Pipelayer and method of loading pipelayer or excavator for transportation

a technology of excavating and pipelayers, applied in the directions of transportation and packaging, mechanical equipment, soil shifting machines/dredgers, etc., can solve the problems of increasing the cost of transportation, pipelayers may idle in the yard, and a substantial period of tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

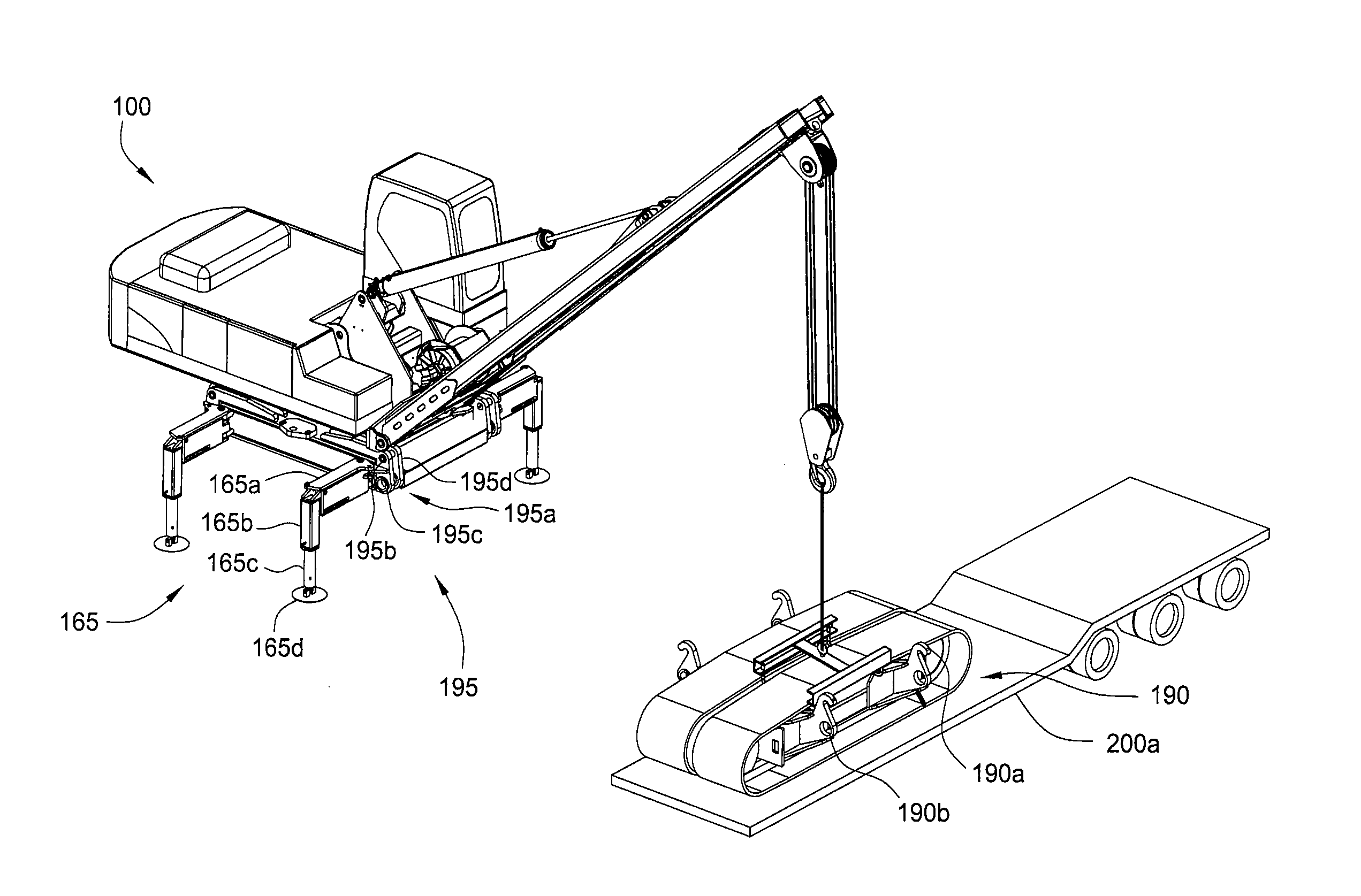

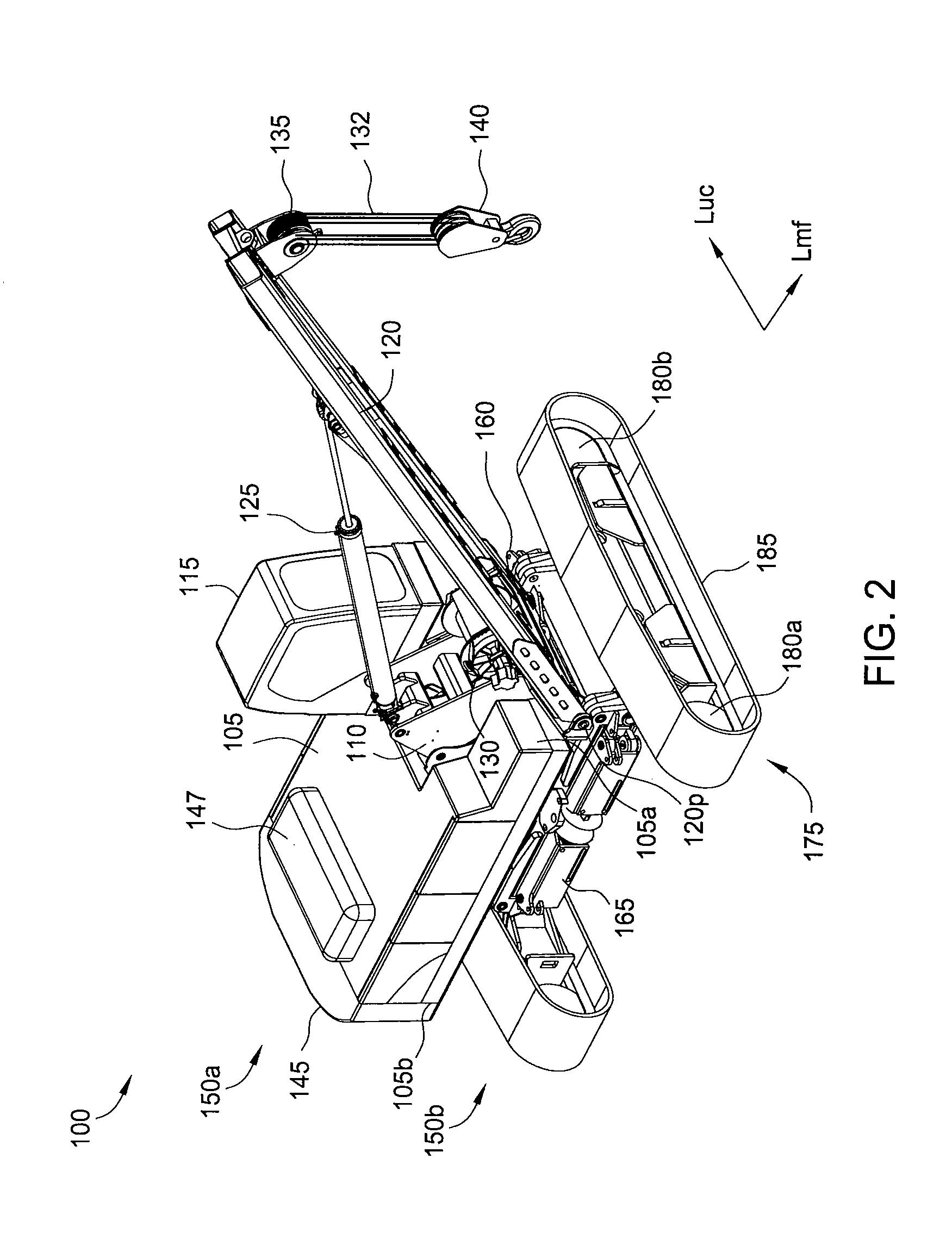

[0041]FIGS. 2-6 are various views of a pipelayer 100, according to one embodiment of the present invention. The pipelayer 100 includes a main assembly 150a mounted on an undercarriage 150b so that the main assembly 150a may rotate relative to the undercarriage 150b. FIG. 2 illustrates a perspective view of the pipelayer 100, wherein a longitudinal axis Lmf of the main assembly 150a is perpendicular to a longitudinal axis Luc of the undercarriage 150b. FIG. 3 illustrates another perspective view of the pipelayer 100, wherein the longitudinal axis Lmf of the main assembly 150a is parallel to a longitudinal axis Luc of the undercarriage 150b. FIG. 4 illustrates another perspective view of the pipelayer 100, wherein the longitudinal axis Lmf of the main assembly 150a is parallel to a longitudinal axis Luc, of the undercarriage 150b. FIG. 5 illustrates an orthogonal view of the pipelayer 100, wherein the longitudinal axis Lmf of the main assembly 150a is perpendicular to a longitudinal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com