Tension straightening method and device for wide and thick sheet metal straightener

A metal sheet and straightening machine technology, which is applied in the field of metal sheet straightening, can solve the problems of large tension, cannot be given, and cannot meet the tension straightening requirements of wide and thick metal sheets, and achieve the effect of improving the straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

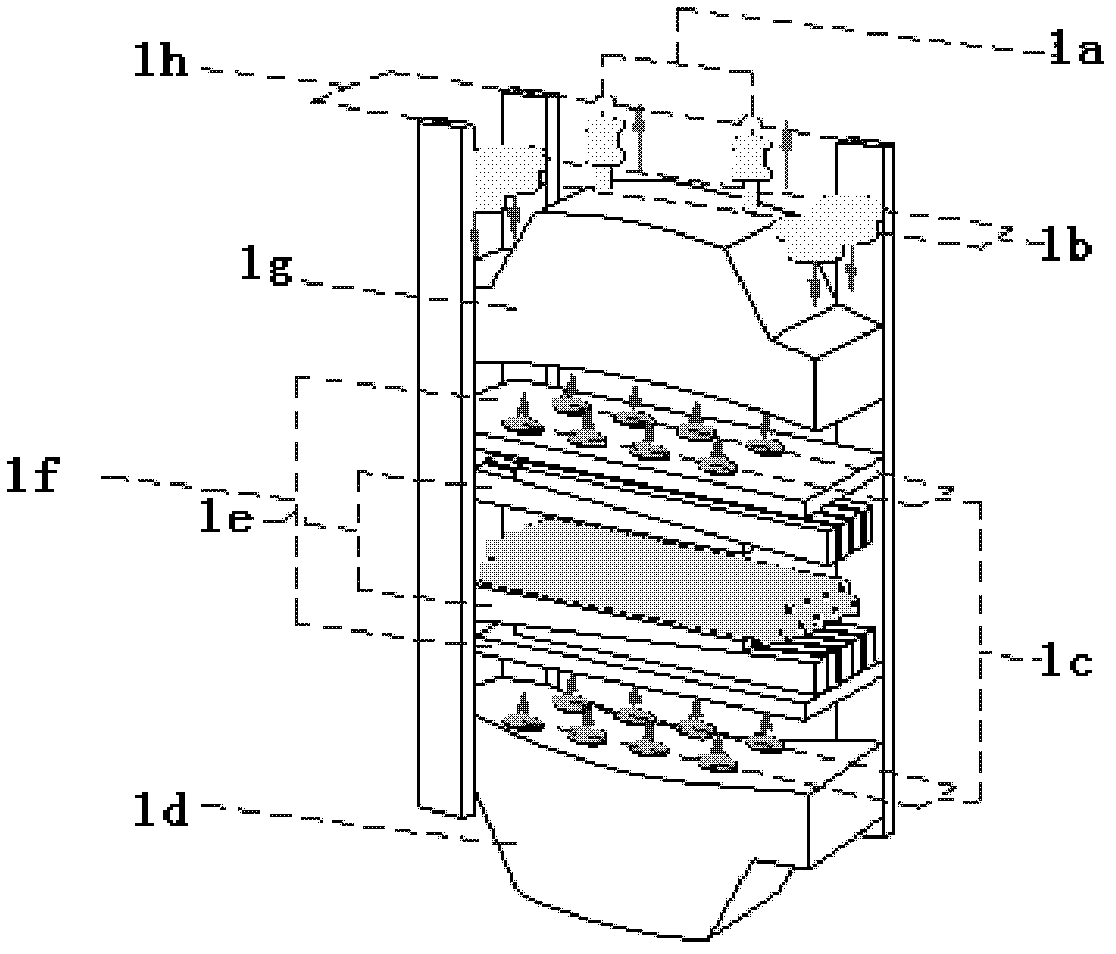

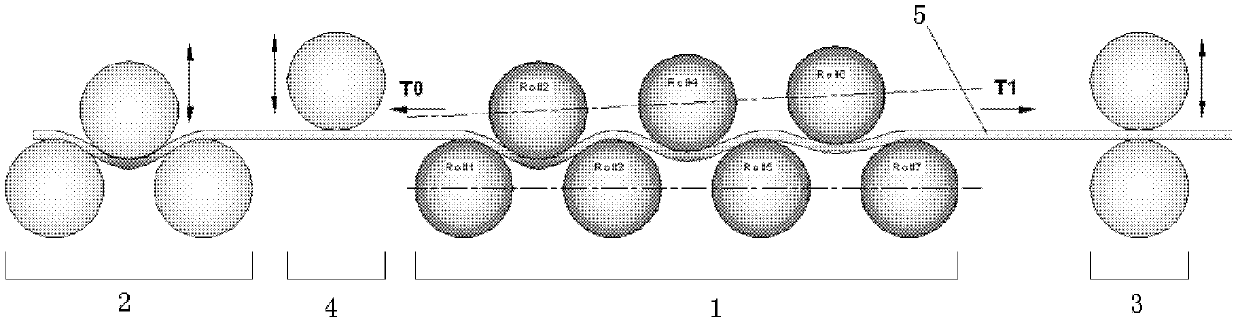

[0053] Please see attached Figure 3-5 , a tension straightening method for wide and thick metal sheet straightening machines, through the tension rollers respectively set at the entrance and exit of the straightening machine, in conjunction with the speed of each straightening roller, the speed difference is used to generate additional tension during the straightening process of the sheet metal, thereby Expand the height of the plastic zone when the plate is bent and deformed, and improve the straightening effect, such as image 3 As shown, the specific steps are as follows: Wherein, a wide and thick steel plate is taken as an example.

[0054] Step 1, determine the relevant parameters of the plate.

[0055] Plate thickness, t=10mm;

[0056] Plate width, B=1000mm;

[0057] Plate yield strength, σ s =400MPa;

[0058] The elastic modulus of the plate, E=210Gpa;

[0059] The distance between the exit pinch roller and the exit of the straightener, L=2000mm;

[0060] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com