Door frame type multi-functional support trolley for tunnel

A gantry-type, multi-functional technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of long single process time, occupying tunnel space, and low arch efficiency, so as to improve competitive advantages, improve safety, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

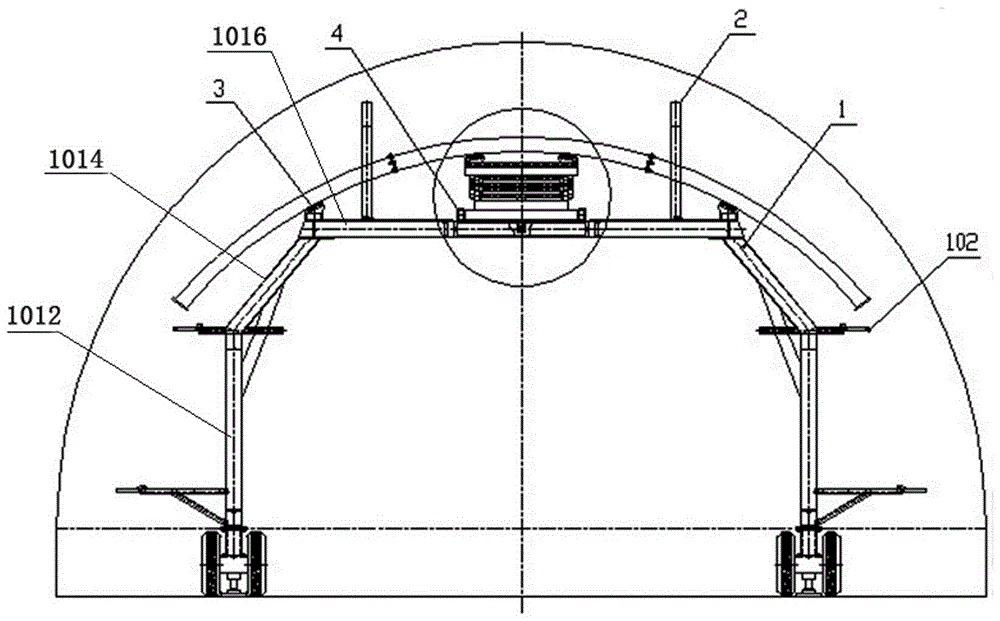

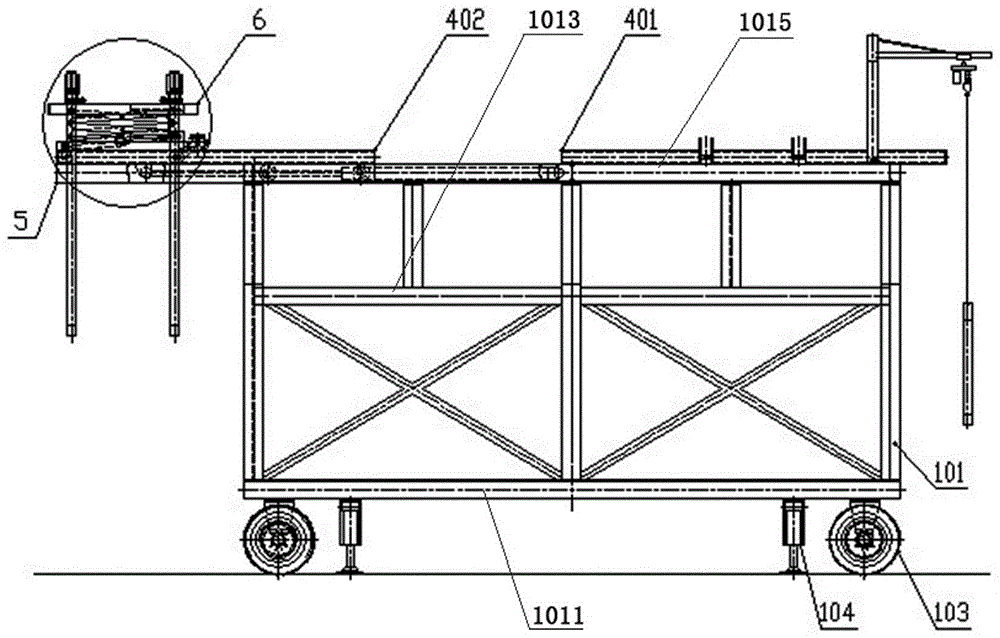

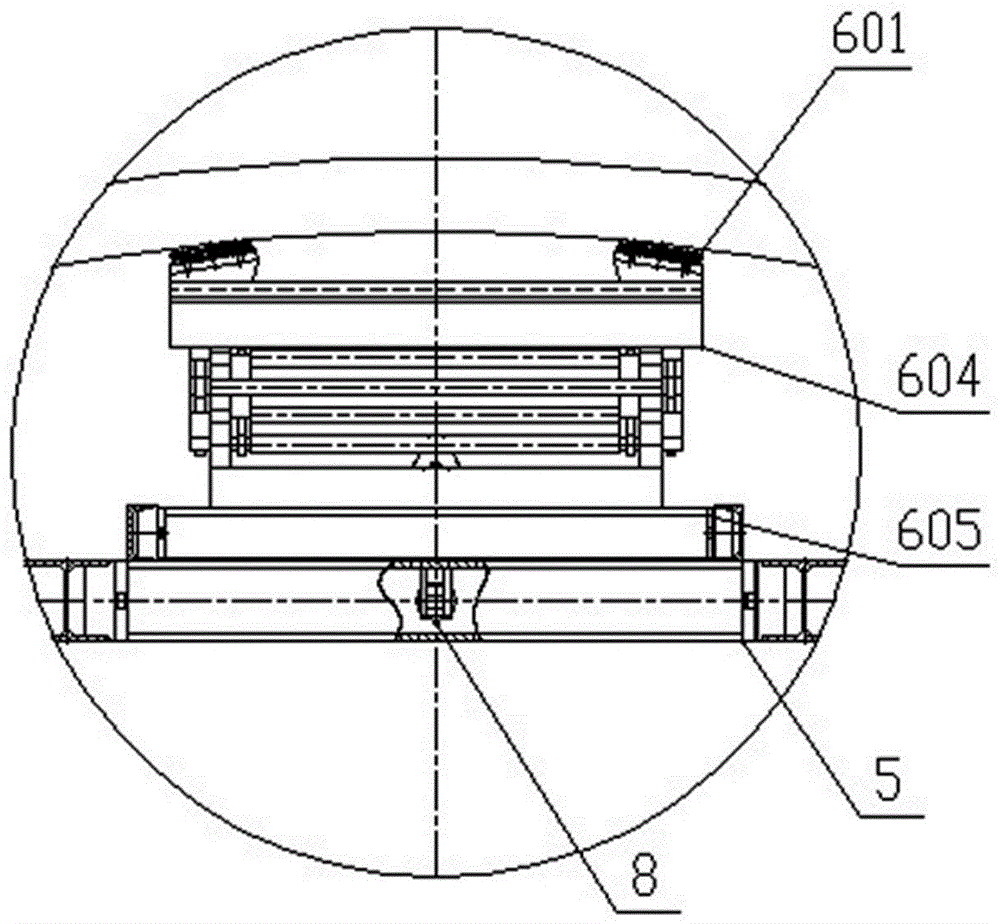

[0024] Embodiment 1: In this embodiment, as Figure 1-4 As shown, a portal frame 101 type multifunctional support trolley for tunnels includes a portal frame 101 assembly 1 and a walking mechanism that drives the portal frame 101 assembly 1 to move back and forth along the tunnel. The portal frame 101 assembly 1 includes The door frame 101 and a number of working platforms 102 symmetrically arranged on the left and right sides of the door frame 101, the top of the door frame 101 is provided with a chute rail 4, and an arch installation device 6 is provided on the chute rail 4, the arch The installation device 6 includes a transport trolley 605 that can move back and forth on the chute rail 4 and a lifting device 604. The lifting device 604 is fixed on the transport trolley 605 below the lifting device 604. Left and right moving mechanisms are provided on the left and right sides of the lifting device 604. And the left and right moving rails for moving the left and right moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com