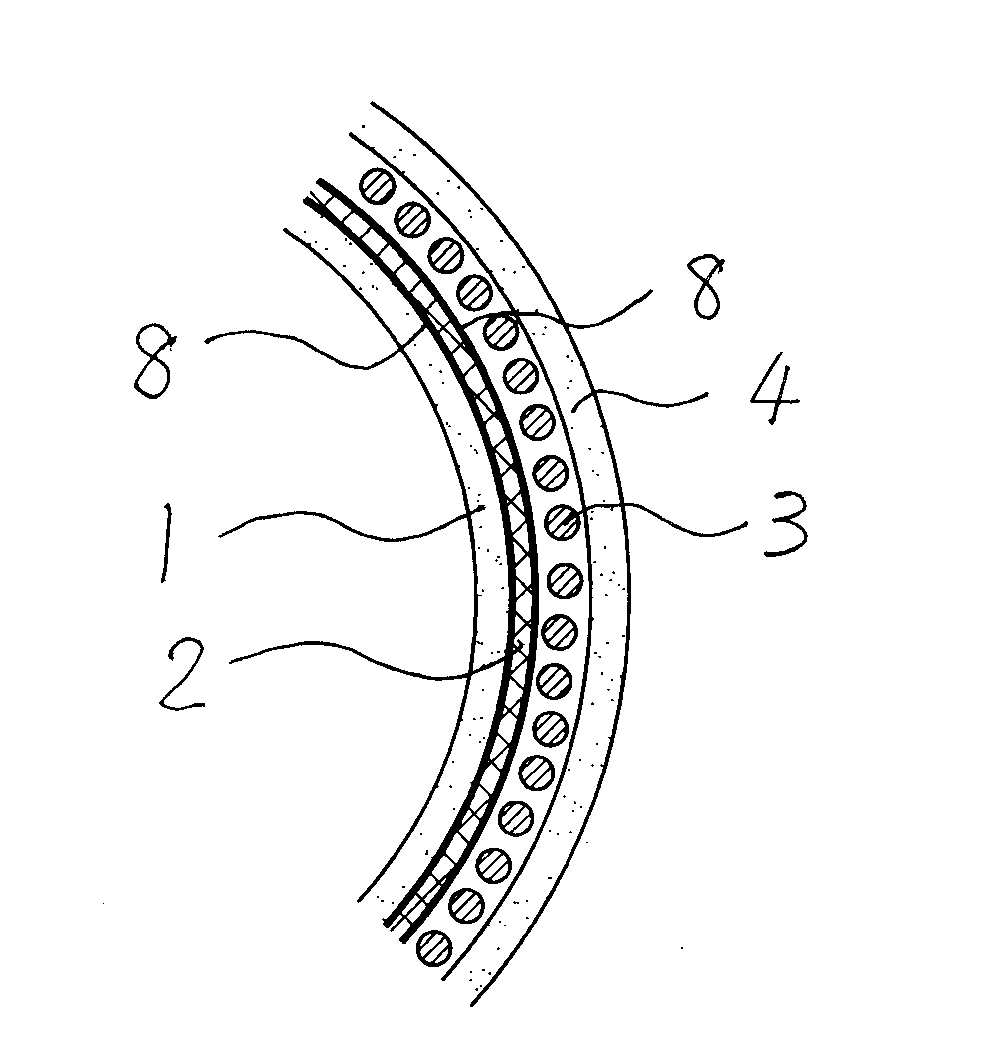

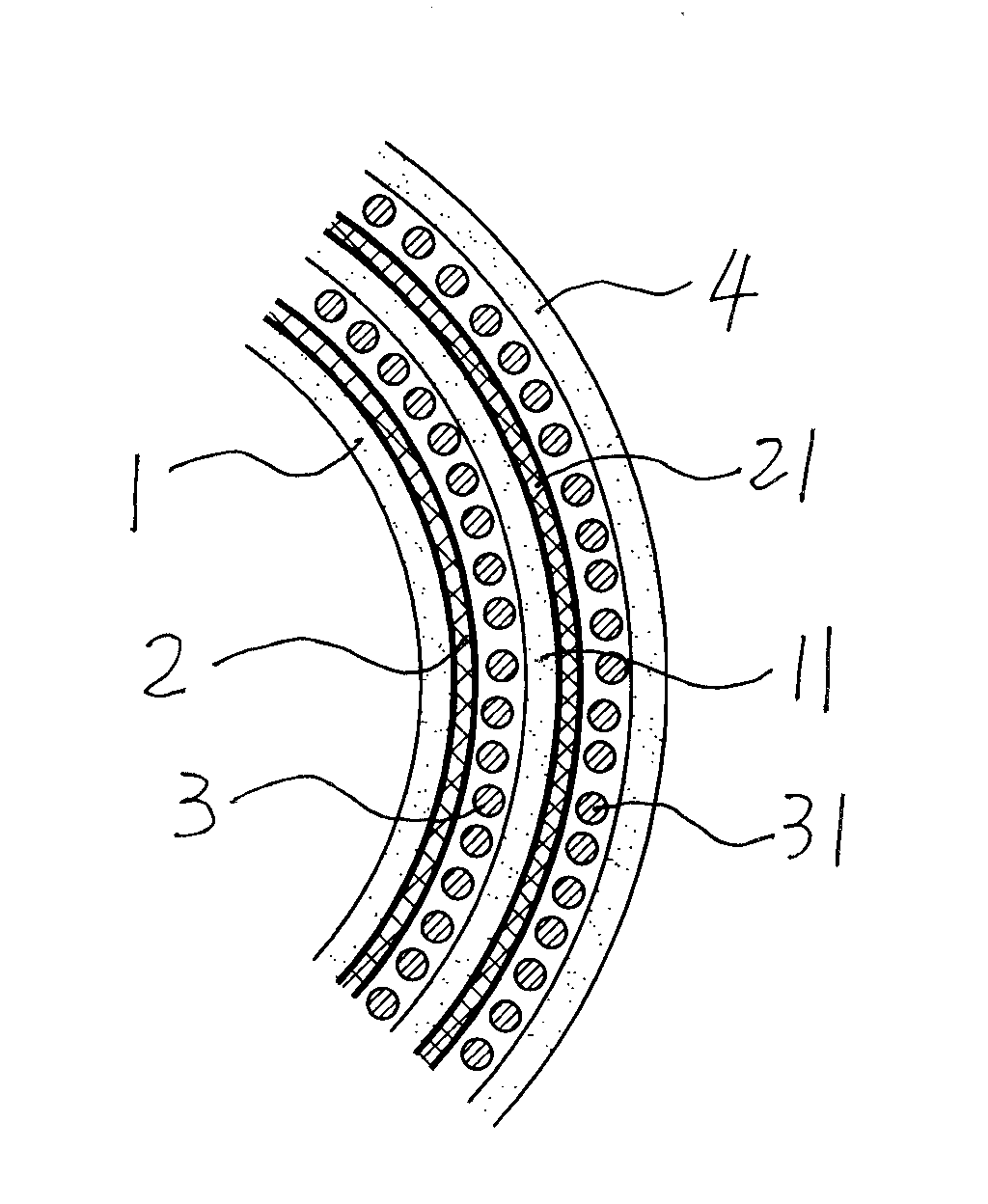

High-pressure hydraulic oil pipe and production method thereof

A technology of hydraulic oil pipe and high pressure, which is applied in the field of high pressure or ultra-high pressure hydraulic oil pipe and its preparation, can solve the problems of difficulty in meeting the requirements of the pressure resistance of the rubber hose, the decline of the yield, and the thinning, and achieves firm bonding performance, increased diameter, The effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

