Patents

Literature

75results about How to "Fast automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical arm kinematics parameter calibration method based on measuring of laser tracker

InactiveCN110281241ARealize offline calibrationImprove robustnessProgramme-controlled manipulatorThree-dimensional spaceEngineering

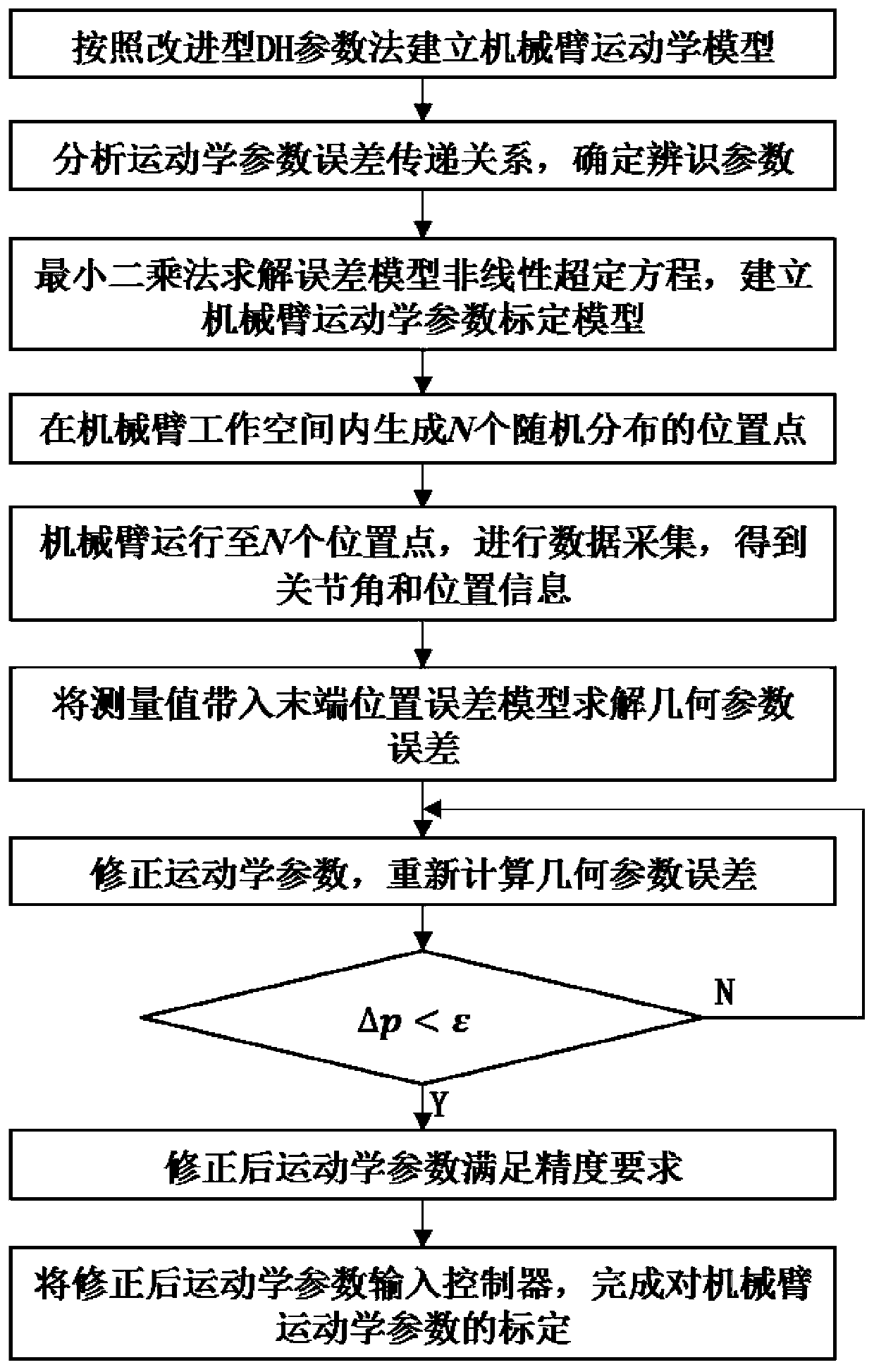

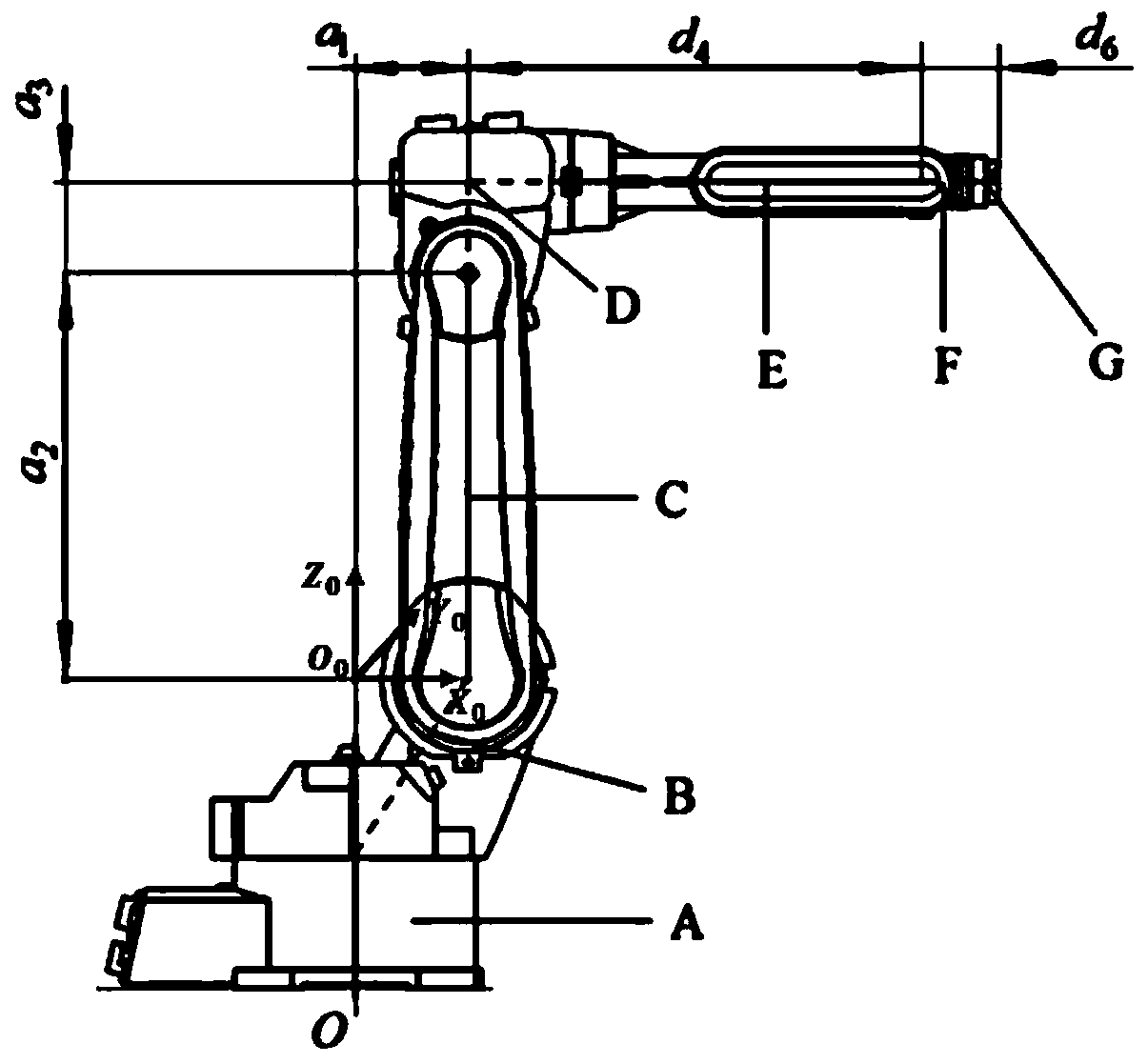

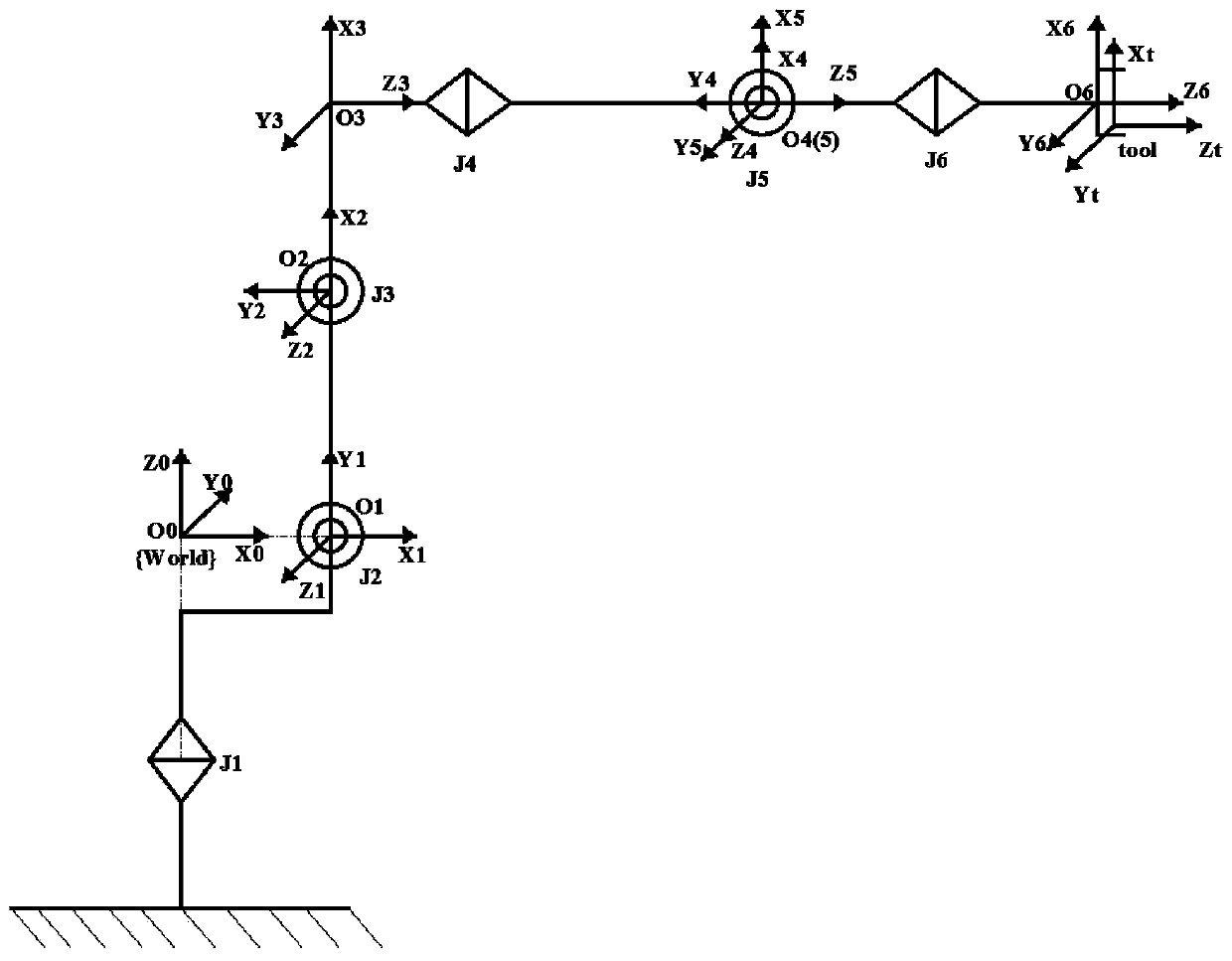

The invention discloses a mechanical arm kinematics parameter calibration method based on measuring of a laser tracker, and belongs to the field of industrial mechanical arm kinematics, and relates to the mechanical arm kinematics parameter calibration method based on measuring of the laser tracker. The method is based on the mechanical arm joint construction. An improved DH parameter method is adopted for building a mechanical arm kinematics model, a kinematics modeling result is used for building a mechanical arm kinematics parameter error calibration model, in consideration with the mechanical arm three-dimensional space work range, the laser tracker is adopted for measuring N absolute position coordinates of the tail end of the mechanical arm, on the basis of the kinematics parameter error calibration model, through repeated iteration, the mechanical arm kinematics parameter error is solved, a corrected kinematics parameter is input into a mechanical arm controller, and offline calibration of the mechanical arm is achieved; the mechanical arm tail end position measuring method is high in robustness, high in speed, and high in process automation degree, the adopted error solving method is high in speed, high in precision and simple in process, and the high-precision rapid calibration of joint type mechanical arm kinematics parameters can be achieved.

Owner:DALIAN UNIV OF TECH

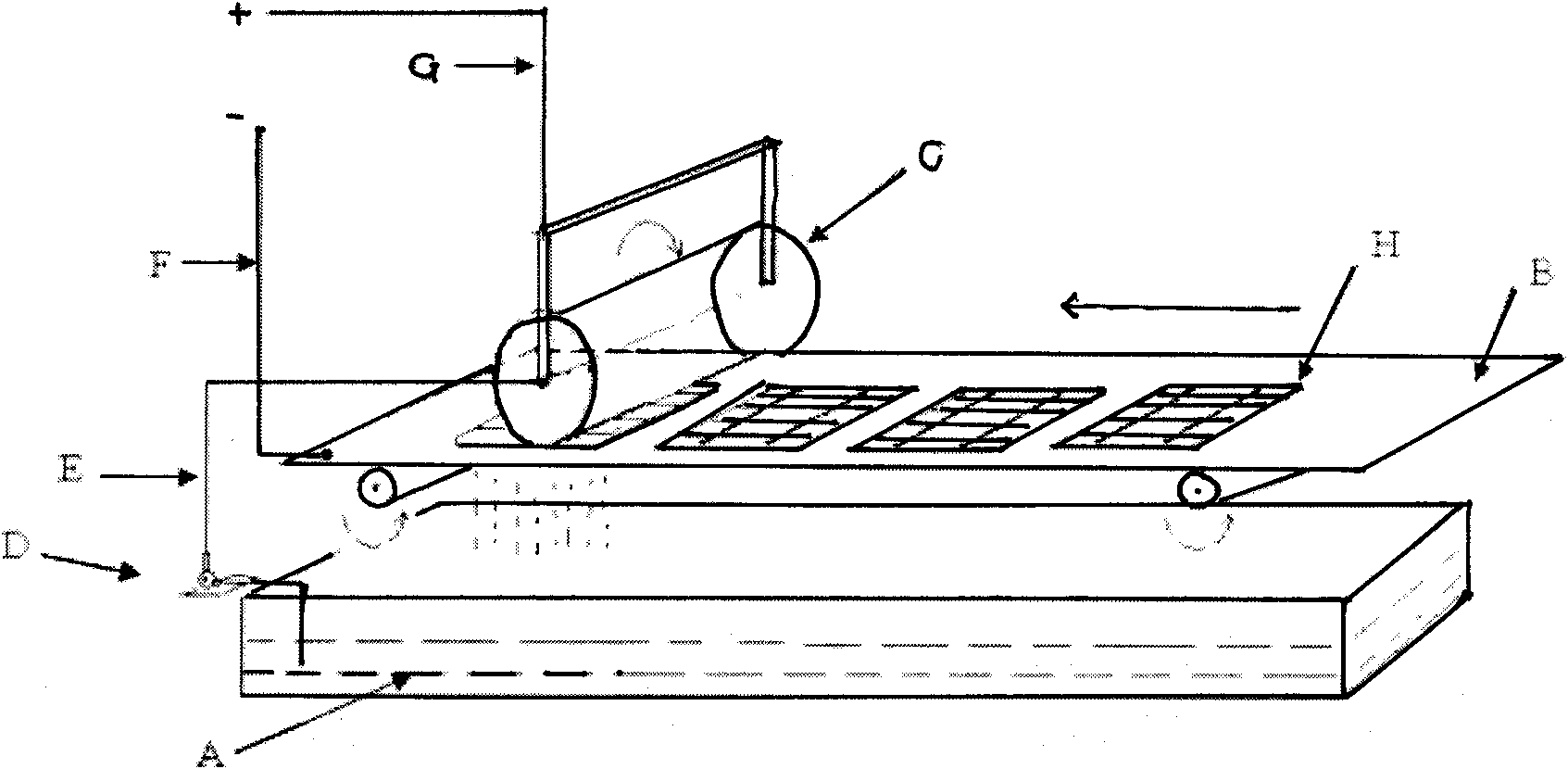

Method for preparing solar array electrode by electro-brush plating

ActiveCN101789468AImprove conversion efficiencyImprove collection effectFinal product manufactureSemiconductor devicesElectrical resistance and conductanceSilicon solar cell

The invention discloses a method for preparing a silicon solar array electrode by electro-brush plating, which comprises the steps of: (1) coating of a protective film; (2) laser grooving; (3) surface activation treatment; (4) electro-brush plating: a general electroplating power supply is adopted; a cathode of the power supply is connected with a pretreated silicon semiconductor; an anode of the power supply is connected with an plating pen immersed with a plating solution; the power supply is started; the electro-brush plating is carried out on the plating pen on the surface of the pretreated silicon semiconductor; and the plating pen is a mobile plating pen or a pictographic plating pen; and (5) the removal of the protective film. The invention obviously enhances the production efficiency by adopting the electro-brush plating and realizes the preparation of the array electrode within a shorter time; the prepared electrode is uniform and bright; at the same time, the electroplating bath solution has easy maintenance; the electrode has high bonding strength with a base body and plating layers have high bonding force, thereby reducing contact resistance between the base body and a conducting wire; and the invention has good automatic degree, high electroplating speed, simple technological operation, easy mastery, relatively lower cost, high efficiency and less required tooling equipment.

Owner:SOUTH CHINA NORMAL UNIVERSITY

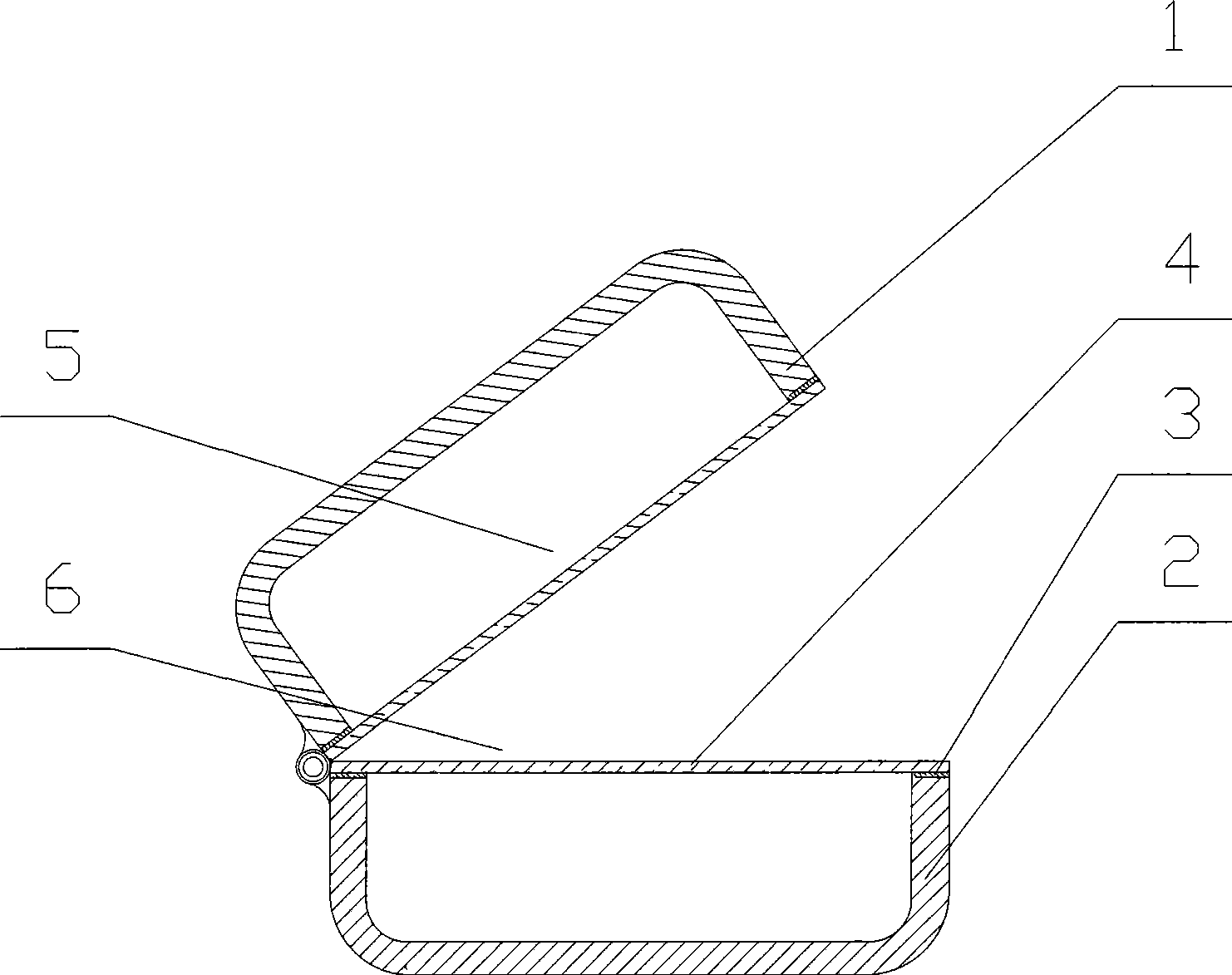

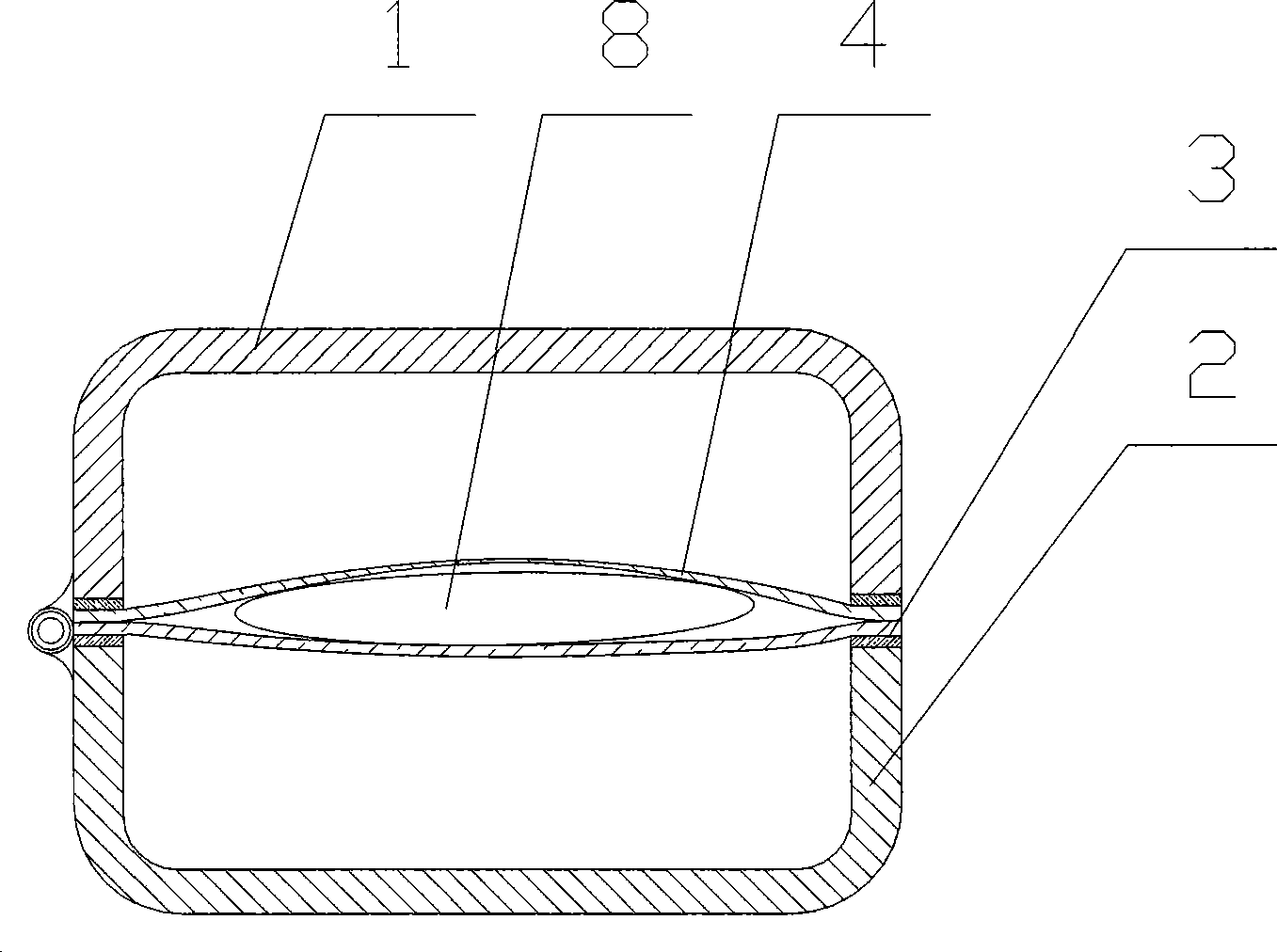

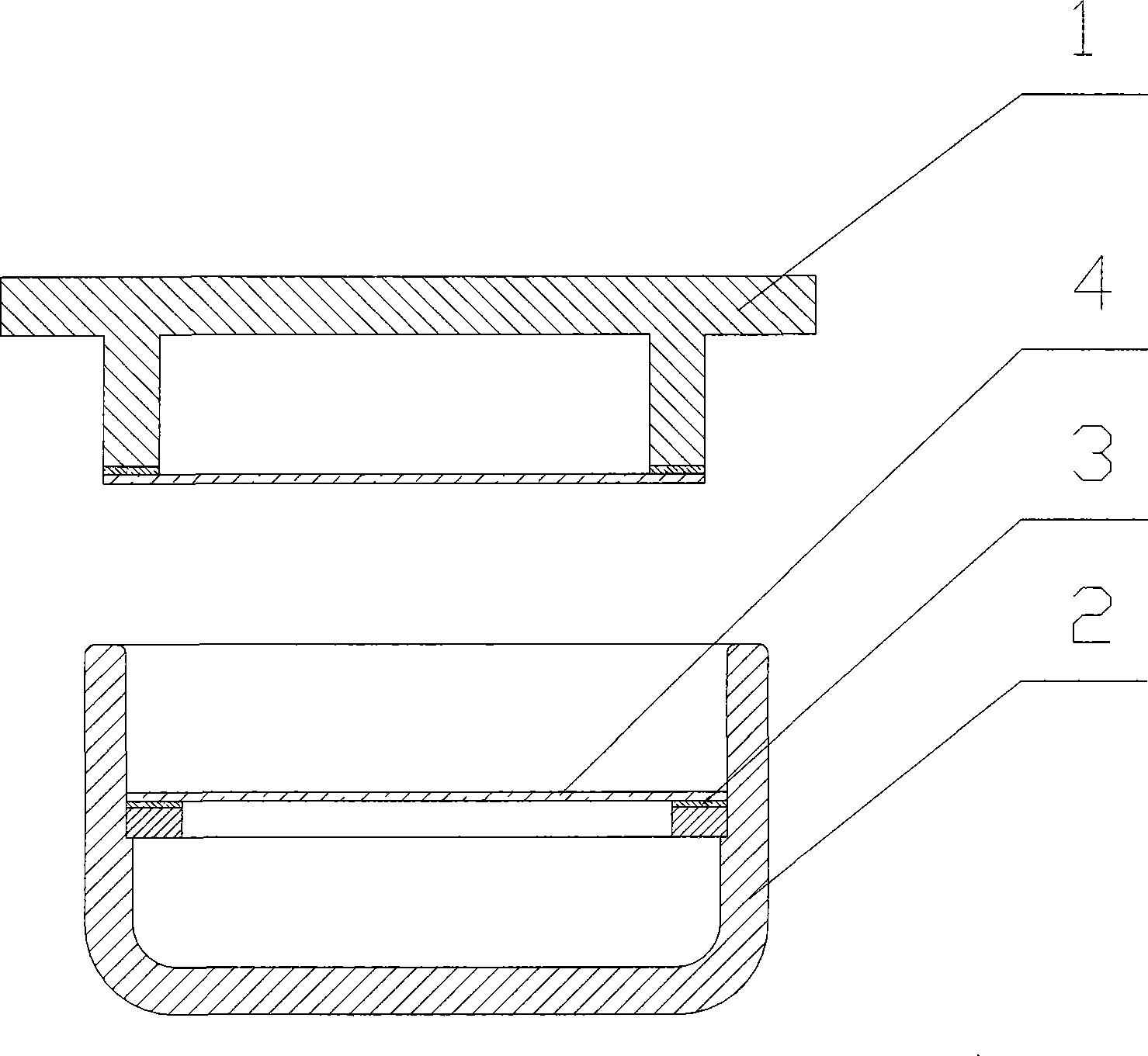

Novel packaging box and manufacturing technology thereof

ActiveCN101362529AFast curingReaction is easy to controlClosure with auxillary devicesBoxesManufacturing technologyAdhesive

The invention relates to a novel packing case and the manufacturing process thereof, which is characterized in that the novel packing case comprises an upper casing body and a lower casing body which are oppositely covered, and an elastic tensioning diaphragm which can elastically clip objects when the casing bodies are oppositely covered is respectively adhered to the upper casing body and the lower casing body by adopting UV adhesive. The novel packing case has the advantages that the structure is simple, the design is reasonable, is in favor of simplifying the production processes, reducing the production cost and re-utilization. Due to the advantages of the UV adhesive, the elastic tensioning diaphragm which is adhered by adopting the adhesive has the significant advantages of high bonding strength, high speed and high degree of automation, etc.

