Bearing fault detection algorithm combining genetic algorithm optimization parameters and machine vision

A technology of fault detection and machine vision, applied in the field of analysis and measurement control, to achieve the effect of clear weak features and accurate classification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to complete bearing fault detection, the following describes specific implementations of the present invention in conjunction with the accompanying drawings.

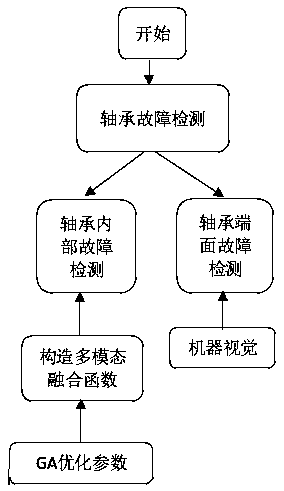

[0031] The invention is an algorithm for detecting faults inside and on the end face of a bearing combined with genetic algorithm optimization parameters and machine vision. figure 1 Check out the flowchart for its system.

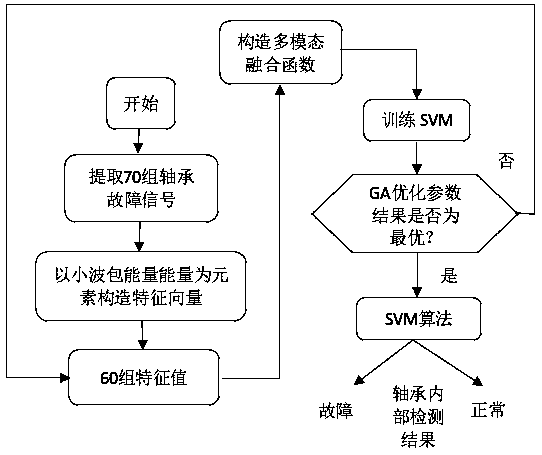

[0032] The algorithm system first detects the fault inside the bearing, the method is as follows:

[0033] Firstly, the energy of each sub-frequency band after the vibration signal wavelet packet decomposition is used as the fault detection feature, and the wavelet packet decomposition coefficient is obtained Among them, d is the number of wavelet packet decomposition layers, and k is the number of signal sub-bands. Reconstructing the wavelet packet decomposition coefficients, the total signal can be expressed as Therefore, the signal energy E of each sub-band is obtained, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com