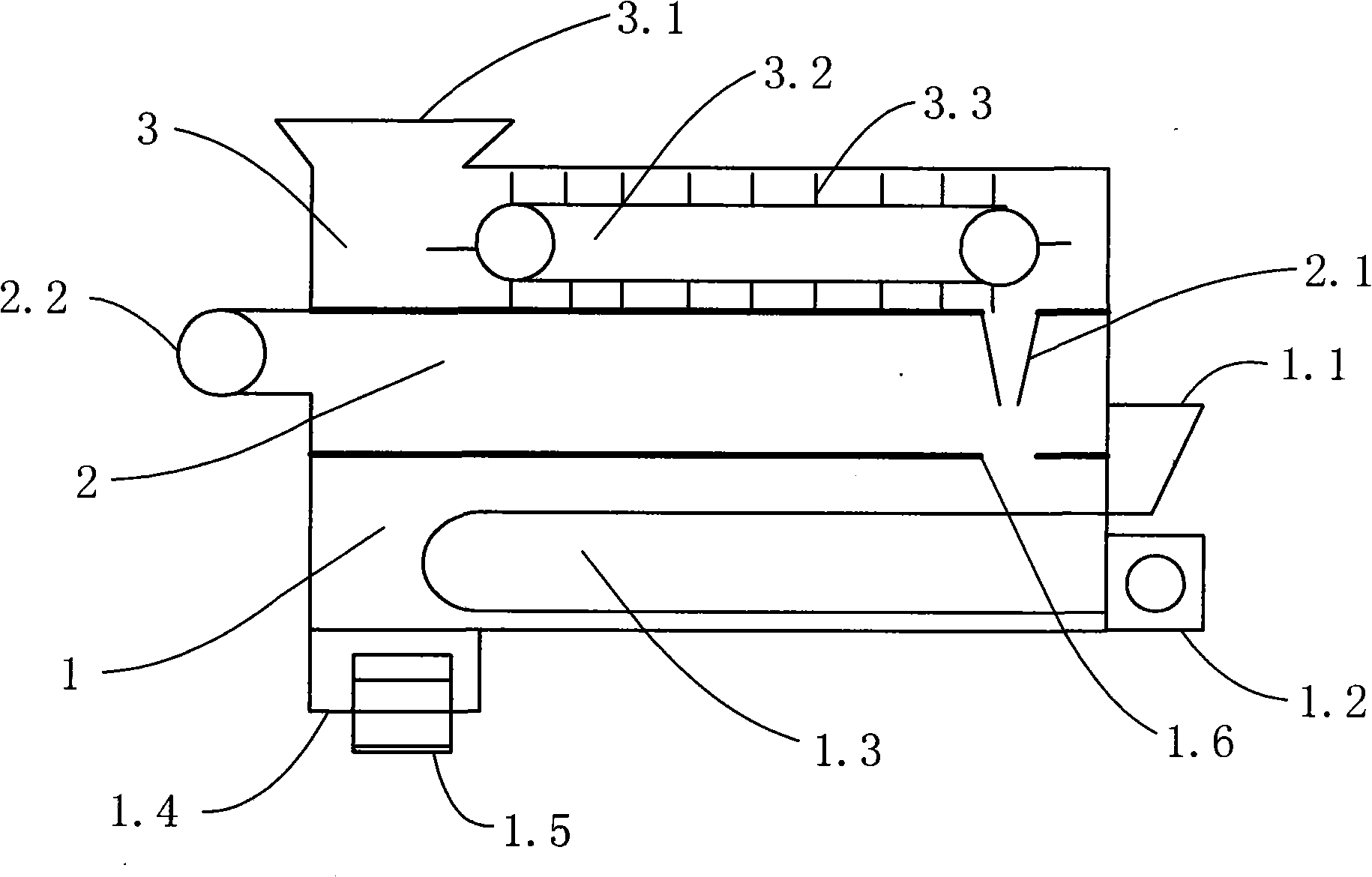

Device for baking lightweight aggregate for building materials by domestic garbage in cities and towns

A technology for urban domestic waste and light aggregates, which is applied in the field of devices for burning urban domestic wastes to light aggregates for building materials, and achieves the effects of high speed, continuous sintering and short stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The grate adopts a chain grate, and the driving machine adopts the structure form of a double-speed reducer matched with electrodes. The driving machine drives the grate to move from front to back and adds coal to the grate from the coal hopper. The discharge machine adopts the scraper form.

[0031] The temperature of the combustion layer of the light aggregate sintering furnace is controlled at 1000-1200°C, the temperature of the flue gas decomposition furnace is controlled at 800-1000°C, and the temperature of the drying furnace is controlled at 200-300°C.

[0032] The working process of the device of the present invention

[0033] Put the coal into the coal hopper, after granulating the mixed material of garbage material, coal and flux, add it into the material hopper manually or by a feeding machine, and the scraper machine runs to push the material particles from the back to the front, and at the same time Receive the heat from the top of the calciner to dry the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com