Owner:福州康派克光电科技有限公司

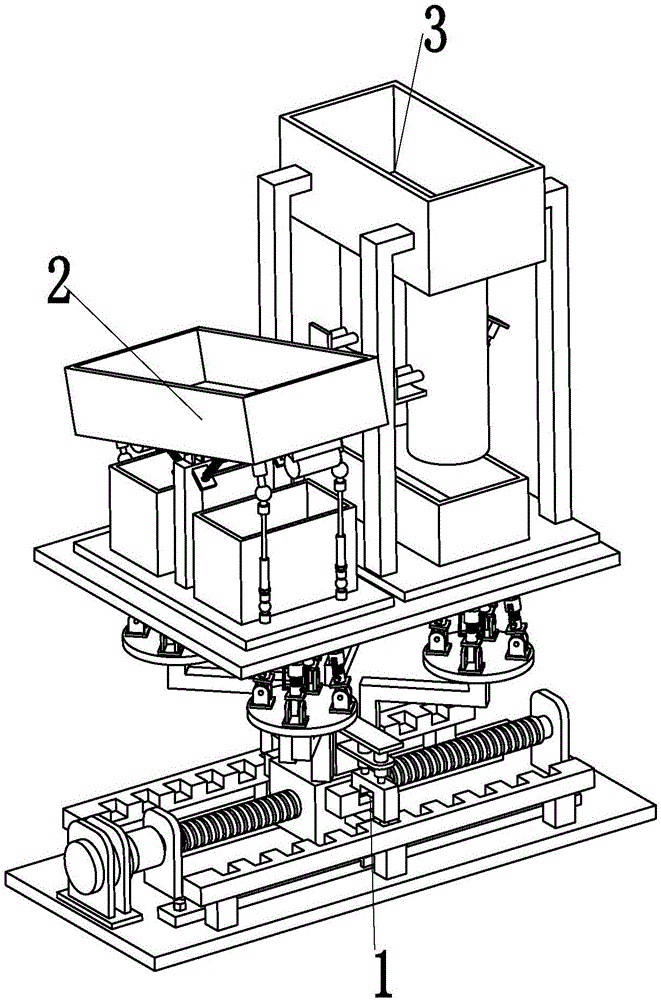

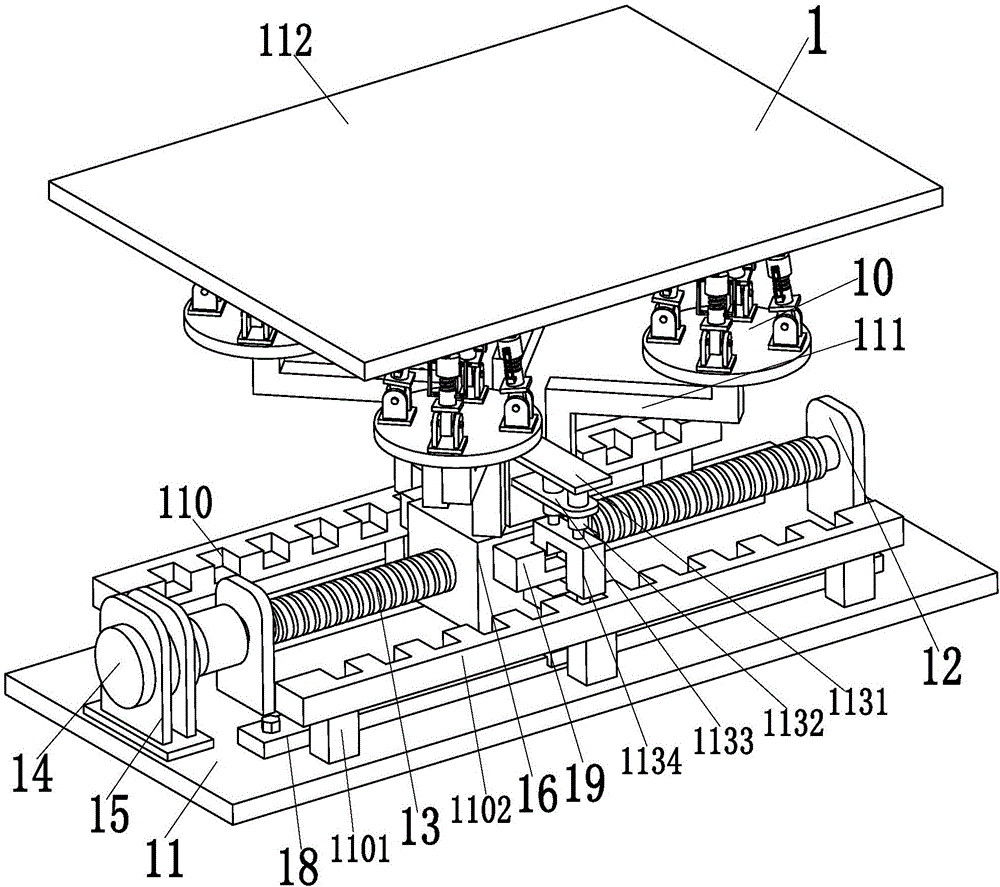

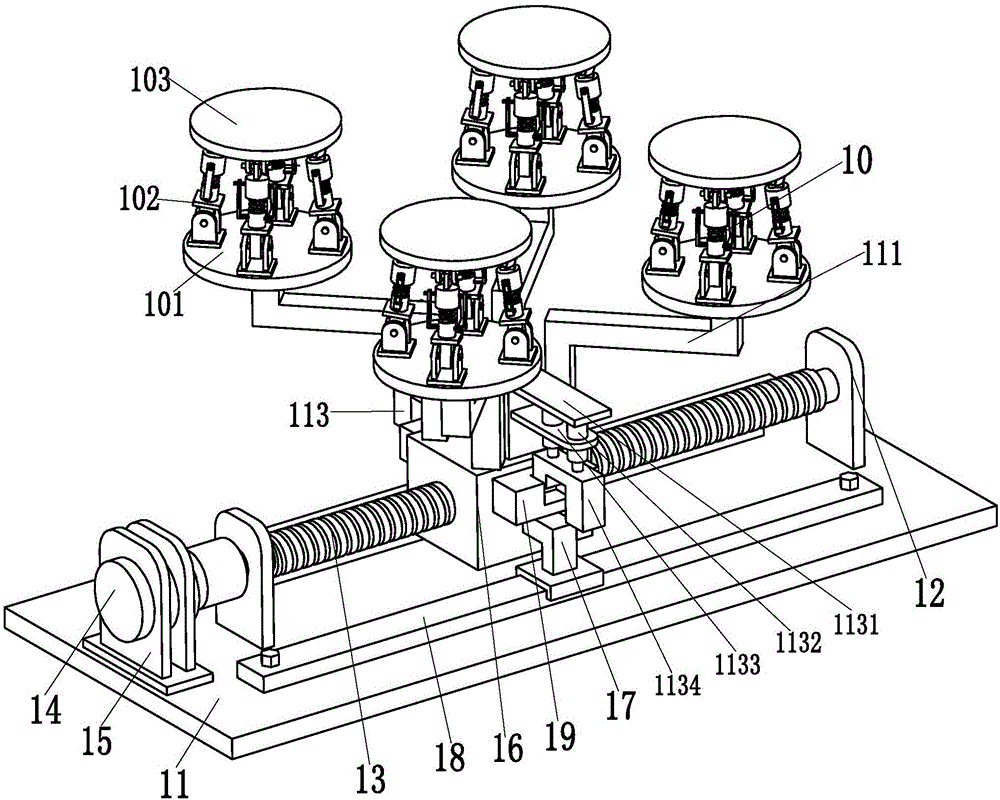

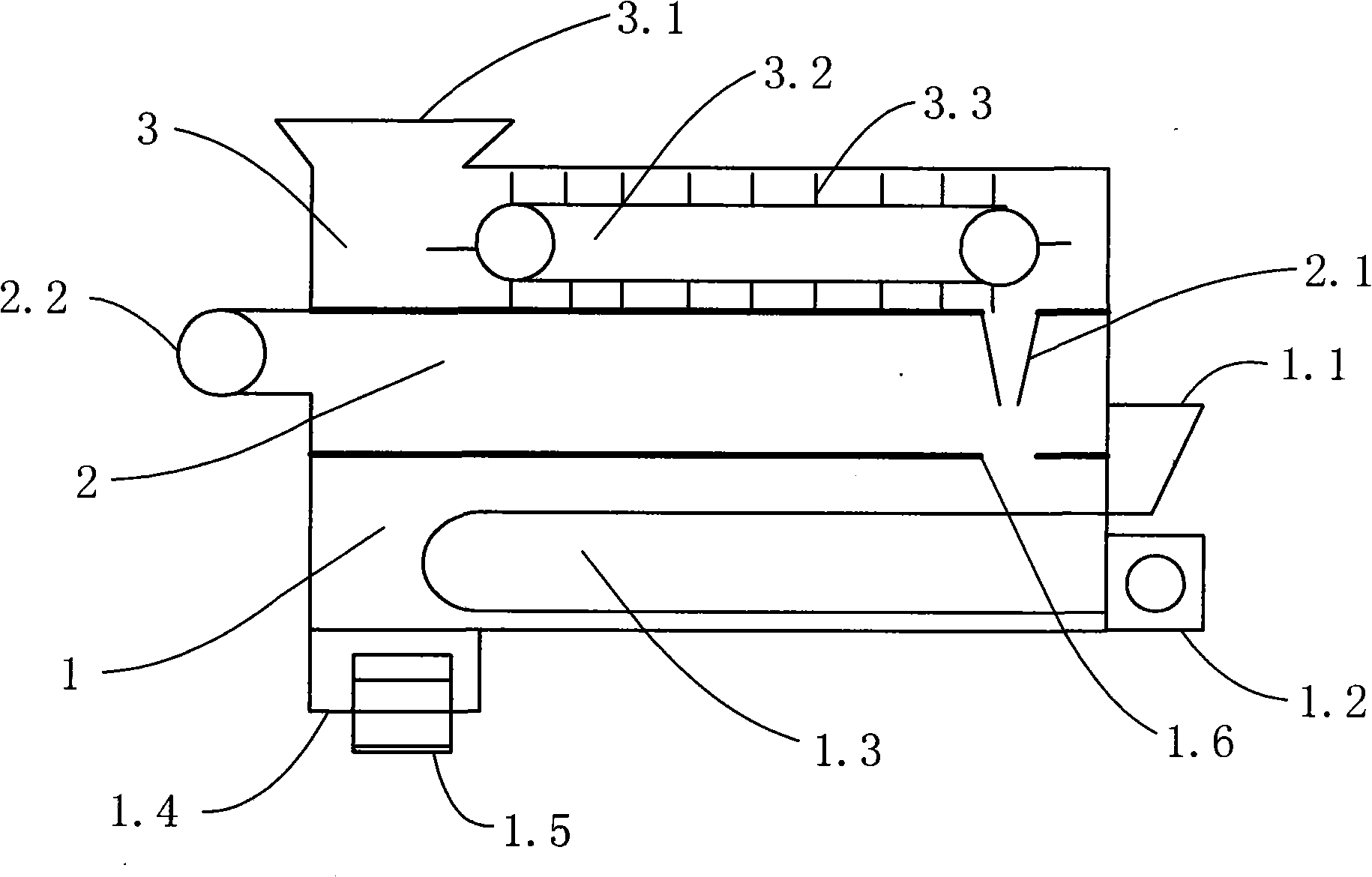

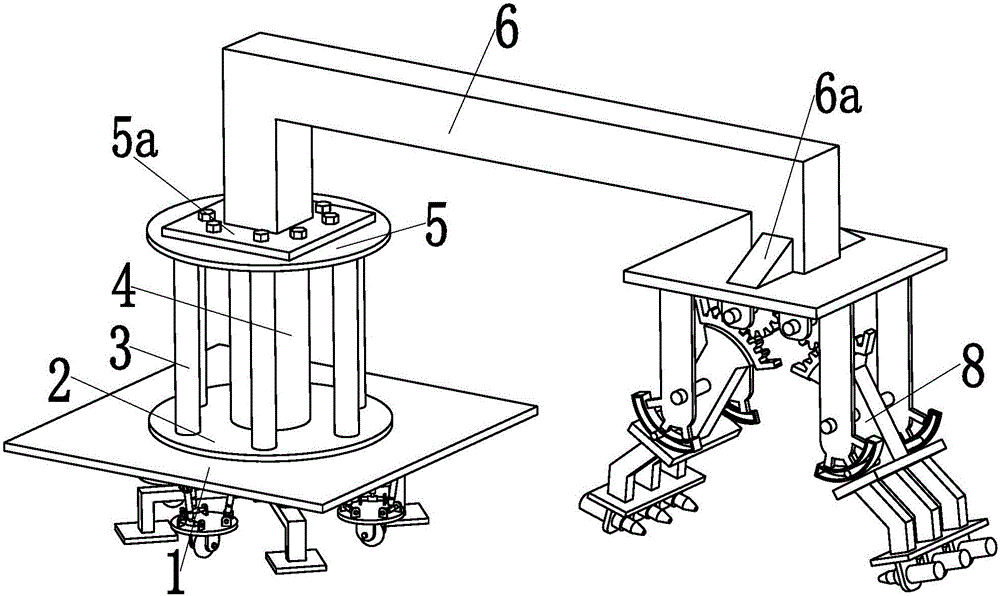

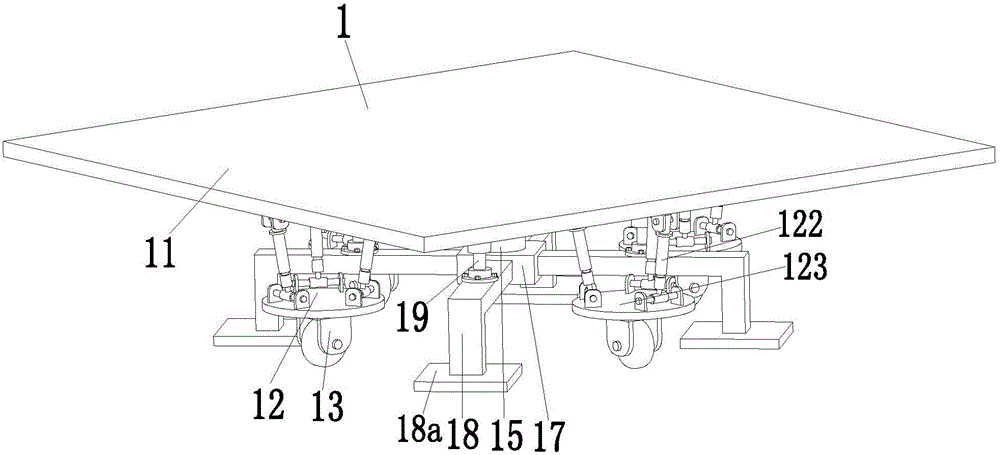

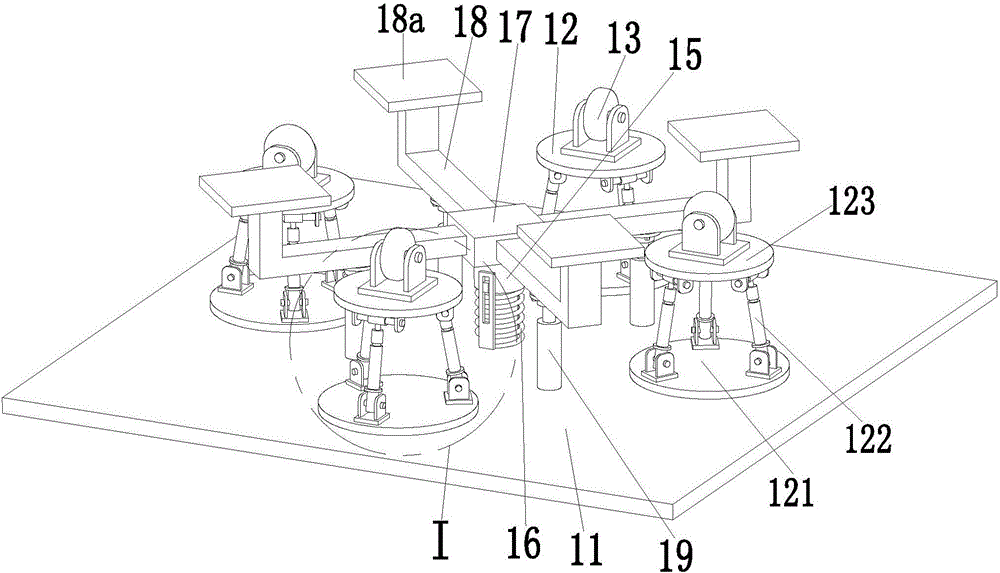

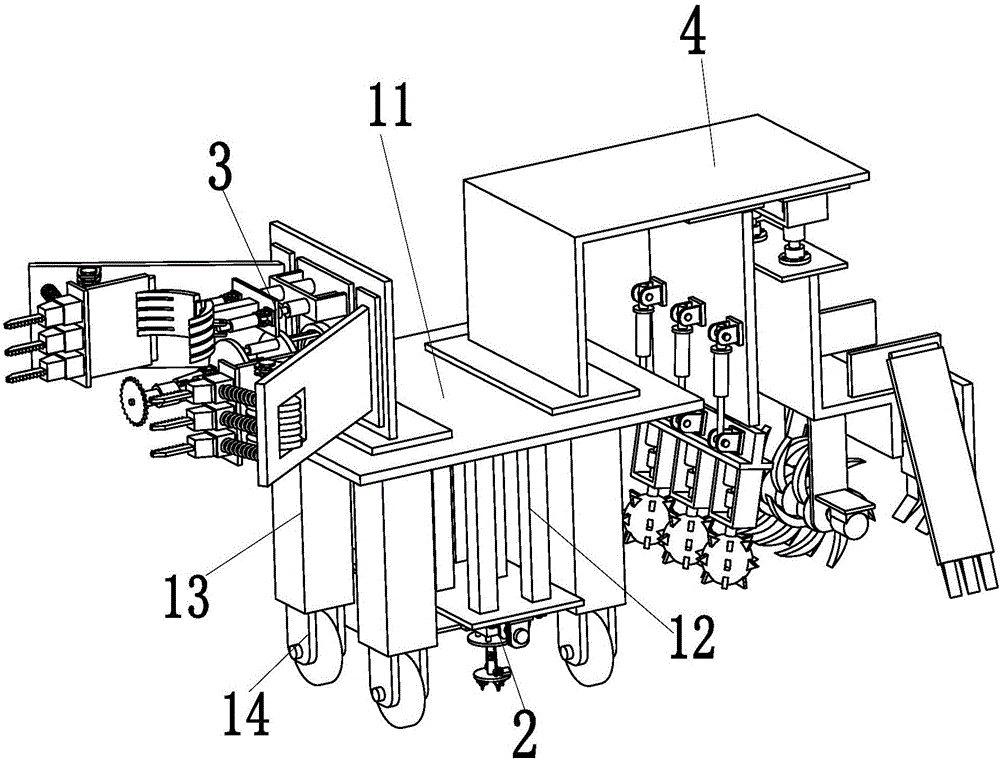

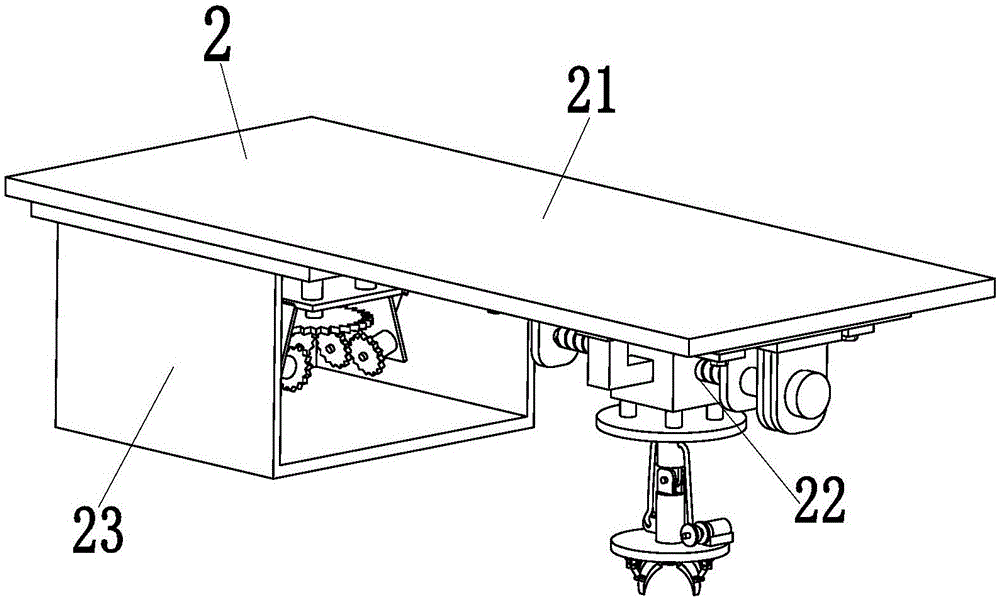

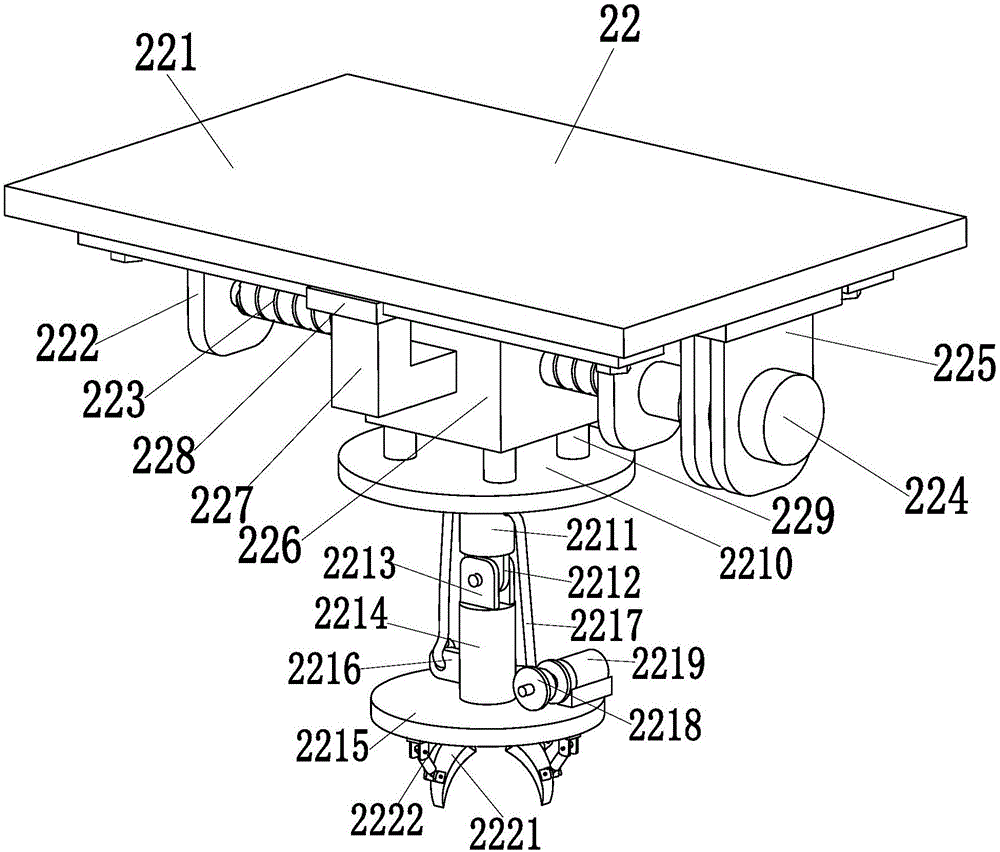

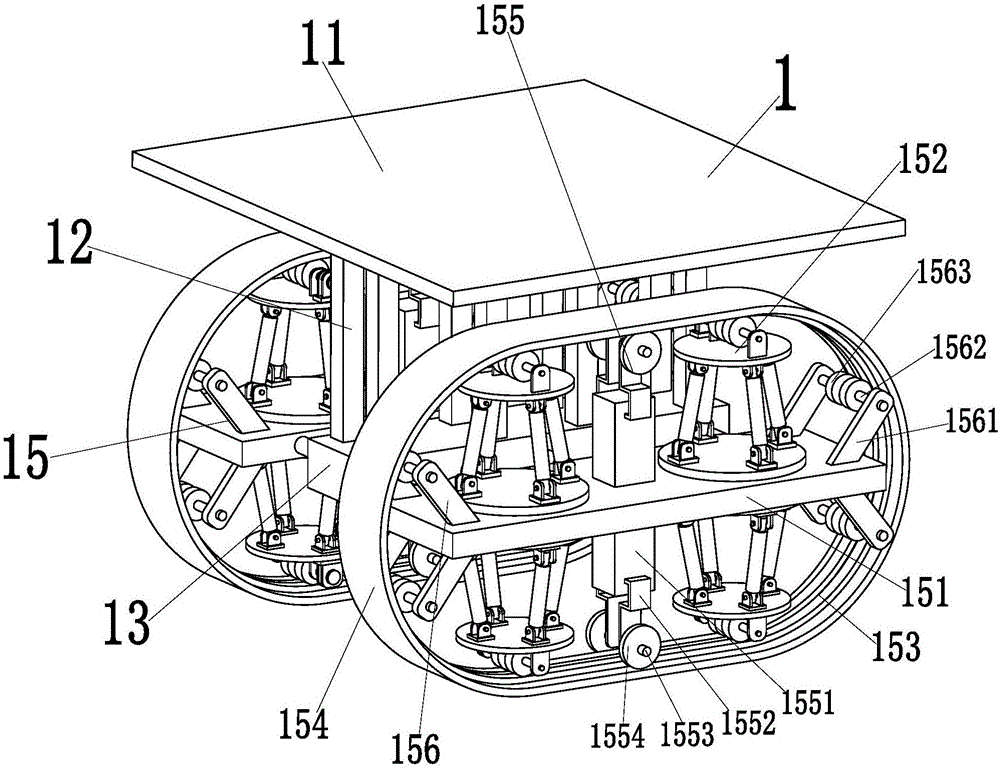

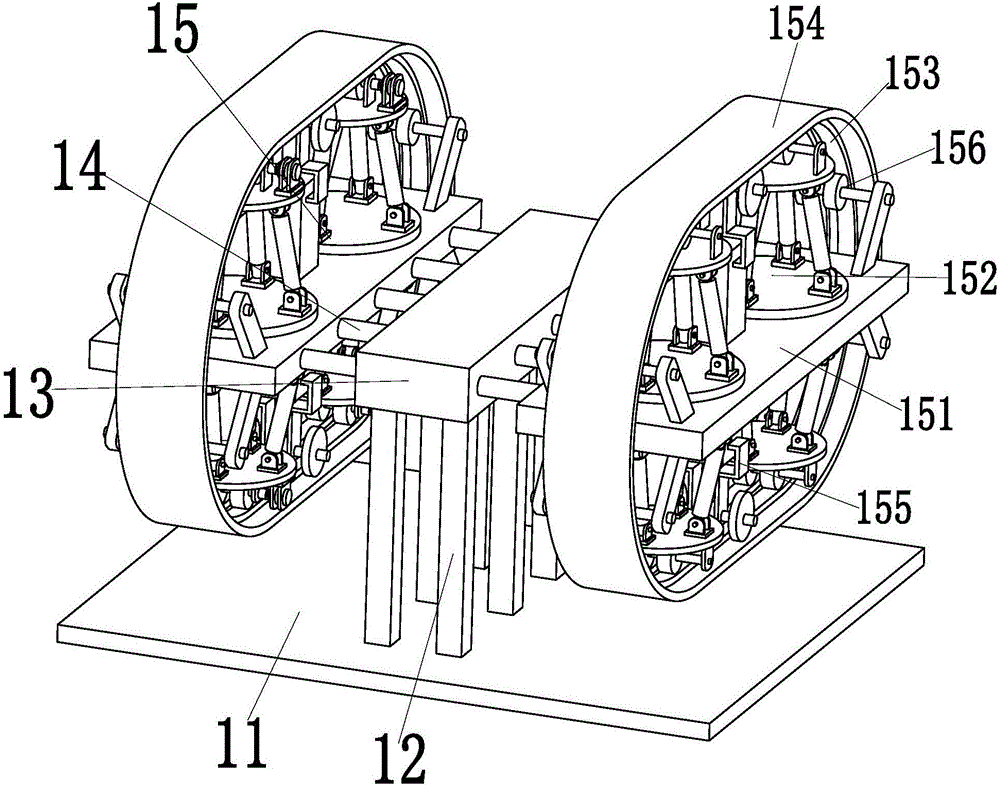

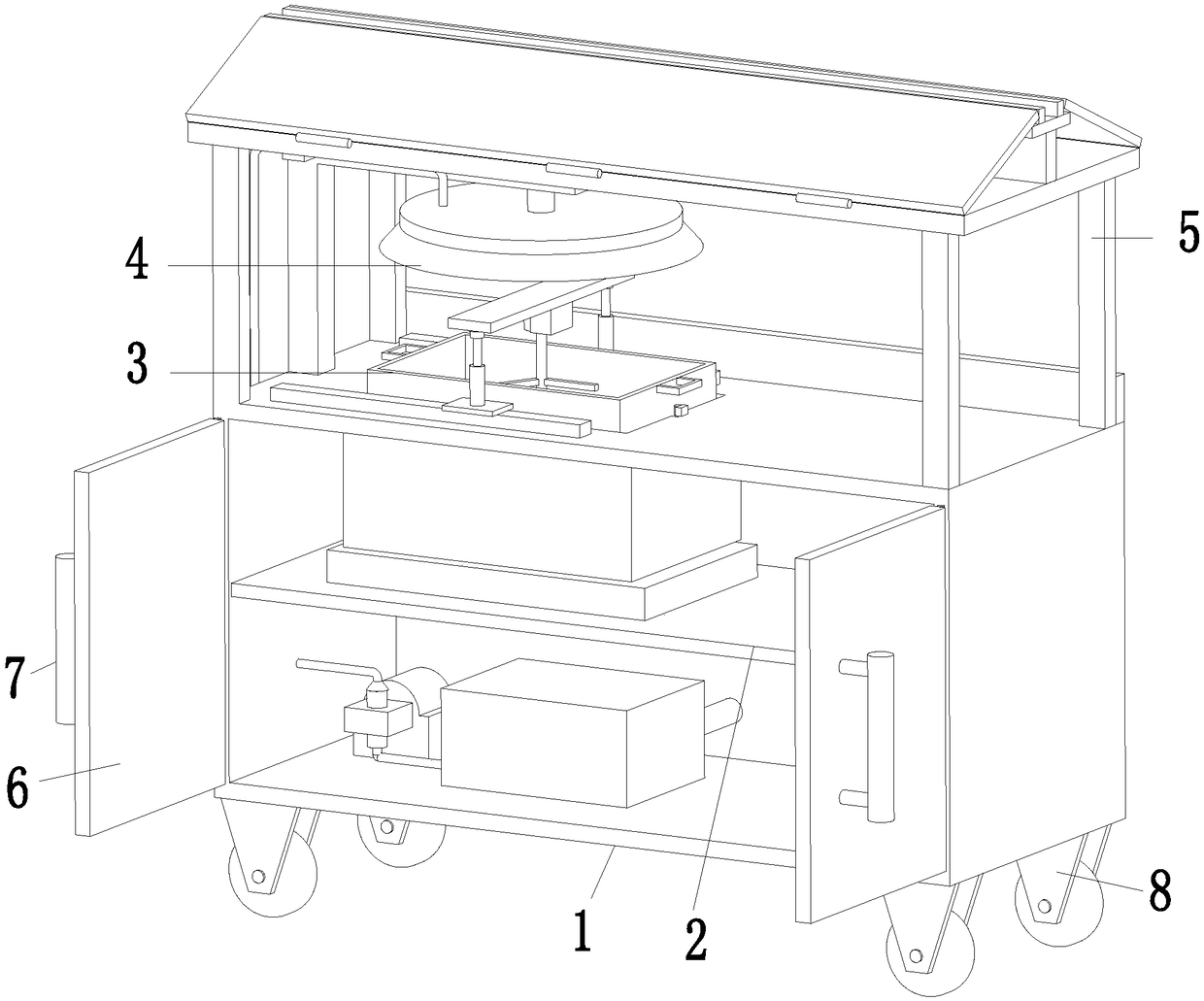

Full-automatic processing equipment for reutilization of capsules

ActiveCN106269477AEasy to moveImprove stabilitySievingScreeningScreening effectAutomatic test equipment

The invention relates to full-automatic processing equipment for reutilization of capsules. The full-automatic processing equipment comprises a positioning and moving device which can achieve a precise capsule movable-collecting function, manual picking is not needed, the automation degree is high, and work efficiency is high. A capsule screening device is mounted on the left side of the upper end face of the positioning and moving device and can achieve an automatic unqualified-capsule screening function, and a capsule crushing device is mounted on the right side of the upper end face of the positioning and moving device and can achieve an automatic unqualified-capsule crushing and reutilizing function. According to the full-automatic processing equipment, the precise capsule movable-collecting function, the automatic unqualified-capsule screening function and the automatic unqualified-capsule crushing and reutilizing function can be achieved, and the full-automatic processing equipment for reutilization of capsules has the advantages that manual back-and-forth picking is not needed, the shaking condition is avoided in the movable picking process, and the equipment is good in mobility; manual screening of unqualified capsules is not needed, the screening time is short, the screening speed is high, and the screening effect is good; and unqualified capsules can be recycled, and work efficiency is high.

