Patents

Literature

47 results about "Hilbert envelope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wind turbine generator bearing fault diagnosis method under variable speed

InactiveCN105784366AEliminate the effects of analysisImprove accuracyMachine bearings testingElectricityBearing vibration

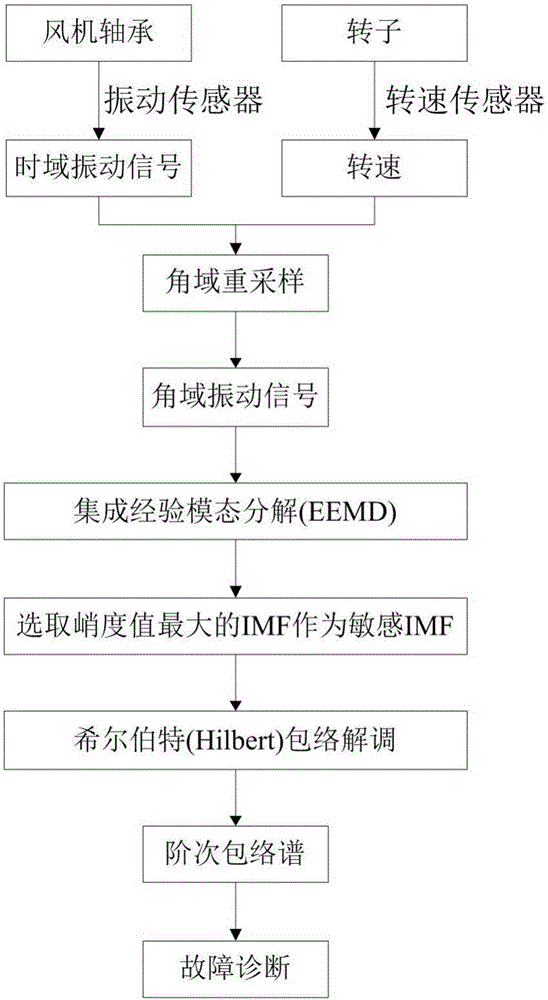

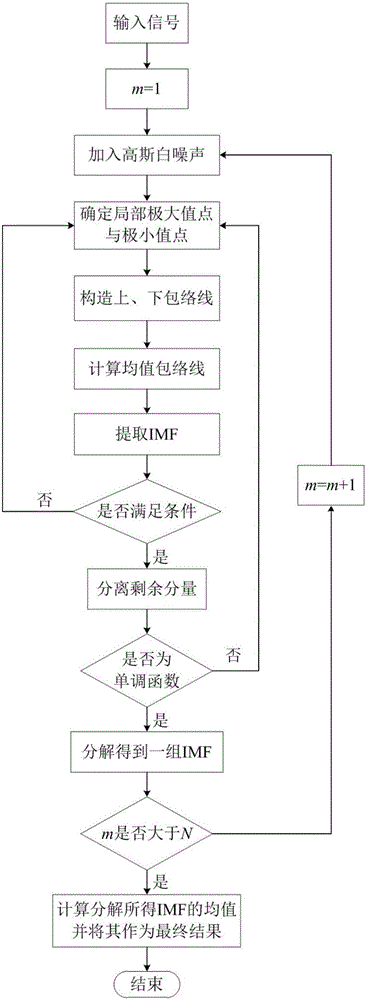

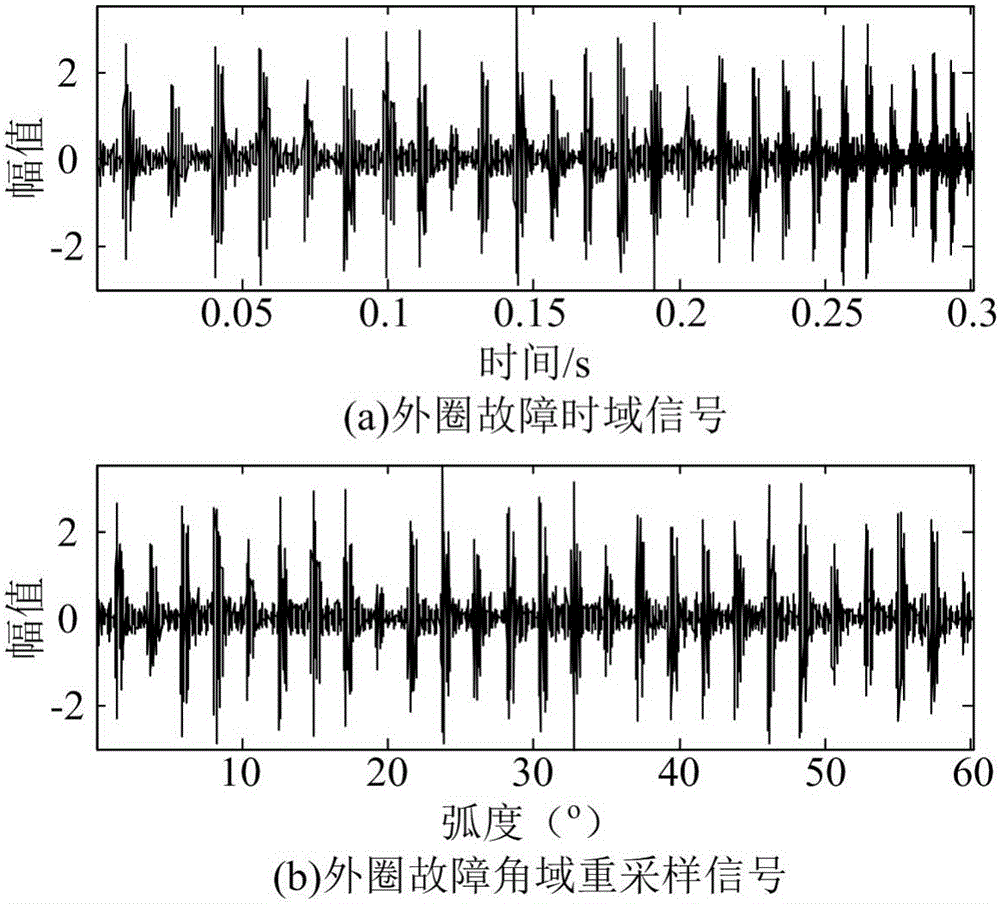

The invention discloses a wind turbine generator bearing fault diagnosis method under the variable speed. According to the method, a rotation angle change curve is drafted according to the bearing rotation speed; equal angle division for the rotation angle change curve is carried out, and an equal angle re-sampling time sequence is determined; interpolation for a bearing vibration signal is carried out according to the time sequence, a random Gauss white noise sequence is added to an angle domain vibration signal, and the signal added with the white noise is processed by utilizing an empirical mode decomposition (EMD) algorithm to acquire multiple sets of IMF; a kurtosis value of each IMF component is calculated; the IMF with the largest kurtosis value is selected and taken as a sensitive IMF; Hilbert envelope demodulation for the sensitive IMF is carried out to obtain an envelope signal, the envelope signal is processed by utilizing Fourier transform to obtain order envelope spectrum of the sensitive IMF, the fault characteristic frequency is extracted, and fault diagnosis on the wind turbine generator bearing is realized. The method is advantaged in that influence of rotation speed change on vibration signal analysis can be eliminated, and accuracy and validity of fault diagnosis can be improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

