Pre-stressed steel strand packaging method and device

A technology of prestressed steel strands and steel strands, which is applied in the direction of rotation and wrapping of articles, etc., can solve the problems of automatic precise positioning and low degree of automation, uneven overlap and tightness of packaging tapes, and unsatisfactory packaging quality. , to achieve good operation effect, uniform overlap and tightness, improve service life and degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing:

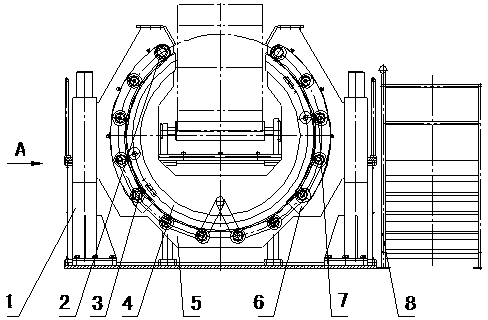

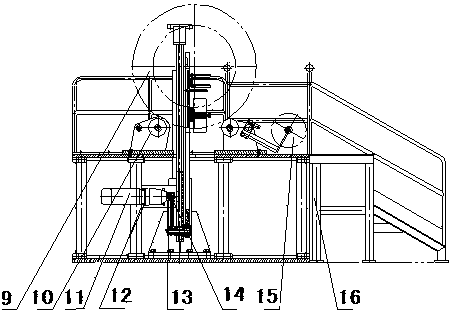

[0011] figure 1 Among them, the prestressed steel strand packaging device of the present invention consists of a frame 1, a passive pulley 2, a driving pulley 3, a packaging ring 4, a track seat 5, a shield 6, an adjustable pulley 7, stairs 8, and idlers 10 , motor reducer 11, reducer base 12, synchronous belt group 13, synchronous pulley 14, packing belt seat 15, operation control box 16; track seat 5, packing belt seat 15, motor reducer 11, reducer base 12 , operation control box 16, stairs 8 and guard cover 6 are fixed on the frame 1, and packing ring 4 is an open ring, is installed on the passive pulley 2 of track seat 5, driving pulley 3 and adjustable pulley 7, driving pulley The synchronous pulley 14 on the 3 links to each other with synchronous belt and forms synchronous belt group 13, and idler roller 10 is housed on the packing belt seat 15, is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com