Bearing fault detection method based on convolution multi-head self-attention mechanism

A technology of fault detection and attention, applied in the field of bearing fault diagnosis, can solve the problems of failure to effectively learn the local characteristics of bearings, failure to learn bearing fault characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

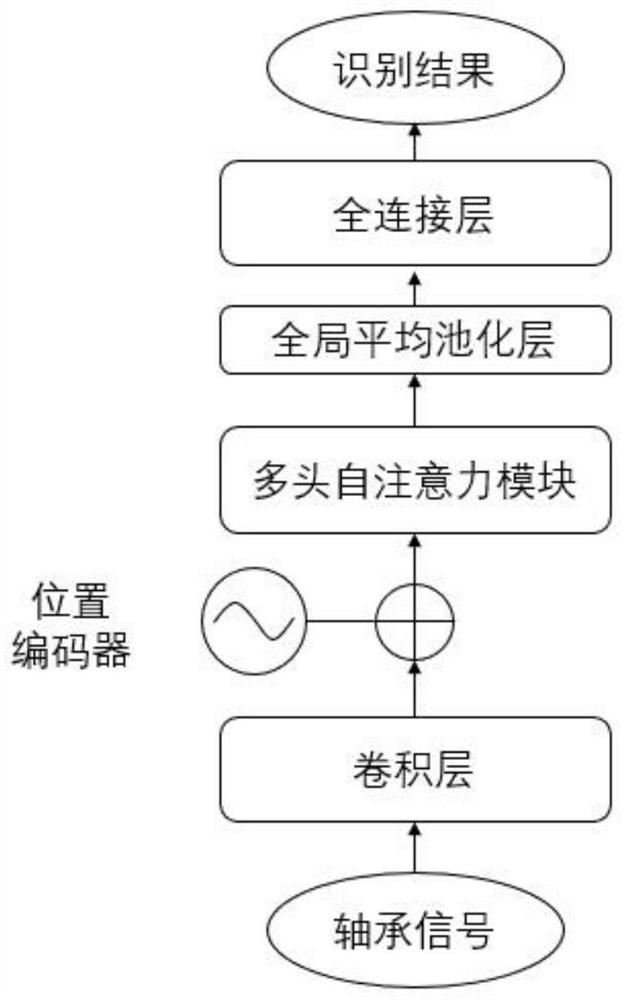

[0035] Embodiment 1 of the present invention, a bearing fault detection method based on convolutional multi-head attention, see figure 1 , follow the steps below:

[0036] Collect the fault signal of the bearing, collect 10 different types of fault bearing vibration signal parameter information through the sensor, and record the bearing fault label.

[0037] The bearing signal preprocessing operation is to perform standard normalization processing on the bearing signal, and then cut the bearing signal according to the equal length of 2048 sampling points. The standard normalization function is:

[0038]

[0039] Among them, x represents the sample signal, μ represents the average value of the sample signal, and σ represents the standard deviation of the sample signal.