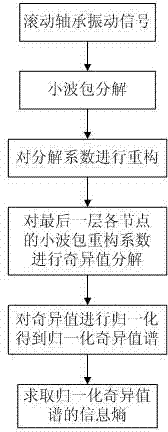

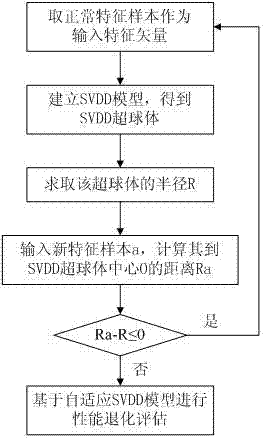

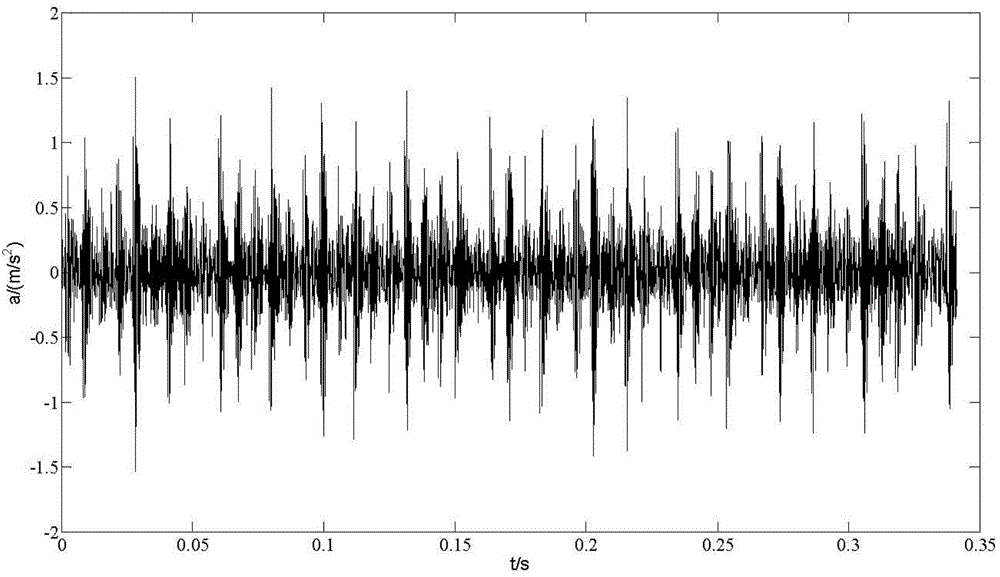

Rolling bearing performance degradation evaluation device and method

InactiveCN104729853AImprove accuracyEnsure correctnessMachine bearings testingVibration testingData acquisitionEngineering

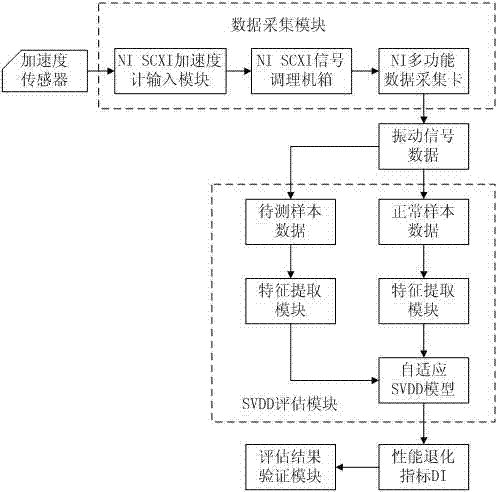

The invention provides a rolling bearing performance degradation evaluation device and method. The device comprises an acceleration sensor, a data acquisition module, a feature extraction module, an SVDD evaluation module and a verification module. According to the method, the acceleration sensor is made to be used for acquiring vibration signals of a bearing to be measured and converting the vibration signals to simulation signals; the data acquisition module is made to be used for conducting amplifying, smoothing and other processing on the simulation signals, converting the simulation signals into digital signals and then transmitting the digital signals to a computer; the feature extraction module is used for extracting wavelet packet singular spectrum entropies of the vibration signals to serve as input feature vectors so as to be used for the SVDD evaluation module; The SVDD evaluation module is used for establishing a self-adaption SVDD model and evaluates the performance degradation process of the rolling bearing through the self-adaption SVDD module to obtain a performance degradation index DI; the verification module verifies the correctness of the evaluation result through an Hilbert envelope demodulation method based on EMD. The rolling bearing performance degradation evaluation device and method are applied to performance degradation evaluation of the rolling bearing in the whole life cycle.