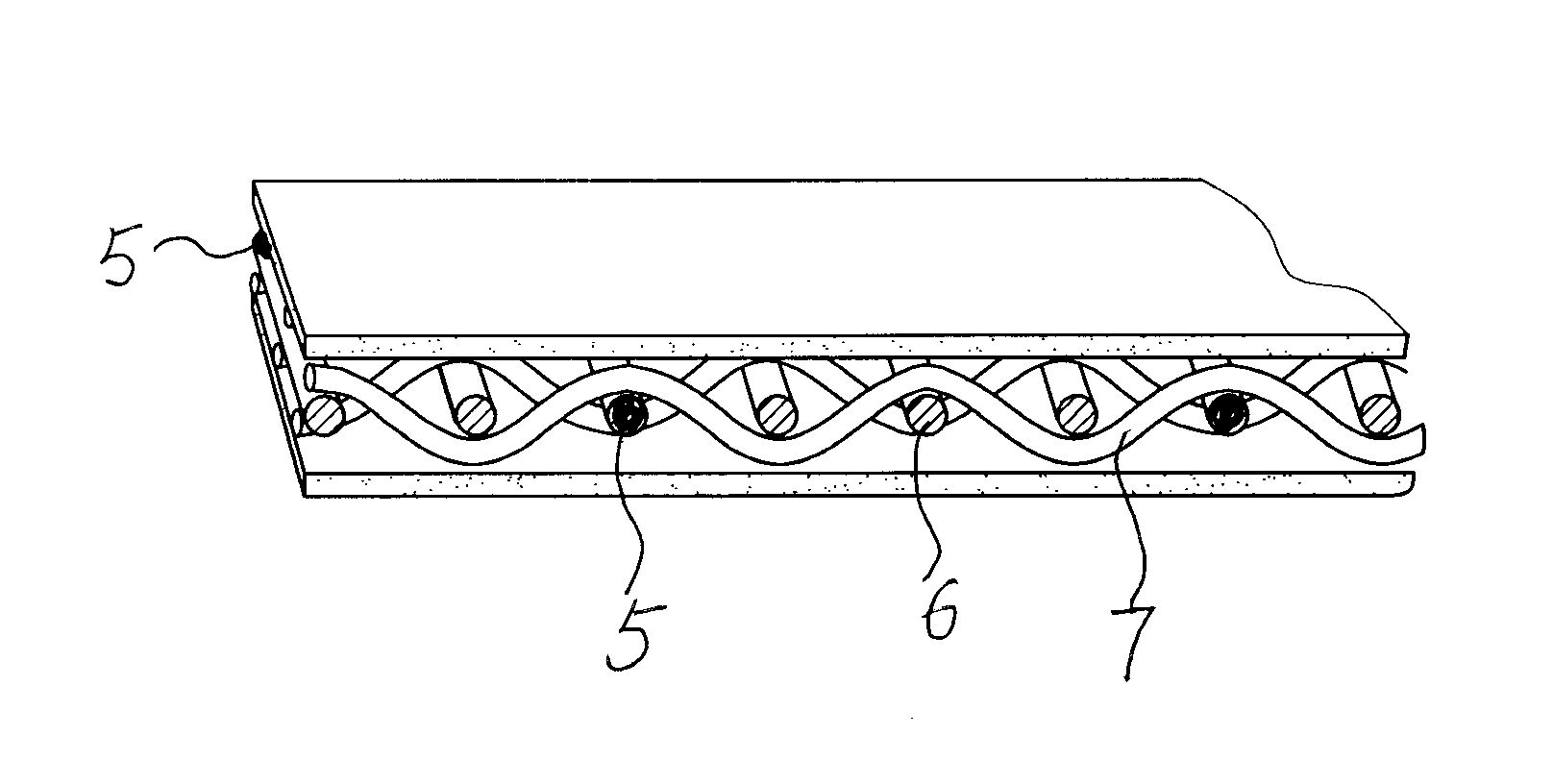

Embodiment 1

[0041] Get the nitrile rubber of 20 parts by weight, the white carbon black of 8 parts by weight, the dibutyl ester of 5 parts by weight, the coumarone of 1.0 parts by weight, the stearic acid of 0.15 parts by weight as release agent, 0.20 parts by weight of anti-aging After the agent A is mixed, put it into the internal mixer and stir evenly, then put 1.0 parts by weight of rubber adhesive AS-88, 0.30 parts by weight of vulcanization accelerator D and 0.6 parts by weight of sulfur as the vulcanizing agent into the internal mixer and stir After 15 minutes, the material is discharged; after the material is discharged, it is packaged 6 times on the open mill to produce the film; the produced film is placed for 50 hours to mature to form an adhesive glue; the cloth formed by weaving the warp and weft is woven at a temperature of 190 by the wiping mechanism. In the state of ℃, the adhesive glue is evenly coated on both sides, and the thickness of the adhesive glue on each side is 0...

Embodiment 2

[0043]Get the nitrile rubber of 15 parts by weight, the light calcium carbonate of 8 parts by weight, the white carbon black of 6 parts by weight, the dibutyl ester of 4 parts by weight, the coumarone of 0.6 parts by weight, the paraffin of 0.30 parts by weight for demoulding Anti-aging agent 4020 of 0.35 parts by weight is mixed and then put into the internal mixer and stirred evenly, then 0.6 parts by weight of rubber adhesive A, 0.25 parts by weight of vulcanization accelerator DM and 0.7 parts by weight of sulfur are used as vulcanizing agents. Stir in the internal mixer for 20 minutes and discharge the material; after discharging, go to the open mixer to pack 4 times to produce the film; place the produced film for 40 hours to mature to form adhesive glue; use the cloth formed by weaving the warp and weft The mechanism applies the adhesive evenly on both sides at a temperature of 195°C, and the thickness of the adhesive on each side is 0.5 kg / square meter; it will be coate...

Embodiment 3

[0045] Get the nitrile rubber of 22 parts by weight, the light calcium carbonate of 6 parts by weight, the white carbon black of 10 parts by weight, the magnesium oxide of 2.0 parts by weight, the ferric oxide of 2.0 parts by weight, the dibutyl ester of 8 parts by weight, The coumarone of 1.2 weight parts, the stearic acid of 0.2 weight parts and the paraffin of 0.2 weight parts are made release agent, the antiaging agent MB of 0.40 weight parts is mixed and packed in the internal mixer and stirred evenly, then 0.5 weight parts of Rubber adhesive homogenizer A78, the vulcanization accelerator CZ of 0.20 parts by weight and the sulfur of 0.8 parts by weight are put into the internal mixer and stirred for 25 minutes and then discharged; Place the resulting sheet for 45 hours to mature to form an adhesive glue; use a wiping mechanism to evenly coat the adhesive glue on both sides of the cloth formed by weaving warp and weft threads at a temperature of 180°C. The thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com