Rolling bearing fault detection method based on DS adaptive spectrum reconstruction

A rolling bearing and fault detection technology, applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc., can solve problems such as low recognition accuracy and bearing failure mode judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0067] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

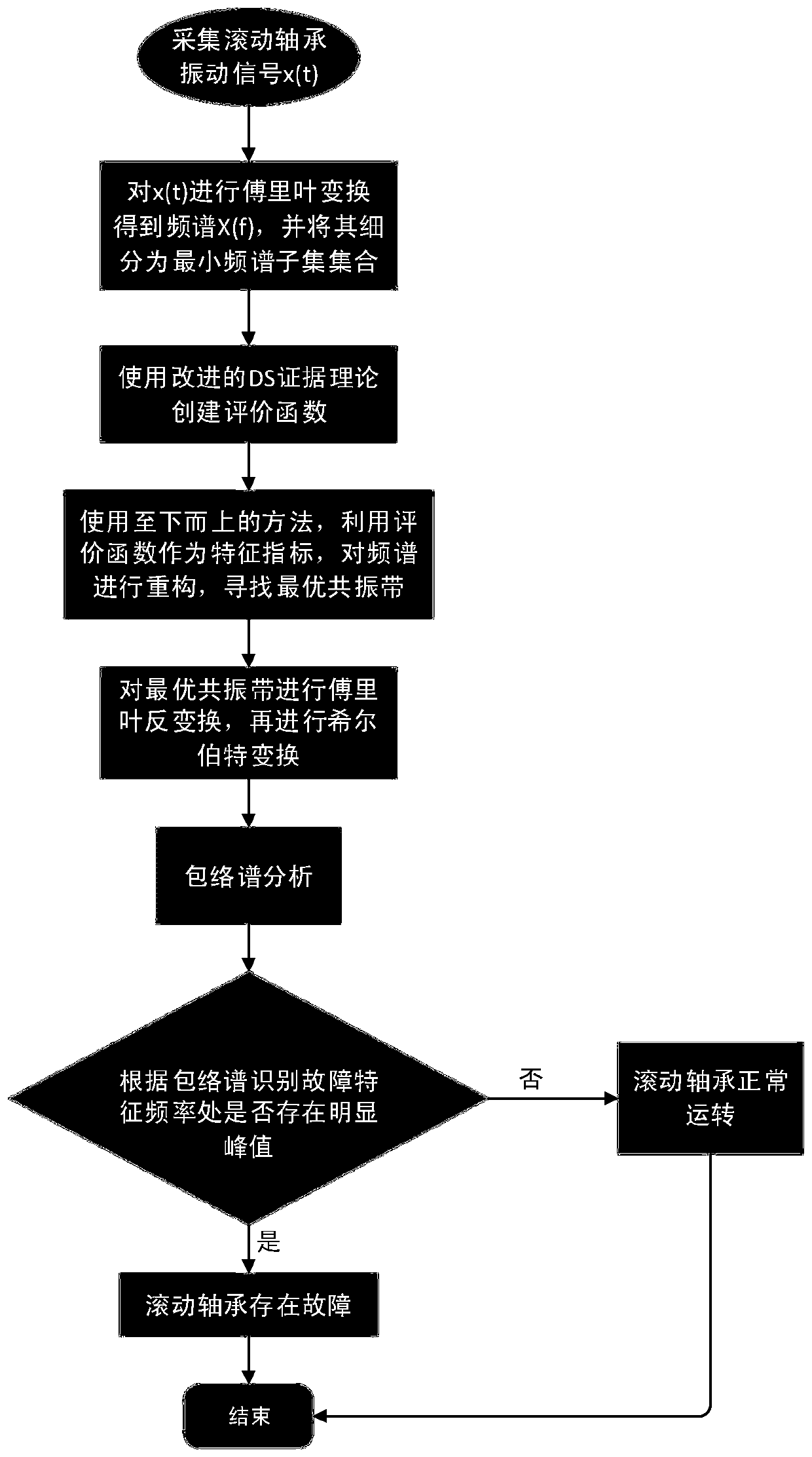

[0068] Such as figure 1 As shown, the purpose of the present invention is to provide a rolling bearing fault detection method based on DS adaptive spectrum reconstruction, and the specific extraction process of the feature vector includes:

