Method for regenerating waste lubricating oil

A technology for waste lubricating oil and lubricating oil, applied in the field of lubricating oil, can solve problems such as affecting product quality and yield, and impurities generated by cracking of lubricating oil, so as to achieve the effect of improving the yield of lubricating oil and reducing the distillation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

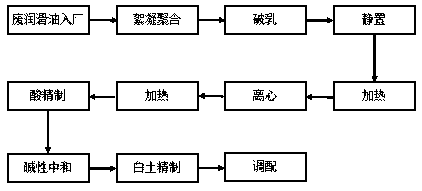

Image

Examples

Embodiment 1

[0030] A method for regenerating waste lubricating oil, comprising the steps of:

[0031] 1) Waste lubricating oil enters the factory: Before the waste lubricating oil enters the factory, the water content of the waste lubricating oil needs to be detected, and the waste lubricating oil with a water content of less than 5% is put into the storage tank, and those that do not meet the requirements are not allowed to enter factory;

[0032] 2) Flocculation and aggregation: add flocculant polymerized ferric chloride into the storage tank, the amount of flocculant added accounts for 1% of the waste lubricating oil, and stir evenly at 60°C for 1 hour;

[0033] 3) Demulsification: add demulsifier polyoxyethylene polyoxypropylene stearyl ether to the flocculation polymer, the amount of demulsifier added accounts for 1% of the waste lubricating oil, and stir evenly at 60°C for 1 hour;

[0034] 4) Stand still: put the waste lubricating oil after demulsification into layers, the standing...

Embodiment 2

[0043] A method for regenerating waste lubricating oil, comprising the steps of:

[0044] 1) Waste lubricating oil enters the factory: Before the waste lubricating oil enters the factory, the water content of the waste lubricating oil needs to be detected, and the waste lubricating oil with a water content of less than 5% is put into the storage tank, and those that do not meet the requirements are not allowed to enter factory;

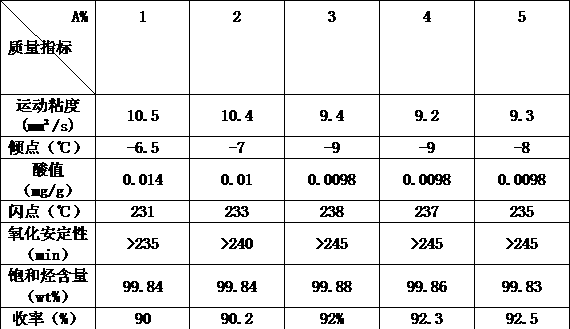

[0045] 2) Flocculation and aggregation: Add flocculant polymerized ferric chloride into the storage tank, the amount of flocculant added accounts for A% of the waste lubricating oil, and stir evenly at 60°C for 1 hour;

[0046] 3) Demulsification: add demulsifier polyoxyethylene polyoxypropylene stearyl ether to the flocculation polymer, the amount of demulsifier added accounts for 1% of the waste lubricating oil, and stir evenly at 60°C for 1 hour;

[0047] 4) Stand still: put the waste lubricating oil after demulsification into layers, the standing...

Embodiment 3

[0060] A method for regenerating waste lubricating oil, comprising the steps of:

[0061] 1) Waste lubricating oil enters the factory: Before the waste lubricating oil enters the factory, the water content of the waste lubricating oil needs to be detected, and the waste lubricating oil with a water content of less than 5% is put into the storage tank, and those that do not meet the requirements are not allowed to enter factory;

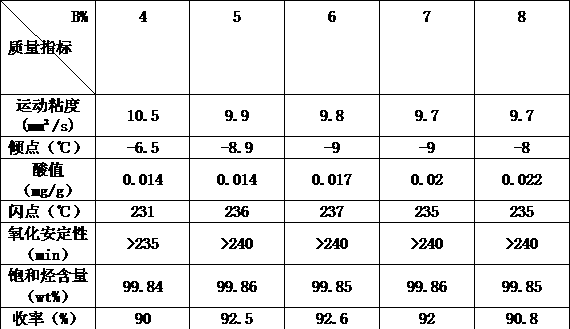

[0062] 2) Flocculation and aggregation: add flocculant polymerized ferric chloride into the storage tank, the amount of flocculant added accounts for 1% of the waste lubricating oil, and stir evenly at 60°C for 1 hour;

[0063] 3) Demulsification: add demulsifier polyoxyethylene polyoxypropylene stearyl ether to the flocculation polymer, the amount of demulsifier added accounts for 1% of the waste lubricating oil, and stir evenly at 60°C for 1 hour;

[0064] 4) Stand still: put the waste lubricating oil after demulsification into layers, the standing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com