Wedge-shaped plate straightening technology based on cooperating roll systems

A wedge-shaped plate and matching roller technology, which is applied in the field of plate straightening, can solve problems such as unreasonable straightening, inability to straighten wedge-shaped plates, and plate thickness difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

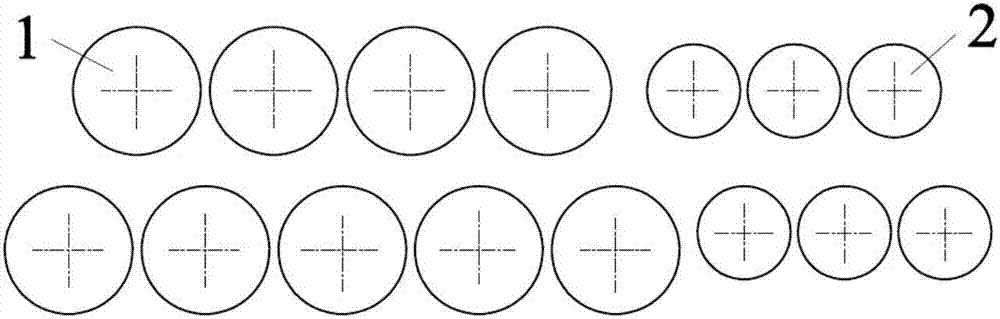

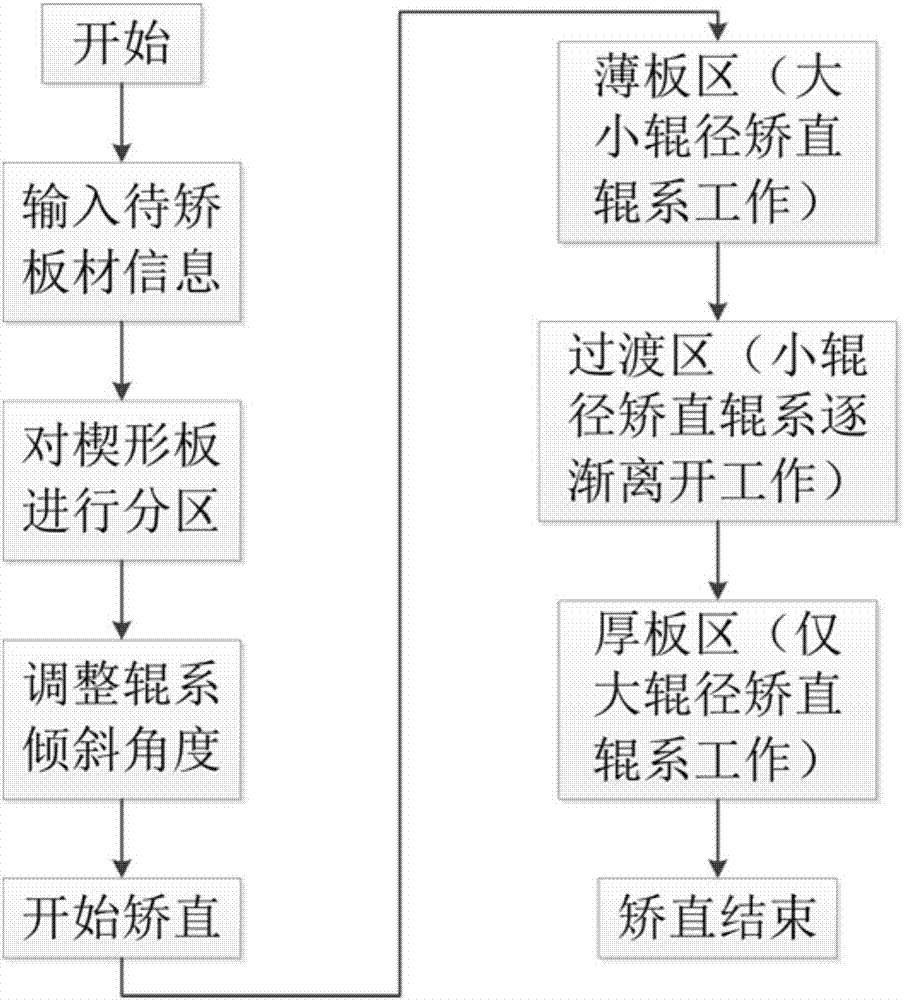

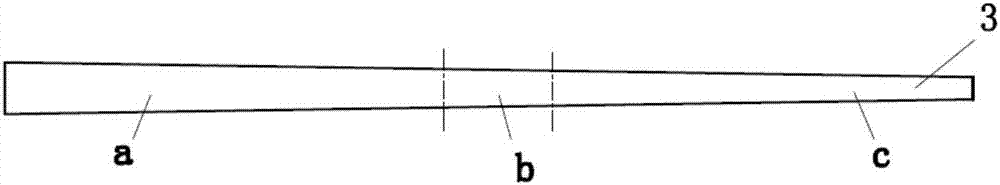

[0024] like figure 1 As shown, a wedge-shaped plate straightening process based on a matching roll system according to an embodiment of the present invention, the straightening roll system adopts two types of roll systems, a large roll diameter and a small roll diameter, and the large roll diameter straightening roll system 1 is arranged in On the entrance side, the small roll diameter straightening roll system 2 is arranged on the exit side. The straightening rolls of the straightening roll system with large and small roll diameters can be adjusted online according to the change of wedge plate thickness during the straightening process, and the upper roll of the straightening roll set 2 with small roll diameter can be lifted up and down to realize the reduction of small rolls. Diameter straightening roller system 2 puts in / out of work to realize the reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com