Automatic packaging machine achieving equal cutting and opposite combination forming bag-making for washing powder

A technology of automatic packaging machine and washing powder, which is applied in packaging, multiple packages, transportation and packaging, etc. It can solve the problems of backward shape, rough appearance, poor stability and reliability, etc., and achieve complete specifications and a wide range of specification changes , to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

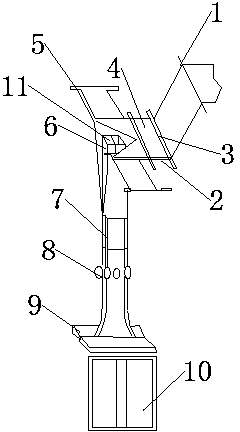

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 Shown: an automatic bag-making packaging machine for washing powder, including a shaper 7, and a feeding cylinder 6 is connected above the shaper 7, and a turning guide roller 5 is connected to the feeding cylinder 6 , the turning guide roller 5 is provided with a cutting hob 4, and one end of the cutting hob 4 is provided with a gap conduit 2 and a pressure roller 3, and the gap conduit 2 and the pressure roller 3 are parallel, and the The other end of the slitting hob 4 is provided with a guide roller 1, and the former 7 is provided with a plurality of longitudinal sealing rollers 8, and the bottom of the former 7 is connected with a horizontal sealing roller 9, and the film raw material passes through the guide roller 1. It is sent into the notch guide plate 2, and the film material is cut in the center by the slitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com