Process for the production of impact resistant pipe

A technology for pipes and pipe walls, which is applied in the field of producing pipes containing polypropylene layers and reinforced impact-resistant pipes, which can solve the problems of low impact strength, failure to reach, and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] 1. Definition and measurement method

[0103] The terms and assay methods used to measure properties, which are used to explain the present invention, apply generally to the description above and to the examples and claims below, unless otherwise stated:

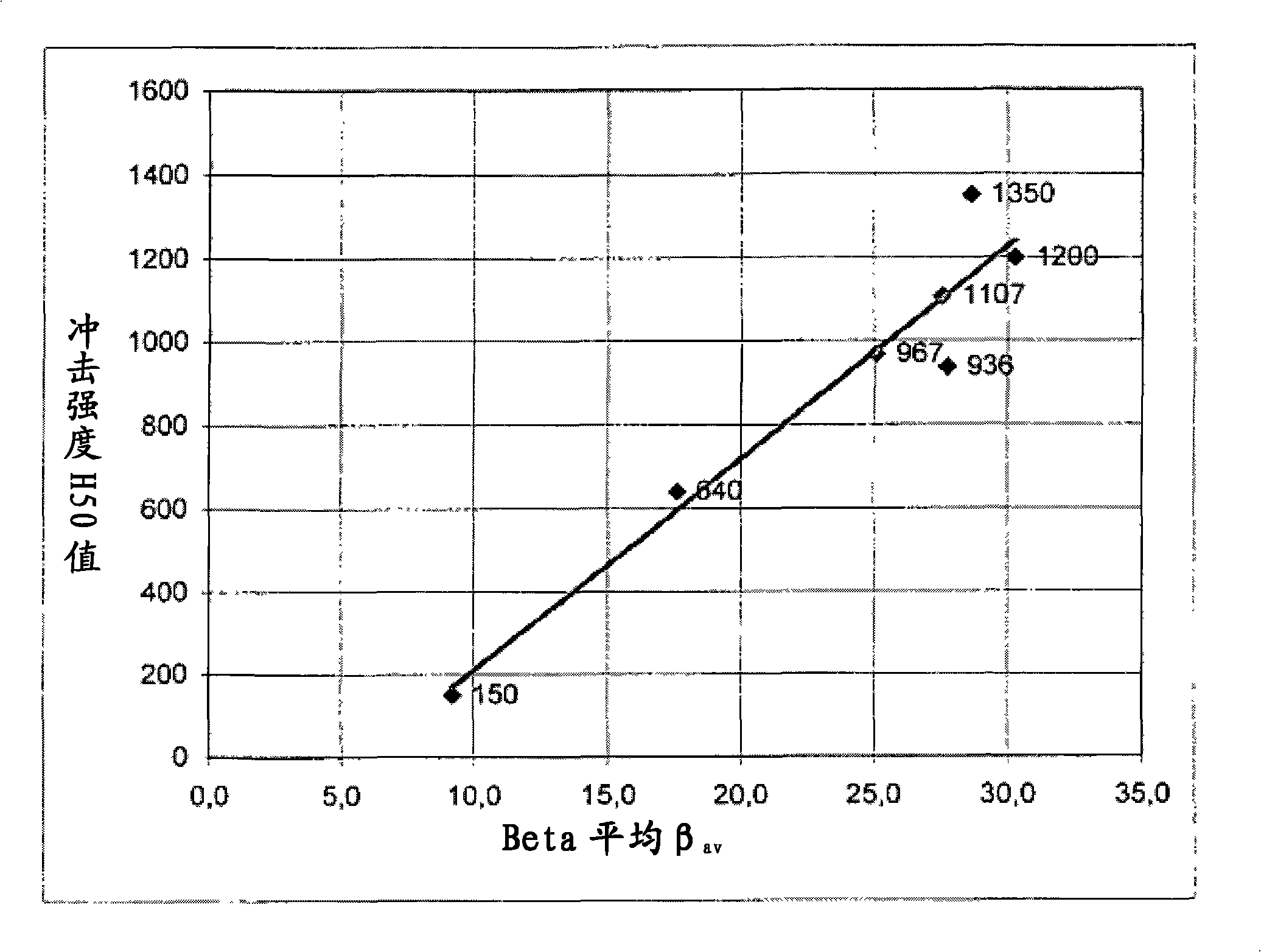

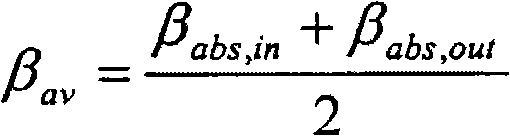

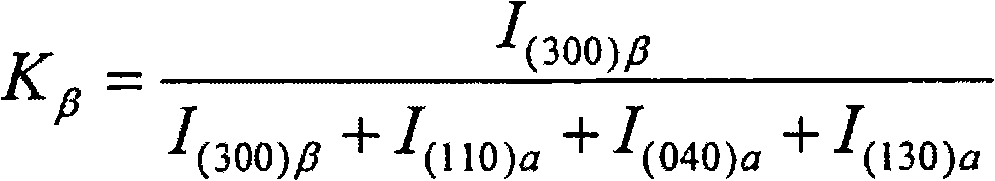

[0104] a) WAXS analysis and β-crystallinity: The overall crystallinity and β-phase content in PP were determined by WAXS (Wide Angle X-ray Diffraction) scanning of 200 μm thick sample flakes prepared mechanically from the production pipe ( Compare, Moore, J., Polypropylene Handbook, p. 134-135, Hanser Publishers Munich 1996). WAXS maps were recorded with a Philips X'Pert Pro goniometer using Cu Ka rays at an accelerating voltage of 40 kV and in 0.02° steps over the 2Θ range of 10-30°. Measurements are made in reflected light with a divergence slit of 0.5° and a graphite monochromator. Amorphous rings detected on fully irregular polypropylene samples were subtracted from the overall diffractogram before calculating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com