Owner:九江昂泰胶囊有限公司

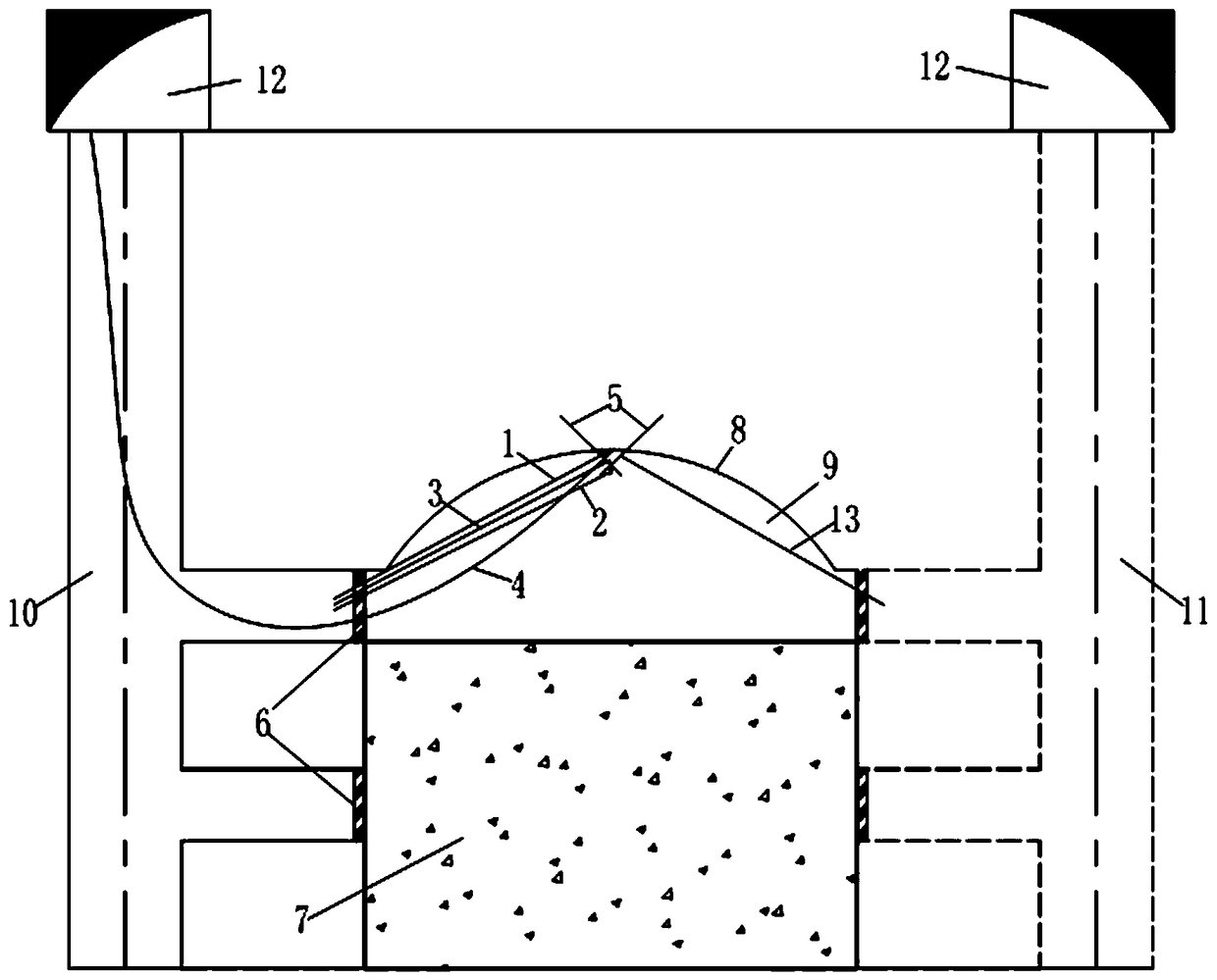

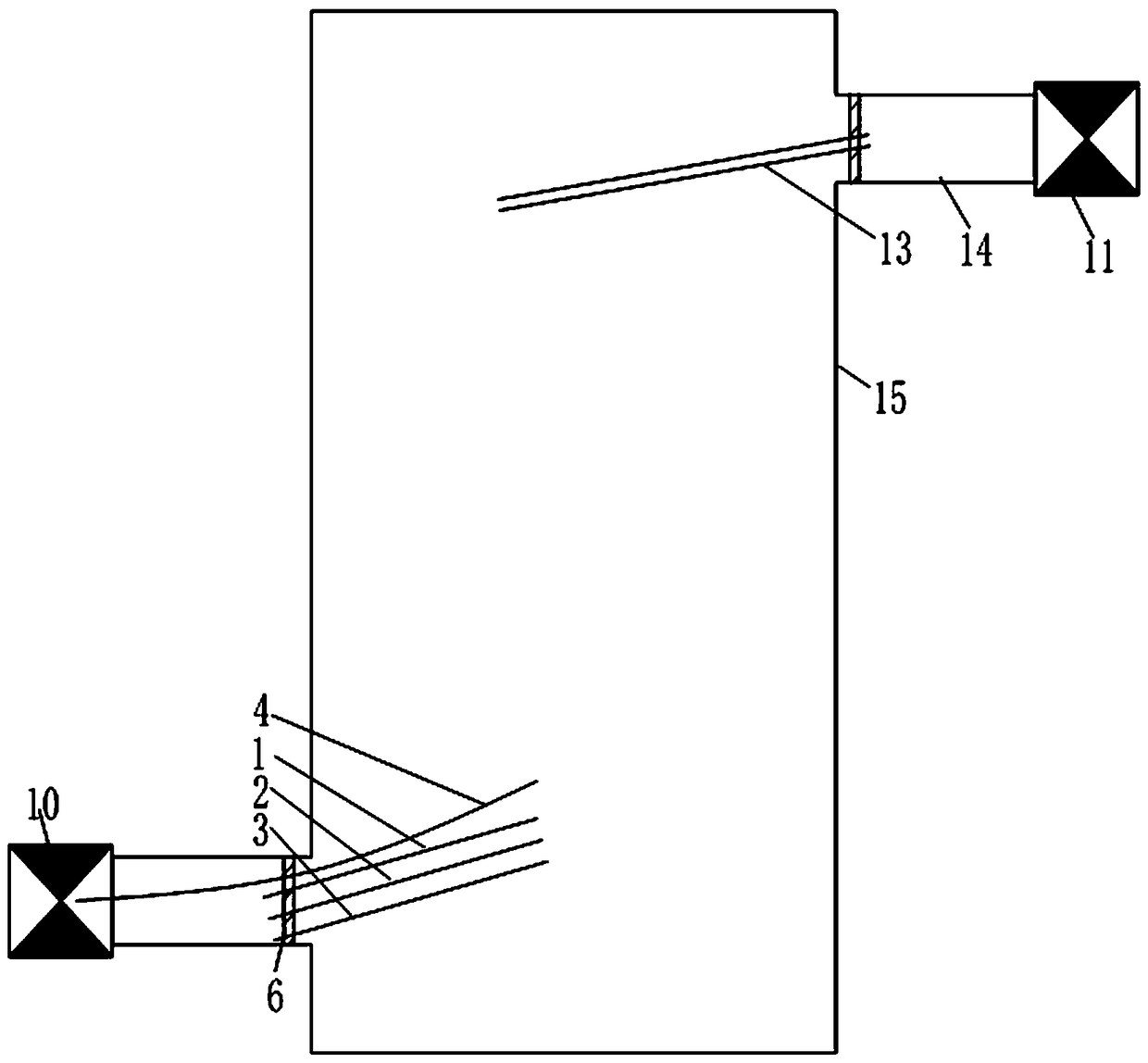

Roof contact method for stope filling

The invention relates to the technical field of combustion water heaters, and relates to a roof contact method for stope filling. The roof contact method for the stope filling comprises the followingstep that a stope empty area is filled with slag to a certain height to obtain a residual empty area, the height of the residual empty area is measured, the position of the highest point is determined, a hollow anchor rod is installed at the highest point, and a filling pipe is installed on the hollow anchor rod; a first dewatering pipe and a dewatering pipe are installed at the highest point, anda third dewatering pipe and a second dewatering pipe are installed from top to bottom according to the height difference; and the opening between the residual empty area and an inlet or a connectingchannel is blocked, and then filling slurry is conveyed into the filling pipe to realize roof-contacted filling of the residual empty area. The roof contact method for the stope filling has the characteristics of realizing effective roof-contacted filling of the stope empty area, and effectively ensuring the strength of the stope empty area.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

