Vehicle bearing failure testing instrument and failure testing method

A technology for detectors and bearings, applied in the field of vehicle bearing fault detectors and fault detection, can solve problems such as damaged steering bridges, unusable, economic losses, etc., to achieve the effect of improving accuracy and avoiding uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Vehicle bearing fault detector

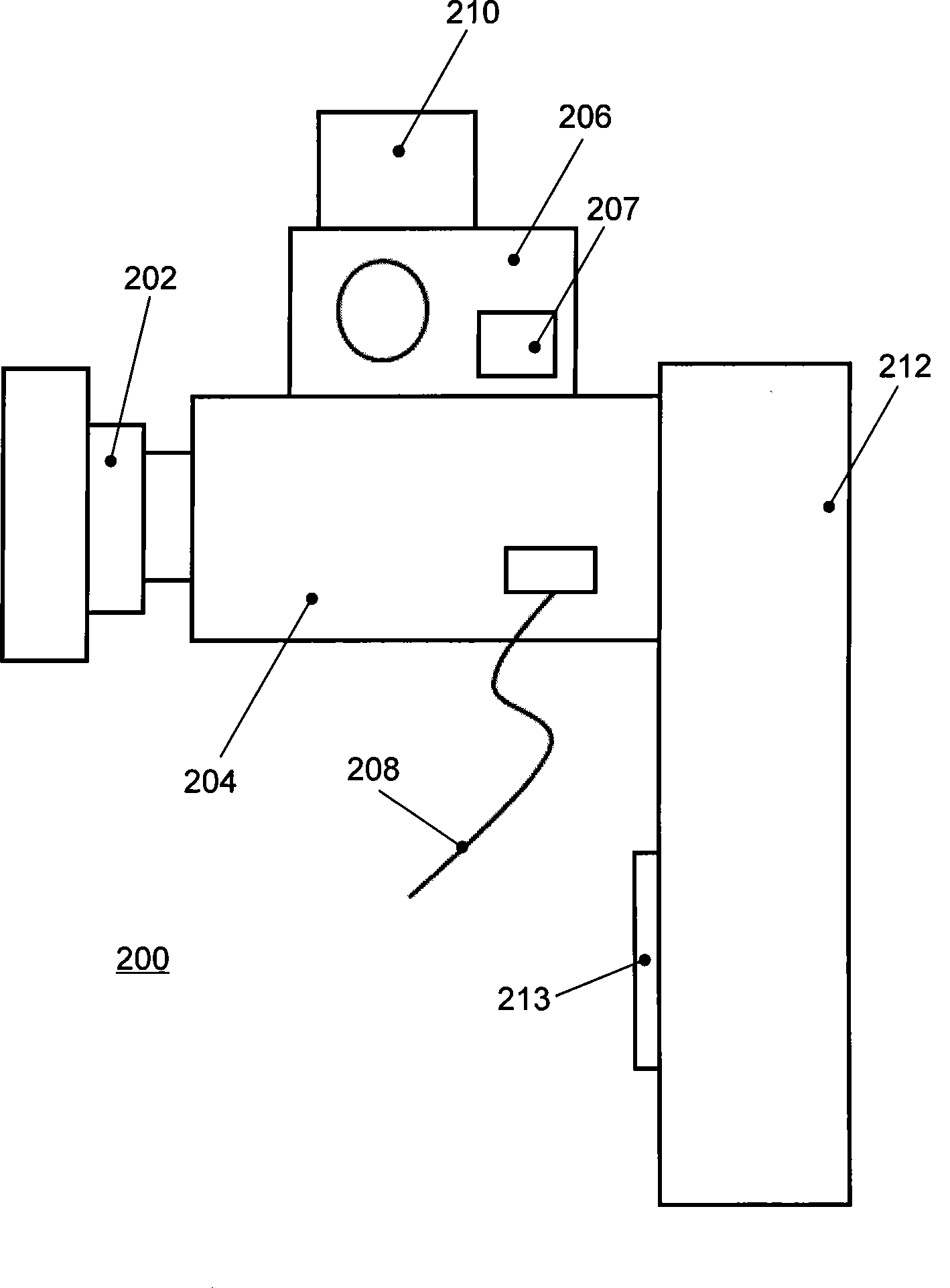

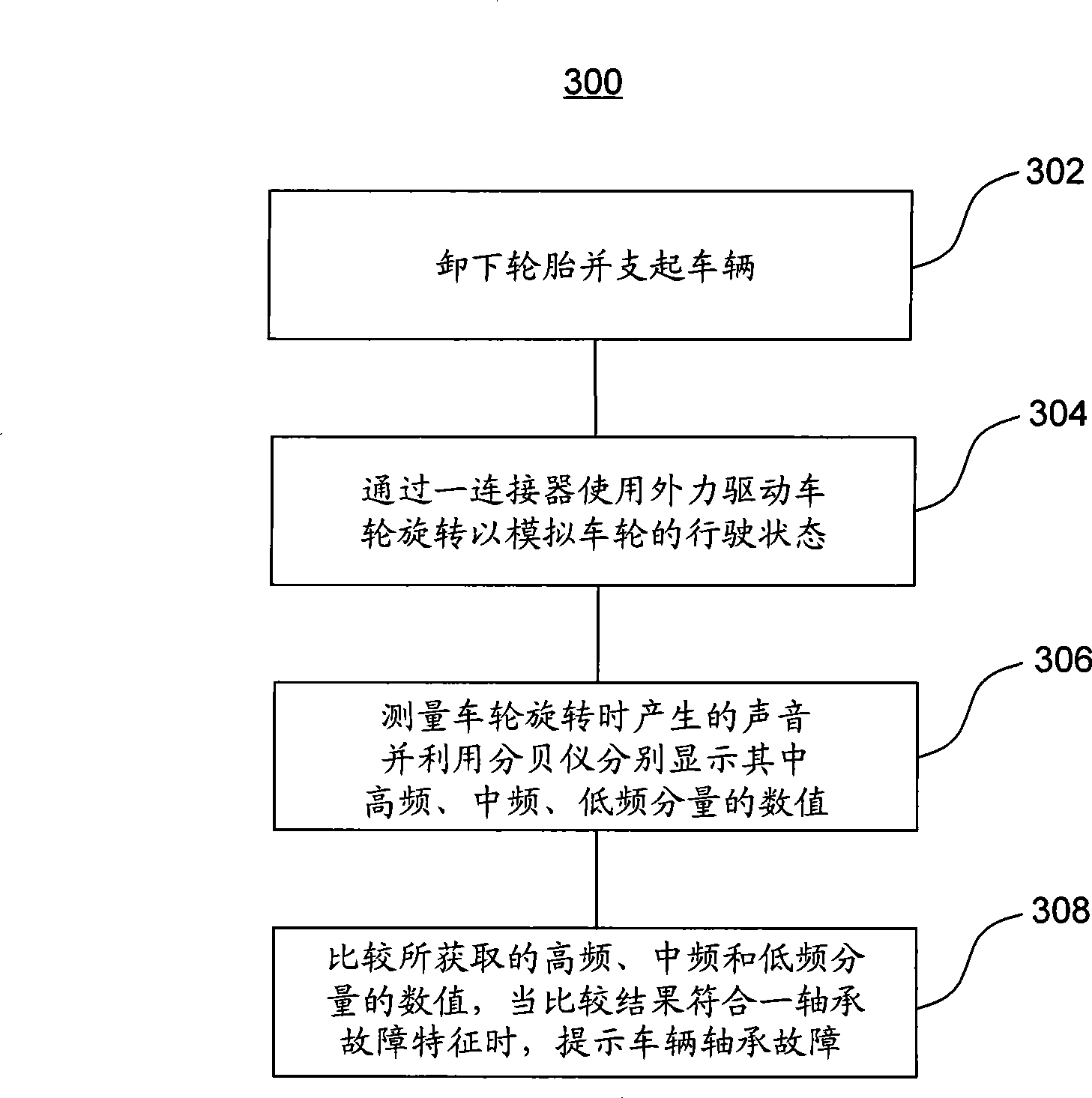

[0028] The first aspect of the present invention provides a vehicle bearing fault detector, refer to figure 2 , shows a structural diagram of a vehicle bearing fault detector 200 according to an embodiment, including:

