Casing pipe type water conveying pipeline applied to crossing bridge and installation and construction method thereof

A technology for water pipelines and construction methods, which is applied in the direction of pipeline support, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., which can solve the problems of low construction efficiency, damage to plastic flexible pipes, and the lack of pressure resistance of the core layer, etc. problems, to achieve the effect of improving construction efficiency, ensuring stability, and preventing water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

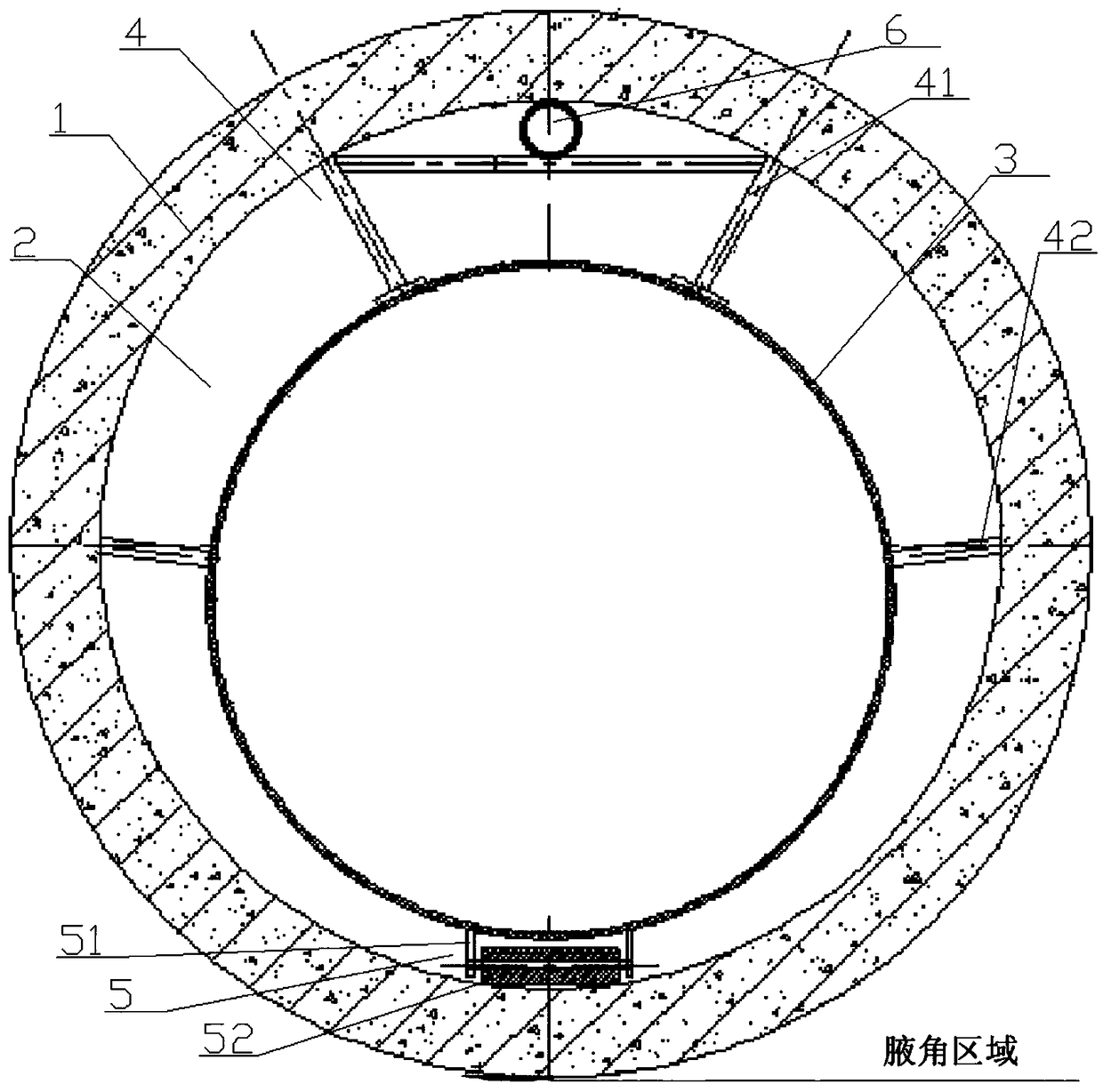

[0039] as attached figure 1 As shown, a casing-type water delivery pipeline for crossing bridges includes DN2400 concrete casing 1, concrete pouring layer 2 and pressure steel pipe 3. 1 set is arranged on the outside of the concrete pouring layer 2, and a supporting device 4 is connected between the DN2400 concrete casing 1 and the pressure steel pipe 3, and a steel roller 5 is fixed at the bottom of the pressure steel pipe 3.

[0040] The steel roller 5 includes a steel frame 51 welded to the bottom end of the penstock 3 and a rotatable steel roller 52 fixed on the steel frame 51 .

[0041] The supporting device 4 includes a steel support frame 41 welded on the top of the pressure steel pipe 3 and a steel support rod 42 welded on the side end of the pressure steel pipe 3, wherein both the steel support frame 41 and the steel support rod 42 abut against the inner wall of the DN2400 concrete casing 1 , There is also a space for placing the steel wire hose 6 between the steel s...

Embodiment 2

[0064] Step 2 also includes the steps of inserting steel rods in the reserved grouting holes in the outer middle section of the casing as external tension points, and linking 3t electric hoists to form an external tension system between the installed pipeline and the pipeline to be installed. In this embodiment, only the steps of inserting a steel rod as an external tension point and linking the 3t electric hoist are limited, and everything else is the same as in Embodiment 1.

Embodiment 3

[0066] Step 3 also includes the step of filling and compacting the axillary corner area of the DN2400 concrete casing 1 with crushed stones, wherein a vibrating machine is used for compacting. In this embodiment, only the steps of filling and compacting are limited, and everything else is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com