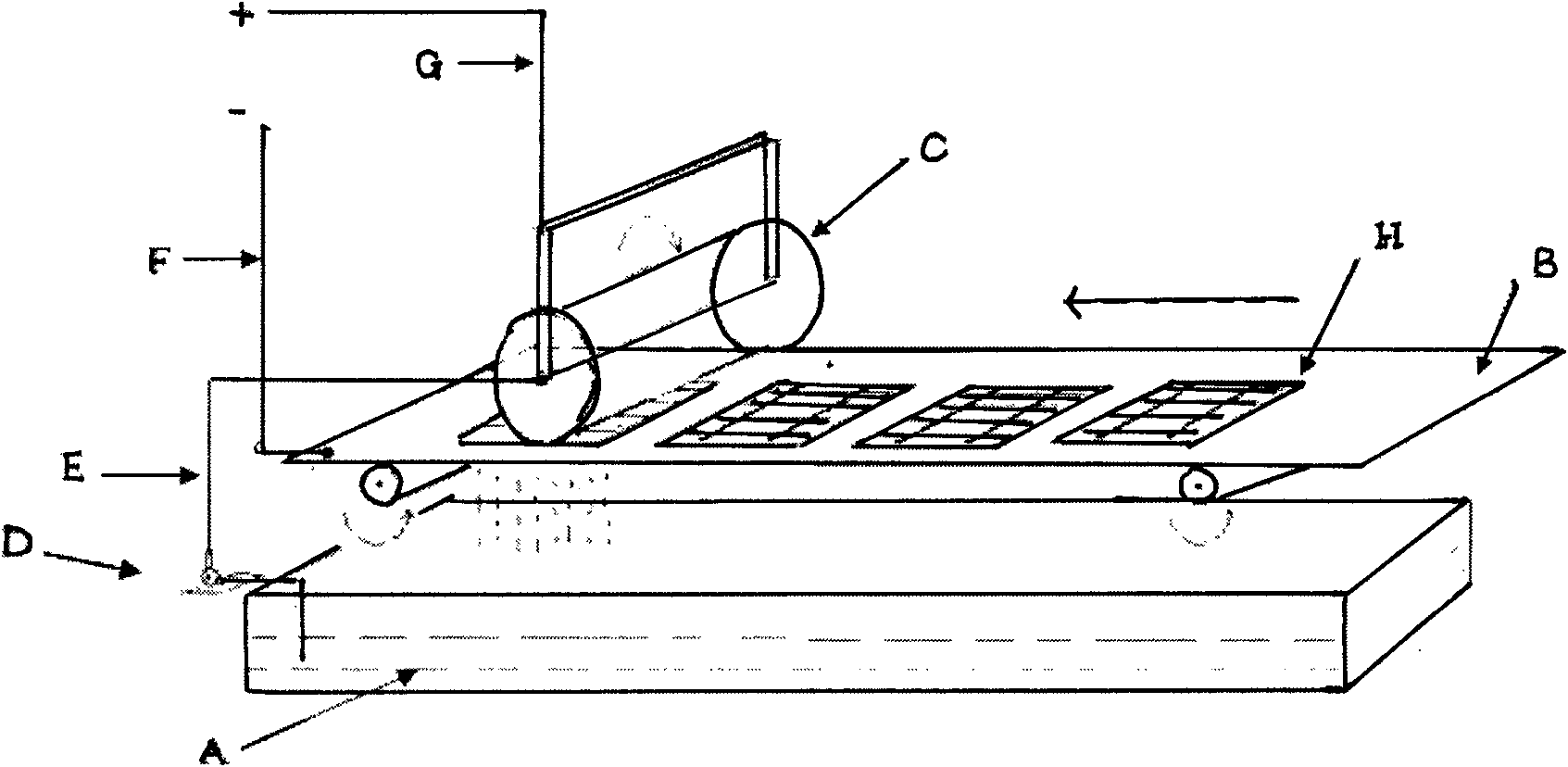

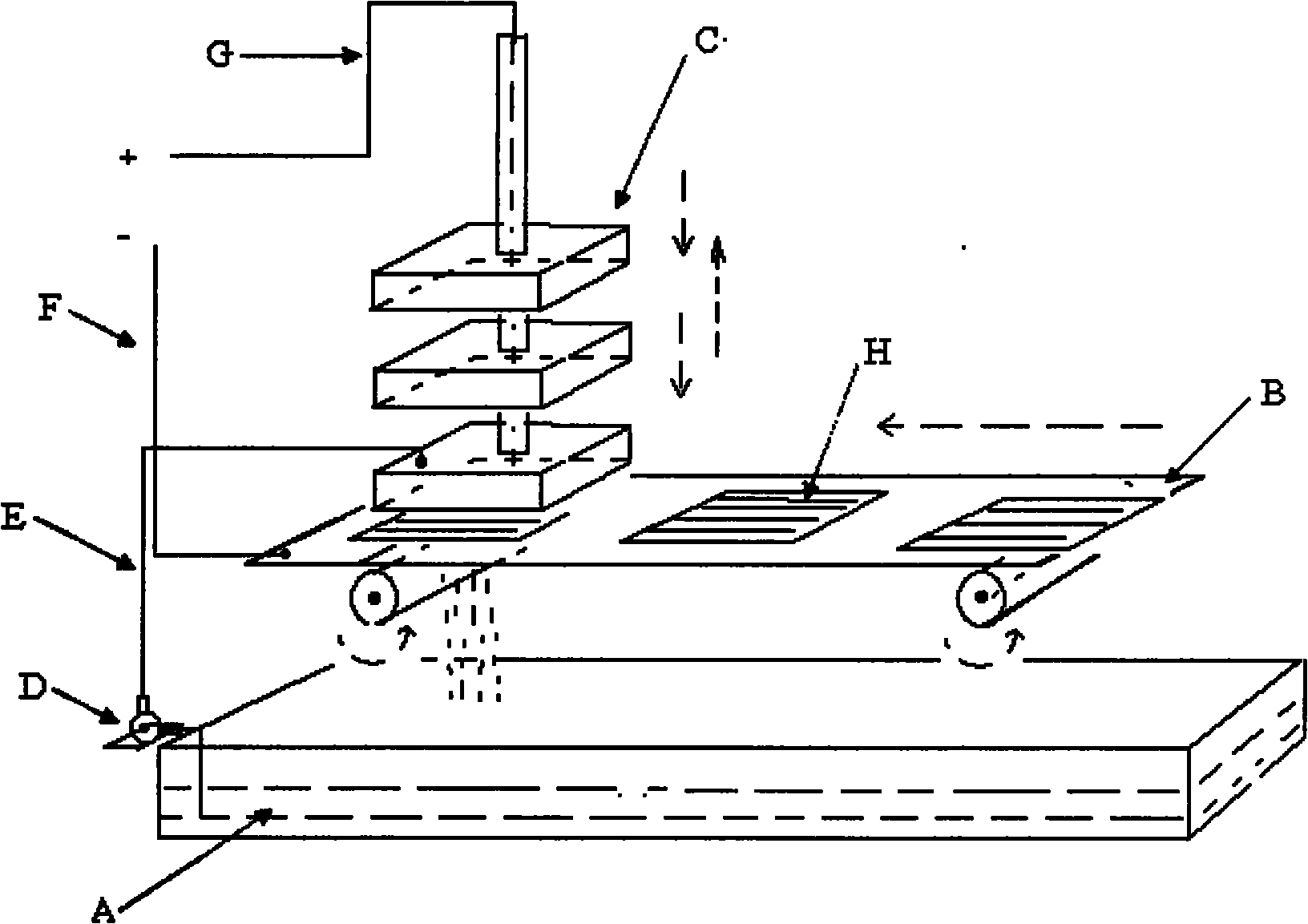

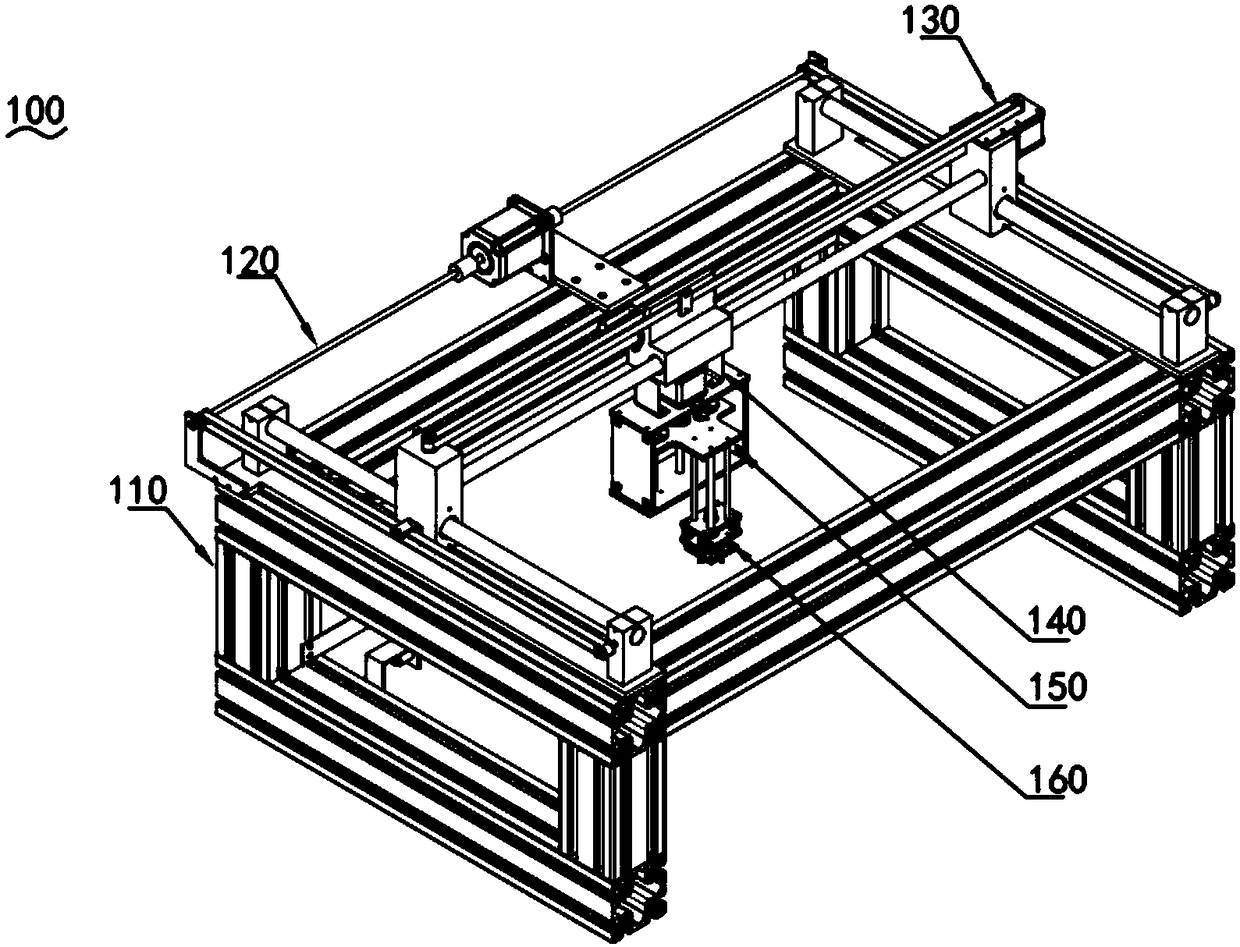

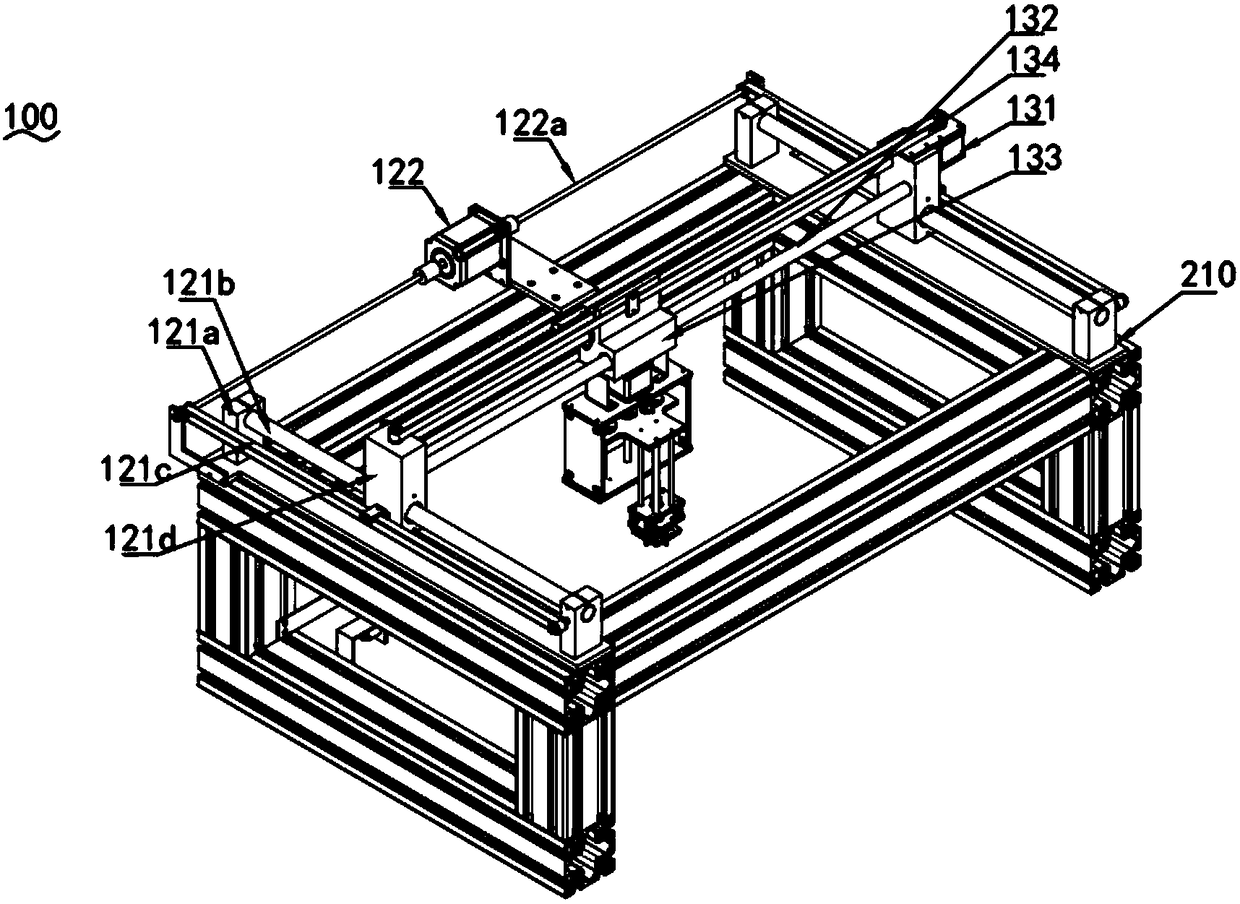

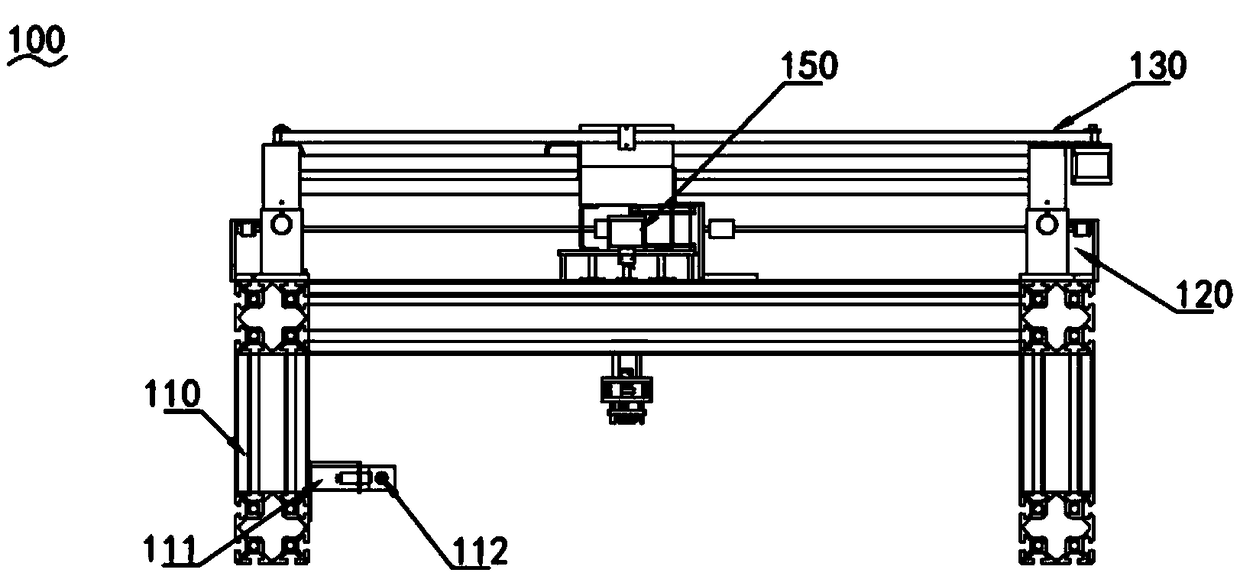

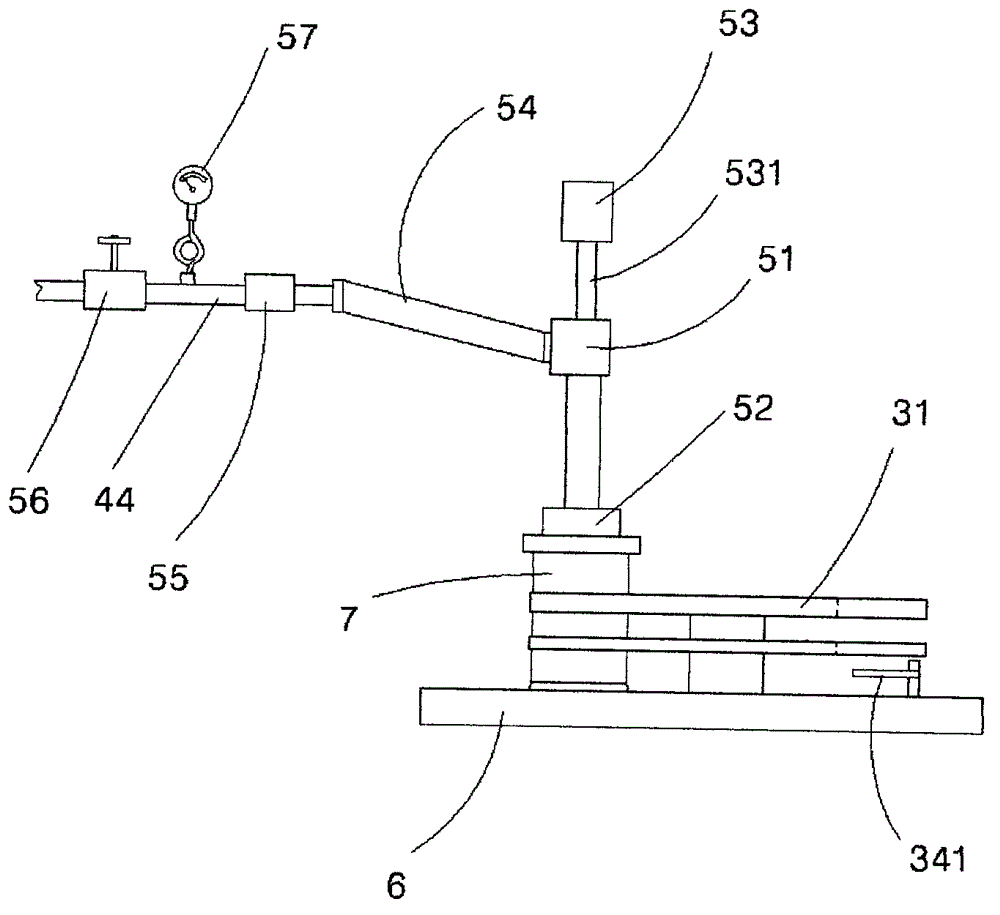

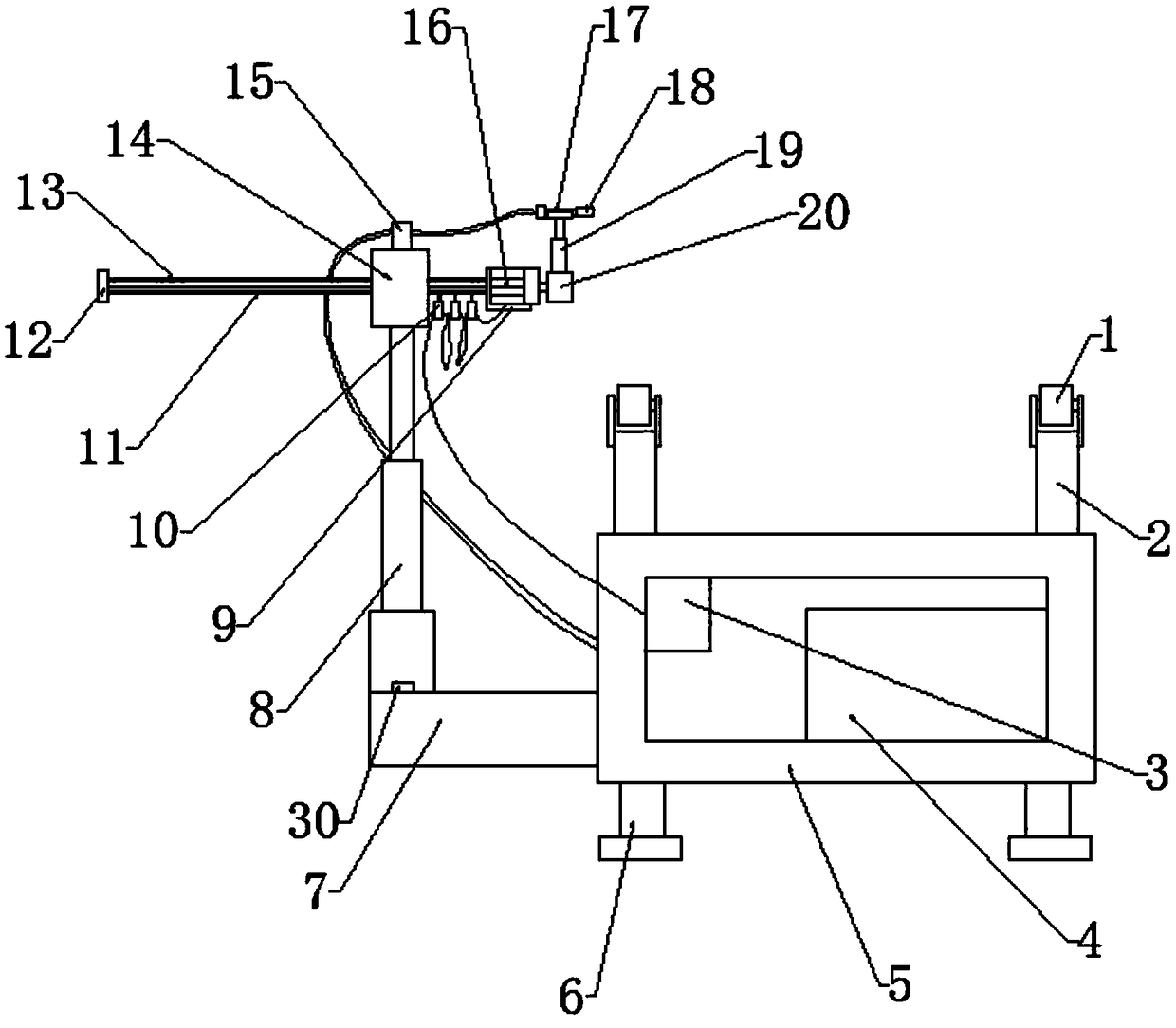

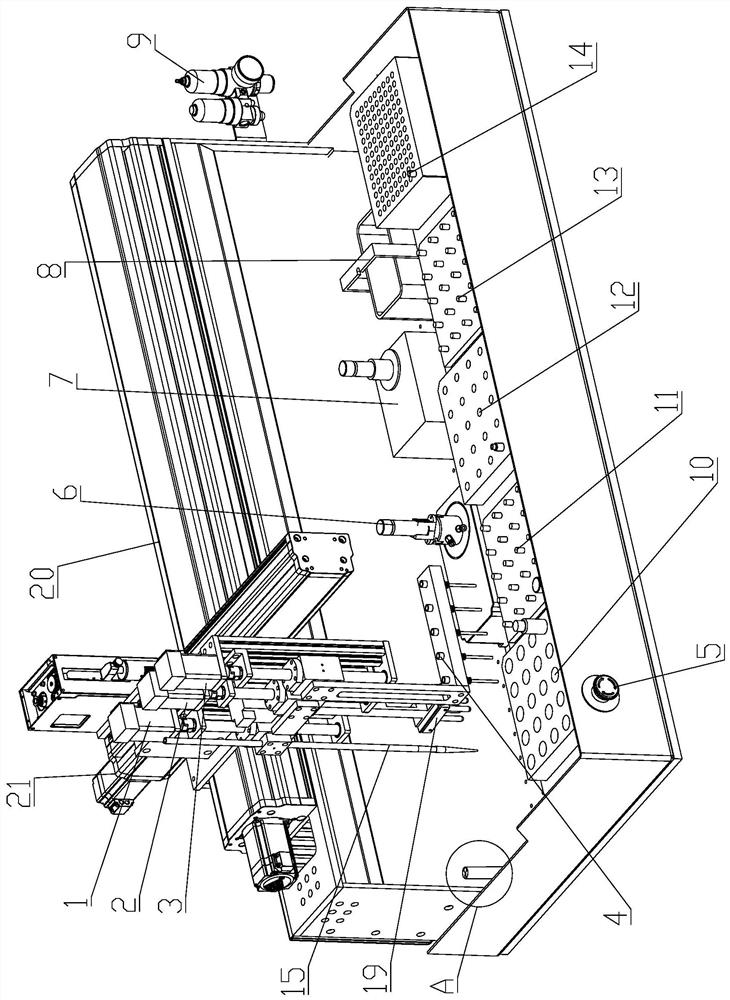

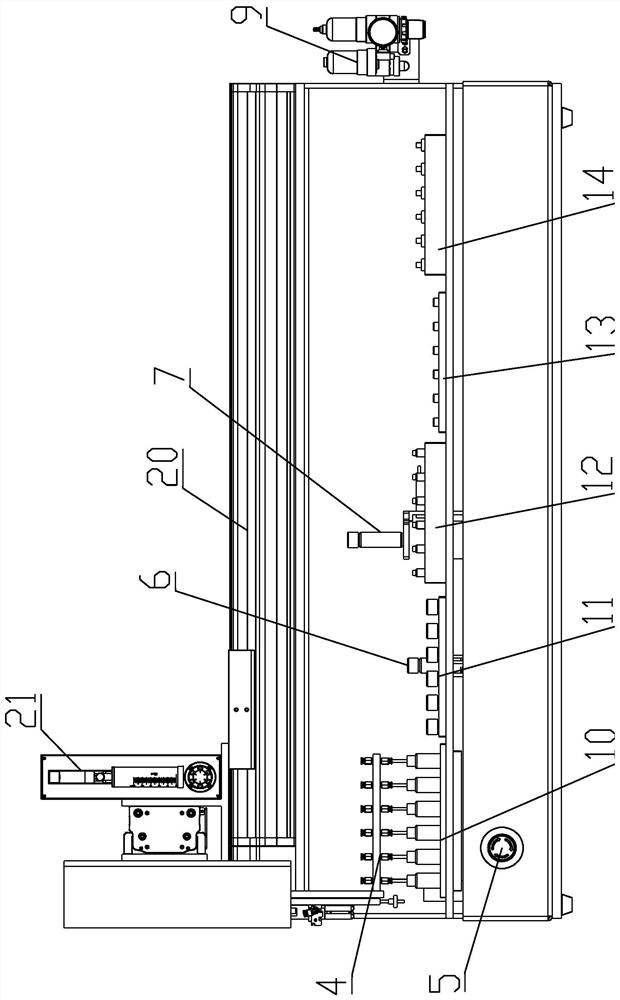

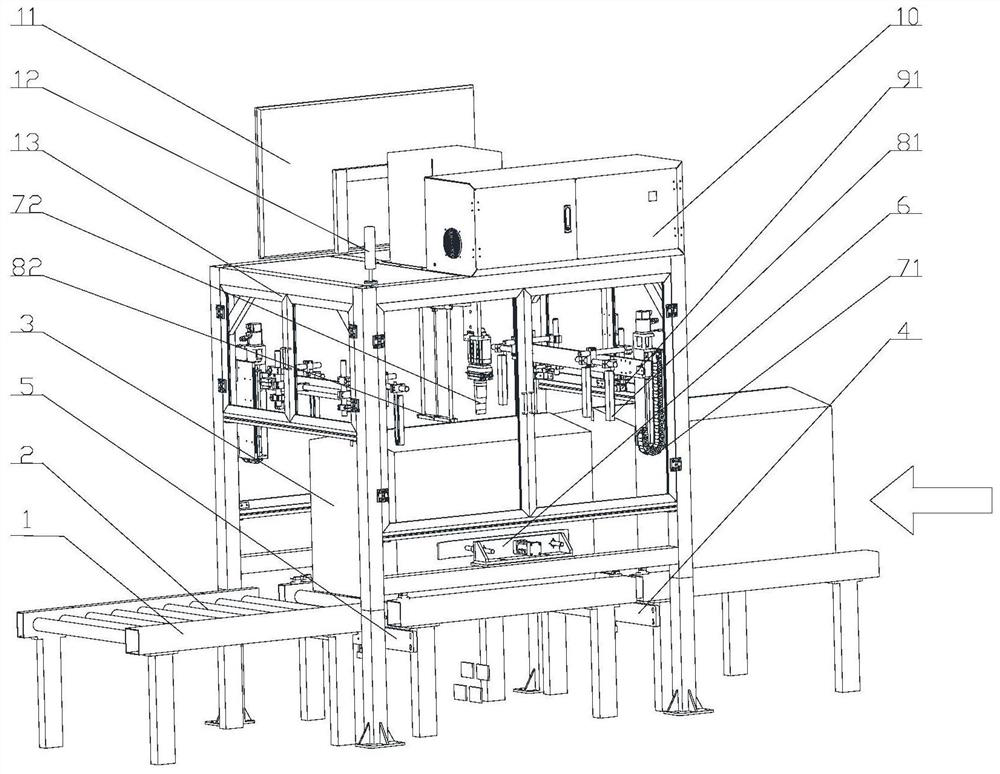

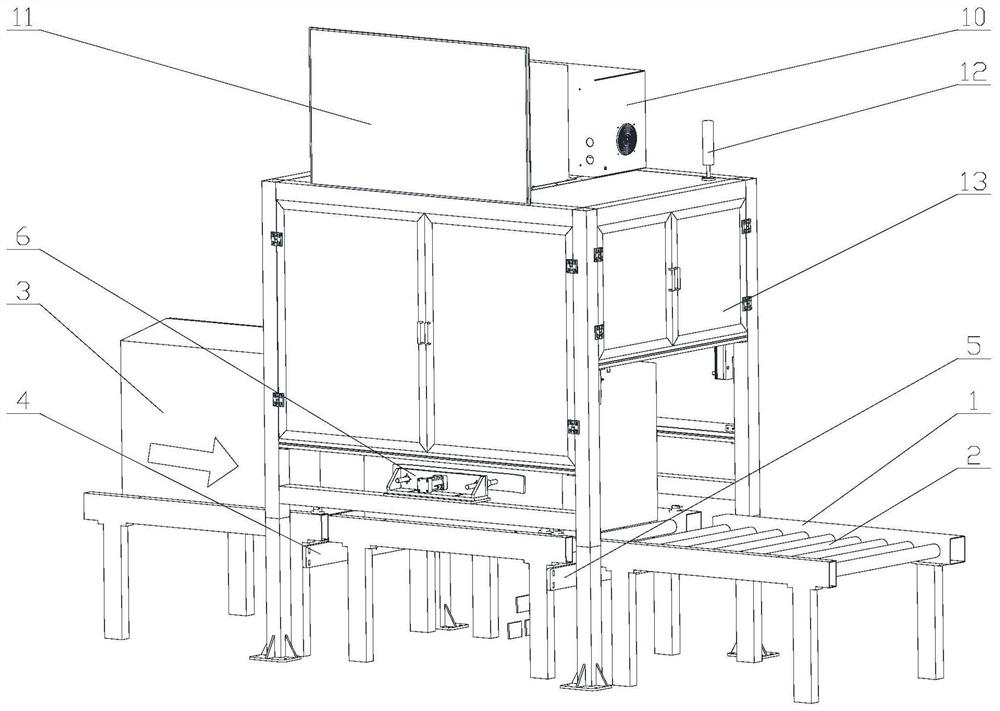

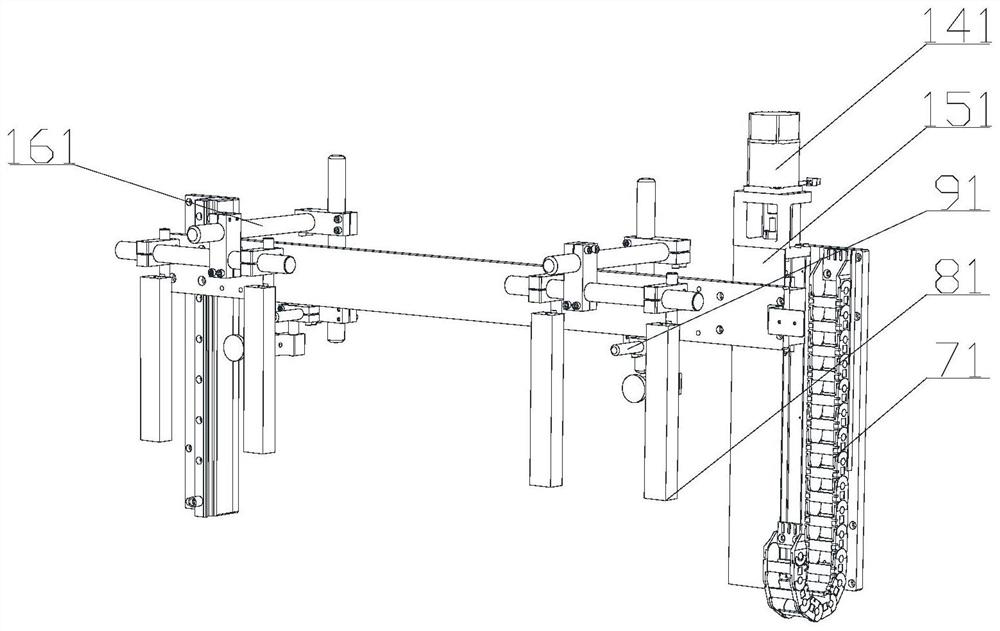

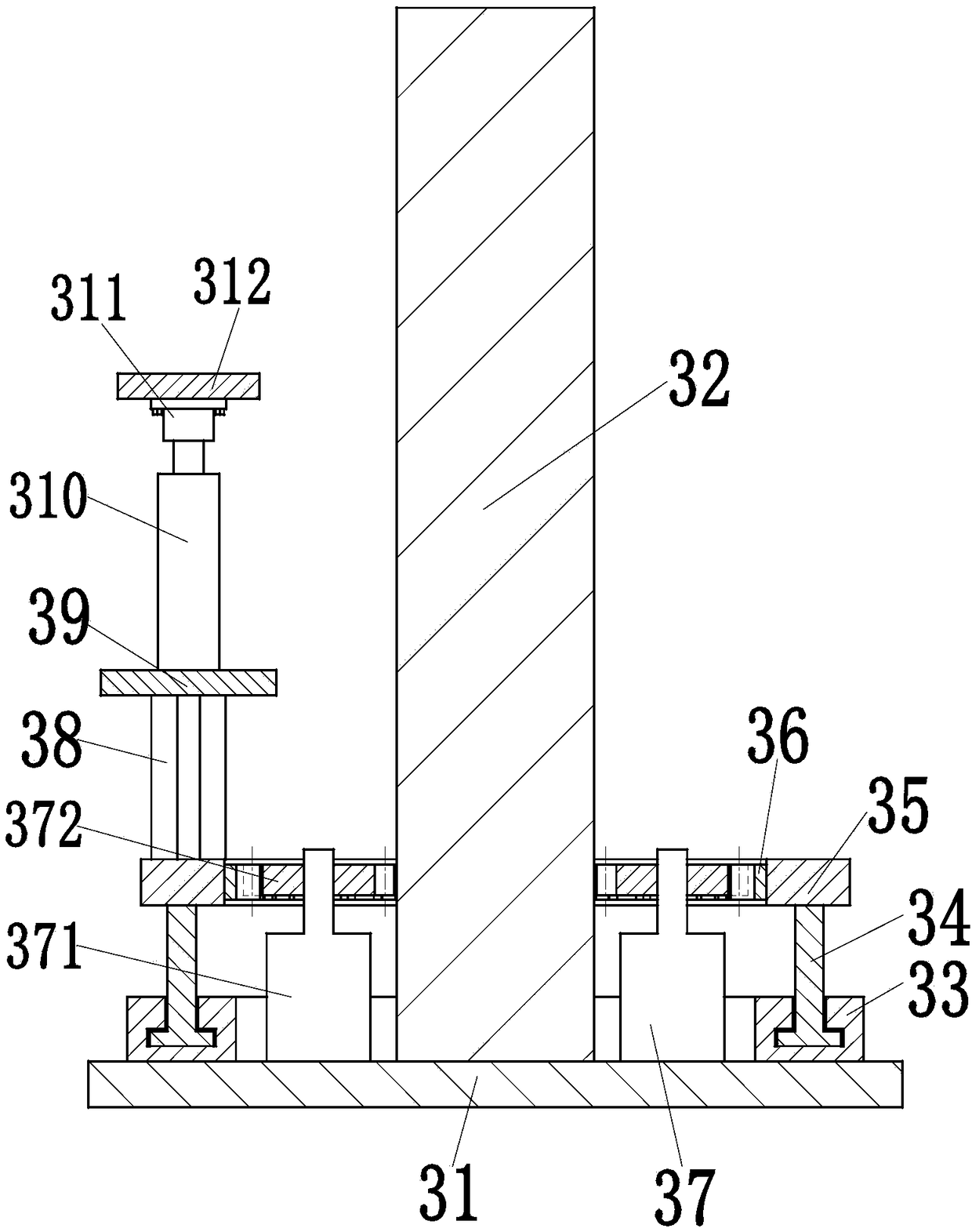

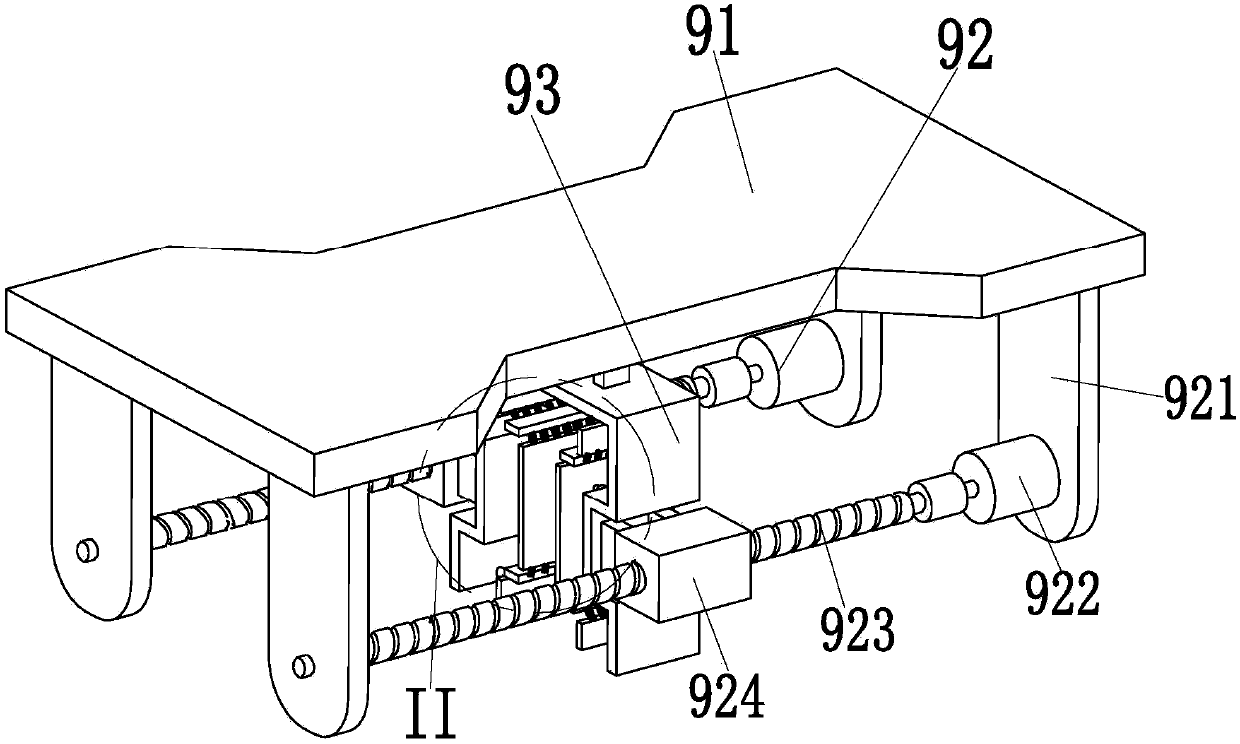

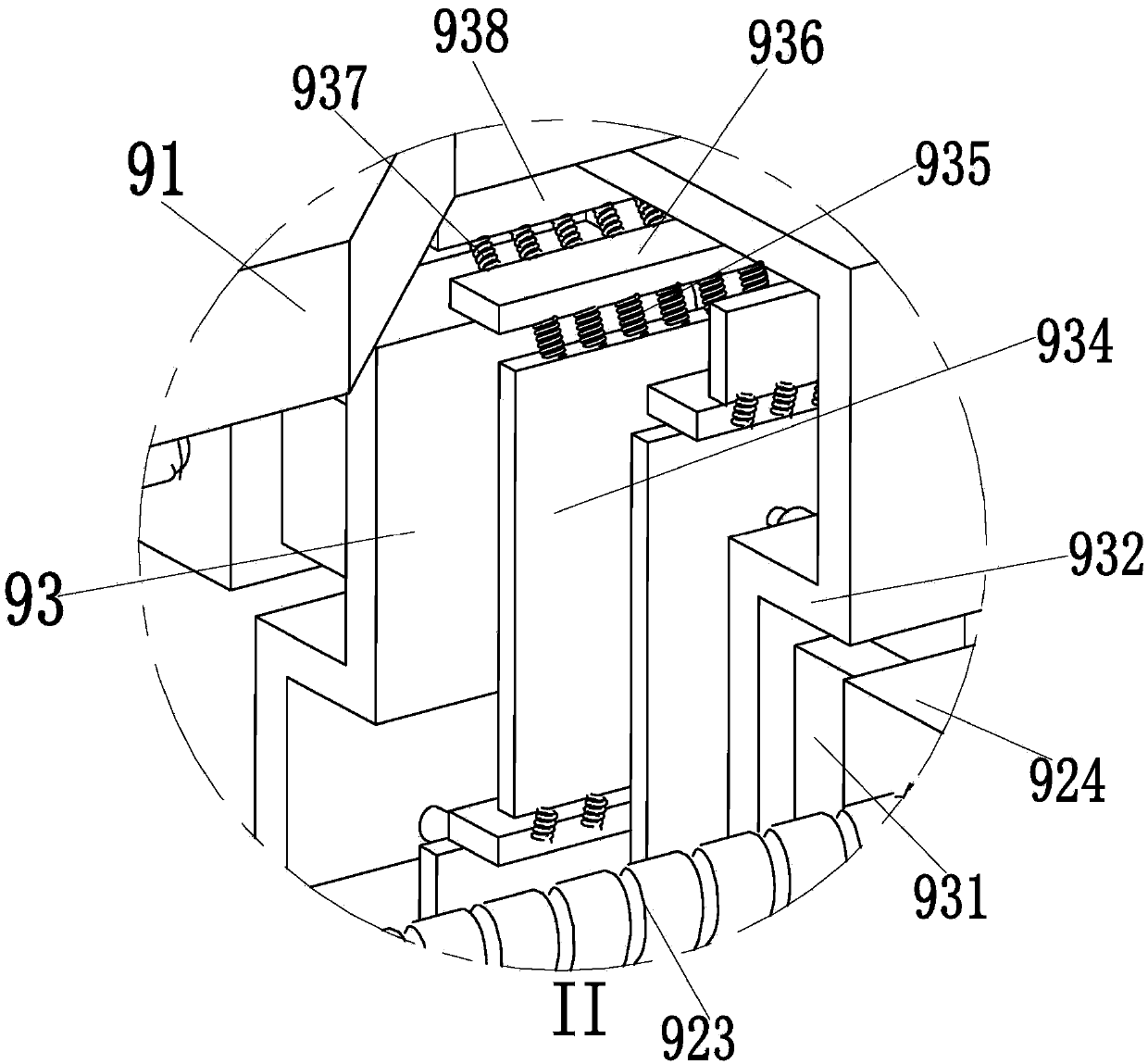

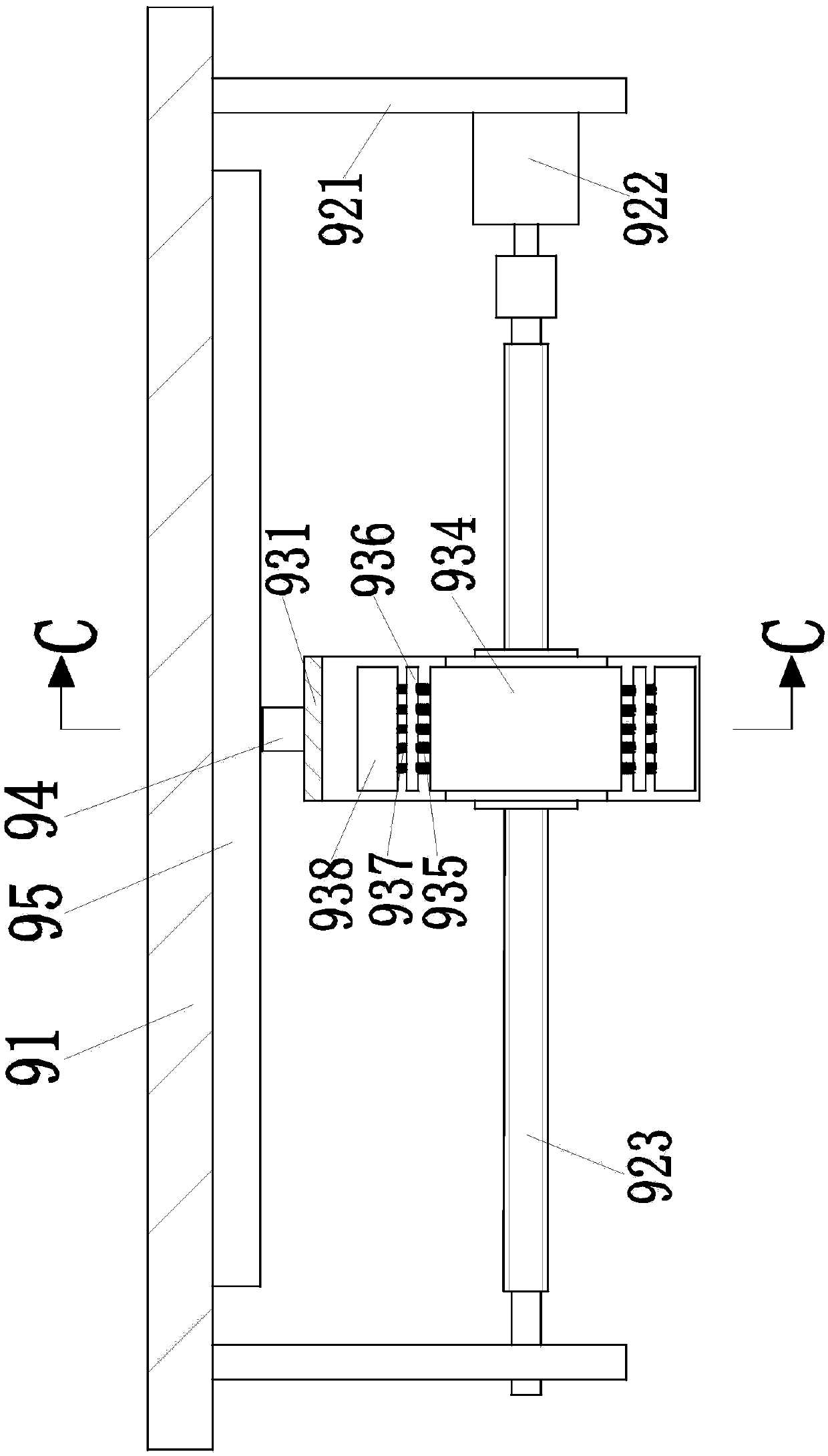

Automatic ultrasonic nondestructive test apparatus for dies and control system and test control method thereof

PendingCN108152377AThe detection process is fastFast automationAnalysing solids using sonic/ultrasonic/infrasonic wavesControl using feedbackAviationMaterials testing

The invention relates to the technical field of ultrasonic nondestructive test, in particular to an automatic ultrasonic nondestructive test apparatus for dies and a control system and test control method thereof. The automatic ultrasonic nondestructive test apparatus for dies comprises a frame, an X-axis transmission device, a Y-axis transmission device and a test manipulator; the test manipulator comprises a connection seat connected with the Y-axis transmission device, a Z-axis transmission device, and a testing device; the testing device comprises a connection bar, a fixing plate and an ultrasonic test probe, as well as a probe clamp plate for fixing the ultrasonic test probe; a buffer spring is arranged between the probe clamp plate and the fixing plate; the part of the probe clamp plate close to the ultrasonic test probe is provided with a plurality of first proximity switches. The automatic ultrasonic nondestructive test apparatus for dies can test a material at high speed and is beyond traditional handheld ultrasonic single-point scanning in terms of reliability, automation level, testing operation stability and other technical indexes; benefits of the apparatus to the society involve both material testing and major social aspects, such as aviation, national defense and economy.