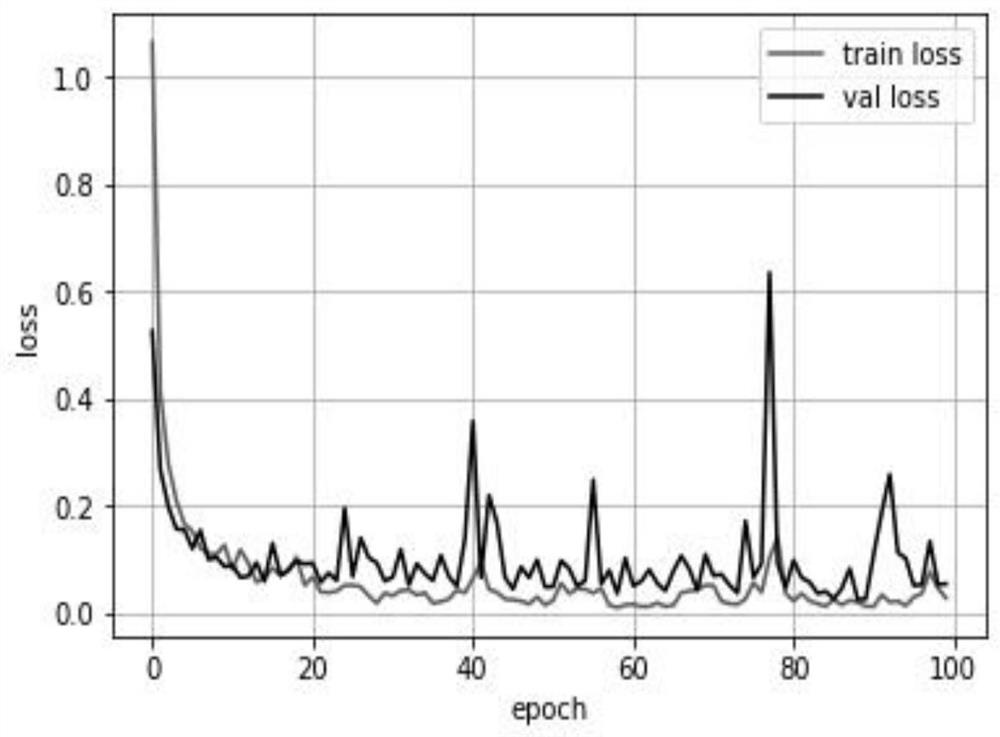

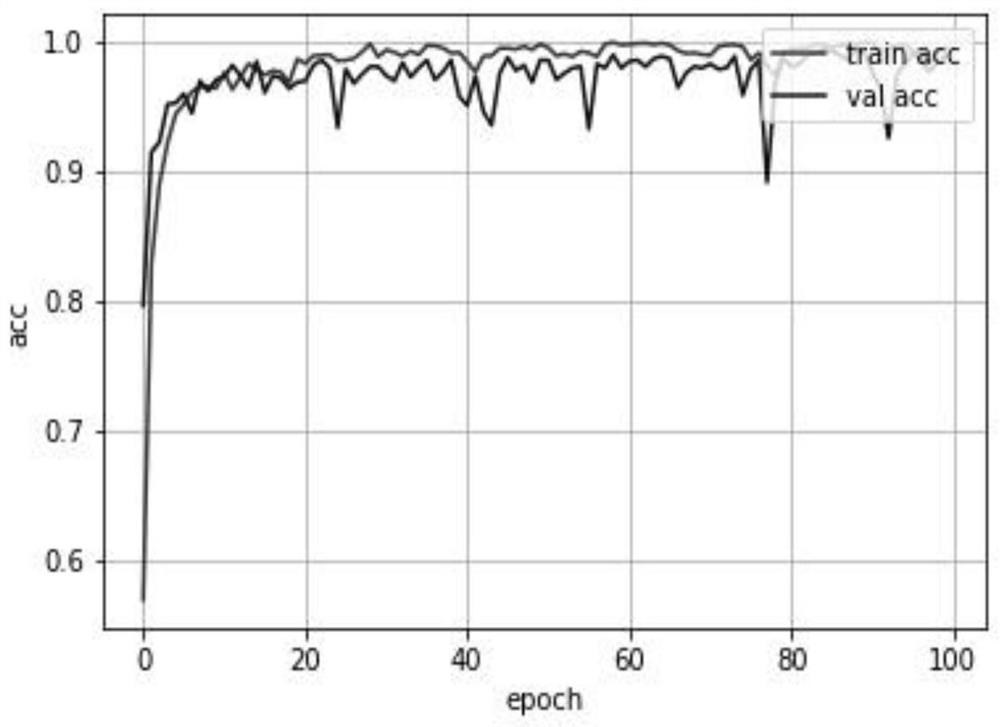

[0040] Generate a bearing fault data set, randomly select 1000 copies of 10 different types of fault bearing signals, and randomly divide them into training set, verification set and test set according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com