Secondary impression device of corrugated case

A corrugated box and secondary pressing technology, which is applied in the field of corrugated box production equipment, can solve problems such as low production efficiency, slow adjustment speed, and difficulty in installing a horizontal positioning and finishing mechanism, so as to improve production efficiency and achieve accurate secondary indentation , Adjust the effect of high synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

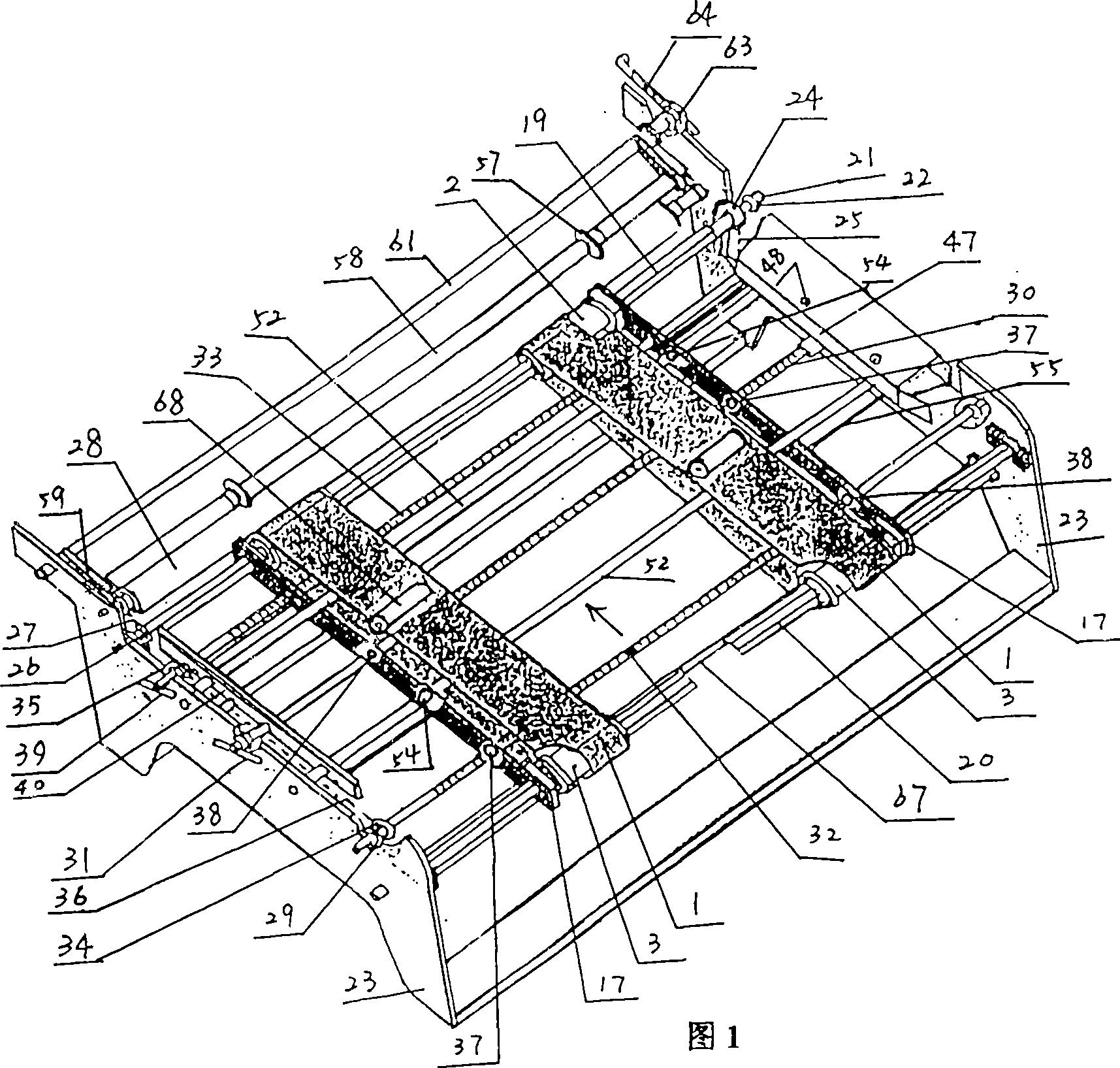

[0014] Further explain in detail in conjunction with accompanying drawings;