Owner:DONGGUAN UNIV OF TECH +1

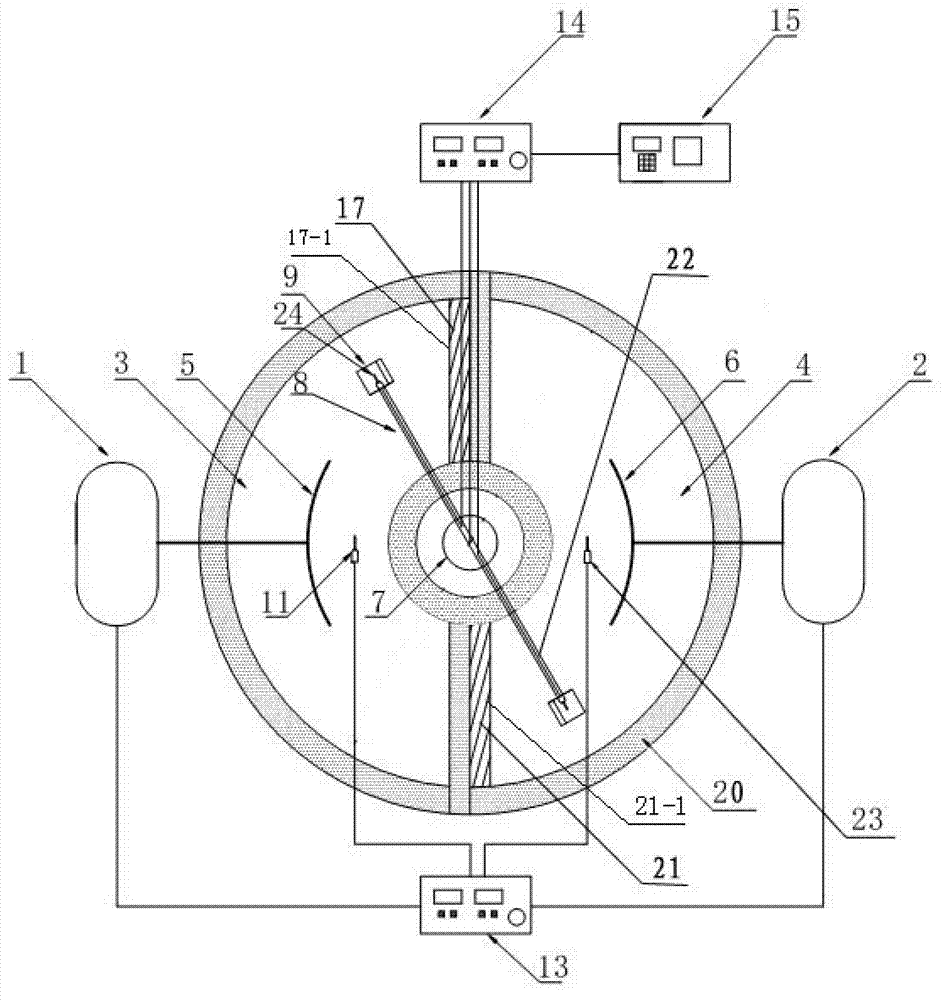

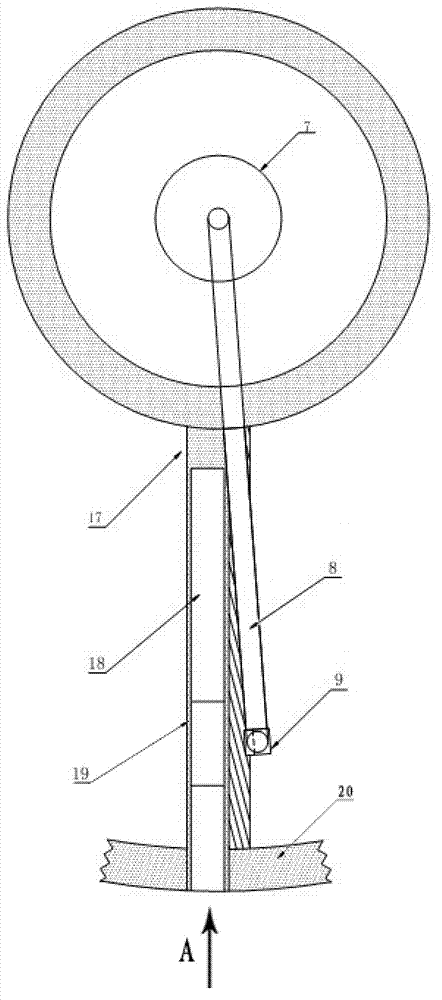

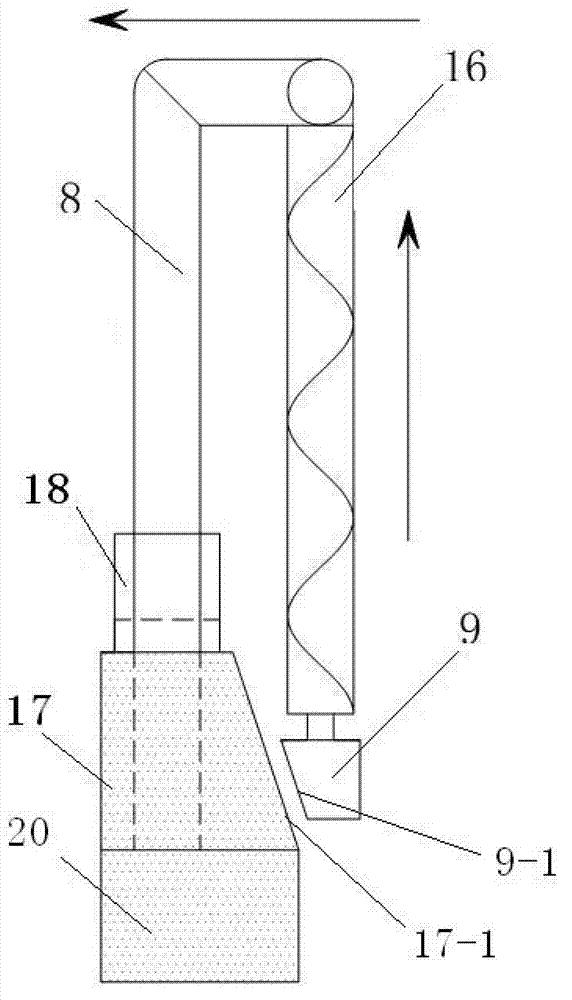

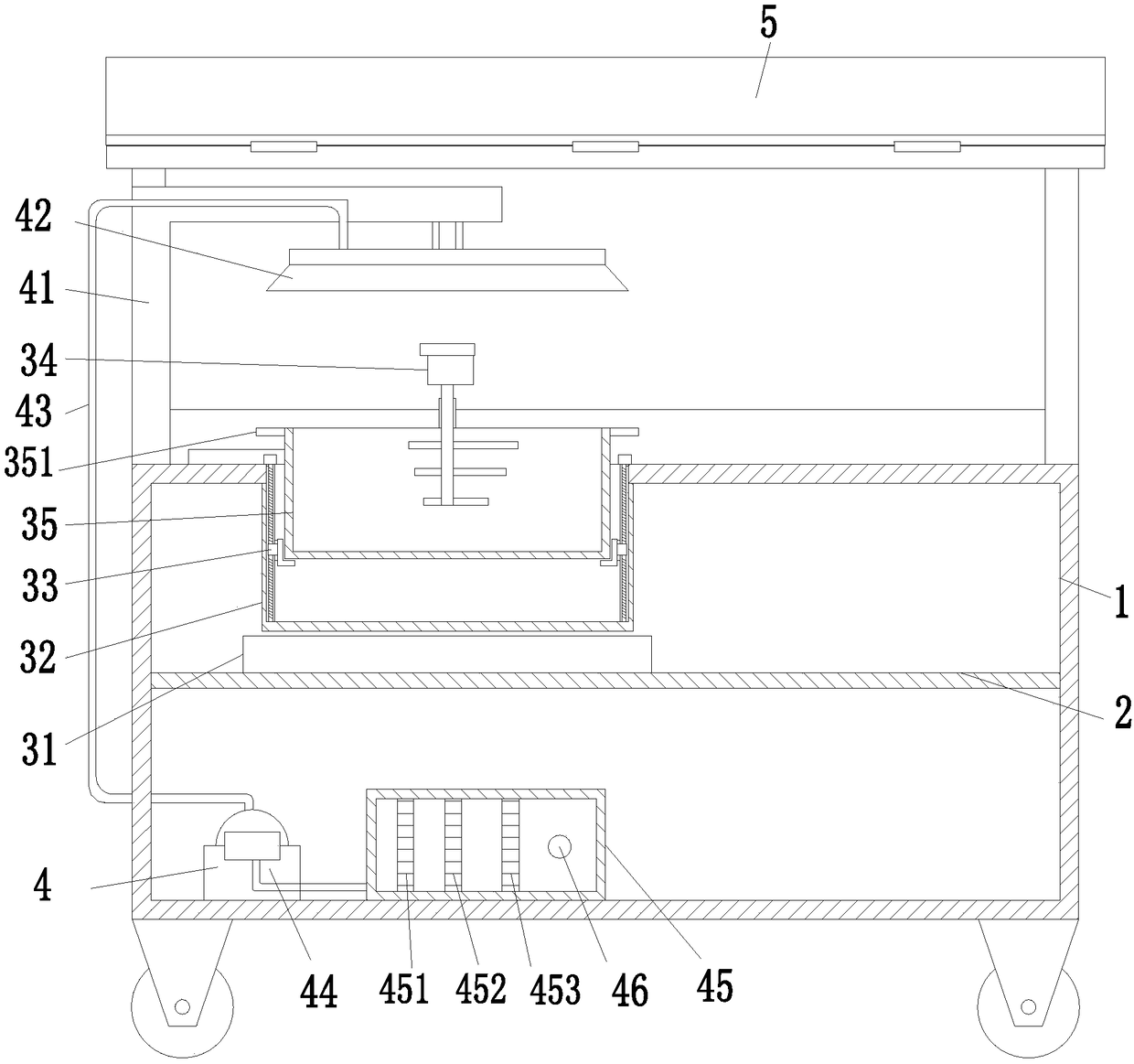

Rapid automatic phase-change material thermal cycle experiment instrument

InactiveCN103091350AImprove timelinessReduce energy consumptionInvestigating phase/state changeHigh energyEngineering

The invention discloses a rapid automatic phase-change material thermal cycle experiment instrument. The instrument comprises a water tank with a cold liquid tank and a hot liquid tank, a first dividing wall arranged inside the cold liquid tank, a second dividing wall arranged inside the hot liquid tank, a motor which is arranged inside the water tank and is isolated from the cold liquid tank and the hot liquid tank, a first sample drawing and loading mechanism driven by the motor, a second sample drawing and loading mechanism driven by the motor, a refrigeration device which is arranged inside the cold liquid tank and is used for refrigerating cold liquid, a heating device which is arranged inside the hot liquid tank and is used for heating hot liquid, and a control module for enabling the instrument to carry out automatic operation. The rapid automatic thermal cycle experimental instrument has the advantages of high energy efficiency, high time effectiveness and capability of accomplishing the rated cycle times with low energy consumption and rapid speed; the heat conduction liquid is constant, precise and controllable in temperature; the instrument is automatically monitored through the process with high automation degree; and the situations that the conventional thermal cycle experiment is manually carried out, low in efficiency, low in precision and poor in repeatability are changed.

Owner:SOUTHEAST UNIV

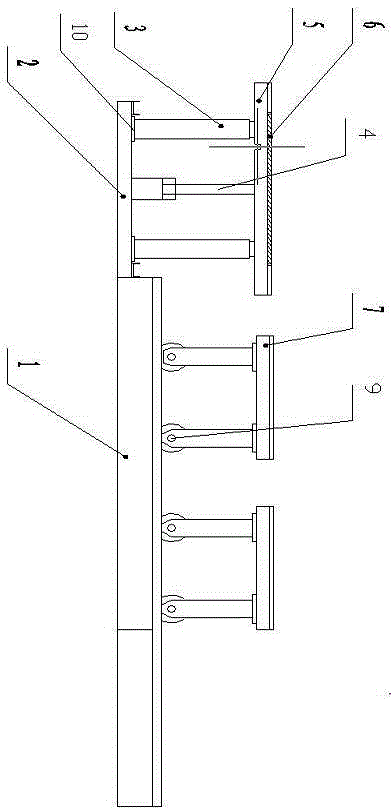

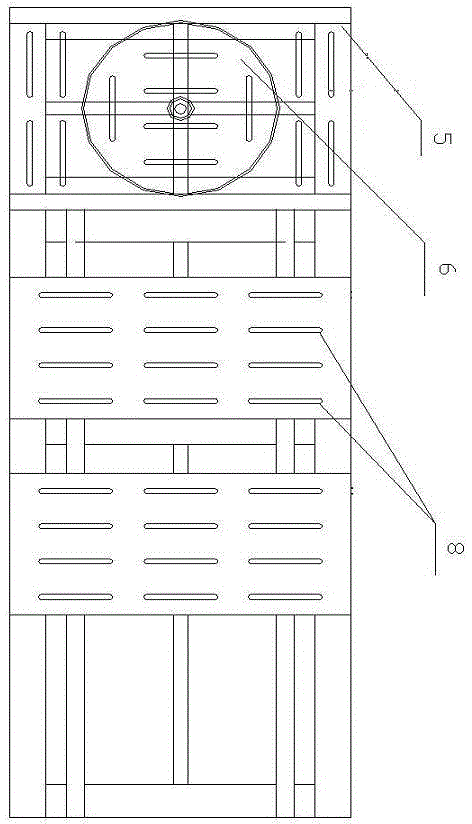

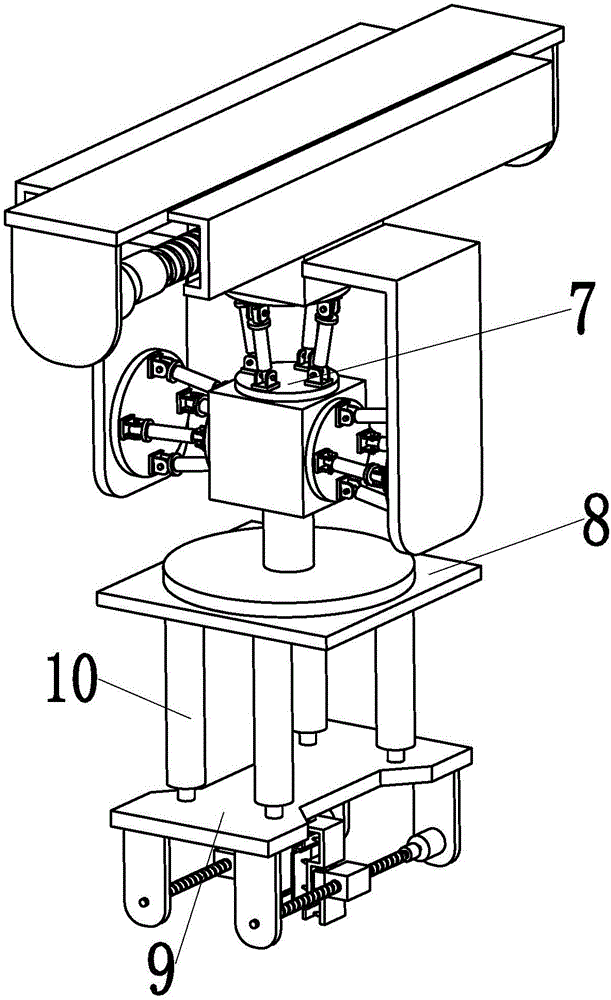

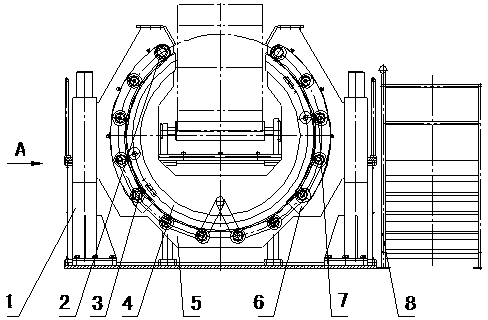

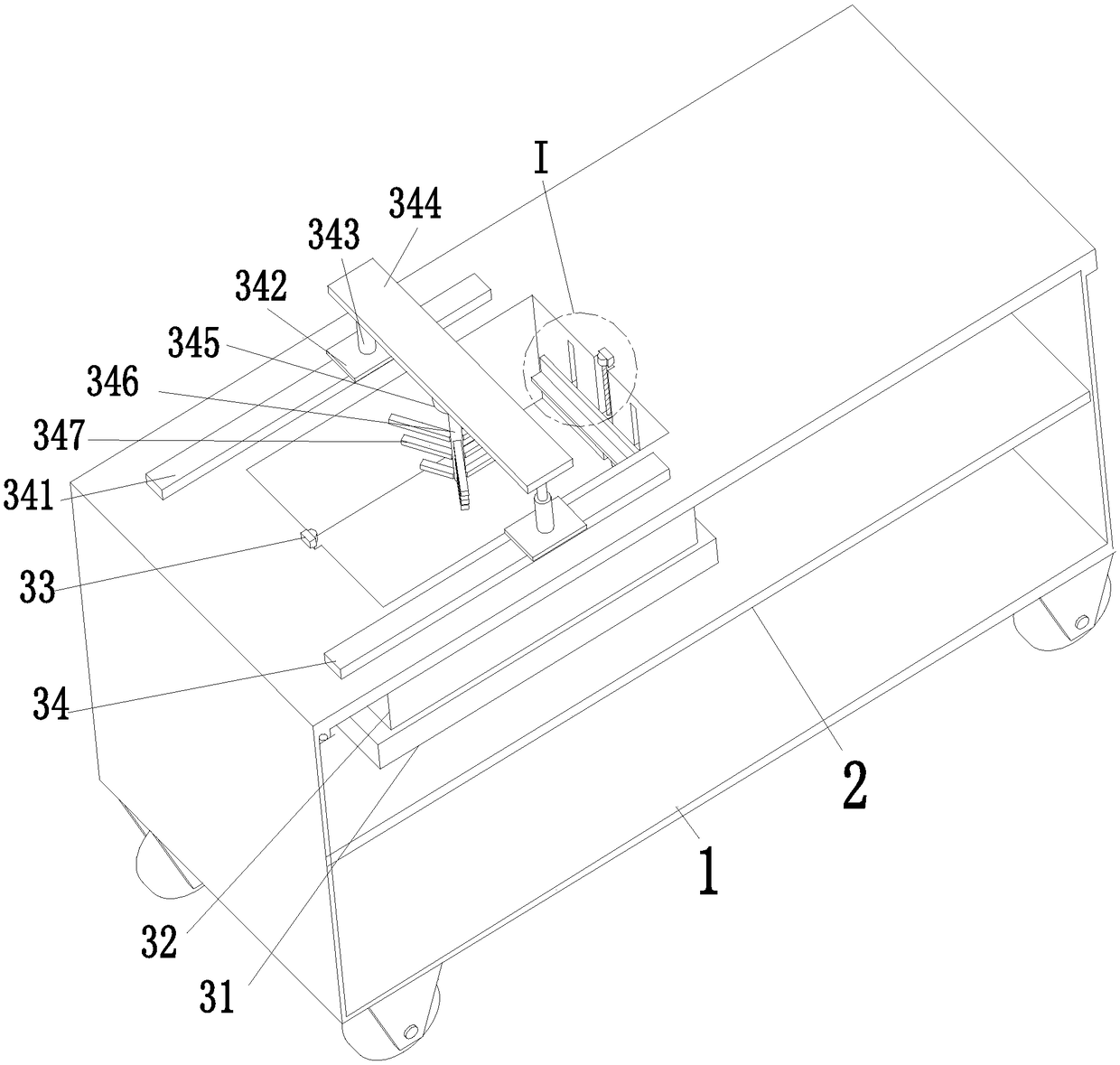

Multifunctional pipeline welding and assembling device

InactiveCN104858606AWide range of pairsRich application functionsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMultiple applications

The invention provides a multifunctional pipeline welding and assembling device. The multifunctional pipeline welding and assembling device comprises a base I, wherein a base II is connected to one end of the base I, and four stand columns are symmetrically arranged on the periphery of the base II; each stand column is formed by connecting a pipe with the diameter being 89 and a round bar with the diameter being 60 in a sleeving mode, a base plate is welded to the lower ends of the pipes of the stand columns, a lifting platform is connected to the round bars of the stand columns, and a rotary disc is arranged on the lifting platform; a hydraulic lifting column is further arranged in the middle of the base II, and an ejector rod of the hydraulic column is connected with the lifting platform. Multiple movable platforms are arranged on the base I, and the movable platforms slide on the base I. According to the multifunctional pipeline welding and assembling device, the assembling range is wide, multiple application functions can be achieved, and automatic operation is achieved; the heights of the platforms can be adjusted through automatic operation, and the labor intensity can be relieved due to automatic assembling; meanwhile, the automatic operation speed is high, assembling efficiency is improved, and economical benefits are remarkably improved; furthermore, product quality is improved.

Owner:XIAN CHANGQING TECH ENG

Integrated tea leaf tedding and screening machine

ActiveCN106269518AUniform transmission forceGood transmission effectSievingGas current separationScreening effectEngineering

The invention relates to an integrated tea leaf tedding and screening machine which comprises a bottom plate, four universal wheels are symmetrically installed on the lower end face of the bottom plate, the integrated tea leaf tedding and screening machine is moved to a processing position through the four universal wheels, a condensation tedding device is installed on the left side of the upper end face of the bottom plate and achieves the function of condensing light and rapidly tedding tea leaves, the tedding time is greatly shortened, the tedding speed is high, and the tedding effect is good; a multilevel screening device is installed on the right side of the upper end face of the bottom plate and achieves the function of automatically screening the tea leaves at multiple levels, the screening time is short, the screening speed is high, and the screening effect is good; the condensation tedding device comprises a tedding support plate installed on the left side of the upper end face of the bottom plate, an installation cylinder is welded at the middle part of the upper end face of the tedding support plate, and an annular limit groove is installed on the upper end face of the tedding bottom plate. The integrated tea leaf tedding and screening machine achieves the functions of integrally automatically tedding and screening the tea leaves, no manual operation is needed, the operation is simple and convenient, and the degree of automation is high.

Owner:岳阳县洞庭春纯天然茶叶有限公司

Device for baking lightweight aggregate for building materials by domestic garbage in cities and towns

InactiveCN101284715ATake advantage ofHigh speedSolid waste managementIncinerator apparatusCombustion chamberLitter

The invention provides a device for producing building material used lightweight aggregate through firing the domestic garbage in cities and towns. A lightweight aggregate sintering furnace is arranged at the lower part of a furnace body, a grate is arranged in the sintering furnace and is connected with a grate driver, a dump chest and a discharging machine are arranged at the lower part of the tail end of the grate, a smoke exhausting and blanking port is formed on the upper side of the combustion chamber of the sintering furnace, and a coal feeding hopper is arranged in front of the furnace body. A smoke decomposing furnace is arranged on the upper side of the lightweight aggregate sintering furnace, a material blanking hopper is arranged in the corresponding position of the chamber of the smoke decomposing furnace and the smoke exhausting and blanking port, and a smoke exhausting port is arranged on one side of the chamber. A material drying furnace is arranged on the upper side of the smoke decomposing furnace, a material feeding hopper is arranged on the material drying furnace, and a scraper chain conveyor and scrapers are arranged in the chamber of the drying furnace. As the device integrates the lightweight aggregate sintering furnace, the smoke decomposing furnace and the material drying furnace into a whole, thereby solving the problems of the material continuous sintering, the smoke thermal decomposition and the material drying through the waste heat. The device is applicable to the production of the building material used lightweight aggregate through firing the domestic garbage in cities and towns.

Owner:兴城市鑫隆海节能建材有限公司

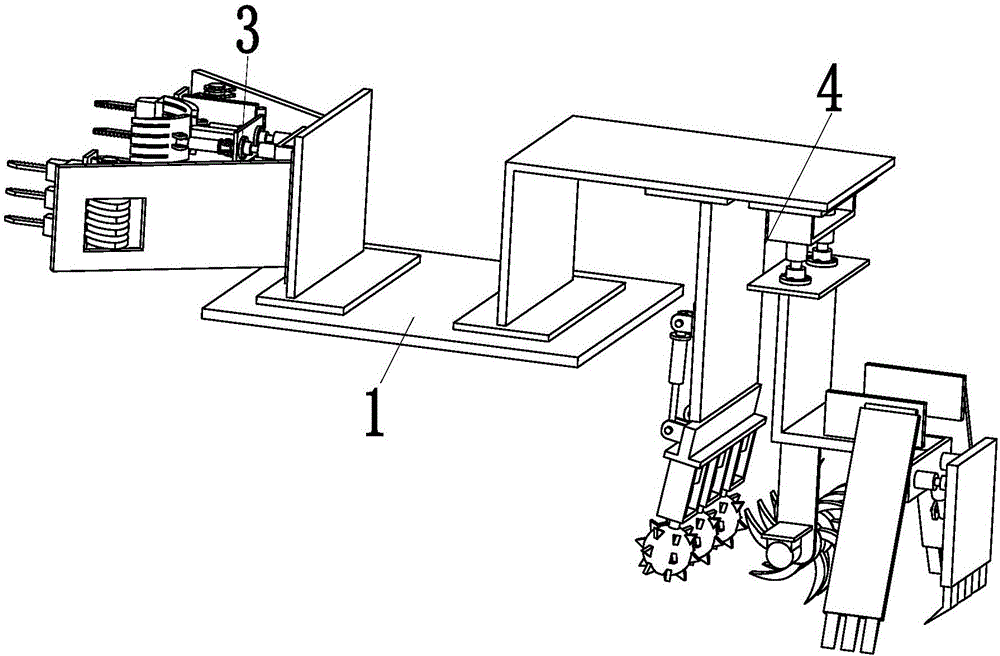

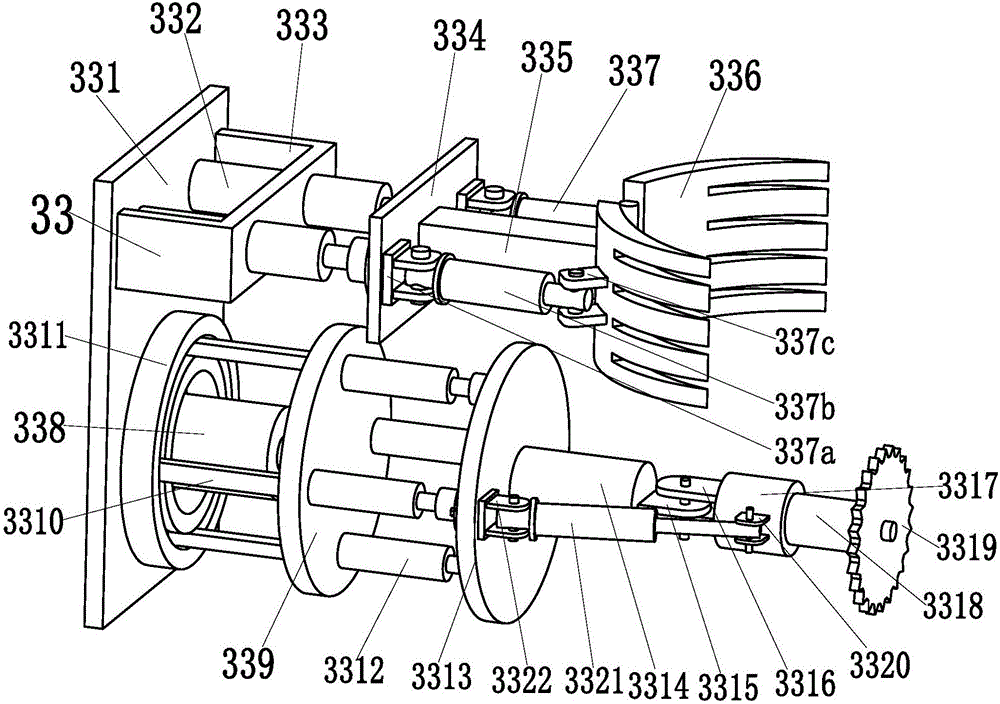

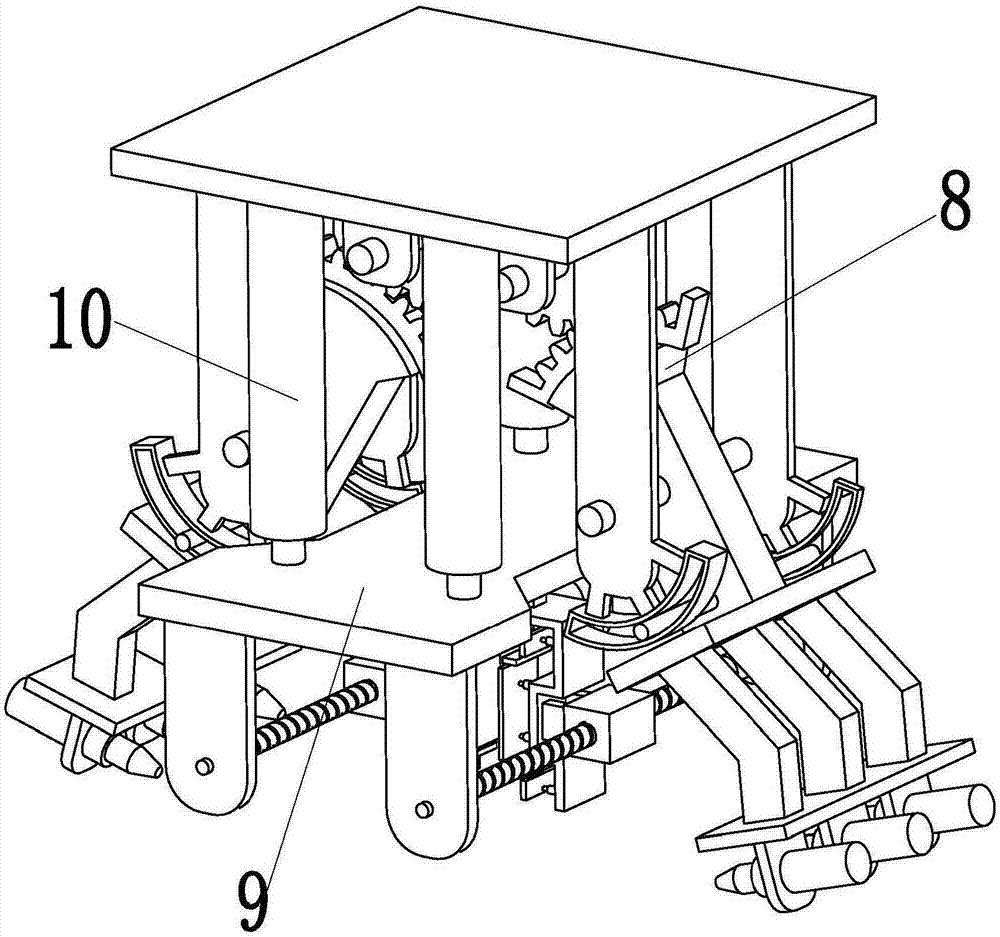

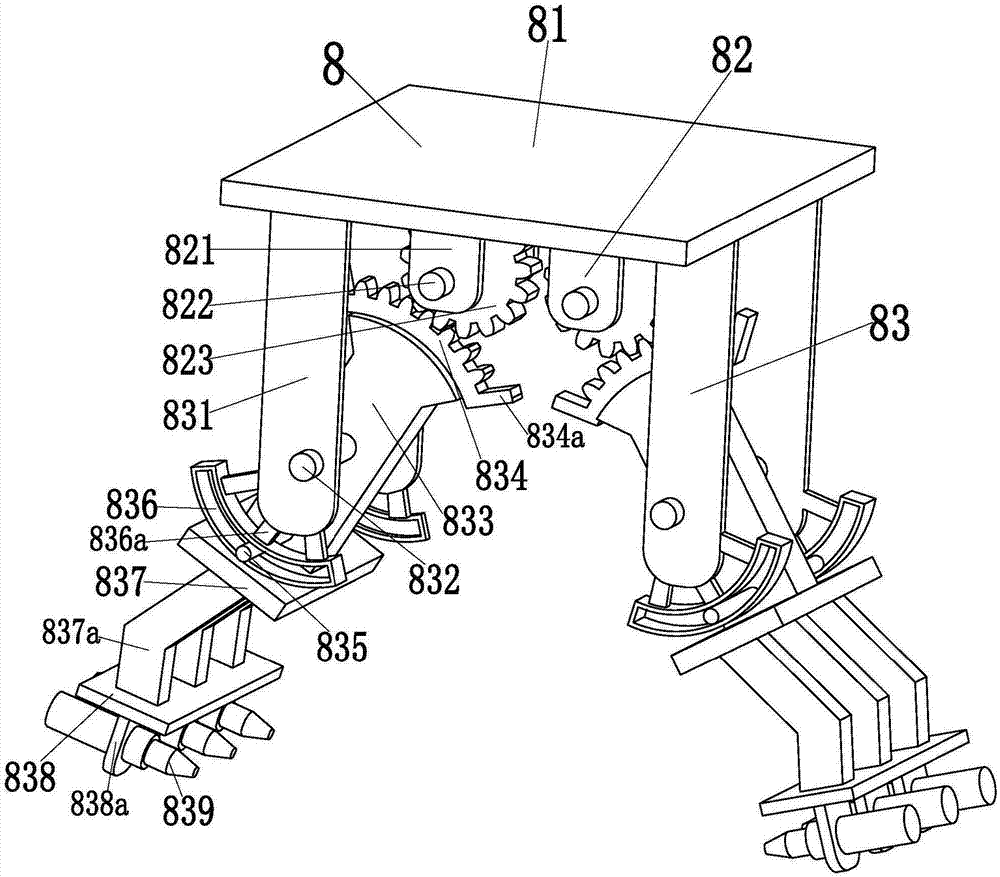

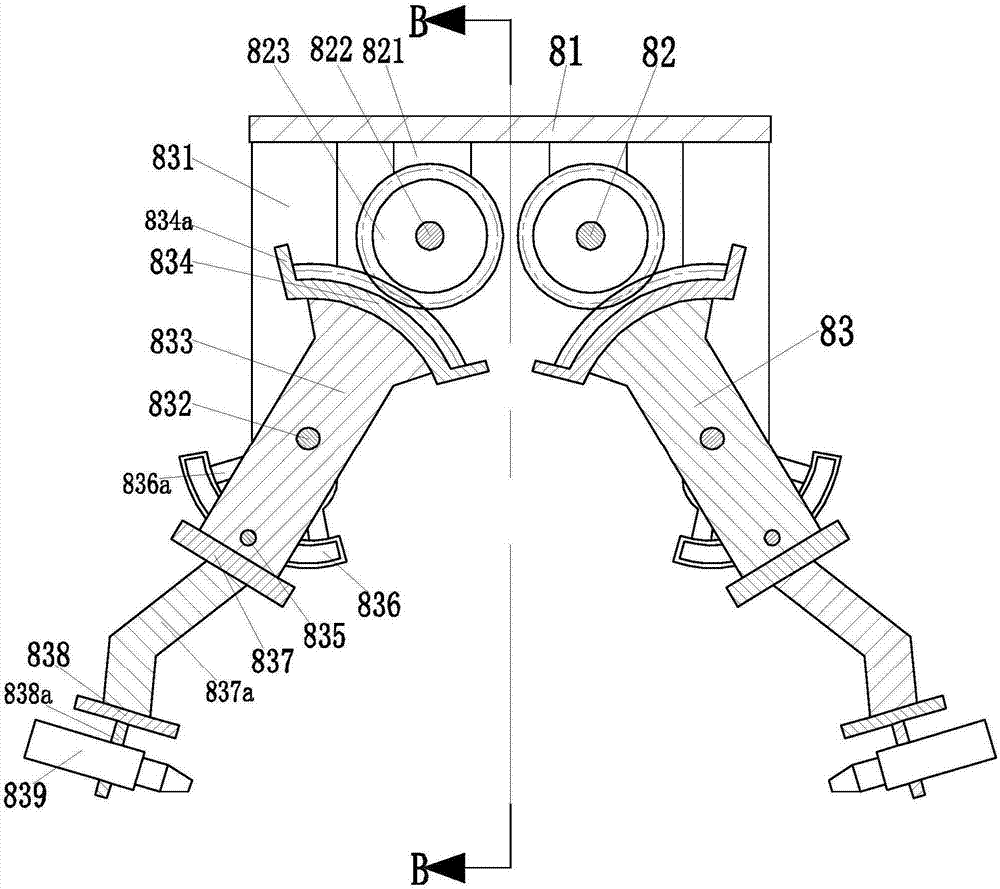

Automatic treatment maintenance equipment for high-speed rails

ActiveCN106347409ARealize the automatic pruning functionRealize automatic pushing functionBallastwayCuttersEngineeringAutomatic processing

The invention relates to automatic treatment maintenance equipment for high-speed rails. The automatic treatment maintenance equipment comprises a baseplate, a rail tree trimming device is mounted on the left side of the upper end face of the baseplate and can realize automatic trimming of rail protection trees, and a rail stone squeezing and pushing device is mounted on the right side of the upper end face of the baseplate and can realize automatic squeezing and pushing of rail damping stone; the rail tree trimming device comprises a trimming bottom plate welded on the left side of the upper end face of the baseplate, a trimming supporting plate is welded on the trimming bottom plate, a clamping rotary cutting branched chain is mounted in the middle of the side face of the trimming supporting plate and can realize clamping rotary cutting of the rail protection trees, and two sawing patting branched chains are symmetrically mounted on two sides of the side face of the trimming supporting plate and symmetrically positioned on two sides of the clamping rotary cutting branched chain. The automatic treatment maintenance equipment can realize an automatic maintenance function of tree trimming and stone squeezing and pushing of rails.

