Multifunctional pipeline welding and assembling device

A multi-functional and pipeline technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high work intensity and low efficiency of workers, and meet the requirements of reducing the technical level of riveters, with multiple application functions and operating speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

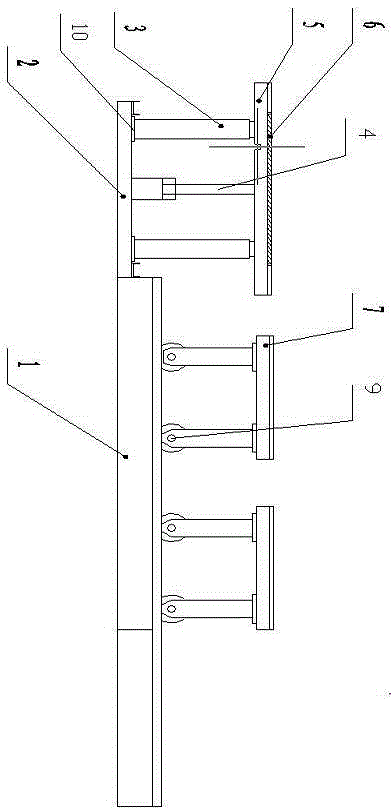

[0020] In order to overcome the problems of low efficiency and high work intensity of workers in the existing pairing devices, the present invention provides such as figure 1 , figure 2 The multi-functional pipeline welding assembly device shown in the figure reduces the requirements for the technical level of the pipe worker, and at the same time achieves the purpose of reducing the labor intensity of workers, improving the efficiency of assembly, and ensuring the quality of pipe assembly.

[0021] Including base I1, one end of base I1 is connected with base II2, four columns 3 are arranged symmetrically around the base II2; The lower end of the pipe is welded with a backing plate 10, the round bar of the column 3 is connected with a lifting platform 5, and the lifting platform 5 is provided with a rotating disc 6;

[0022] A hydraulic lifting column 4 is also arranged in the middle of the base II2, and the ejector rod of the hydraulic lifting column 4 is connected with the...

Embodiment 2

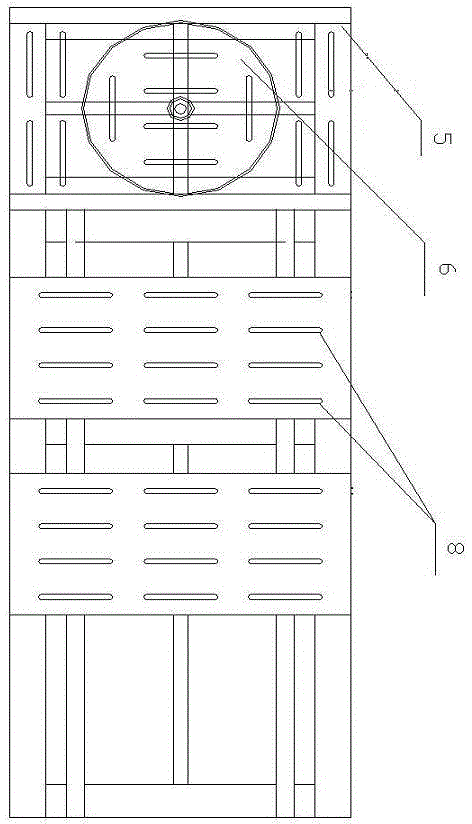

[0032] Based on Embodiment 1, a plurality of movable platforms 7 are arranged on the base I1 in this embodiment, and the movable platforms 7 slide on the base I1.

[0033] The movable platform 7 is composed of a steel platform, a sliding platform leg, and a sliding wheel 9. There are two cast iron platforms, and the platforms are provided with horizontal and vertical strip locking holes 8, and four sliding platforms are respectively arranged under each platform. Support leg and four sliding wheels 9, the upper end of the sliding platform supporting leg is welded to the lower plane of the platform, and the lower end of the sliding platform supporting leg is connected with the sliding wheel 9 with bolts. At the same time, the sliding wheel 9 is provided with a locking device so that its stability can be enhanced sex.

[0034] A plurality of locking holes 8 are arranged in an array on the platform of the movable platform 7 .

[0035] Both the lifting platform 5 and the movable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com