Tool wear state detection method for industrial unbalanced data

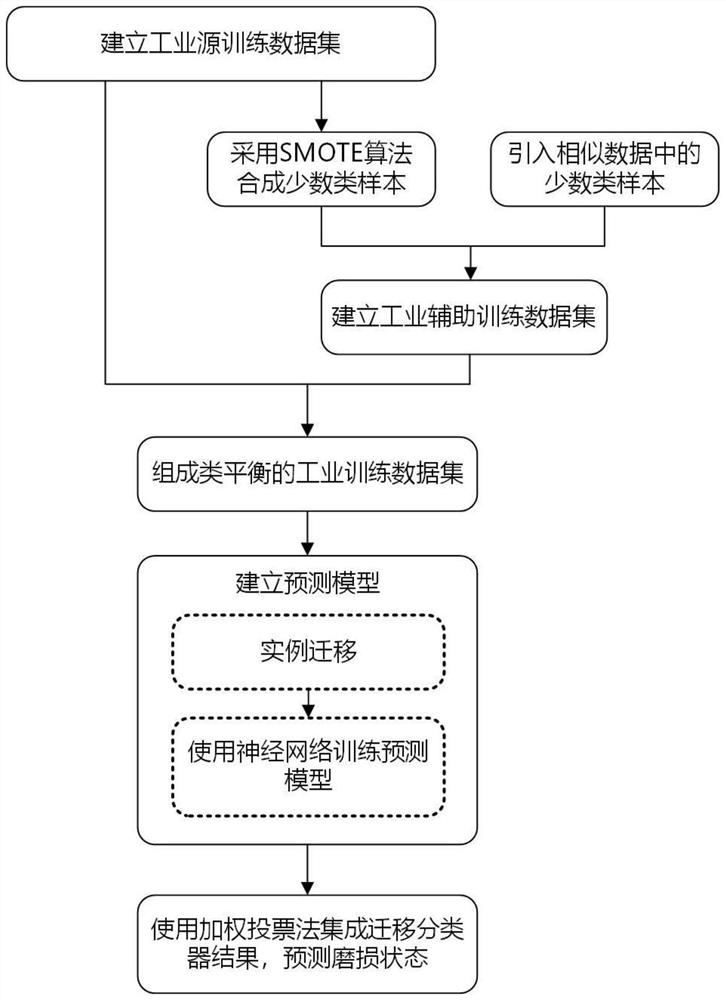

A tool wear and balance data technology, applied in the field of CNC machine tool state detection, can solve the problems of insufficient high-quality sensor data and uneven distribution, so as to improve the real-time detection effect, ensure the distribution consistency, and realize the effect of high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

