Optical fiber on-line vehicle bearing fault detection device

A technology of fault detection and optical fiber, which is applied in the direction of optical testing for flaws/defects, can solve problems such as interference and low accuracy of real-time health monitoring of heavy-duty rails, and achieve the effect of improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

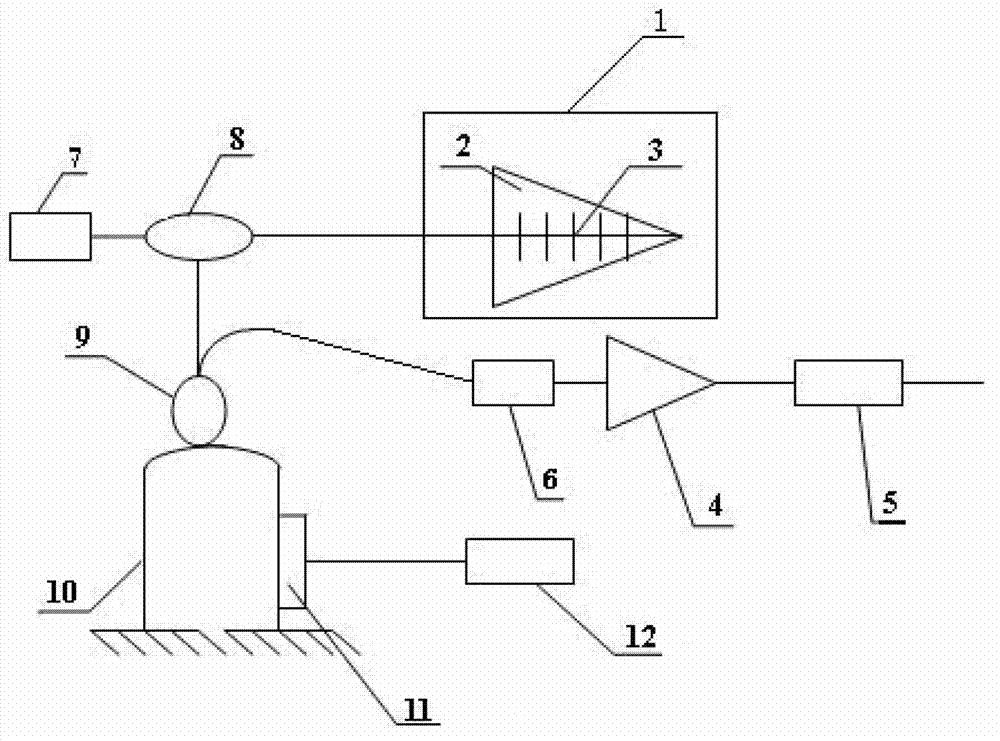

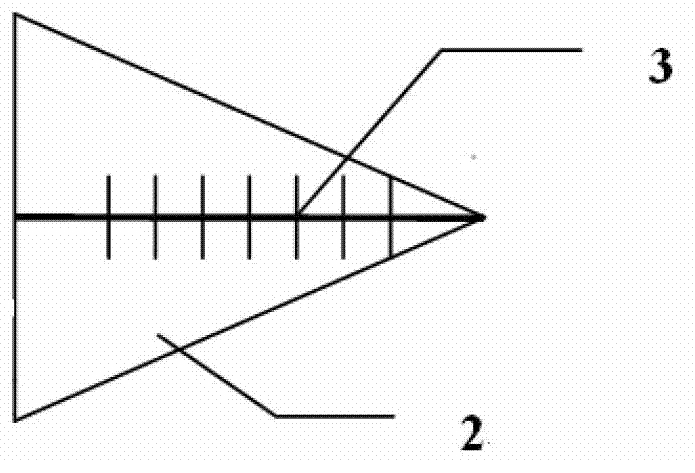

[0009] Specific embodiment one: combine figure 1 , figure 2 , image 3 with Figure 4 Describe this embodiment, the optical fiber online vehicle bearing fault detection device of this embodiment, it comprises sensor 1, A / D converter 4, signal processing system 5, photodetector 6, broadband light source 7, wavelength division multiplexer 8 , coupler 9, scanning interferometer 10 and signal generator 12, the output end of the sensing signal of sensor 1 is connected with the input end of the sensing signal of wavelength division multiplexer 8, the output end of broadband light source 7 is connected with wavelength division multiplexing The input end of the laser of the use device 8 is communicated, the output end of the wavelength division multiplexer 8 is