Method for manufacturing an interior lining part and corresponding part

A technology for parts and linings, applied in the field of a method and parts obtained by the method, can solve problems such as the inability to use the skin molding technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

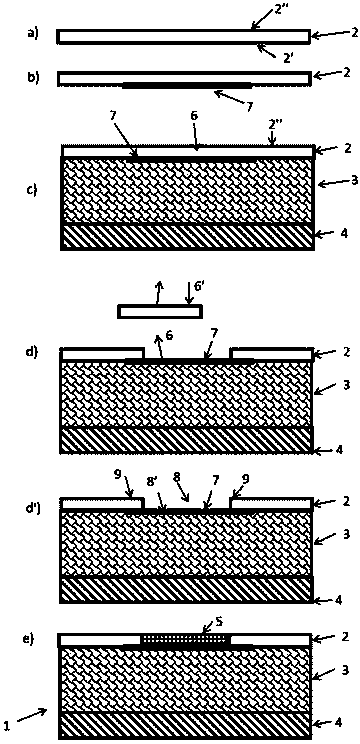

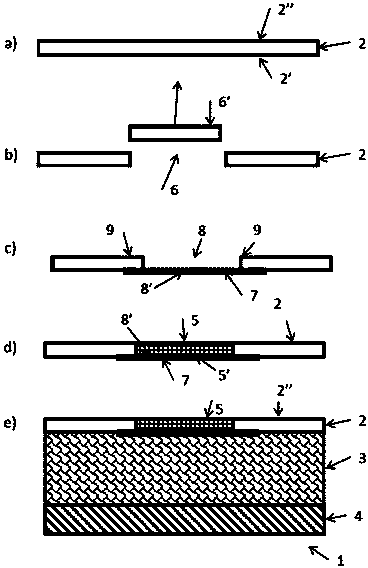

[0030] figure 1 and figure 2 A method for producing an interior trim or lining part 1 , in particular for a motor vehicle, is shown.

[0031] Parts 1 of this type generally consist of a surface skin 2 (flexible and soft to the touch), an intermediate layer 3 of a foam or honeycomb substance, and a support layer 4 (usually rigid). In addition at least one decorative and / or functional insert 5 is integrated, that is to say in such a way that the insert is visible and embedded in the skin 2 .

[0032] The method consists in producing a skin 2 (formed according to the surface topology of the part 1 in question), then placing the skin with a support layer 4 in a foaming mold, and then carrying out foaming of the intermediate layer 3, said method also comprising The step of cutting open the skin 2 and placing the insert 5 in the concerned area 6 of the skin 2 takes place after removing the cut portion 6'.

[0033] According to the invention, the method additionally comprises the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com