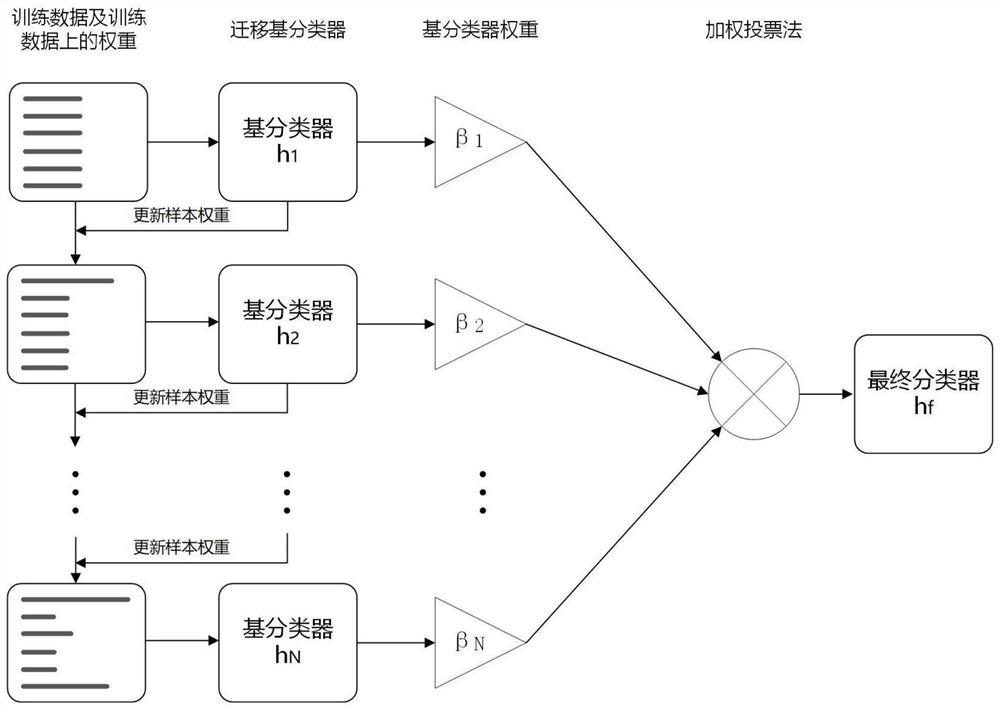

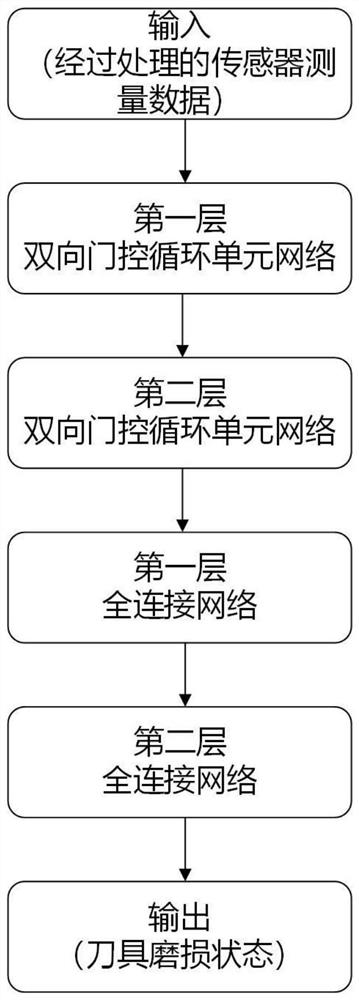

Method used

Image

Examples

specific Embodiment

[0060] This example uses the game data of the 2010 PHM (Fault Diagnosis and Health Management) Association Data Contest to verify the method for detecting the wear state of the CNC machine tools proposed by the present invention.

[0061] The processing parameters of the CNC machine tools are: the spindle speed is 10400rpm, the feed rate in the x-axis direction is 1555mm / min, the radial cutting depth is 0.125mm, and the axial cutting depth is 0.2mm. The sampling frequency of the measurement system is 50kHz. Each machining process consists of 315 milling operations. After each milling operation, the tool is stopped and the wear of the tool is measured using a LEICA MZ12 microscope. The data used in this example includes the data of 6 processing processes, and 6 sets of sensor measurement data are obtained, namely C1, C2, C3, C4, C5, and C6.

[0062] The experimental task of this example is to use the preprocessed tool sensor measurement data and the corresponding tool wear sta...

specific Embodiment approach

[0065] S1. Setting of training data and test data:

[0066] In order to meet the basic requirements of the tool wear state detection method proposed in the present invention, the competition data is divided into a test data set, a source training data set and an auxiliary training data set. The distribution of the source training data set and the test data set must be consistent, and the distribution of the auxiliary training data set and the test data set is similar but not consistent.

[0067] Based on this requirement, in the competition data, three data sets C1, C4, and C6 were selected as training and testing data for verifying the method proposed by the present invention. The specific method is as follows: randomly select one-third of the data in a data set as the test set; use the remaining two-thirds of the data in the data set as the source training set; use the minority class samples in the remaining two data sets as the auxiliary training set . In this way, since ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com