Device and method for automatically detecting redried tobacco strip identification and box core temperature based on visual identification

A visual recognition and automatic detection technology, applied in the field of tobacco, can solve the problems of long temperature measurement time, large number of off-line cigarette boxes, and low detection efficiency, and achieve the effects of fast response, improved accuracy, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

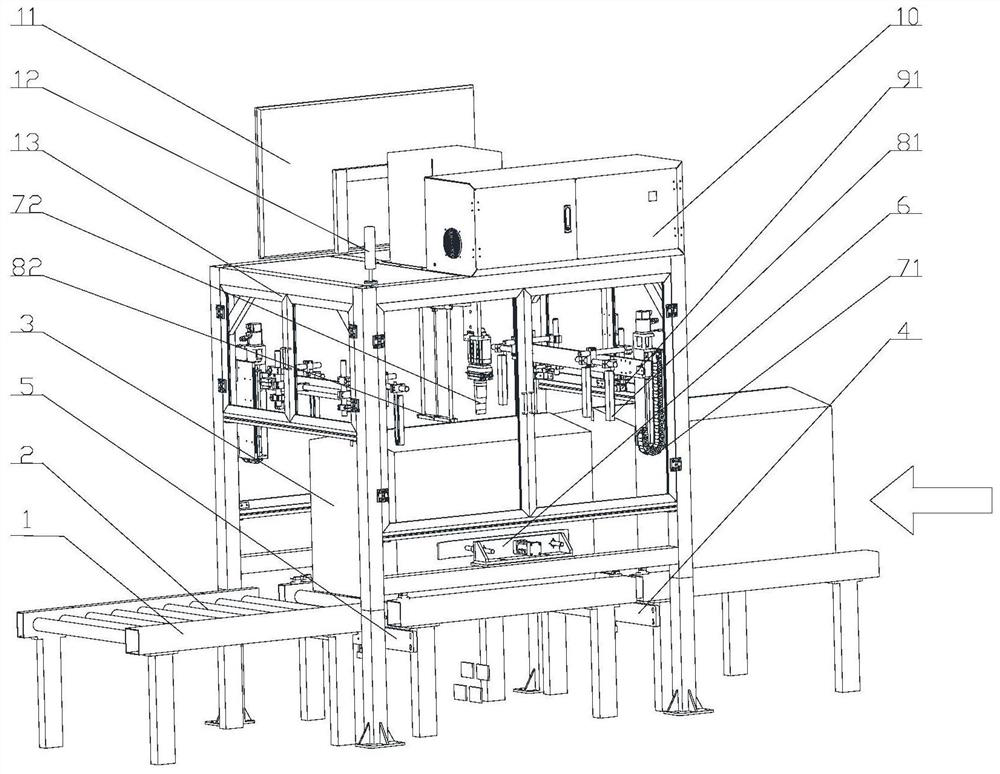

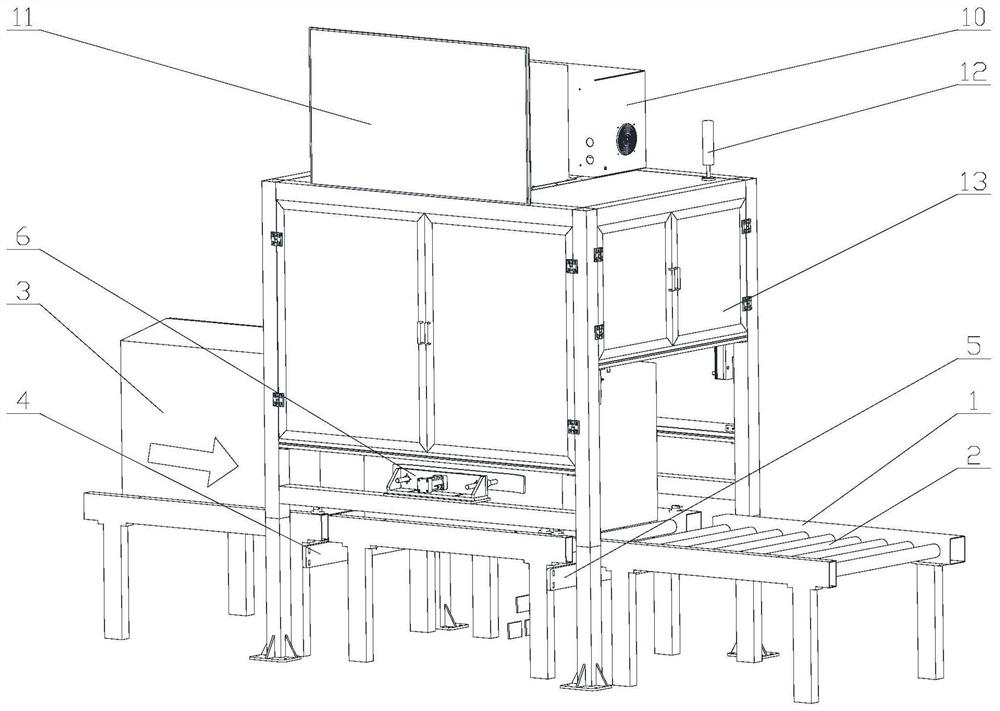

