On-line solid solution furnace

A solid solution furnace and heating furnace technology, applied in the direction of furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of not being able to meet the requirements of large aluminum alloy plates, and achieve the effects of short quenching transfer time, wide coverage and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

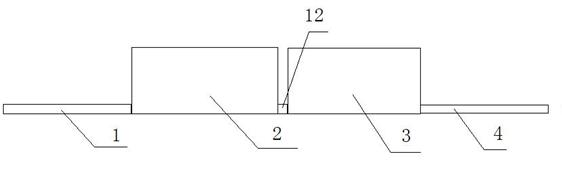

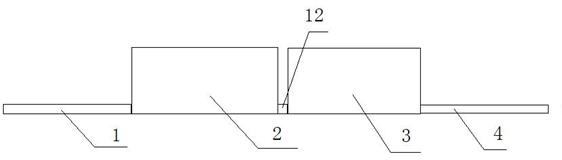

[0020] like Figure 1-2 As shown, the present invention comprises a heating furnace 2, a quenching chamber 3 arranged horizontally adjacent to the heating furnace 2; A transition roller 12 is provided between the feed ends, and a discharge roller table 4 is provided at the discharge end of the quenching chamber 3 rear end; the feeding roller table 1, the heating furnace 2, the quenching chamber 3 and the discharge roller are arranged using existing driving equipment. Road 4 is driven separately.

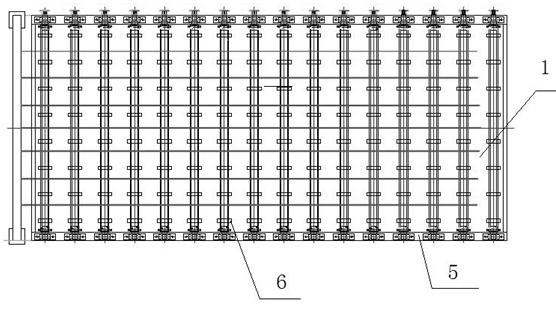

[0021] Positioning guide rails 5 are provided on the feeding roller table 1 and the unloading roller table 4 . Each roller bar on the feeding roller table 1 and the unloading roller table 4 is sleeved with eight bakelite backing wheels 6, and the backing wheels 6 are evenly distributed along the roller bars; the feeding roller table and the unloading roller table The rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com