[0015] In the figure: 1—shows a small belt, 67—shows a belt tensioning mechanism, 68—shows a paper pressing mechanism, and the arrow shows the direction in which the corrugated cardboard advances;

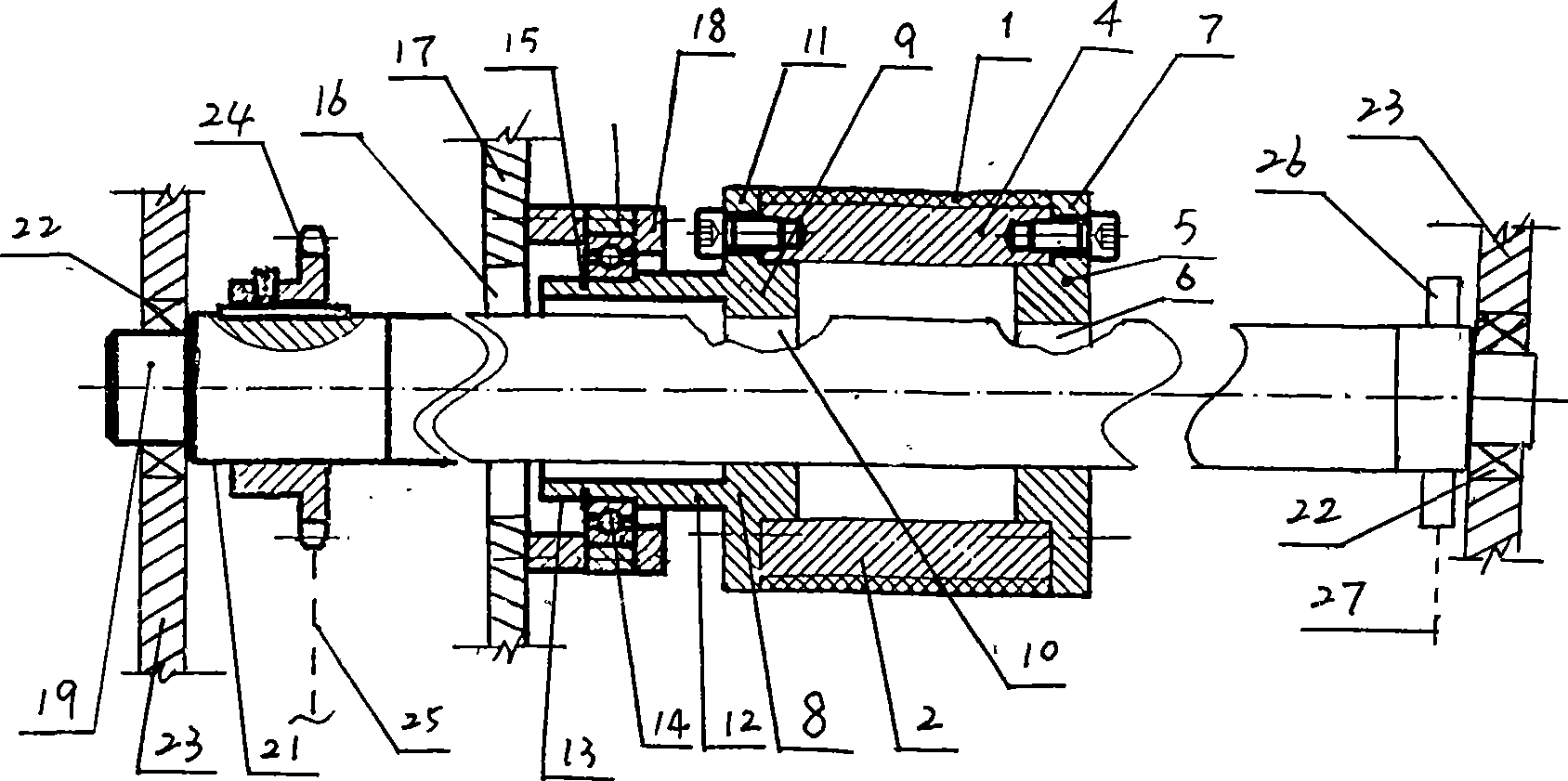

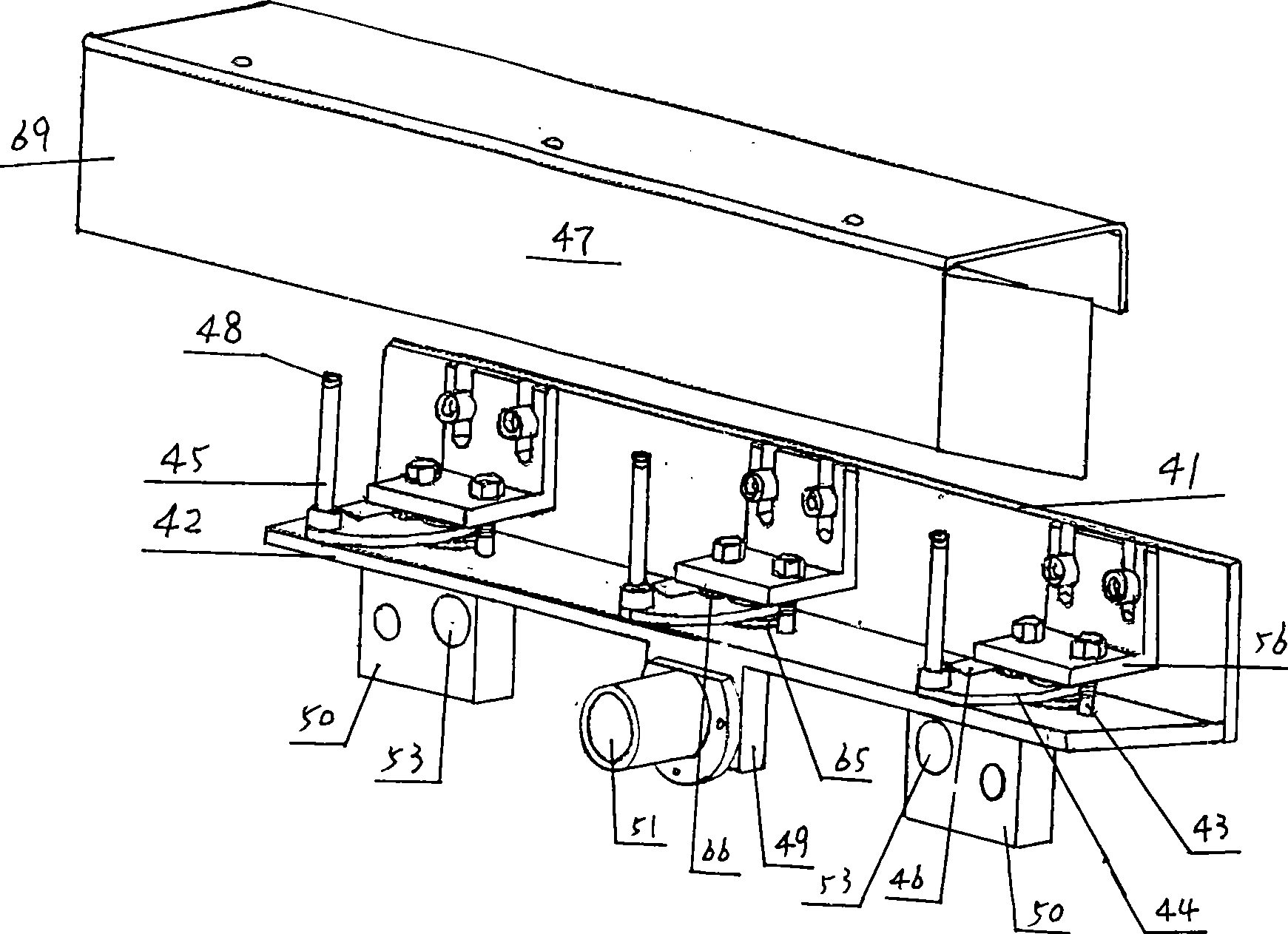

[0016] As shown in Figures 1 and 2, the structure of the paper feeding mechanism matched with the indentation mechanism is that it has two hexagonal steel-shaped transmission shafts, the active hexagonal steel-shaped rotating shaft 19 and the driven hexagonal steel-shaped rotating shaft 20, and two synchronous small The belt 1 is located under the same small belt 1 on the same side, and the driving roller 2 and the driven roller 3 driven by the driving hexagonal steel shaft 19 and the driven hexagonal steel shaft 20 respectively pass through the small wallboard on the same side 17 are connected together, and the structure of the driven roller 3 and the driving roller 2 is the same, with a sleeve 4, one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com