Steel tube cargo shipping accessory and operating method employing same

A technology for cargo and steel pipes, which is applied in the field of steel pipe cargo ship loading attachments and the use of their operation fields, can solve the problems of high technical requirements for door operators and commanders, easy decoupling of hook and thread buckle noses, and high frequency of buckle damage. , to achieve the effect of adapting to a wide range of steel pipe cargo specifications, enhancing the binding force, and reducing unsafe hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The steel pipe cargo shipping attachment of the present invention and its operation method will be described below in conjunction with the accompanying drawings.

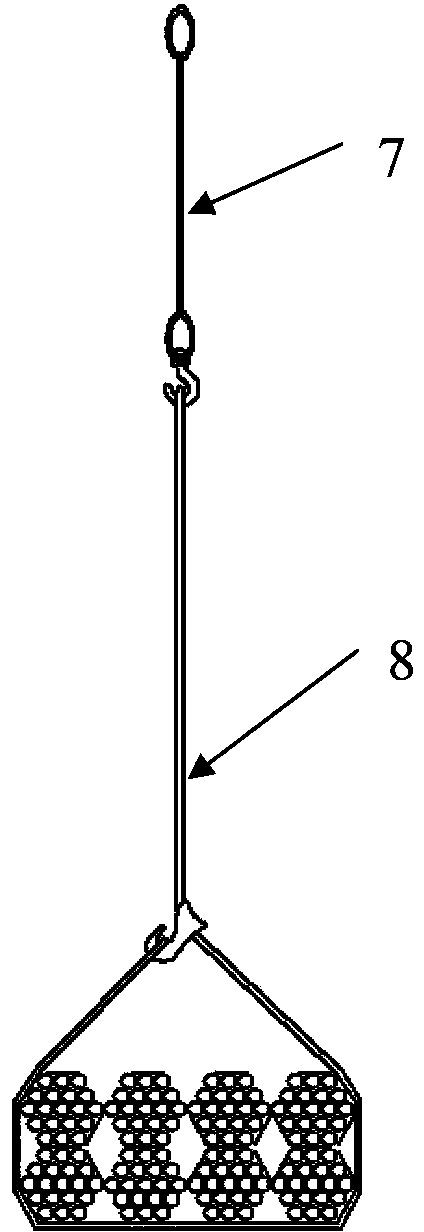

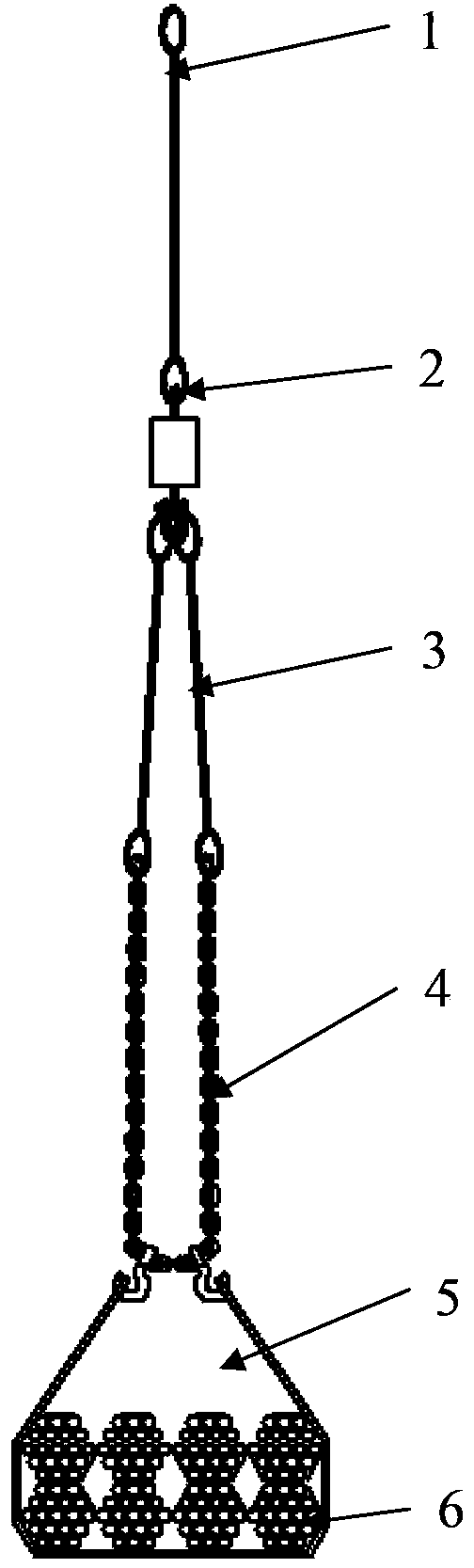

[0039] Such as image 3 , 4 As shown, the structure of the steel pipe cargo shipping attachment of the present invention is that the attachment structure includes: a support bar suspension system 1, a support bar 2, a short suspension system 3, a chain 4, a sliding hook 5, and a wire sling 6, The support bar 2 is hung on the shackle of the support bar suspension system 1, the short suspension system 3 is hung on the suspension point under the support bar 2, and the two ends of the chain 4 are hung on the shackle of the short suspension system 3. The sliding hook 5 is slidably hung on the chain 4 , and the wire lock 6 is connected to the chain 4 through the sliding hook 5 .

[0040] The operation method of utilizing the steel pipe cargo shipping attachment described in claim 1 comprises the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com