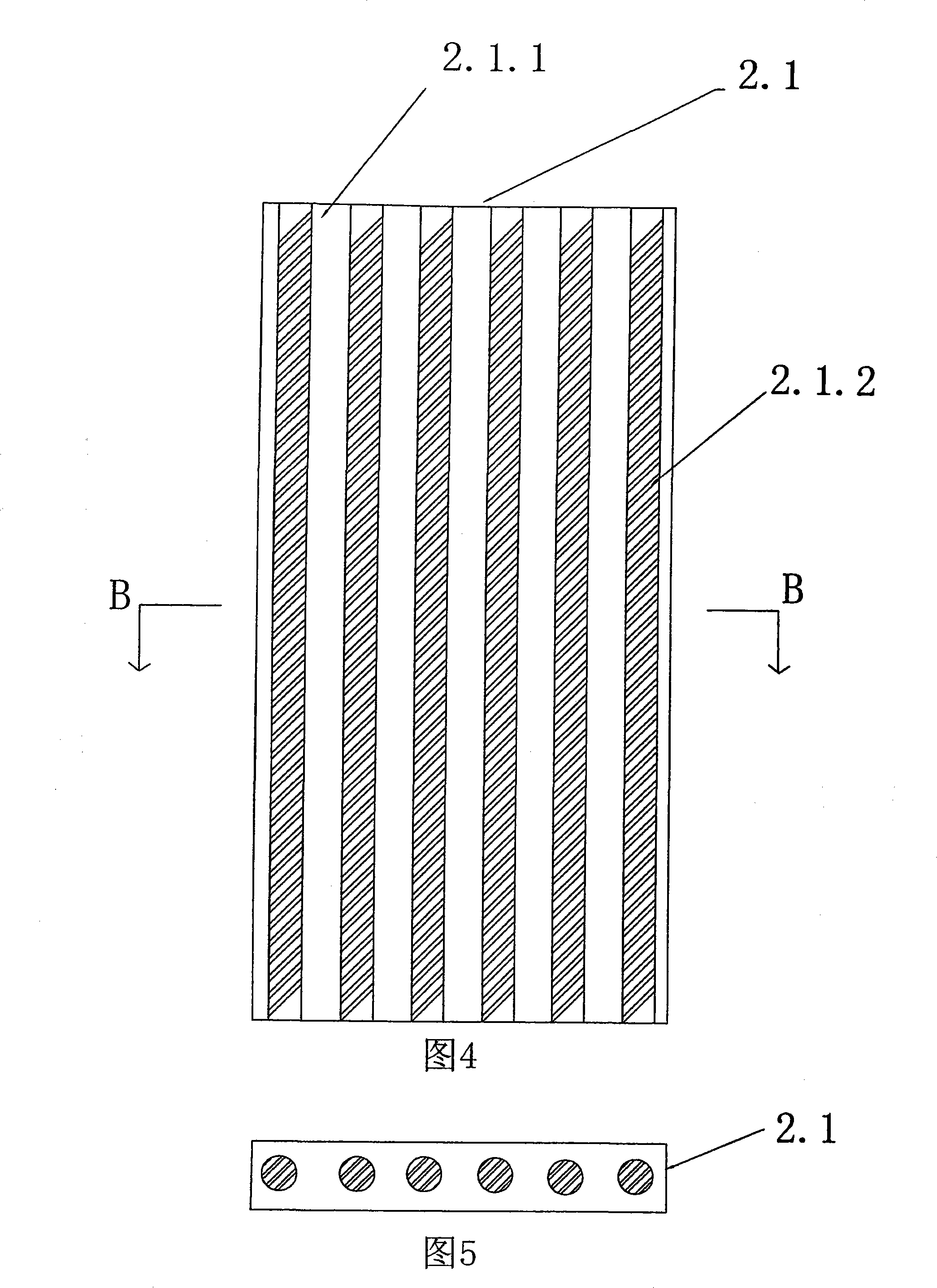

[0025] Referring to Fig. 2 , the steel mesh plastic composite pipe of the winding belt reinforced structure according to the present invention is composed of an inner germ tube 1, a winding belt reinforcement 2 and an outer layer pipe 3 from inside to outside. The winding tape reinforcement 2 is a winding tape reinforcement structure formed by cross-winding the inner germ tube 1 with multiple layers of winding tape 2.1. The winding tape has n layers, and n is a natural number ≥ 2.

[0026] Said wrapping tape 2.1 is a reinforced tape by a plurality of steel wires 2.1.2 pre-coated with adhesive or a blend of adhesive and plastic 2.1.1, as shown in Figures 3, 4 and 5.

[0027] The wrapping tape 2.1 can also be a reinforcement tape of the steel wire braided tape 2.1.3 pre-coated with an adhesive or a blend of adhesive and plastic 2.1.1, as shown in FIGS. 6 , 7 and 8 .

[0028] The adhesive or the blend of adhesive and plastic covering the steel wire or steel wire braid makes the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com