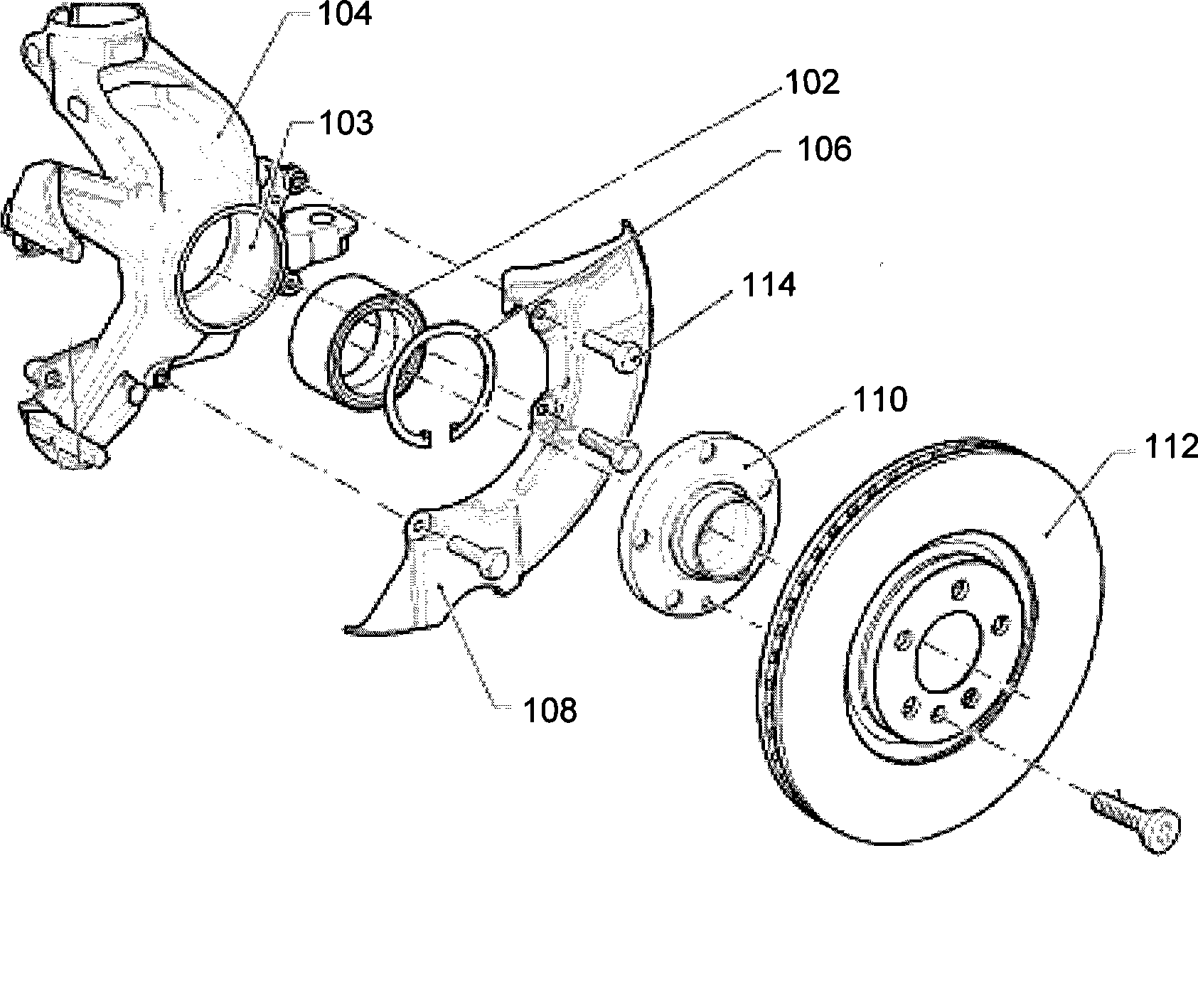

[0029] The connector 202, the connector has a fixing part matched with the axle hole of the wheel, and the connector is connected and fixed on the wheel. Generally, the number of wheel axle holes is 4-6. Correspondingly, the connector 202 of the present invention can also be configured to have 4-6 fixing parts, so as to cooperate with wheel axles with different numbers of wheel axle holes.

[0030] A driver 204, such as a motor. The driver 204 drives the connector 202 to drive the wheels to rotate, simulating the driving state of the wheels.

[0031] The decibel meter 206 measures the sound generated when the wheel rotates, and displays the values of the high frequency, middle frequency and low frequency component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com