Combustion chamber cylinder section-seal head heat insulation layer integrated extrusion molding system and method

A technology of extrusion molding and combustion chamber, which is applied in the direction of coating, household appliances, household components, etc., can solve the problems of low efficiency, difficult forming process of barrel section and head insulation layer, etc., and achieves wide application range and good size and the effect of workpiece structure adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

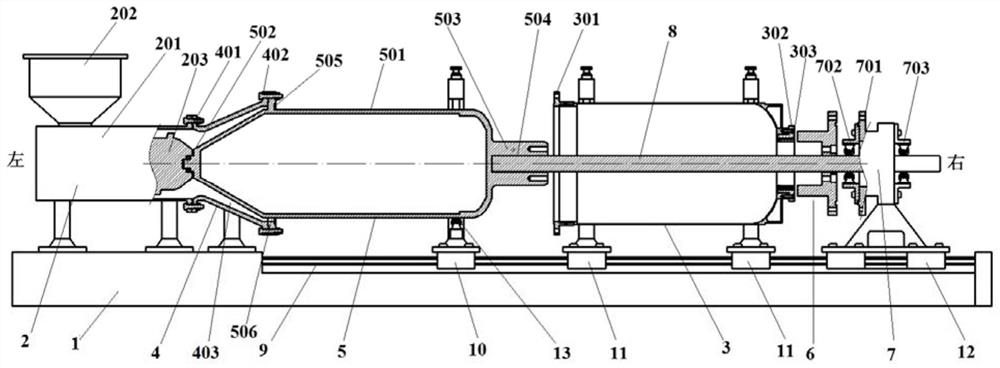

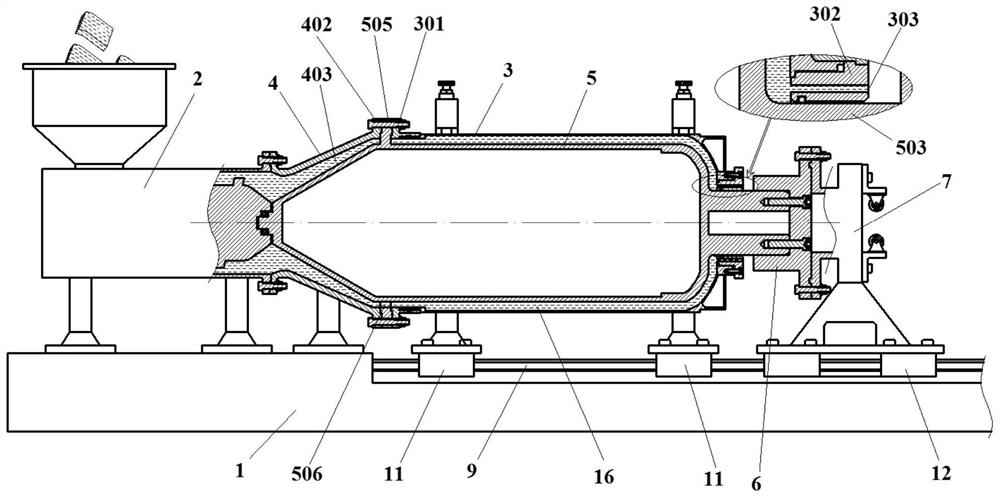

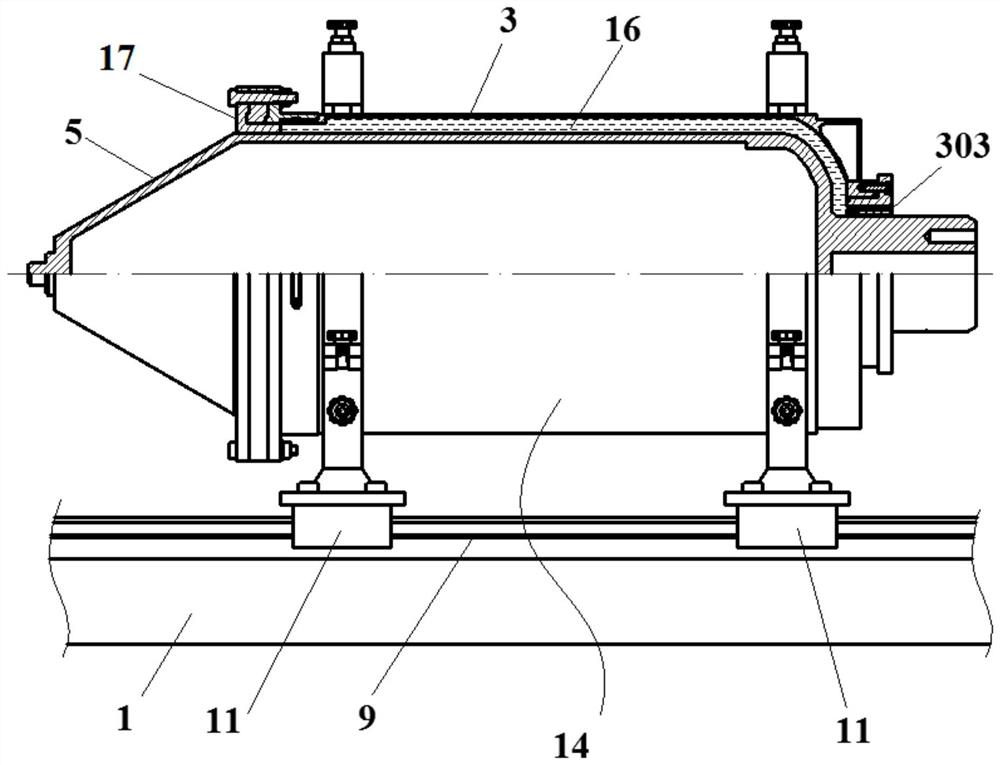

[0055] This embodiment provides an integrated extrusion molding system for the combustion chamber section-head heat insulation layer, such as figure 1 As shown, it includes a base 1, an extruder 2 and a combustion chamber housing 3. The combustion chamber housing 3 is an integral structure of a barrel section-head, and also includes a transition sleeve 4, a mandrel 5, a mandrel adapter flange 6 and Support 7, extruder 2, transition sleeve 4, mandrel 5, combustion chamber shell 3, mandrel adapter flange 6 and support 7 are arranged coaxially from left to right;

[0056] A slide rail 9 is laid on the base 1, an extruder 2 is fixedly installed on the base 1 at the left end of the slide rail 9, and a first center frame 10, which can slide on the slide rail 9, is installed sequentially from left to right on the slide rail 9, The second center frame 11 and the sliding base 12, the first center frame 10 supports the mandrel 5, the second center frame 11 supports the combustion chambe...

Embodiment 2

[0069] This example provides an integrated extrusion molding method for the combustion chamber section-head insulation layer, which uses the combustion chamber section-head insulation layer integrated extrusion molding system in Example 1;

[0070] The method specifically follows the steps below:

[0071] Step 1, preparation stage:

[0072] Such as figure 1 As shown, the inner wall of the combustion chamber casing 3 is polished and cleaned, the casing is connected to the left flange 301 and the casing is connected to the right flange 302, the left flange 401 of the transition sleeve is connected to the right end of the extrusion barrel 201, and the core The left shaft head 502 of the mold 5 is installed on the right end of the extrusion screw 203 through a bearing, the right flange 402 of the transition sleeve is connected with the left flange 505 of the mandrel, the right end of the mandrel 5 is supported by the first center frame 10, and the combustion chamber housing 3 Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com