[0031] Such as Figure 1 to Figure 5 As shown in one of them, the present invention discloses a device based on visual recognition of the identification of rebaked tobacco and automatic detection of box core temperature. The method is successively equipped with identification and temperature measurement stations,

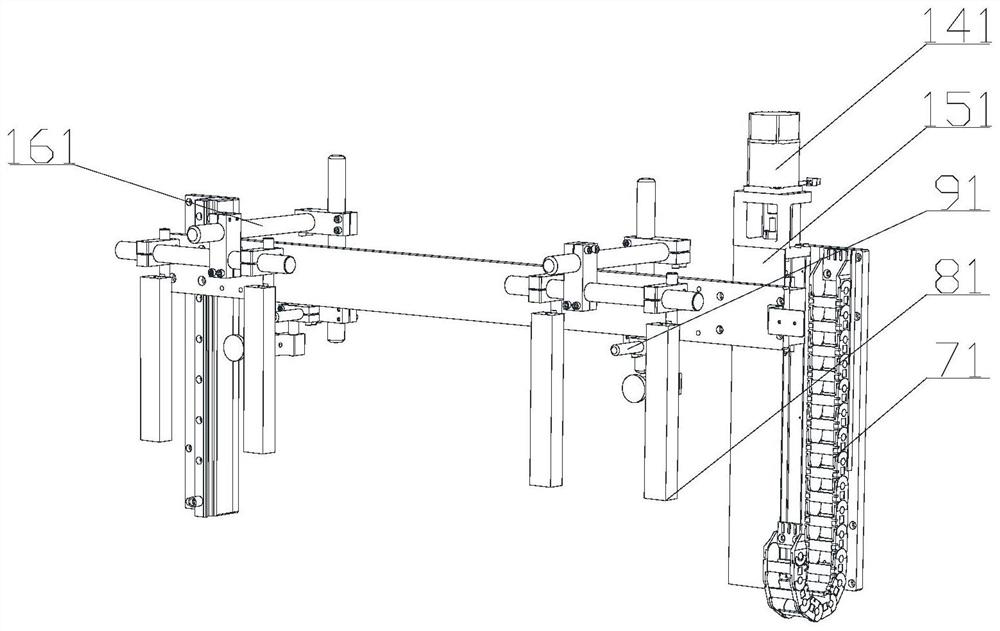

[0032] The identification assembly is installed above the identification station of the detection bracket corresponding to the conveying roller table 2. The identification assembly includes a servo motor 141, a light source 81, and an industrial camera 91; The free end is equipped with an industrial camera fixing bracket 161, and the industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com