communicated with a signal input end of the coupler 9, and the other signal input end of the coupler 9 is communicated with the signal output end of the scanning interferometer 10, The output end of the signal generator 12 ...

specific Embodiment approach 2

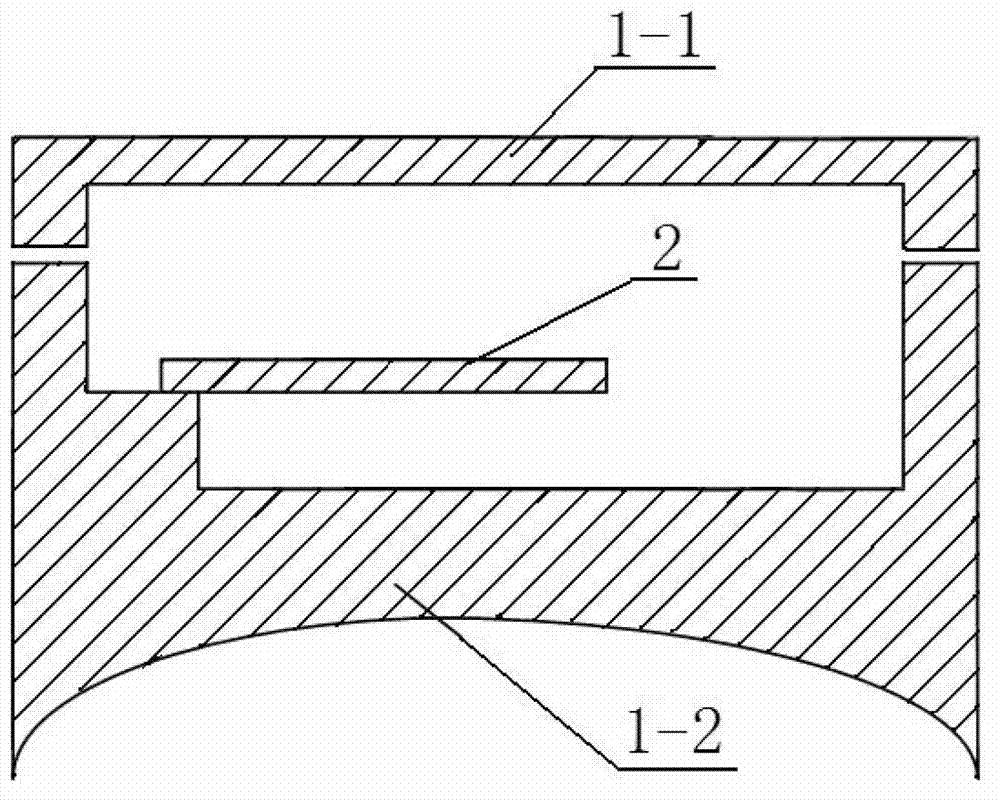

[0012] Specific embodiment two: combine figure 2 This embodiment is described. This embodiment is a further limitation of the optical fiber online vehicle bearing fault detection device described in Embodiment 1. The bottom surface of the base box 1-2 is an arc surface.

[0013] The bottom surface of the base box 1-2 corresponds to the arc of the outer surface of the axle box cover of the vehicle bearing, so that the sensor 1 is closely arranged on the axle box cover.

specific Embodiment approach 3

[0014] Specific embodiment three: combine figure 1 This embodiment is described. This embodiment is a further limitation of the optical fiber online vehicle bearing fault detection device described in Embodiment 1. It also includes a phase demodulator 11, which is connected in series with the signal generator 12 and the scanning In the optical path between interferometers 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com