Straightening process for wedge-shaped plate

A wedge-shaped plate and straightening technology, applied in the field of plate straightening, can solve problems such as unreasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

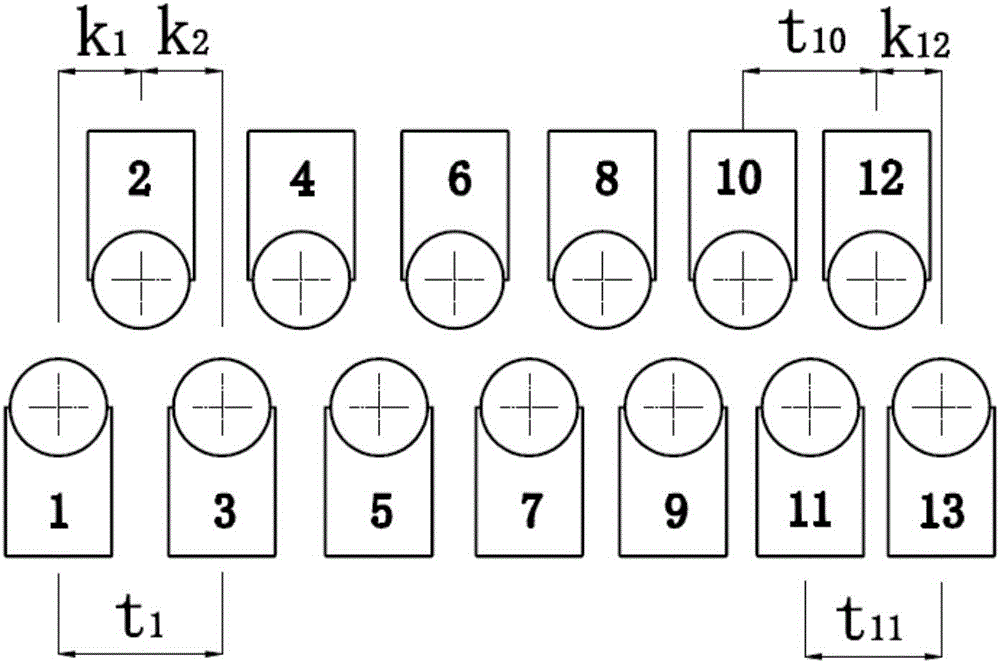

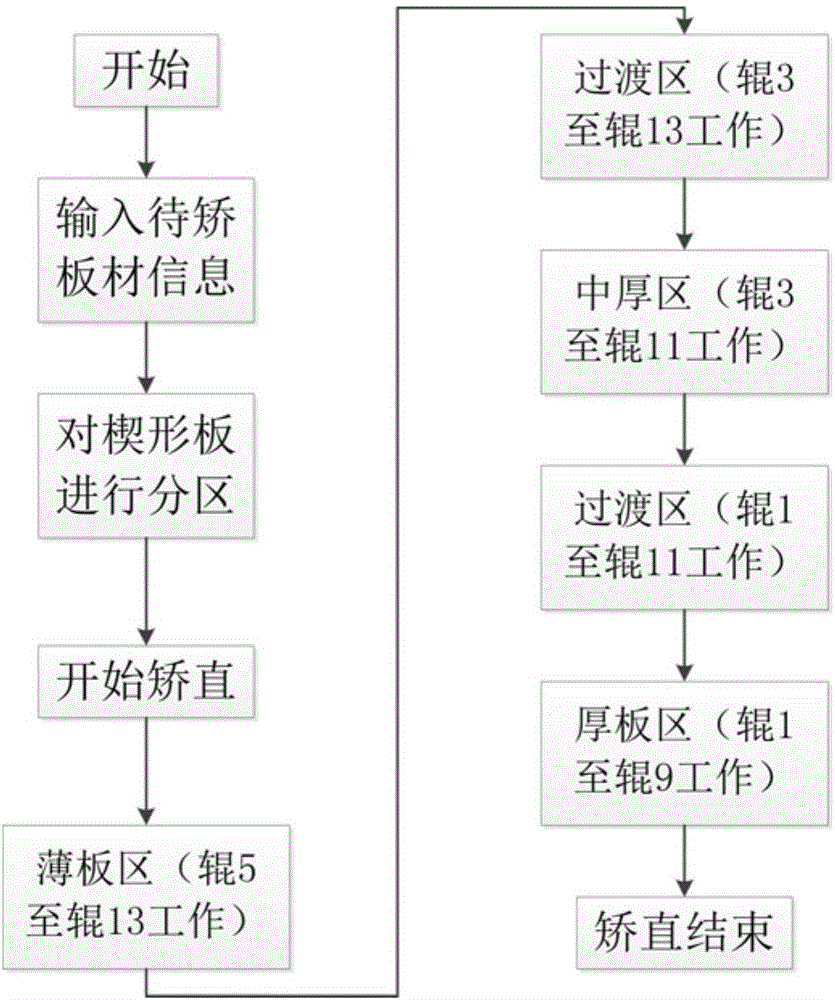

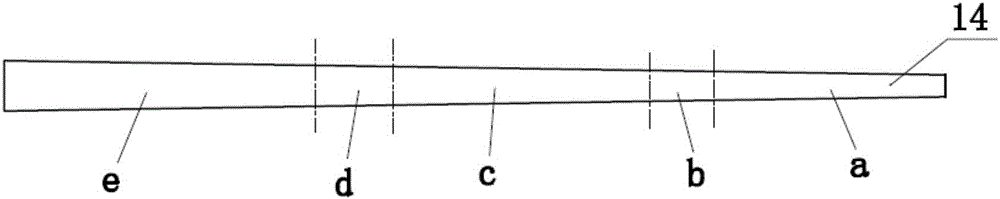

[0024] Such as figure 1 As shown, the present invention is a straightening process for wedge-shaped plates. The straightening roller system adopts 13 rollers, and the settings of each roller distance are not equal. There is a difference in roller distance, and the roller distance is set from large to small. , in descending order (t i -t i+1 =Δt,k i -k i+1 =Δt / 2), which can reduce the pressure of each roller on the entrance side, and at the same time pursue the ideal state of equal strength design. The straightening rollers of the traditional strip straightening machine cannot be adjusted on-line during the straightening process, but the straightening roller system designed by the present invention can realize the on-line reduction adjustment during the straightening process. In the present invention, the wedge-shaped plate is used as a variable-thickness plate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com