Owner:桐乡市腾飞家纺股份有限公司

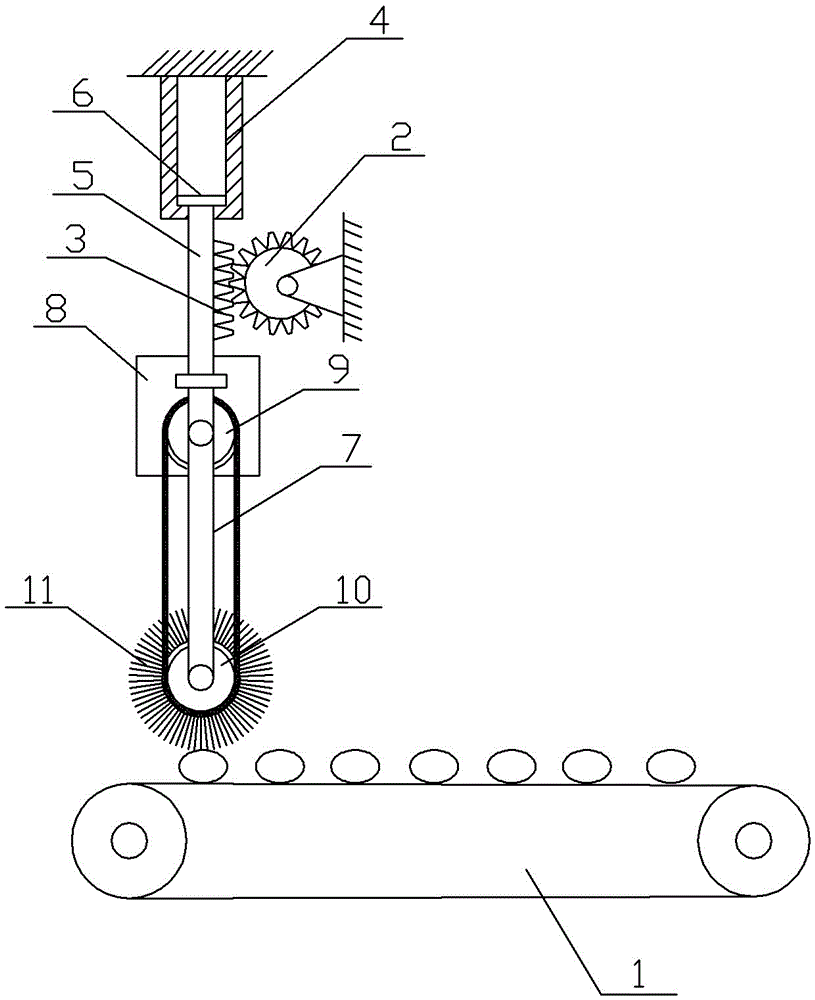

Soil removal device for sweet potatoes

The invention belongs to the technical field of agricultural product processing and provides a soil removal device for sweet potatoes. The soil removal device for sweet potatoes comprises a rack, a horizontal belt conveyor is arranged on the rack, a drive gear is rotatably connected to the rack, a vertical sliding groove is formed above the drive gear side, a groove opening of the sliding groove is bent to form a limiting opening, a sliding block is arranged in the sliding groove in a sliding fit mode, and the diameter of the sliding block is larger than that of the limiting opening; the soil removal device further comprises a sliding rod, the upper end of the sliding rod penetrates through the groove opening of the sliding groove and is welded to the sliding block, and a gear rack meshed with the drive gear is welded to a rod body of the sliding rod; a vertical mounting plate is welded to the lower end of the sliding rod; the mounting plate is rotataly connected with a drive belt wheel and a driven belt wheel in sequence from top to bottom, the drive belt wheel and the driven belt wheel are connected through a triangular belt, and a driven gear is coaxially connected with a brush head. By means of the soil removal device for sweet potatoes, newly unearthed sweet potatoes can be cleaned without consumption of manpower, the automated speed is high, and the soil removal device is easy to popularize.

Owner:CHONGQING PINGWEI CHAOYANG AGRI DEV CO LTD

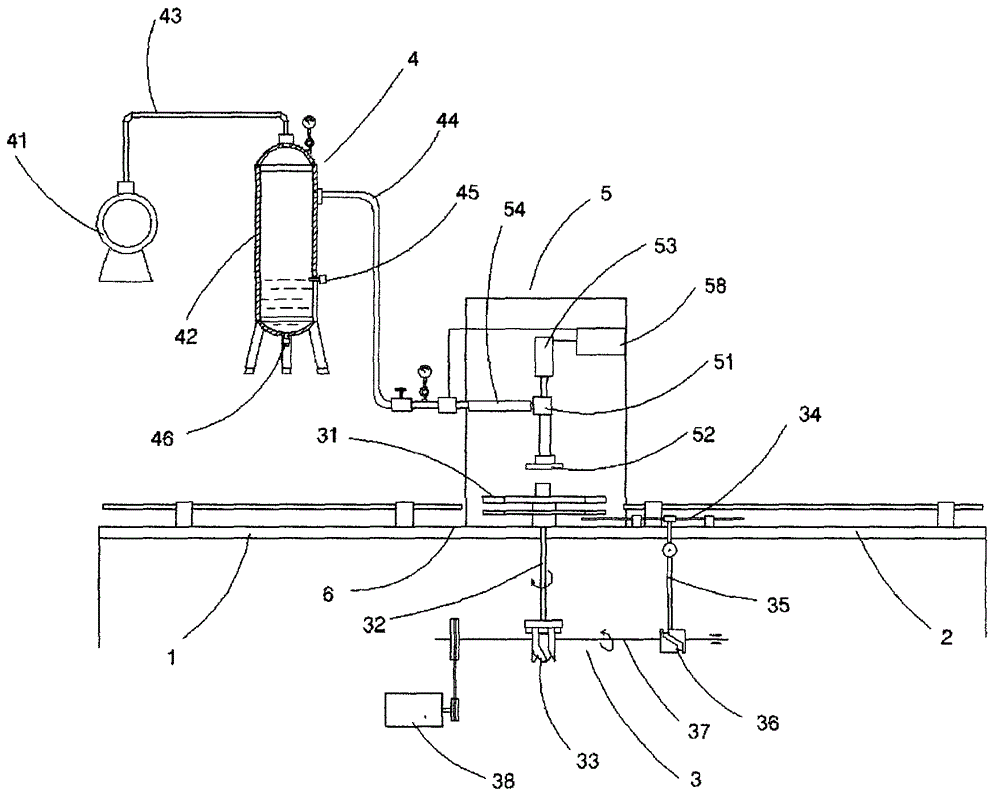

Canning vacuum water-controlling equipment

The invention relates to canning vacuum water-controlling equipment, which comprises a can entering conveying frame, a can exiting conveying frame, a vacuum stabilizing device, a water-sucking device and a transmission mechanism, wherein a can entering rotary disk of the transmission mechanism is axially connected with the can entering conveying frame and the can exiting conveying frame at both sides, a rotary shaft of the can entering rotary disk is connected with an can entering eccentric wheel to enable the can entering rotary disk to make intermittent-type rotary movement, the water-sucking device is positioned above the can entering rotary disk, a water-sucking pipe of the water-sucking device is axially connected with a cylinder and a pressure head, the upward and downward movement of the pressure head is synchronously matched with a can-position hole when the can entering rotary disk makes intermittent-type rotation, the vacuum stabilizing device comprises a vacuum pump and a vacuum can, the vacuum pump is connected with the vacuum can through a pipeline, a water-level sensor is arranged on the lateral wall of the vacuum can, a water-discharging electromagnetic valve is arranged at the bottom of the vacuum can, and a gas pipe which is led out of the vacuum can is connected with the water-sucking pipe of the water-sucking device. Water in a can is sucked out by adopting a vacuum water-sucking method in the invention, and the canning vacuum water-controlling equipment has the advantages of uniformity in water control, high speed and high benefit.

Owner:胡海明

Intelligent cleaning device for motor car rail

ActiveCN106076933AAdjust the high pressure cleaning angleHigh pressure cleaning effect is goodCleaning using liquidsCouplingEngineering

The invention relates to an intelligent cleaning device for a motor car rail. The intelligent cleaning device comprises a cleaning supporting plate. One cleaning adjusting branched chain and one high-pressure cleaning branched chain are mounted on one of two sides of the lower end surface of the cleaning supporting plate. The cleaning adjusting branched chain and the high-pressure cleaning branched chain, which are arranged on one side of the cleaning supporting plate, are symmetrical to those, which are arranged on the other side of the cleaning supporting plate. The two cleaning adjusting branched chains are respectively connected with the two high-pressure cleaning branched chains. The two cleaning adjusting branched chains can be used for accurately adjusting the high-pressure cleaning angles of the two high-pressure cleaning branched chains. After the motor car rail is polished, the two high-pressure cleaning branched chains are adjusted by the two cleaning adjusting branched chains to move downwards, and residual scrap iron generated after polishing and non-cleaned dust, which are attached to the motor car rail, are quickly cleaned by a high-pressure water jet working principle, and the high-pressure cleaning effect is good; each cleaning adjusting branched chain comprises two cleaning lifting lugs welded on the lower end surface of the cleaning supporting plate, an adjusting shaft is mounted between the cleaning lifting lugs, an adjusting gear is mounted in the middle of the adjusting shaft through a key, and an adjusting motor is mounted at the rear end of the adjusting shaft through a coupling. The intelligent cleaning device can realize a full-automatic cleaning function after the motor car rail is polished, manual operation is not required, and the degree of automation is high.

Owner:江苏皋宇科技发展有限公司

Full-automatic polytetrafluoroethylene powder sprayer

InactiveCN108837963AImprove working environmentReasonable designLiquid spraying plantsLiquid surface applicatorsAutomatic controlSprayer

The invention relates to a full-automatic polytetrafluoroethylene powder sprayer and belongs to the technical field of powder spraying equipment. The full-automatic polytetrafluoroethylene powder sprayer comprises supporting rollers, a rack and a powder spraying spray gun. Four supporting legs are welded to four corners below the rack, four supporting racks are symmetrically welded to the upper surface of the rack, the supporting rollers are fixed to the upper ends of the supporting racks through pin rolls, a static powder sprayer is fixed in the rack through screws, a controller is fixed to the side wall of one side of the rack through screws, the controller is electrically connected to the static powder sprayer, and a front fixed rack is welded to the center of one side, vertical to therotating direction of the supporting rollers, of the rack. The full-automatic polytetrafluoroethylene powder sprayer provided by the invention is reasonable in design. The spray gun can be controlledautomatically to enter a tank body to spray powder full-automatically by the controller, so that the manual operation is reduced, the working environment of workers is improved and the working strength is reduced, and meanwhile, the full-automatic polytetrafluoroethylene powder sprayer is high in automatic operating speed and good in quality, improves the work efficiency and guarantees the powderspraying quality.

Owner:无锡百安特防腐设备有限公司

Intelligent grinding apparatus for high-speed rail

ActiveCN106002546AStable self-adjusting grinding directionExpand the grinding rangeGrinding machinesGrinding headsHydraulic cylinderEngineering

The invention relates to an intelligent grinding apparatus for a high-speed rail. The intelligent grinding apparatus comprises a self-stabilized moving device capable of stable self-adjustment of a grinding direction according to a bend shape of a rail such that the intelligent grinding apparatus is applicable to grinding rails of different trajectory shapes, and wide in range of application. A grinding baseplate is mounted on a lower end face of the self-stabilized moving device. Four 4# hydraulic cylinders are symmetrically mounted on a lower end of the grinding baseplate. Adjustable grinding devices are mounted on top ends of the four 4# hydraulic cylinders. The four 4# hydraulic cylinders are capable of adjusting a grinding height of the intelligent grinding apparatus for a high-speed rail such that the intelligent grinding apparatus is suitable for grinding rails at different terrain elevations. The adjustable grinding devices are capable of completely and closely fitting with the surfaces of rails for grinding back and forth, allowing for large grinding range, good grinding effect and high working efficiency. The intelligent grinding apparatus for a high-speed rail is capable of realizing full-automatic grinding function for rails without manual operation, and high in automation degree.

Owner:唐山宏正机械设备有限公司

Dedicated intelligent cleaning machine for subway rail

ActiveCN106076934AGood dynamic responseIncrease stiffnessCleaning using liquidsRound tableEngineering

The invention relates to a dedicated intelligent cleaning machine for a subway rail. The dedicated intelligent cleaning machine comprises a self-stabilization traveling device. A lower supporting round table is welded in the middle of the upper end surface of the self-stabilization traveling device. Six supporting columns are uniformly welded on the upper end surface of the lower supporting round table in the axis direction. A supporting stand column is welded in the middle of the upper end surface of the lower supporting round table. An upper supporting round table is welded on the upper end surfaces of the supporting stand column and the six supporting columns. A connecting plate is mounted on the upper end surface of the upper supporting round table through screws. A supporting bent arm is welded in the middle of the upper end surface of the connecting plate. Variable high-pressure cleaning devices are welded at the tail end of the supporting bent arm, and can be used for adjusting the high-pressure cleaning direction, and residual scrap iron generated after polishing and non-cleaned dust, which are attached to the subway rail, are quickly cleaned by a high-pressure water jet working principle. The dedicated intelligent cleaning machine can realize a full-automatic cleaning function of the polished subway, manual operation is not required, the degree of automation is high, the jetting condition generated during the operation process of the dedicated intelligent cleaning device is eliminated, the stability of the dedicated intelligent cleaning machine is high, and the fixed performance of the dedicated intelligent cleaning machine is high.

Owner:唐山宏正机械设备有限公司

Fully-automatic processing device for tea leaves

ActiveCN106172939AUniform transmission forceGood transmission effectPre-extraction tea treatmentScreening effectEngineering

The invention relates to a fully-automatic processing device for tea leaves. The fully-automatic processing device comprises a base plate, wherein the lower end surface of the base plate is symmetrically provided with four universal wheels; the fully-automatic processing device is moved to the position of processing through the four universal wheels; the left side of the upper end surface of the base plate is provided with a spotlighting tedding unit which can realize the function of rapid spotlighting tedding of the tea leaves, greatly shortens tedding time and has rapid tedding speed and good tedding effect; the central part of the upper end surface of the base plate is provided with a multistage screening unit which can realize the function of multistage automatic screening of the tea leaves and has short screening time, rapid screening speed and good screening effect; and the right side of the upper end surface of the base plate is provided with a controllable rough stir-frying unit which can realize the function of rapid controllable rough stir-frying of the tea leaves, greatly shortens rough stir-frying time by adopting a circular processing manner and has good effect of crude tea leaves. The fully-automatic processing device for the tea leaves provided by the invention can realize integrated automatic processing functions of tedding, screening and rough stir-frying of the tea leaves, does not need manual operation, is simple and convenient to operate, and has high degree of automation.

Owner:武汉大雾山茶业有限公司

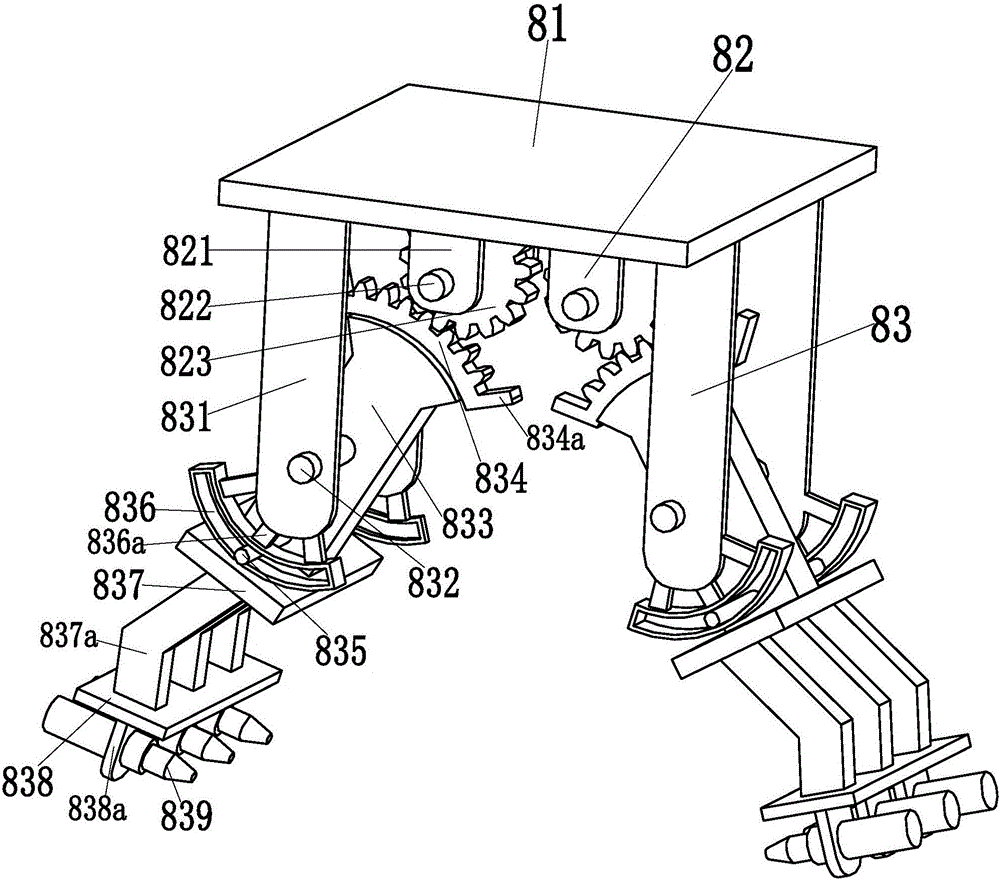

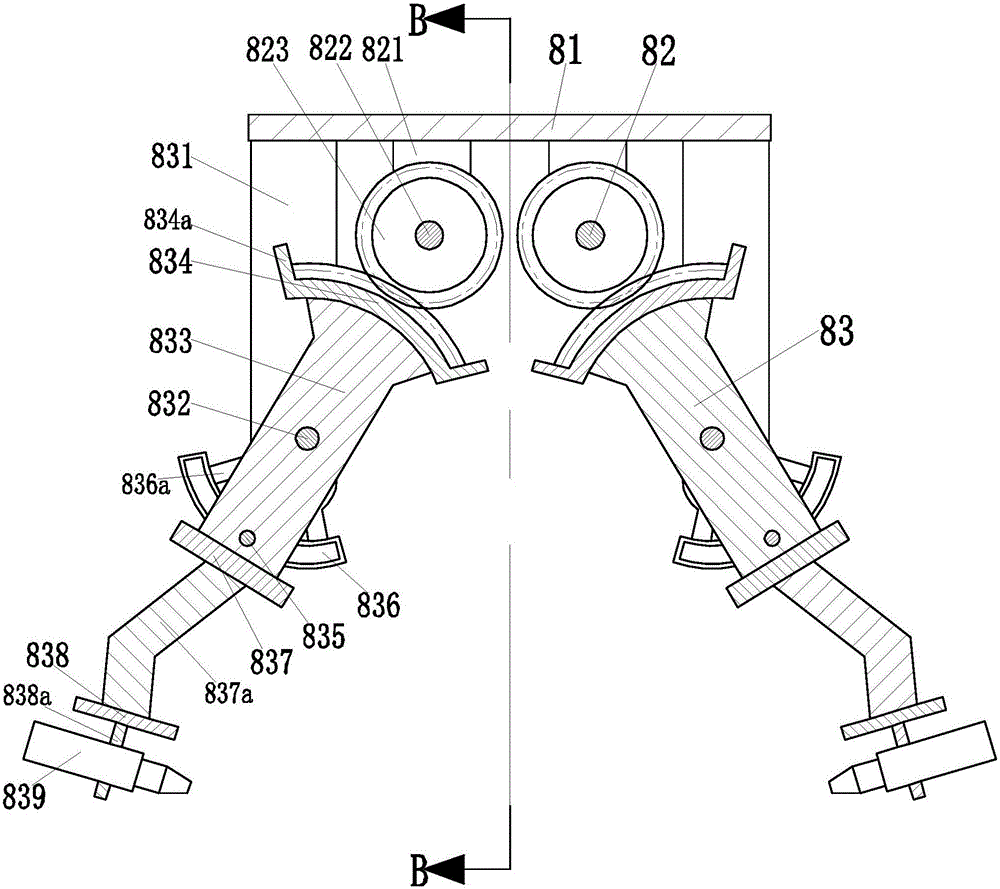

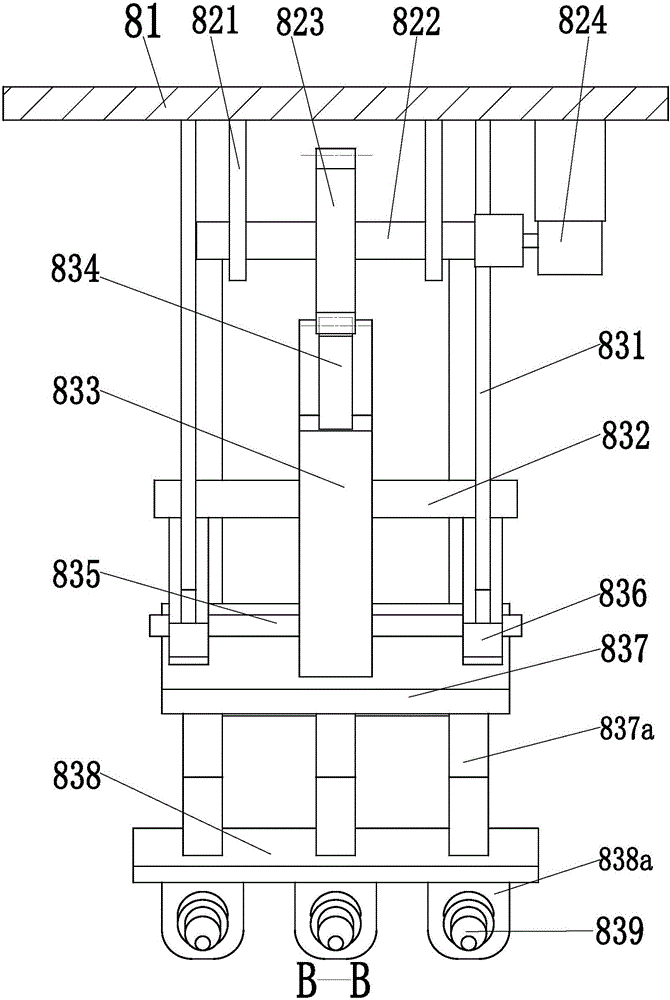

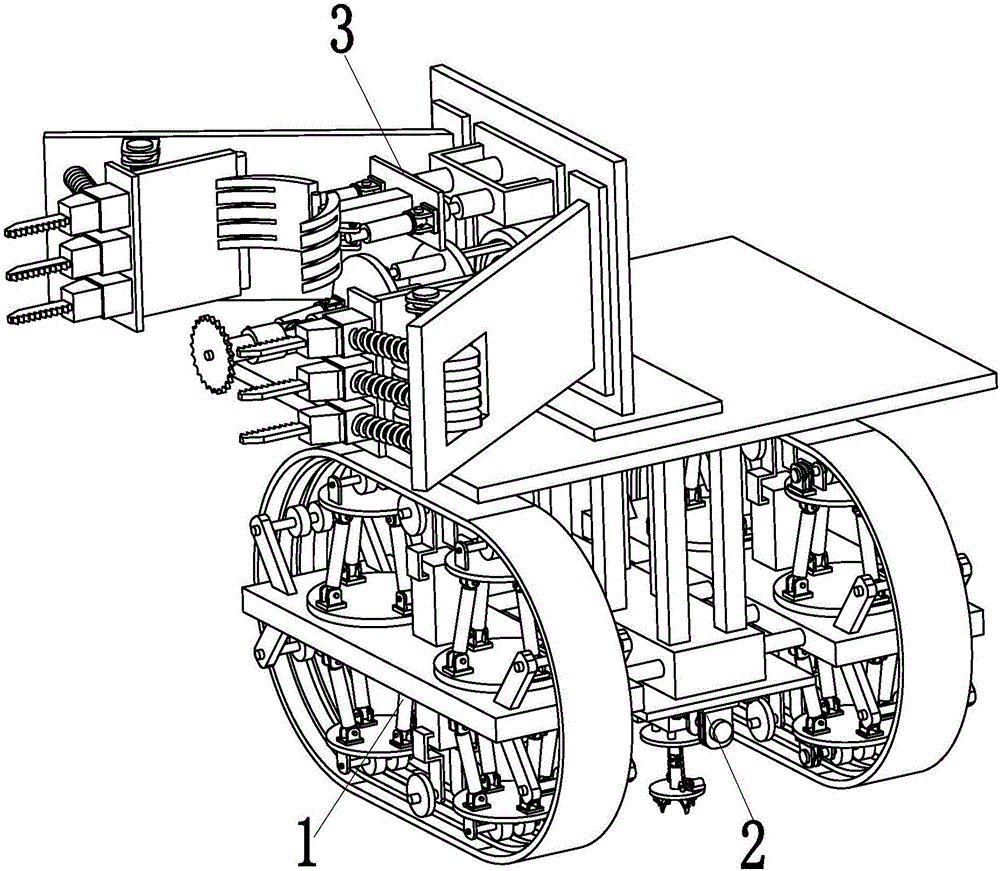

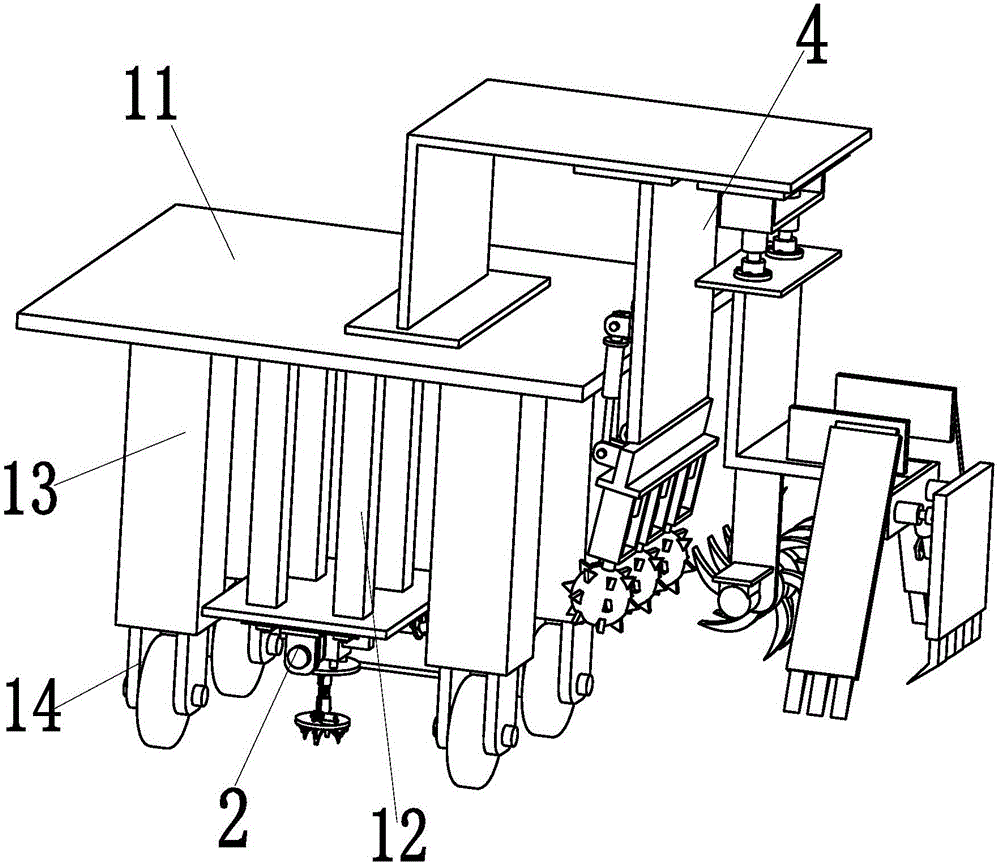

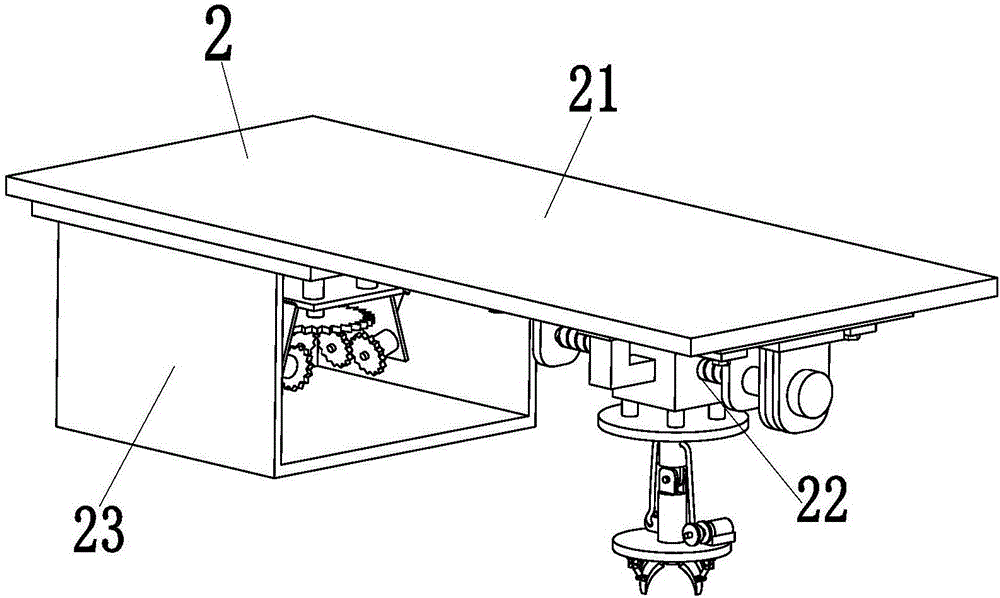

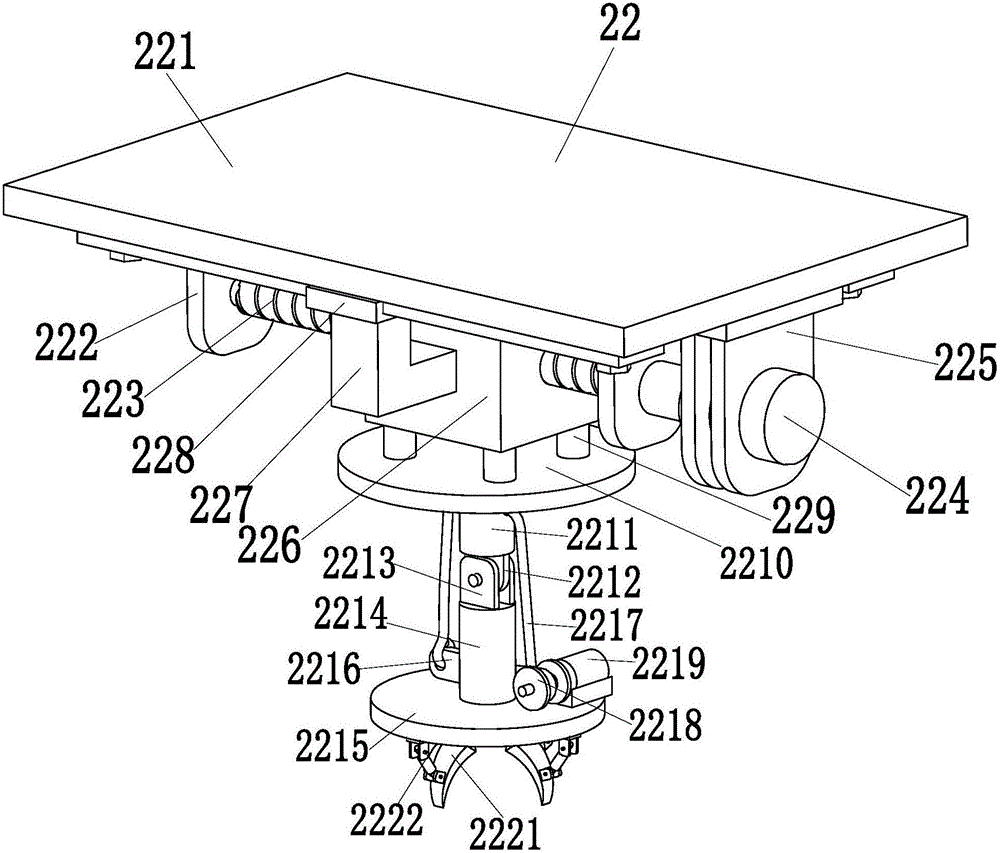

Automatic maintenance vehicle for subway rail

ActiveCN106120499ARealize automatic impurity removal functionRealize the automatic pruning functionRailway cleaningTrack maintainenceEngineering

Owner:临沂恒元城市建设运营有限公司

Bidding and tendering system and a management method

InactiveCN109615491AReduce processing difficultyGuaranteed complianceOffice automationBuying/selling/leasing transactionsNetworking protocolFile comparison

The invention discloses a bidding and tendering system and a management method. The bidding and tendering system comprises a user login module, an information verification module, a process managementmodule, a media publishing module and a processor module, The user login module comprises an administrator permission unit, a bid inviting user login unit and a bid inviting user login unit; the processor module establishes a data archive in a database according to the user information; the administrator authority unit is used for managing and operating the processor module; the information verification module comprises a remote data comparison unit and an integrity recording unit; the remote data comparison unit compares the remote data with the user data according to a network protocol; theintegrity recording unit is based on the data of the remote data comparison unit and carries out integrity management on the bidding users by integrating integrity records in the bidding process; andthe flow management module takes the project scheme of the bid inviting users as a reference, carries out a bid inviting and bidding process, records the violation phenomenon of each bid inviting user, and sends the violation times to the integrity recording unit through the processor module.

