Rapid automatic phase-change material thermal cycle experiment instrument

A technology of phase change materials and experimental instruments, applied in the investigation phase/state change and other directions, can solve the problems of long experimental time, poor repeatability, slow cycle speed, etc., achieve a high degree of automation, improve experimental efficiency, and maintain a constant temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

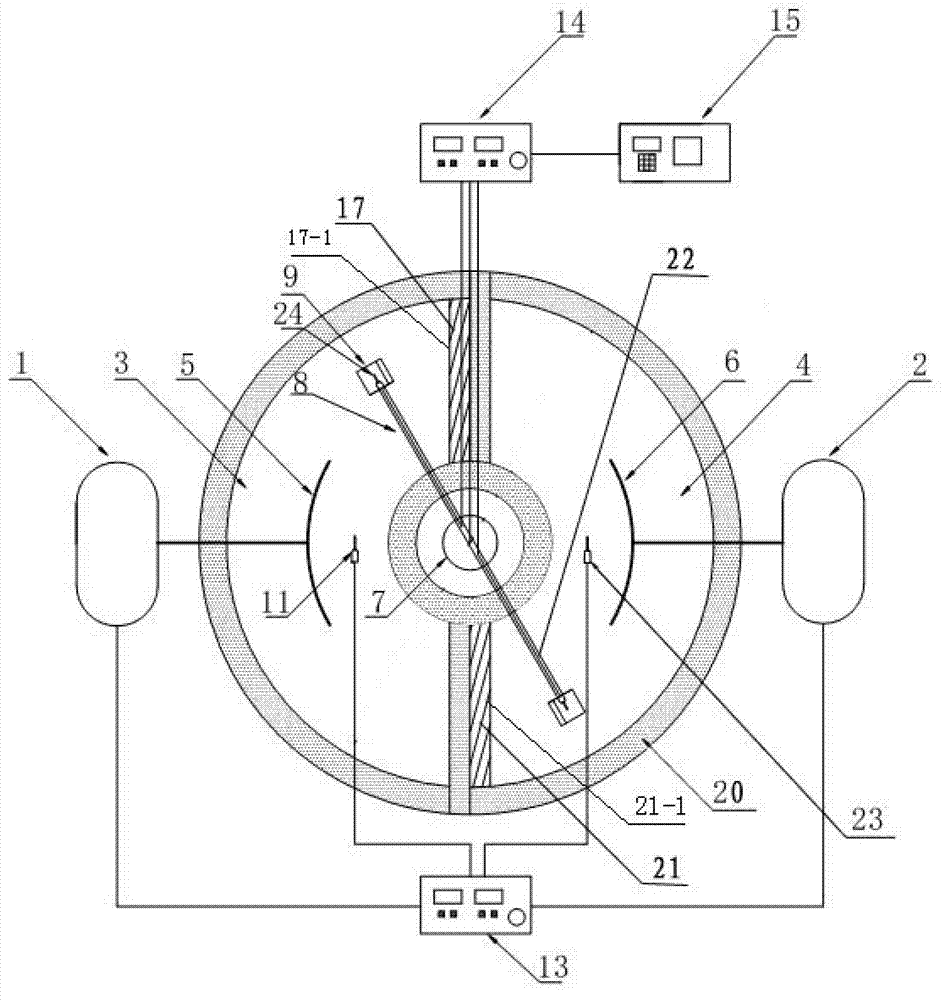

[0056] Thermal Durability Experiment of Expanded Graphite / Montmorillonite / Paraffin Intercalation Composite Phase Change Material

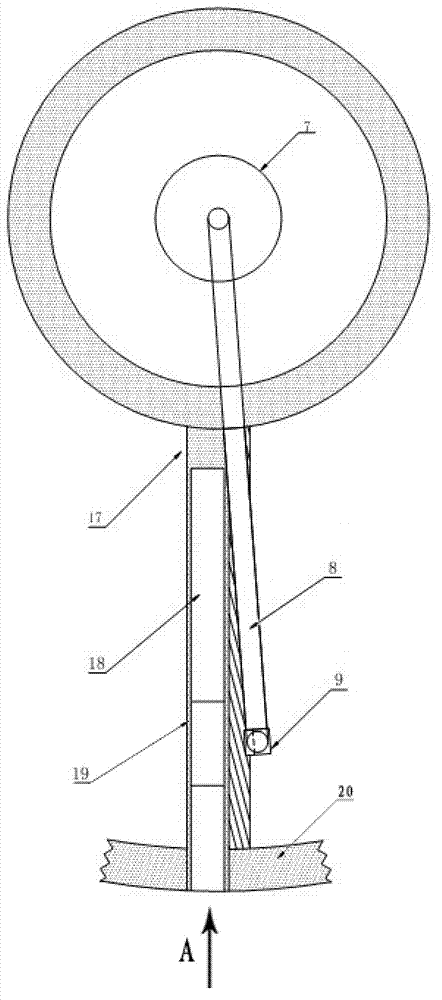

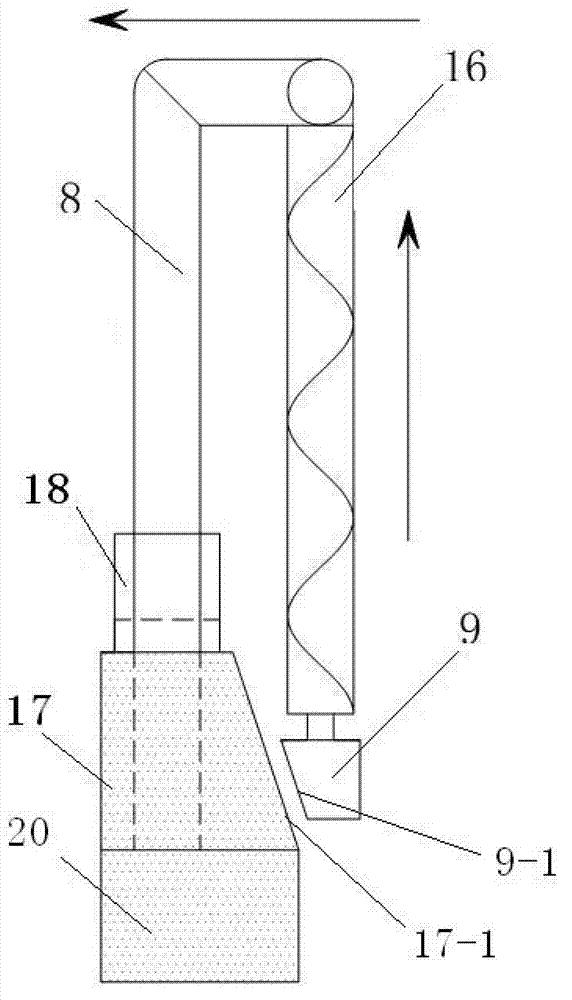

[0057] The phase change range of the material measured by the differential calorimetry scanner is 27-29 degrees Celsius, the latent heat value is 160kJ / kg, and the thermal conductivity measured by the thermal constant analyzer is 1.6W / mk. Set the hot liquid tank temperature at 50 degrees Celsius on the temperature controller, and the cold liquid tank temperature at 5 degrees Celsius; set the transmission temperature of the hot liquid tank 4 at 40 degrees Celsius on the transmission controller 14, and the transmission temperature of the cold liquid tank 3 at 10 degrees Celsius, and output in the record The device 15 sets the number of phase transitions to 500 times. Take 20g of sample, put 10g in each sample chamber, put the first sample chamber 9 and the second sample chamber into respective sampling drawers 18 respectively, and place them on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com