Manufacturing method of ultra-large plate glass pattern and processing equipment thereof

A flat glass and processing equipment technology, applied in the direction of copying/marking methods, printing, rotary printing machines, etc., can solve the problems of inability to thermally transfer large-size flat glass, inability to display products vividly, and environmental pollution in production processes, etc. Achieve low cost, prevent wrinkling or air bubbles, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

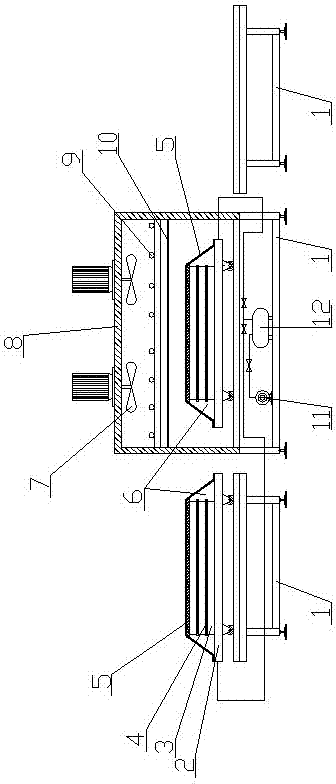

[0025] Such as figure 1 Shown, a kind of manufacturing method of super large plate glass pattern, comprises the following steps:

[0026] (1) Take the cleaned transparent glass 3, apply a resin layer on the surface of the glass 3 and heat, dry and solidify to form a layer of resin on the glass surface. The resin can be varnish, varnish or other transparent coatings;

[0027] (2) On the vacuum thermal transfer workbench 2, place the glass 3 on top of the glass resin layer, lay the sublimation transfer paper 4 on the glass resin layer, and place multiple pieces of glass 3 and transfer paper 4 layer by layer, After the glass 3 and the transfer paper 4 are placed, cover the airtight cloth, that is, the vacuum cloth 5 (if the surface is coated with rubber, silicon rubber cloth, etc. can also be used), so that the vacuum cloth 5 and the surface of the workbench form a vacuum chamber 6 , to carry out vacuuming, the vacuum degree is 0.8 ~ 1MPa;

[0028] (3) Place the workbench with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com