Owner:EAST CHINA JIAOTONG UNIVERSITY

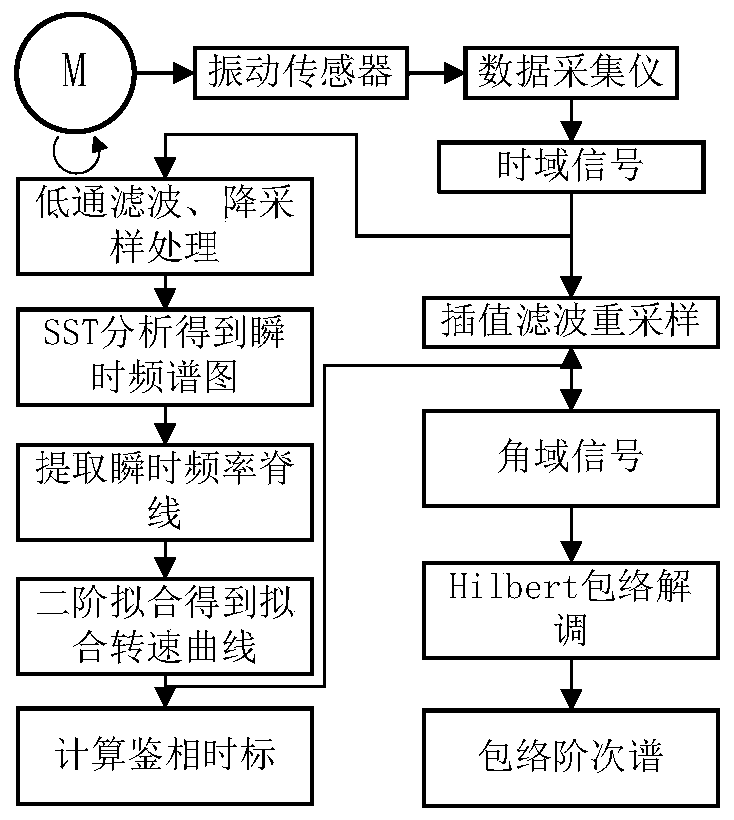

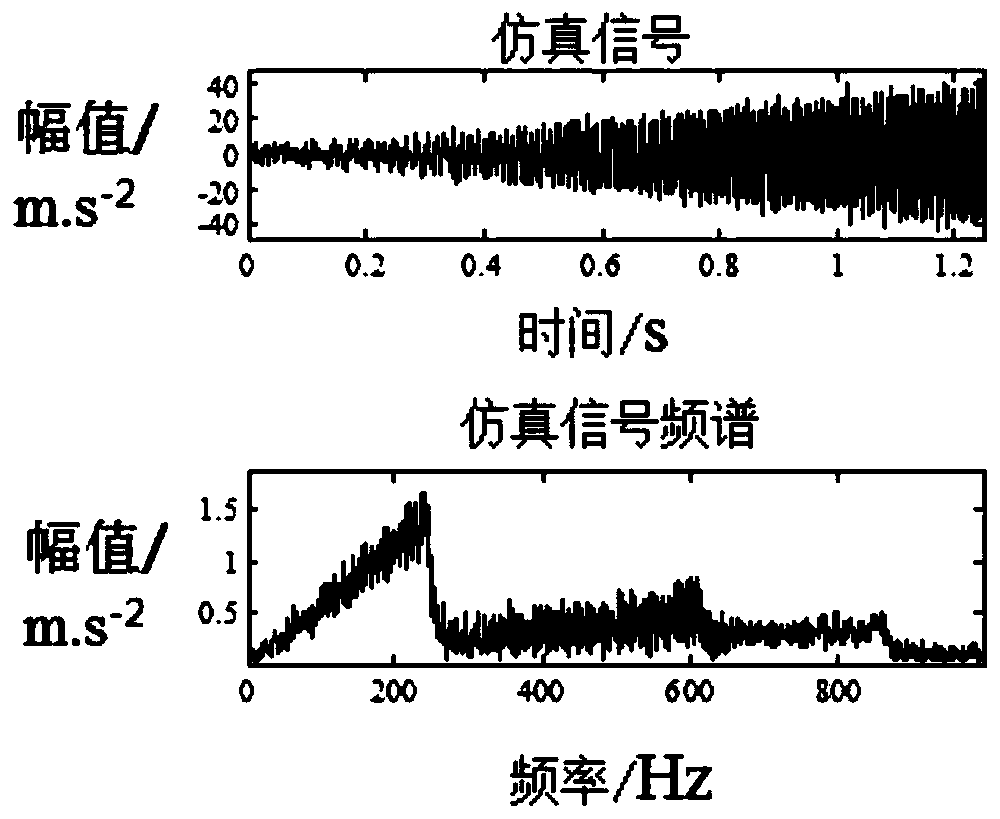