[0069] Step 101: arranging the acceleration sensor to collect the fault vibration signal x(t) of the rolling bearing;

[0070] Step 102: Carry out Fourier transform to x(t), obtain its frequency band X(f), and cut X(f) into the minimum frequency band subset X(f)={X 1 ,X 2 ,...,X K ,...,X M}, K∈[1,M],

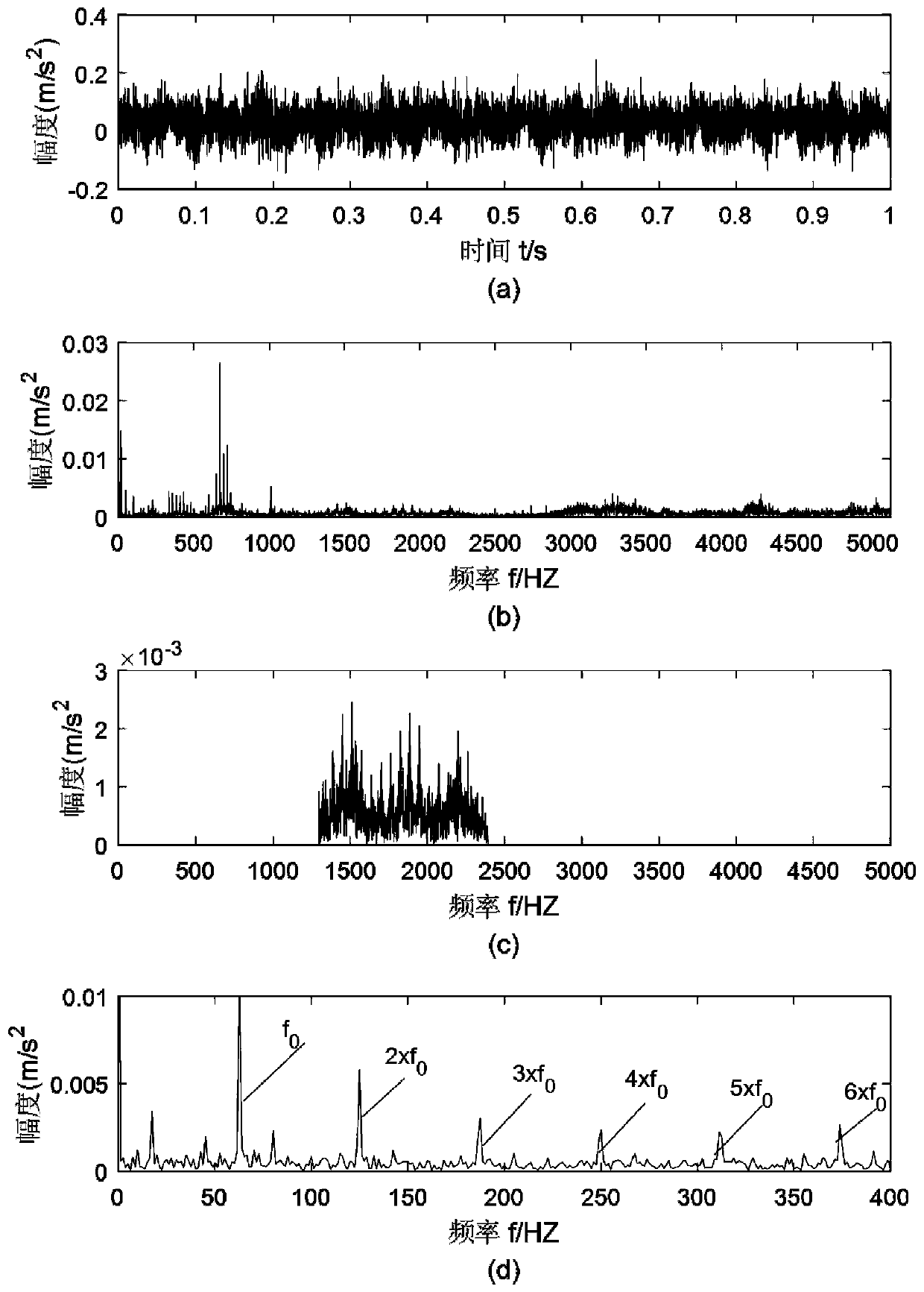

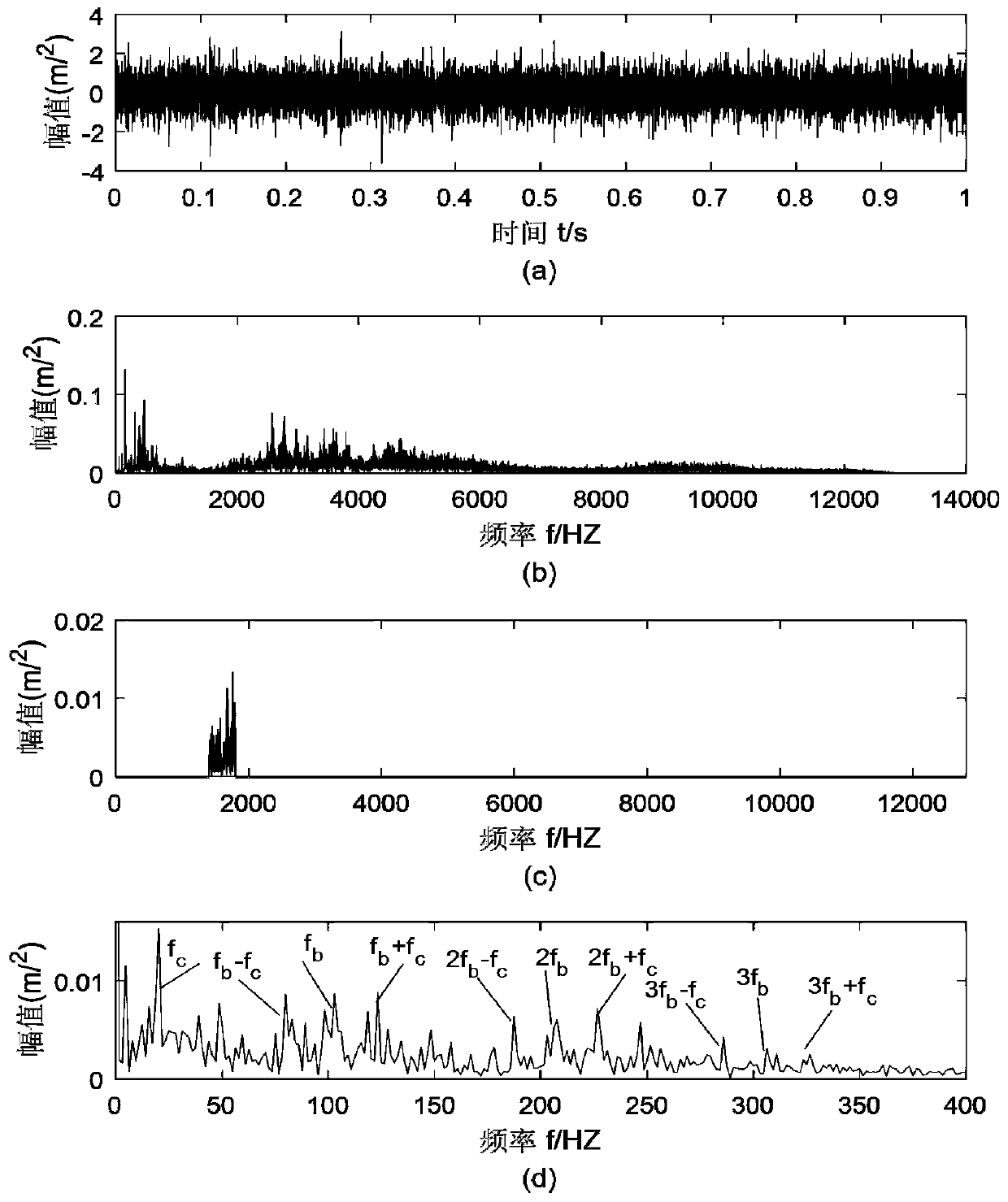

[0071] Extract six time-frequency domain indicators such as frequency band subset kurtosis, impulse factor, sparse factor, margin factor, kurtosis coefficient and Hilbert envel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com