Owner:安徽省招标集团股份有限公司

Automatic maintaining equipment for high-speed rail

InactiveCN106381829ARealize automatic motion detection functionUniform rigid self-steady walking functionCuttersCutting implementsEngineeringMaintaining equipment

The invention relates to automatic maintaining equipment for a high-speed rail. The automatic maintaining equipment comprises a rail moving base which has an automatic rail moving and detecting function. A rail impurity removing device is mounted in the middle of the lower end face of the rail moving base and has an automatic impurity removing function for the middle of the rail. A rail tree trimming device is mounted on the upper end face of the rail moving base and has an automatic trimming function for rail protecting trees. The rail moving base comprises a base plate, two rows of moving support columns are symmetrically mounted in the middle of the lower end face of the base plate, a moving base platform is welded to the lower ends of the two rows of moving support columns, and the two rows of moving support columns play a role in uniformly supporting the moving base platform. Two rows of fixed columns are symmetrically welded to the two ends of the moving base platform, and two movable traveling devices are mounted on the two sides of the two rows of fixed columns correspondingly. The automatic maintaining equipment has the all-in-one automatic maintaining function of rail condition detection, tree trimming and impurity removal.

Owner:靖江市九洲空调设备有限公司

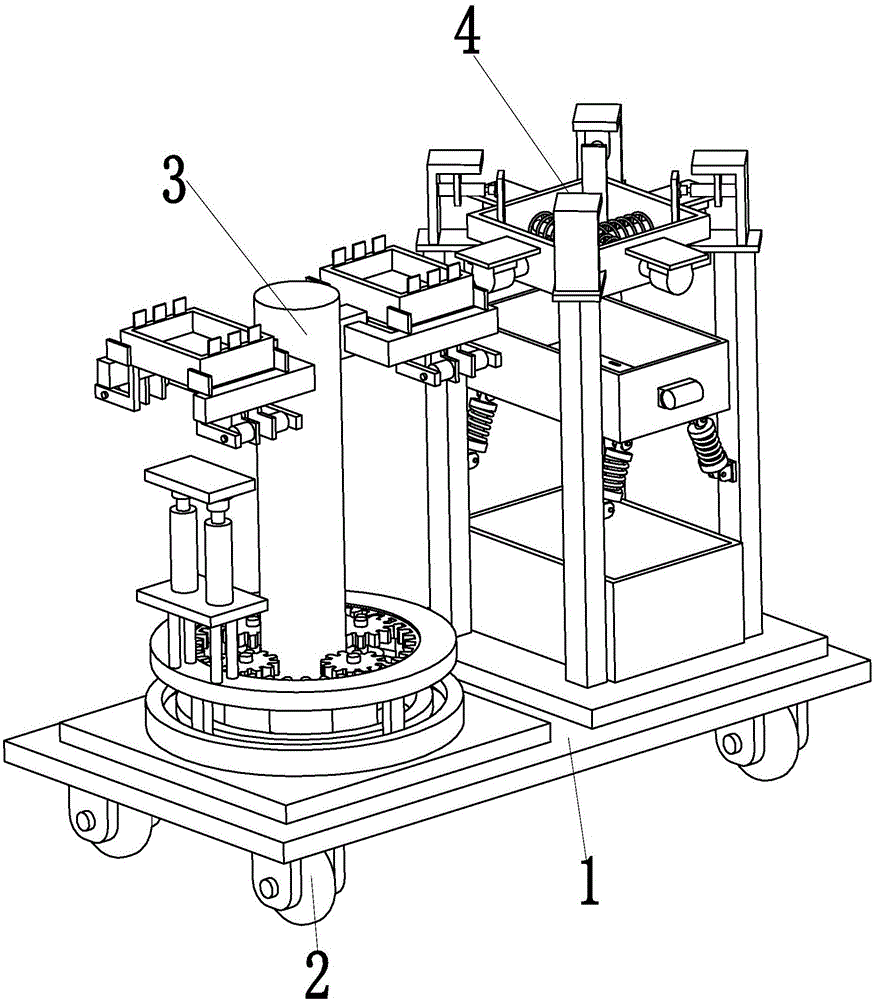

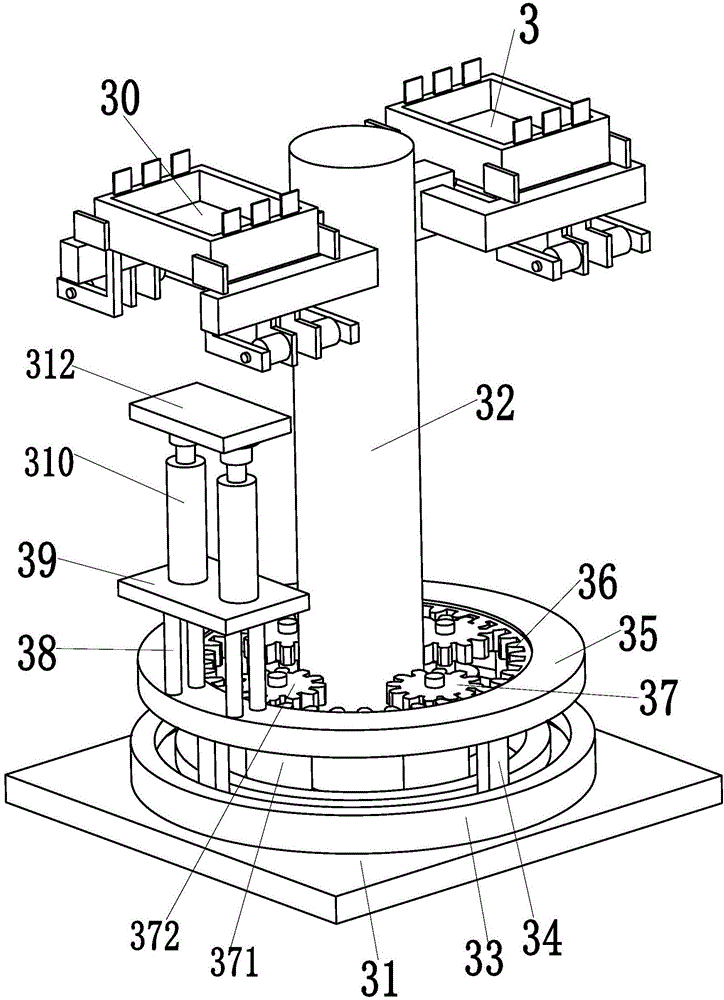

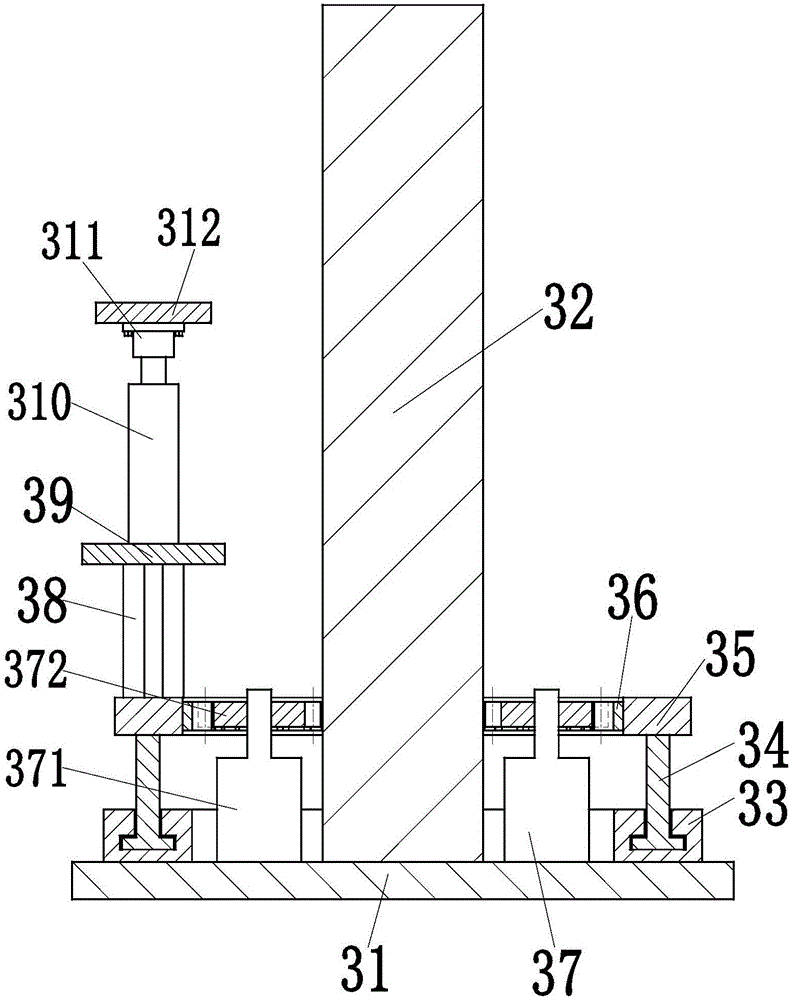

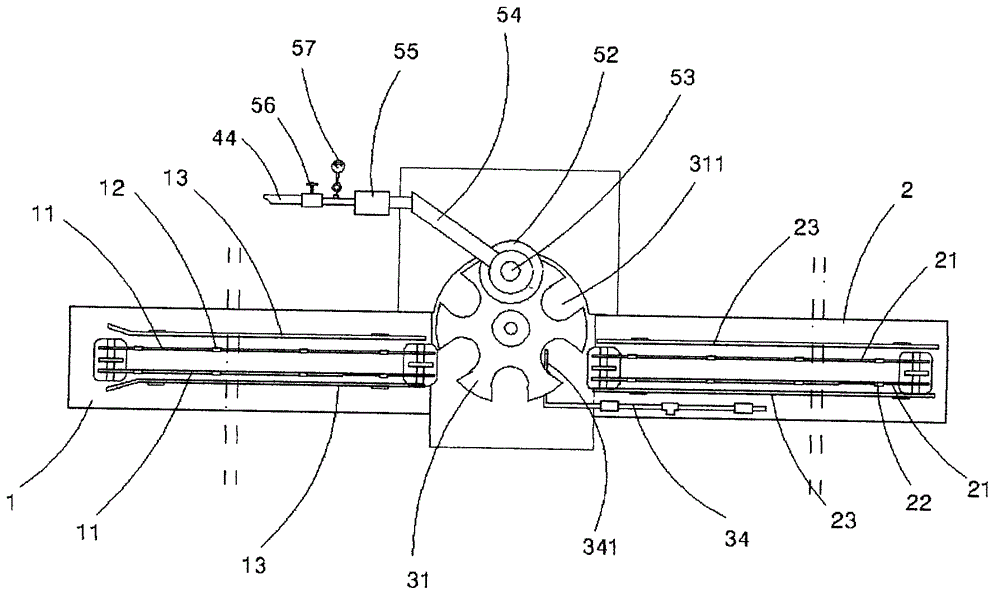

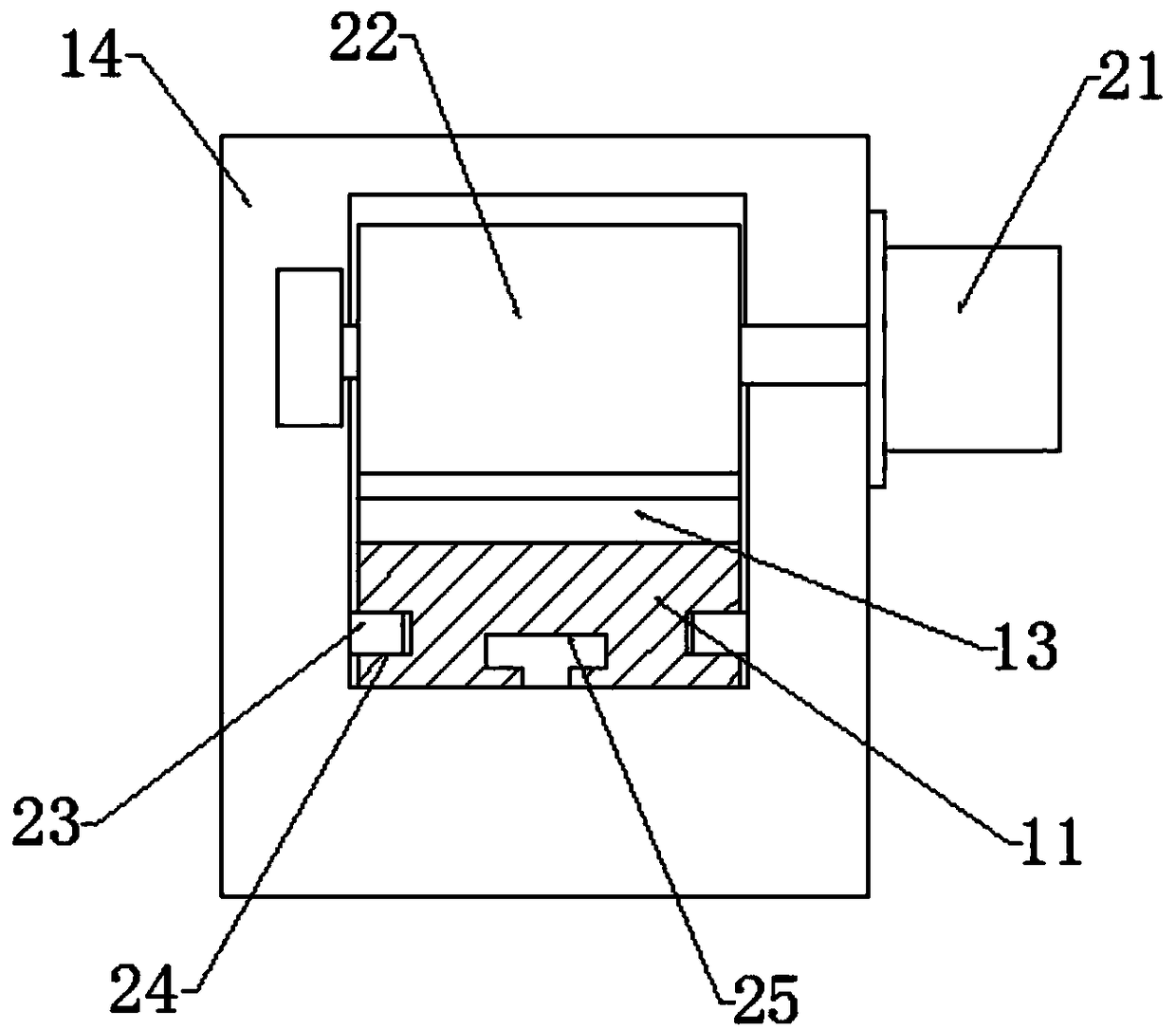

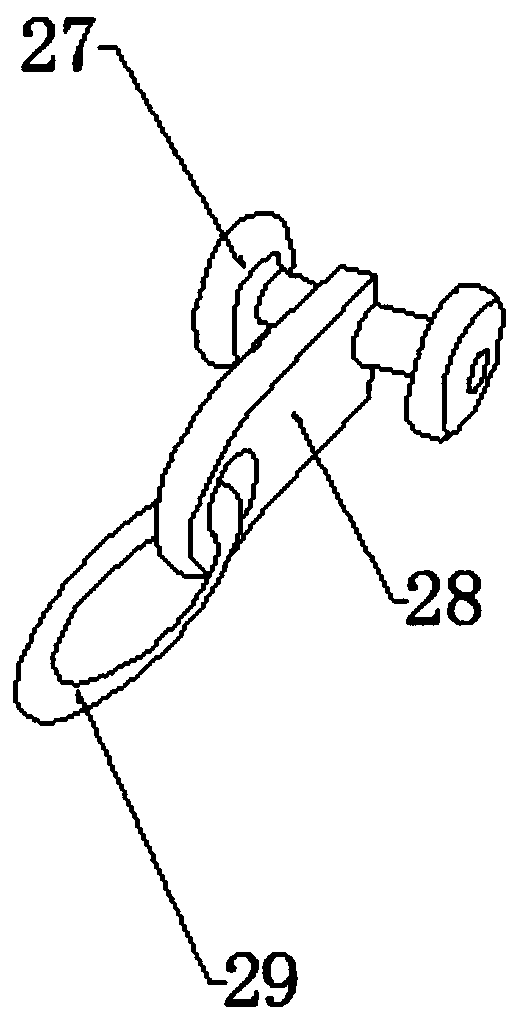

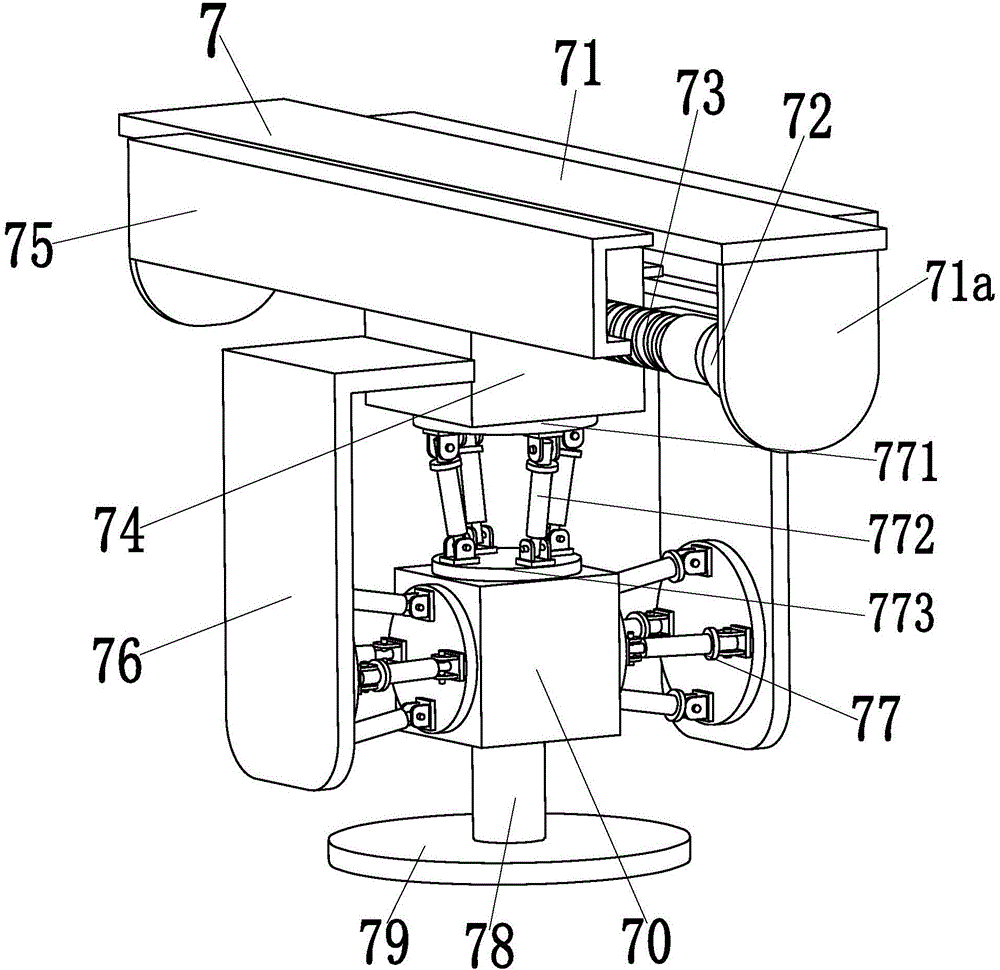

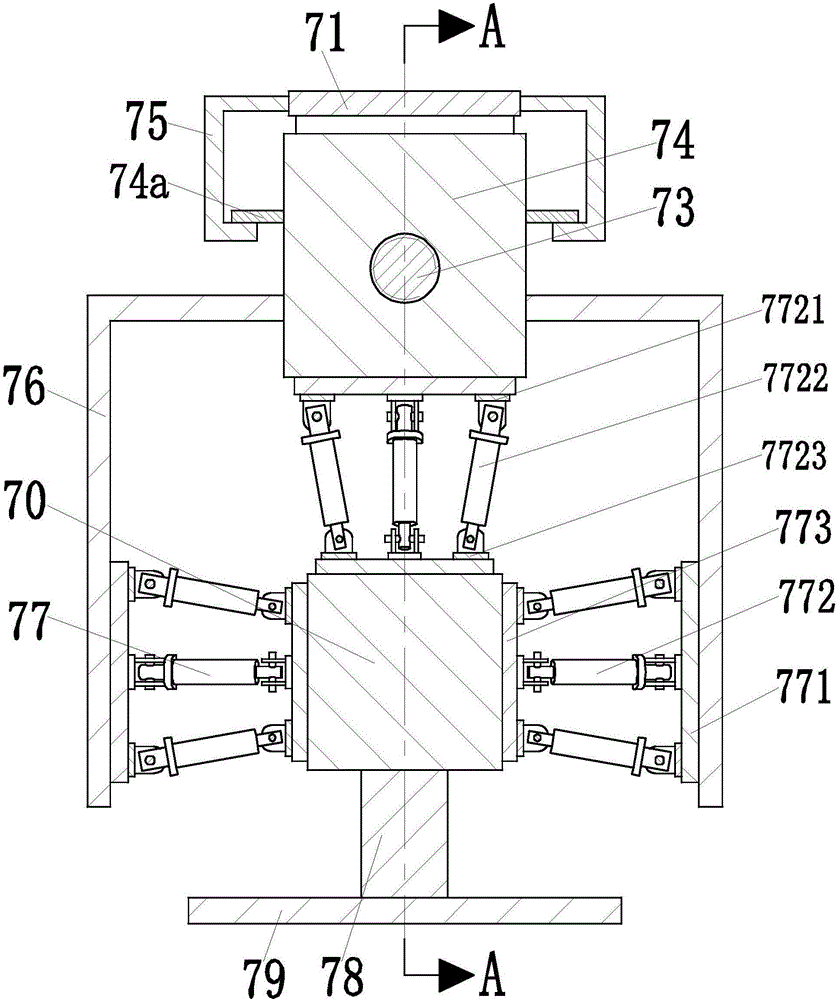

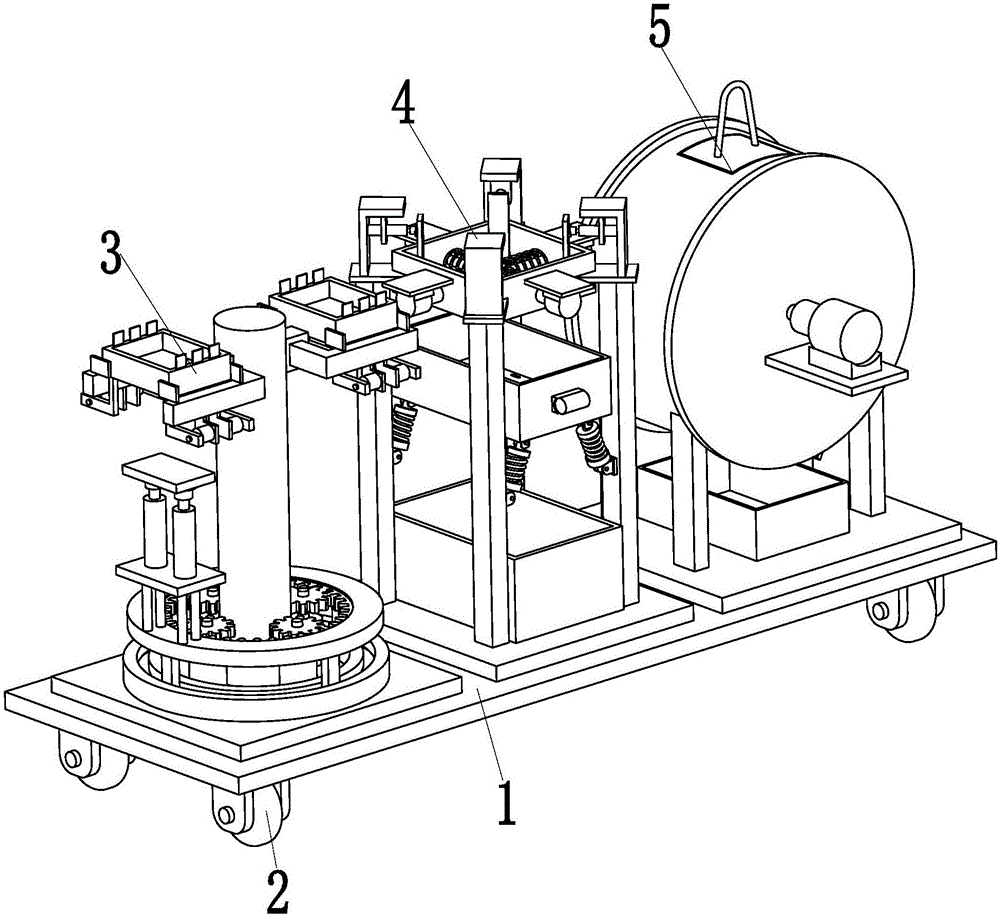

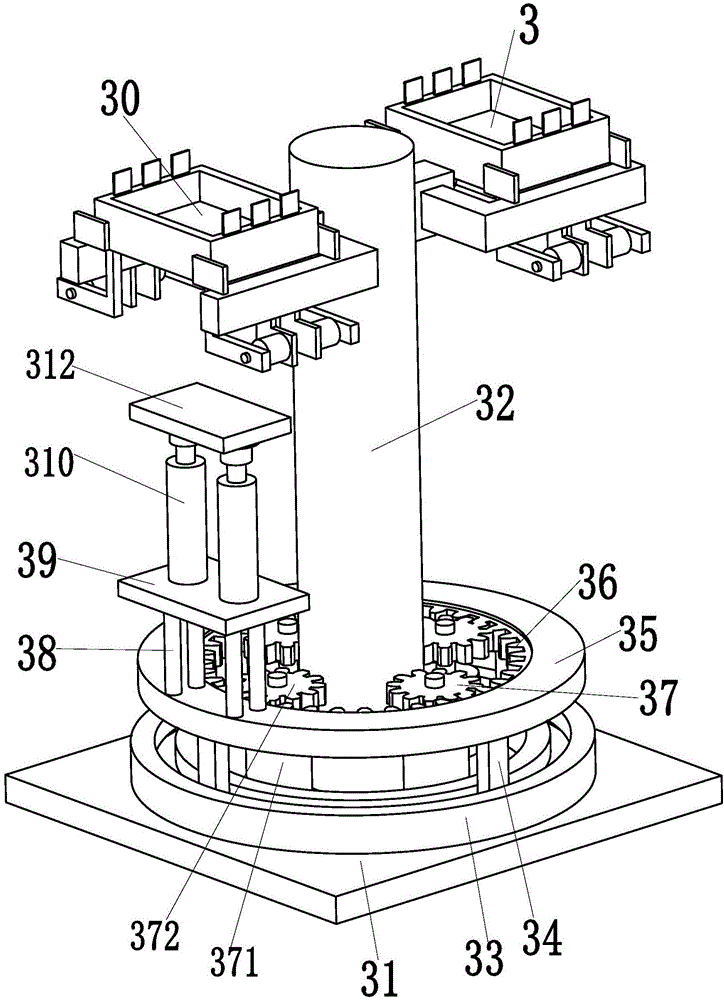

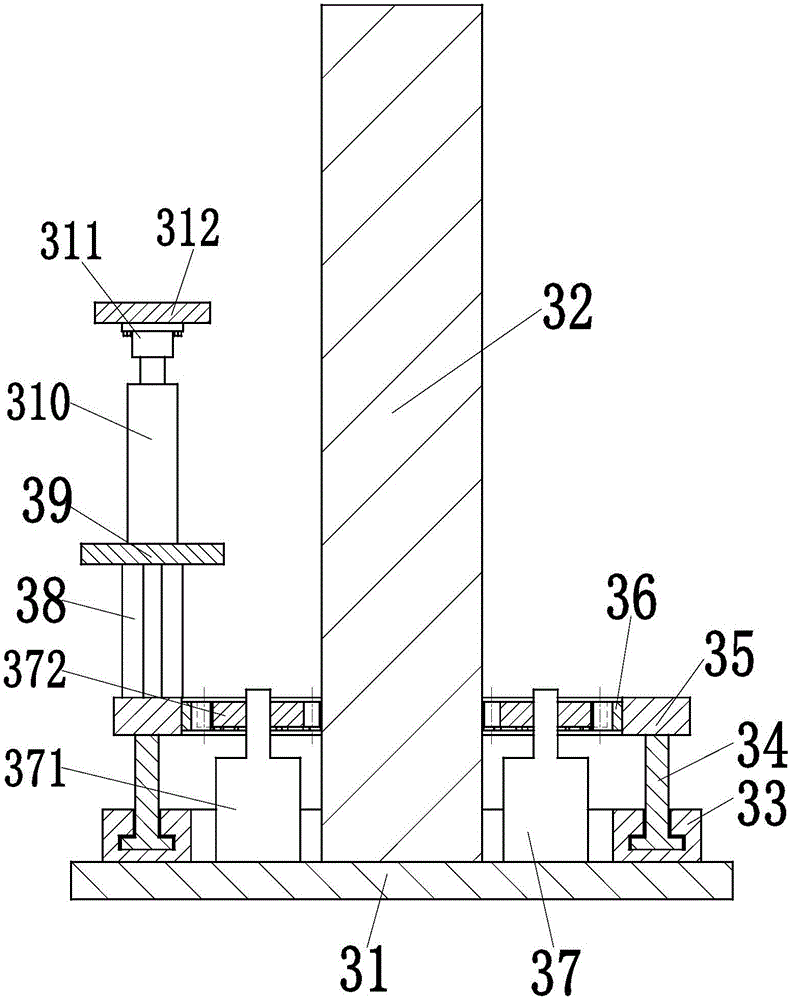

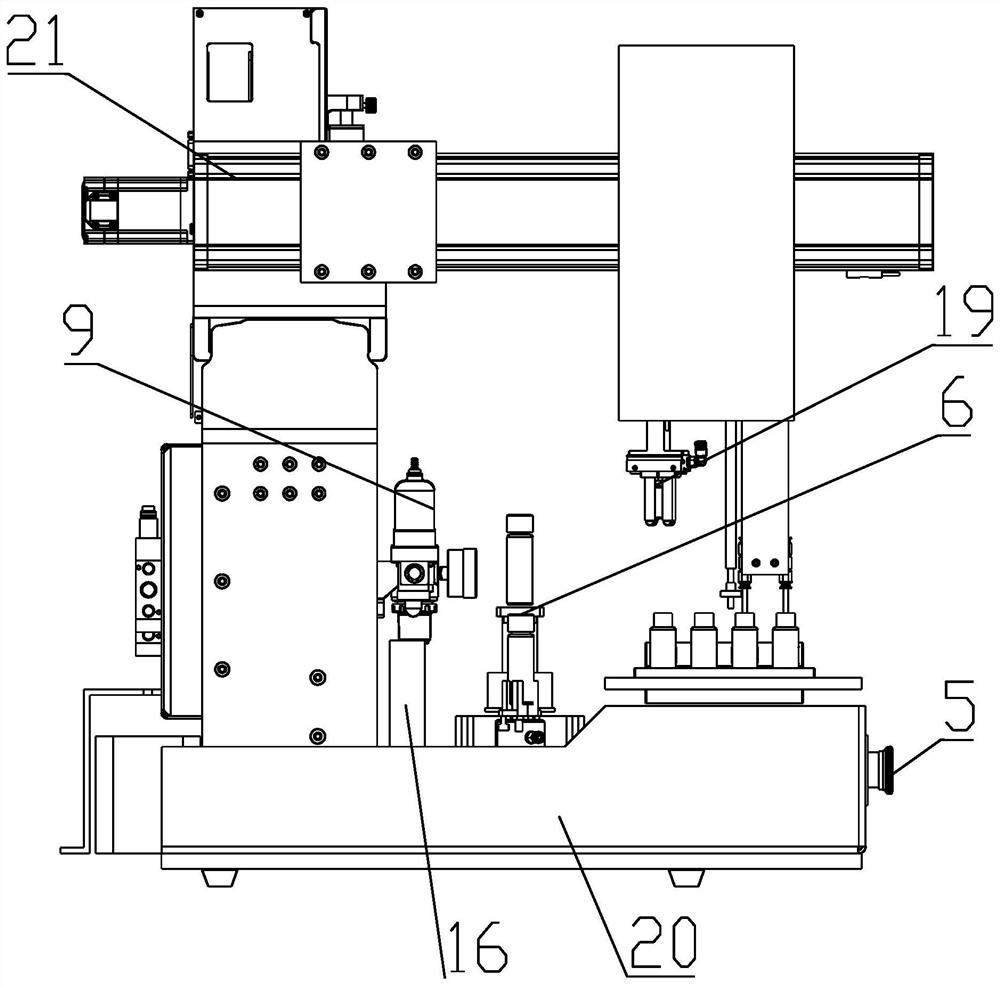

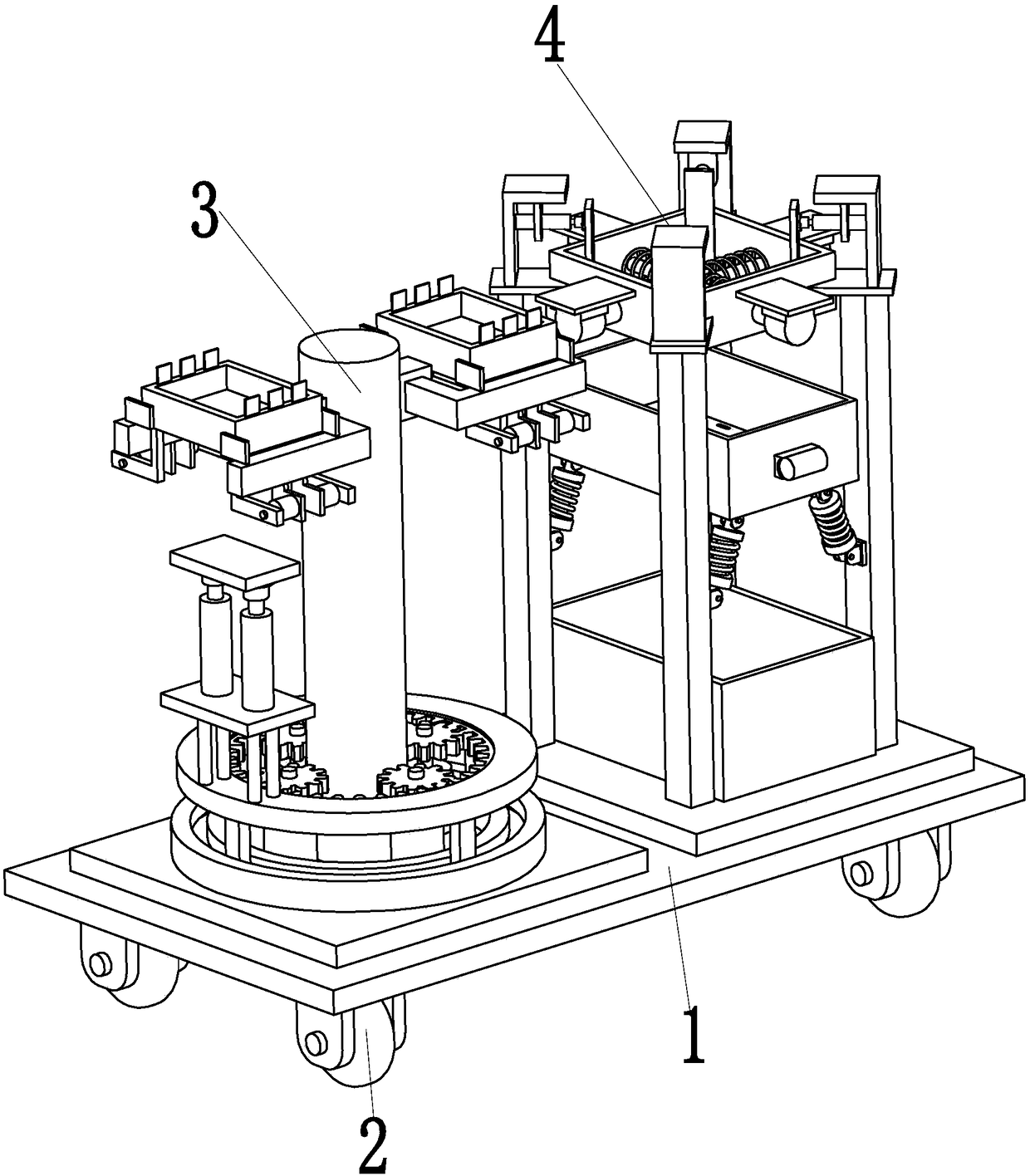

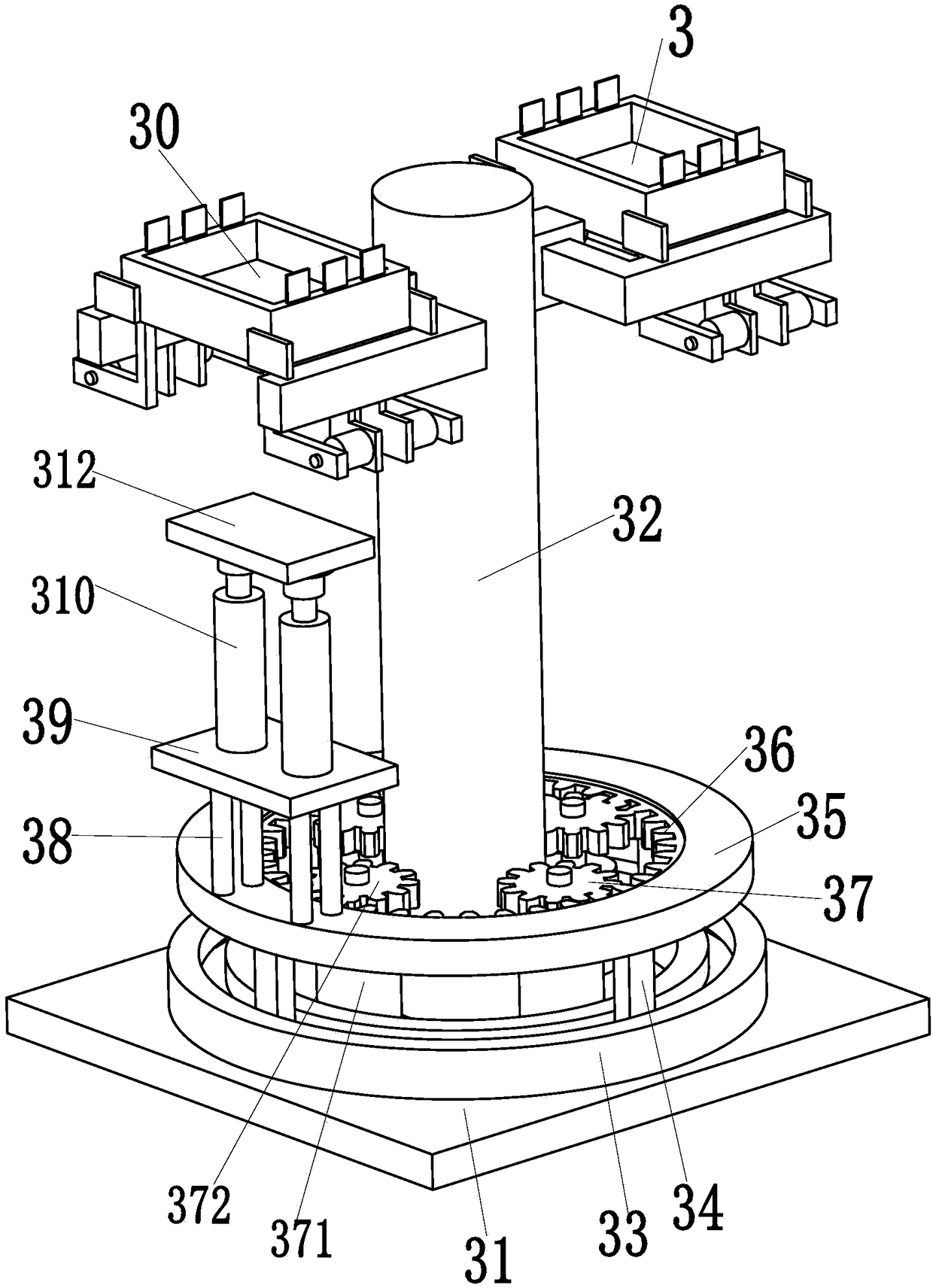

Automatic sampling treatment device

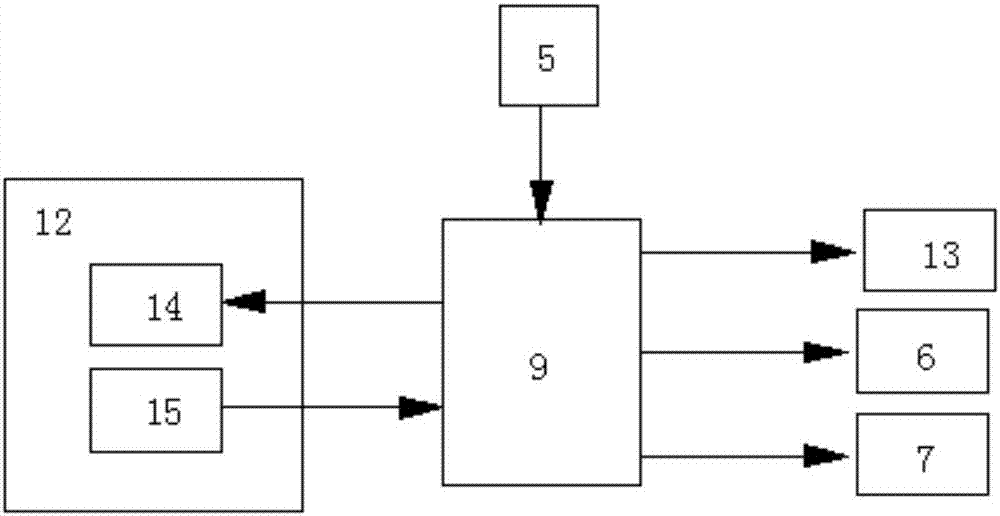

PendingCN112269027AFast automationFully automatedWithdrawing sample devicesPreparing sample for investigationElectric machineAir pump

An automatic sampling treatment device comprises a motor for taking a liquid sample and a filter head, a manipulator up-down moving motor, a first manipulator rotating motor, a nitrogen blowing pipe,an air pump, a fixed seat, a manipulator and a driving assembly, a controller used for controlling equipment is arranged on the fixed seat, and the driving assembly is arranged on the fixed seat and is in communication connection with the controller; the liquid sample taking and filtering head motor, the manipulator up-down moving motor and the first manipulator rotating motor are arranged on thedriving assembly through a bracket frame; an initial sample bottle fixing disc, a sample bottle cap fixing disc, a sample injection bottle fixing disc, a sample injection bottle cap fixing disc and aneedle head filter fixing disc are arranged on the fixed seat side by side; and the nitrogen blowing pipe is arranged on the bracket frame through a bracket and is positioned right above the initial sample bottle fixing disc. The sample sampling treatment automation degree is high, sample pretreatment automation is achieved, the sample injection bottle which can be directly detected on a machine and is provided with an analysis sample is obtained, the speed is high, the precision is high, and the working efficiency is high.

Owner:钱程

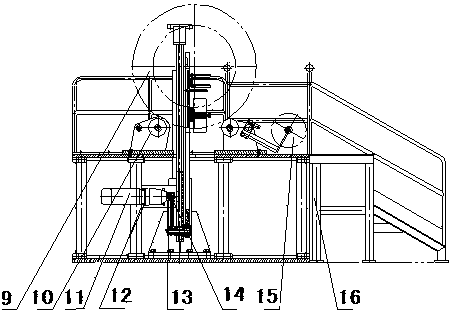

Pre-stressed steel strand packaging method and device

InactiveCN104015950AReduce labor intensitySensitiveWrapping with article rotationMotor speedPre stress

Provided is a pre-stressed steel strand packaging device. A track base, a packaging belt base, a motor speed reducer, a speed reducer base, an operation control box, a stairway and a protecting cover of the device are fixed on a machine frame. Packaging rings are arranged on a passive sliding wheel, an active sliding wheel and an adjustable sliding wheel of the track base. Synchronous pulleys on the active sliding wheel are connected through a synchronous belt to form a synchronous belt group. Carrier rollers are arranged on the packaging belt base and are used for supporting a packaged product steel strand. During packaging, the rolled-formed pre-stressed steel strand is stably hung and conveyed on the left carrier roller and the right carrier roller, then the head of a packaging belt on the packaging belt base is pasted to the pre-stressed steel strand through an adhesive tape, a motor is started, the left carrier roller and the right carrier roller rotate, meanwhile, the head of a packaging belt on the packaging rings is pasted to the pre-stressed steel strand through an adhesive tape, then the motor speed reducer is started, the packaging rings are driven to rotate through the synchronous belt group, and packaging is achieved. The overlapping degree and the tightness degree of the packaging belts are even and consistent, and the packaging requirement of steel strand products with different diameters can be met.

Owner:GUIZHOU WIRE ROPE

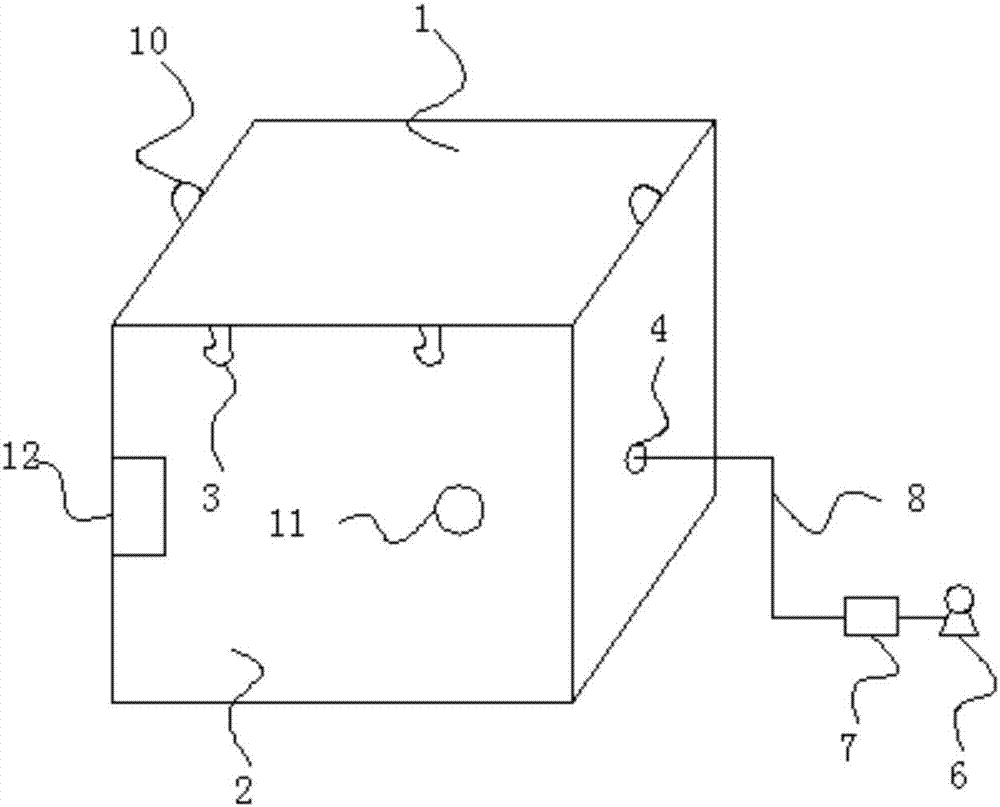

Steel ingot slow cooling hood with controllable cooling speed

The invention discloses a steel ingot slow cooling cover with controllable cooling speed, which comprises a box body, the box body includes an upper cover and a side wall, the rear end of the upper cover is hinged with the upper end of the side wall, and the front end of the upper cover is provided with a door lock Buckle, the upper cover can be opened or closed through the door lock; both the side wall and the upper cover of the box body include an outer layer, an inner layer and a heat insulation layer between the outer layer and the inner layer; There is at least one ventilation hole; it also includes a temperature sensor, an air compressor, a heater, a gas pipe and a PLC controller. Both the air compressor and the air compressor are electrically connected to the PLC controller. The slow cooling cover of the present invention has a good slow cooling and heat preservation effect, so that the steel ingot is cooled according to the cooling curve, which is beneficial to ensure and improve the quality of the steel ingot, and the cooling speed is automatically regulated by the PLC controller, and the degree of automation is high, so that the cooling process can be controlled in real time, reducing Ingot scrap rate.

Owner:TAICANG SHUNCHANG FORGE

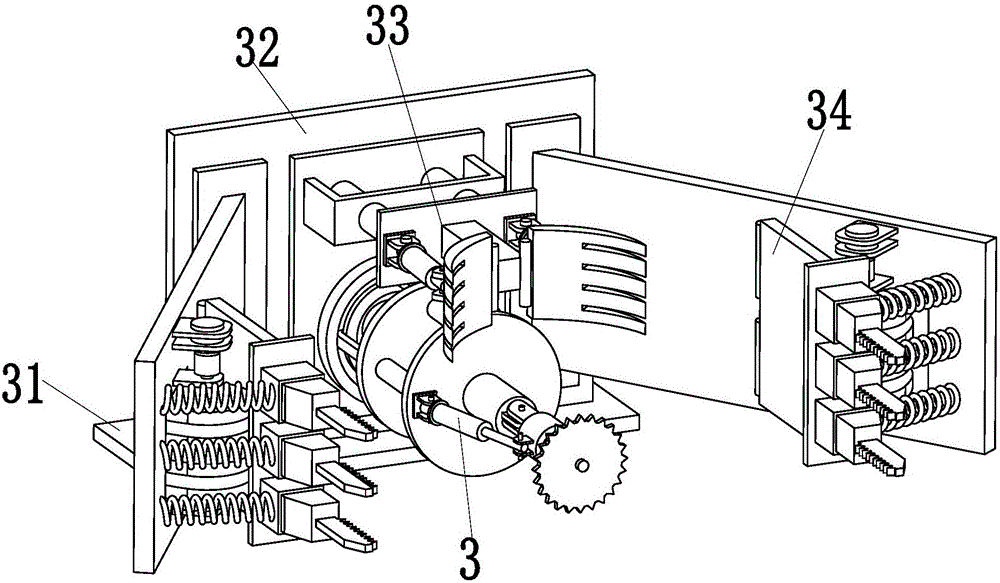

Track damping stone extruding and pushing machine with debris removal function

ActiveCN106368086ARealize automatic impurity removal functionRealize automatic pushing functionRailway tracksRailway cleaningEngineeringMechanical engineering

The invention relates to a track damping stone extruding and pushing machine with a debris removal function. The track damping stone extruding and pushing machine comprises a base plate; two rows of supporting columns are symmetrically arranged at the middle part at the lower end of the base plate; a track debris removal device is mounted at the lower ends of the two rows of supporting columns; the track debris removal device can realize the automatic debris removal function between rails; four supporting legs are symmetrically arranged at the lower end of the base plate, and a universal wheel is arranged at the lower end of each supporting leg; a track stone extruding and pushing device is mounted on the right side at the upper end surface of the base plate, and the track stone extruding and pushing device can realize the automatic extruding and pushing function of track damping stones; the track debris removal device comprises a debris removal supporting plate welded to the lower end surfaces of the two rows of supporting columns; a gripping and conveying mechanism is mounted on the right side at the lower end surface of the debris removal supporting plate; the gripping and conveying mechanism can realize the automatic gripping and conveying function to debris between the rails; and an adjustable crushing mechanism is mounted on the left side at the lower end surface of the debris removal supporting plate. Through the adoption of the track damping stone extruding and pushing machine disclosed by the invention, an automatic maintenance function integrating stone extruding and pushing as well as debris removal of the rails can be realized.

Owner:湖州优研知识产权服务有限公司

Full-automatic intelligent duck clavicle frying and moving system

InactiveCN109381053AAvoid pollutionLabor intensiveDomestic stoves or rangesLighting and heating apparatusEngineeringClavicle

