Steel ingot slow cooling hood with controllable cooling speed

A cooling speed and slow cooling technology, applied in the field of steel ingots, can solve the problems of non-adjustable slow cooling speed, unsatisfactory slow cooling effect, simple slow cooling cover structure, etc., achieve good slow cooling and heat preservation effect, real-time controllable cooling process, The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

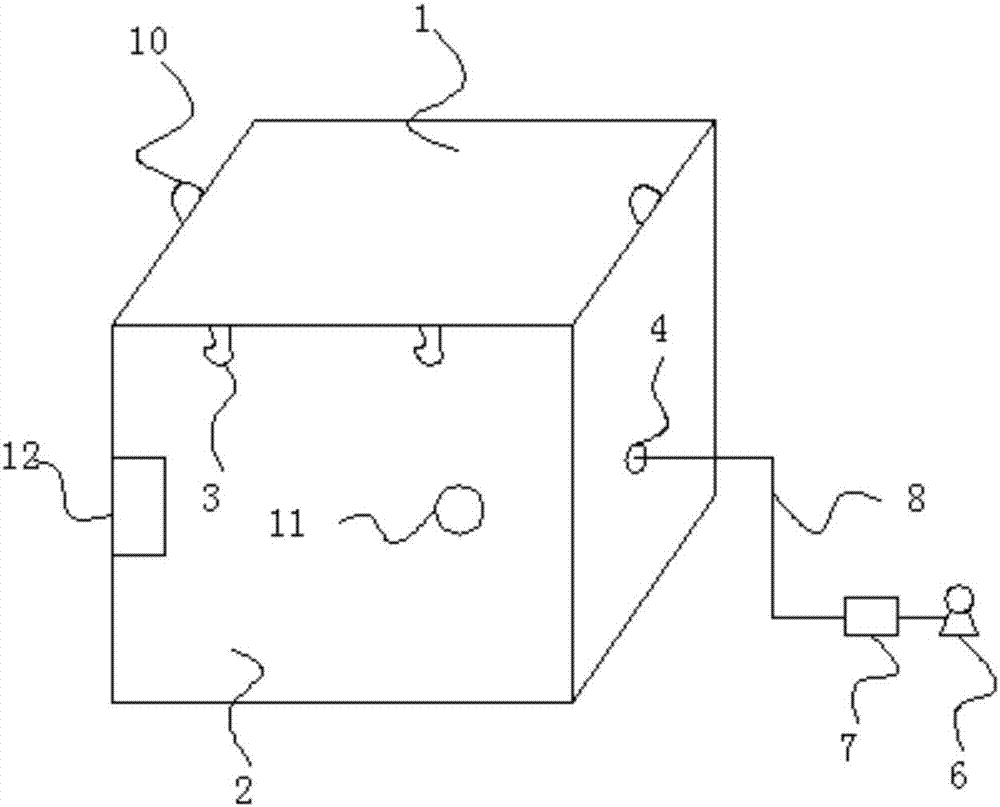

[0025] Embodiment: a steel ingot slow cooling cover with controllable cooling rate, such as figure 1 and figure 2 As shown, the slow cooling cover includes a box body, the box body includes a loam cake 1 and a side wall 2, the rear end of the loam cake is hinged to the upper end of the side wall, and the front end of the loam cake is provided with a door Locking buckle 3, the upper cover can be opened or closed through the locking buckle of the door;

[0026] Both the side wall and the upper cover of the box body include an outer layer, an inner layer and an intermediate layer between the outer layer and the inner layer, the intermediate layer is a thermal insulation layer; the outer layer is an iron sheet, so The inner layer is a support layer; the heat insulation layer has a thickness of 15-20cm;

[0027] The side wall is provided with at least one ventilation hole 4;

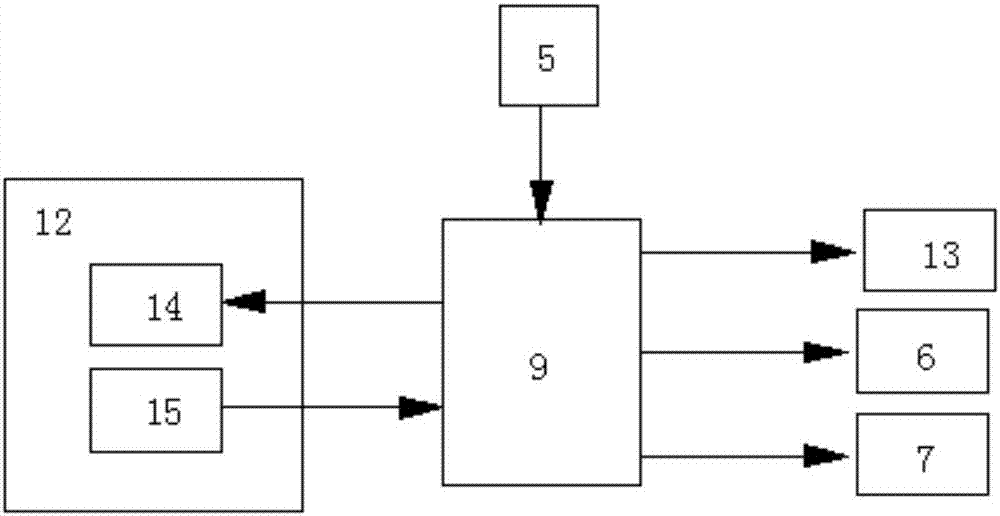

[0028] Also comprise temperature sensor 5, air compressor 6, heater 7, gas pipe 8 and PLC controller 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com