Drying and producing process of traditional Chinese medicine through one-step granulating

A production process and granulation technology, which is applied in the field of one-step granulation traditional Chinese medicine drying production process, can solve the problems of low efficiency, long drying period, fine particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

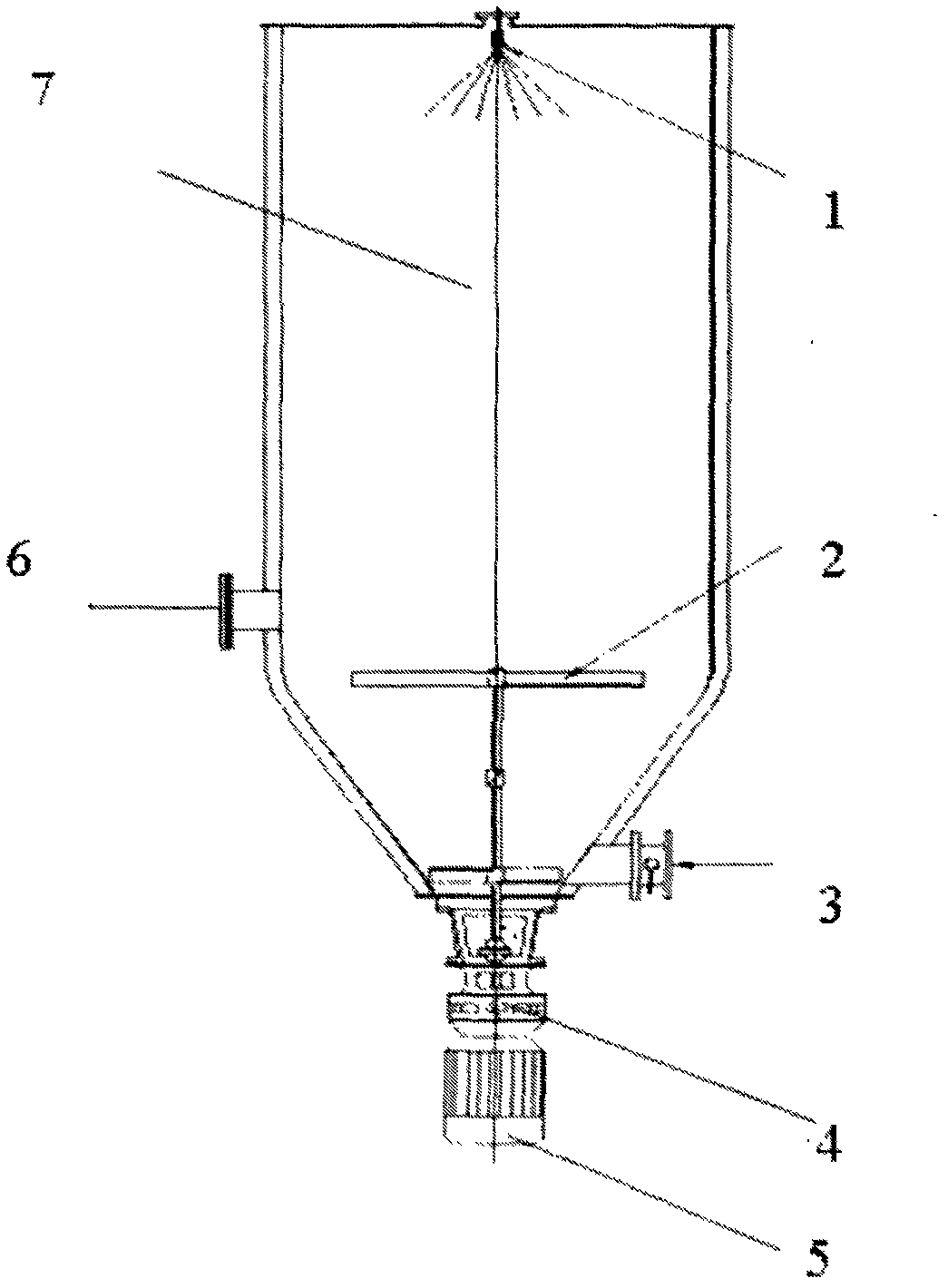

[0014] Referring to the accompanying drawings, one-step granulation of traditional Chinese medicine drying production process: First, the quantitatively dried auxiliary material particles are added from the particle outlet [6], and enter the drying chamber [7] from the upper part, and the filtered air is heated by the heater and then from the hot air inlet. [3] Enter the drying chamber [7]; after the hot air enters, the added dry particles will form a fluidized bed, and the auxiliary particles will be heated to the specified temperature to start the air compressor. After the liquid medicine is pressurized by the compressed air in the storage tank, The nozzle [1] is mixed with compressed air and atomized, and the sprayed liquid medicine is absorbed in the material of the fluidized bed; at the same time, the motor [5] is driven to drive the stirring blade [2] through the stepless speed control box [4] to stir The leaves are constantly stirred, and the particles in the fluidized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com