Method of spinning high-count spun silk yarns

A spun silk and high-count technology, which is applied in the spinning field of high-count spun silk yarns, can solve problems such as increasing production costs, expanding product processing processes, and waste of raw materials, so as to increase production costs, enhance competitive advantages, and expand processing processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

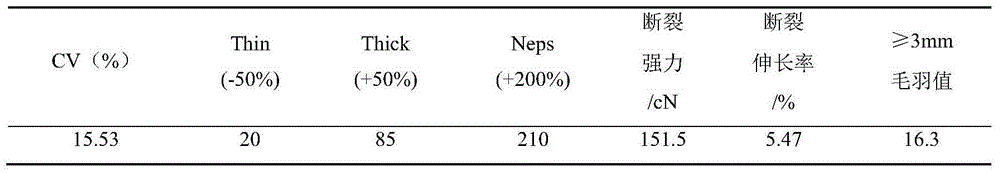

Embodiment 1

[0020] The spinning method of the 240Nm spun silk yarn of the present embodiment, comprises the steps:

[0021] Step 1: Pretreat the spun silk fiber raw material, and use the GYFA311D fiber stretcher to cut the spun silk into fibers with a length of less than 40mm. The average length of the spun silk fiber after stretching is 30mm, which is suitable for processing on cotton spinning equipment .

[0022] Step 2: Based on the weight of the spun silk raw material obtained in the first step, spray 0.33% CAS antistatic agent aqueous solution and 11% water to the spun silk raw material according to the weight percentage, and let it stand for 30 hours to balance and control the moisture regain at 16%.

[0023] Step 3: Put the silk bags obtained in the first two steps on the cotton opening and cleaning equipment for opening and mixing. The beater speed is 465r / min, the beater speed of A076C coiler is 770r / min, and the fan speed is 1500r / min.

[0024] The fourth step: card the silk ...

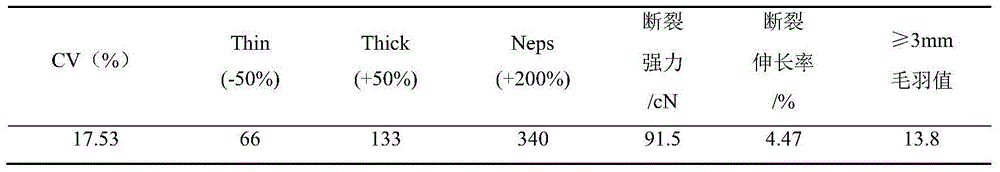

Embodiment 2

[0033] The basic steps of the spinning method of the 300Nm spun silk yarn of the present embodiment are the same as in Example 1, but the specific process parameters of each step are different, specifically as follows:

[0034] Step 1: Pretreat the spun silk fiber raw material, and use the GYFA311D fiber stretcher to cut the spun silk into fibers with a length of less than 40mm. The average length of the spun silk fiber after stretching is 31mm, which is suitable for processing on cotton spinning equipment .

[0035] The second step: based on the weight of the silk raw material obtained in the first step, spray 0.3% CAS antistatic agent aqueous solution and 13% water to the silk raw material according to the weight percentage, and let it stand for 32 hours to balance and control the moisture regain at 17.5%.

[0036] Step 3: Put the silk bag obtained in the first two steps on the cotton opening and cleaning equipment for opening and mixing treatment. The main process paramete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com