The invention relates to a full-automatic intelligent duck clavicle frying and moving system. The full-automatic intelligent duck clavicle frying and moving system comprises a stall cart body, a partition plate, a frying device, a smoke removing device and a shielding device, wherein the inner portion of the stall cart body is provided with the partition plate, the middle of the upper end of the stall cart body is provided with the frying device, the frying device is located at the upper end of the partition plate, the left side of the upper end of the stall cart body is provided with the smoke removing device, the smoke removing device is located above the frying device, the upper end of the stall cart body is provided with the shielding device, and the frying device and the smoke removing device are arranged between the shielding device and the stall cart body. The full-automatic intelligent duck clavicle frying and moving system can solve the problems of an existing duck clavicle frying stall cart that manual frying is usually needed, the manual frying efficiency is slow, the labor intensity is large, the degree of automation is low, during frying, the oil smoke generated by frying cannot be treated, thereby causing serious environmental pollution, in bad weather, no protective measures usually exist, the labor intensity is large, the operation is complex, and the efficiencyis low.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

Device and method for automatically detecting redried tobacco strip identification and box core temperature based on visual identification

PendingCN112964392AImprove accuracyImprove reliabilityCharacter and pattern recognitionThermometer applicationsEngineeringVisual perception

The invention discloses a device and a method for automatically detecting redried tobacco strip identification and box core temperature based on visual identification. A visual identification tobacco strip identification unit is located above a tobacco box conveying roller way, a discharging baffle is automatically opened after a tobacco box enters a main body device, the feeding baffle is lifted after the position of a box body is positioned, a lifter descends to the height of an identification position, when the light source is turned on, an industrial camera takes a picture and then rises to an initial position, visual identification software system acquires, identifies and analyzes information of the picture to automatically identify a smoke box needing temperature measurement, after the infrared locator finds the position accurately, the rotator descends to the surface of the smoke box and rotates according to the size of a central opening gap of the smoke box, the drilling device moves to the center of the surface of the box body for descending drilling, the drilling shaft moves forwards and backwards after ascending, a temperature measuring rod descends to a deep hole after being automatically positioned and automatically returns after temperature measurement is finished, the feeding baffle and the discharging baffle descend at the same time, and the smoke box is discharged out of the main body device. According to the device and the method, the actual requirements of modern equipment on identification and temperature detection of the flue-cured tobacco lamina on a production line are met.

Owner:FUJIAN WUYI TOBACCO +1

Automated tedding-screening machine for tea manufacturing and processing

ActiveCN108311387APlay a role in concentrating lightSpeed up the tetheringSievingGas current separationScreening effectEngineering

The invention relates to an automated tedding-screening machine for tea manufacturing and processing. The automated tedding-screening machine comprises a baseplate, wherein four universal wheels are symmetrically mounted on the lower end surface of the baseplate; through the universal wheels, the automated tedding-screening machine can be moved to a processing position; a light-concentrating tedding device is mounted on the left side of the upper end surface of the baseplate; through the light-concentrating tedding device, the light-concentrating quick tea tedding function can be achieved; thetedding time is greatly shortened, the tedding speed is high, and the tedding effect is good; a multi-stage screening device is mounted on the right side of the upper end surface of the baseplate; through the multi-stage screening device, the multi-stage automatic tea screening function can be achieved; the screening time is short, the screening speed is high, and the screening effect is good; the light-concentrating tedding device comprises a tedding support plate mounted on the left side of the upper end surface of the baseplate; a mounting cylinder is welded with the middle of the upper end surface of the tedding support plate; and a ring-shaped limiting slot is mounted on the upper end surface of the tedding support plate. By adoption of the automated tedding-screening machine provided by the invention, the tea tedding-screening integrated automatic processing function can be achieved; no manual operation is needed, the operation is simple and convenient; and the degree of automation is high.

Owner:湖南瑶园生态农业科技发展有限公司

Intelligent grinding device for adjustable rail surface

InactiveCN108015643AExpand the grinding rangeImprove grinding effectGrinding carriagesGrinding machinesEngineeringAutomation

The invention relates to an intelligent grinding device for an adjustable rail surface. The intelligent grinding device comprises a grinding support plate, and the right and left sides of the lower end of the grinding support plate are symmetrically provided with two moving mechanisms of which the inner sides are provided with two grinding branched chains separately; the two grinding branched chains are connected by welding, and the position between the two grinding branched chains is used for arranging a rail required for grinding; the upper ends of the two grinding branched chains are weldedwith two movable sliding columns separately, and the upper ends of the two movable sliding columns are provided with two movable sliding chutes in a sliding fit manner; the upper ends of the two movable sliding chutes are welded with the lower end faces of the grinding support plates separately; under the auxiliary limit of the two movable sliding columns and the two movable sliding chutes, the two grinding branched chains are driven by the two moving mechanisms to move back and forth for stable grinding; each moving mechanism comprises two grinding lugs welded with the lower end of the grinding support plate symmetrically. According to the intelligent grinding device provided by the invention, the full-automatic grinding function of the rail can be achieved, and manual operation is not required; and the degree of automation is high.

Owner:陈金辉

Polishing and washing machine special for high-speed railway track

InactiveCN108000284AAdjust the high pressure cleaning angleHigh pressure cleaning effect is goodGrinding machinesCleaning using liquidsHydraulic cylinderHigh pressure water

The invention relates to a polishing and washing machine special for a high-speed railway track. The polishing and washing machine special for the high-speed railway track comprises a variable high-pressure washing device. The high-pressure washing direction of the variable high-pressure washing device can be adjusted, so that the polishing and washing machine is not affected in the polishing process; after polishing is completed, the high-pressure washing direction is adjusted so that the variable high-pressure washing device can work, residual polishing scrap iron and non-cleaned dust attached to the track are rapidly washed away through the high-pressure water jet working principle, and the high-pressure washing effect is good; the lower end of the variable high-pressure washing deviceis symmetrically provided with four fourth hydraulic cylinders, and the top ends of the four fourth hydraulic cylinders are provided with adjustable polishing devices; by means of the four fourth hydraulic cylinders, the polishing height of the polishing and washing machine can be adjusted; the variable high-pressure washing device comprises a washing support plate, the two sides of the lower endface of the washing support plate are symmetrically provided with two washing adjusting branch chains and two high-pressure washing branch chains, and the two washing adjusting branch chains are connected with the two high-pressure washing branch chains correspondingly. By means of the polishing and washing machine, the full-automatic polishing and washing functions of the track can be achieved, manual operation is not needed, and the automation degree is high.

Owner:陈金辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com