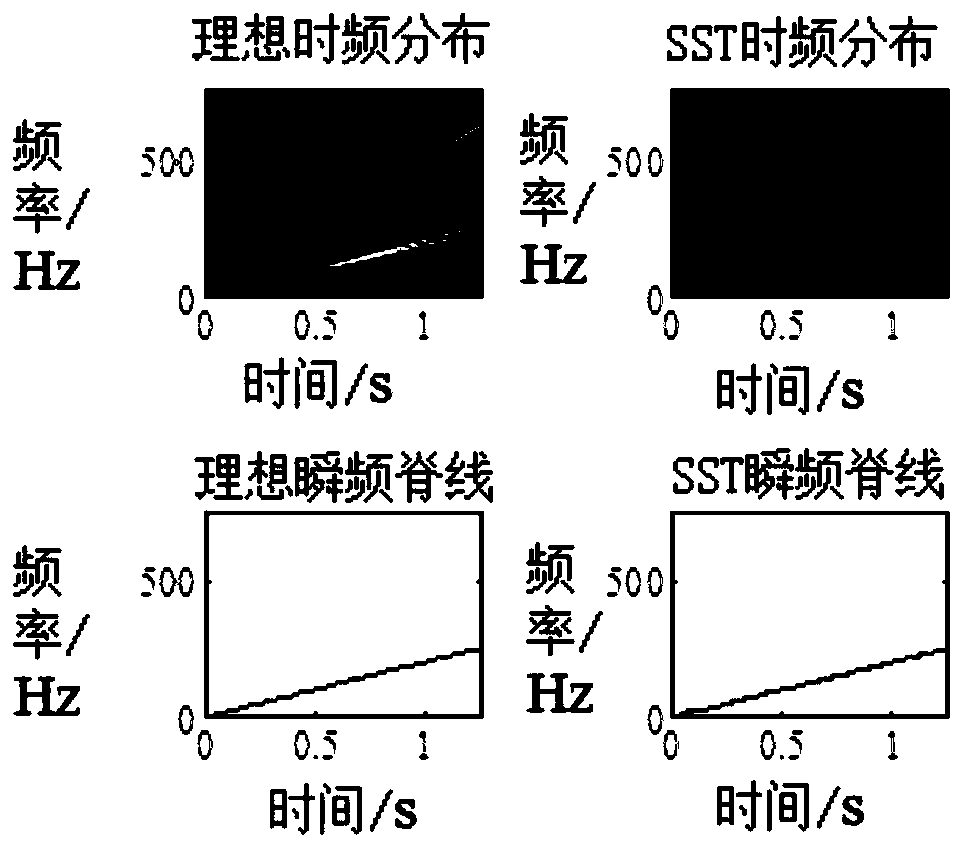

Synchronous compression transformation order analysis method for rolling bearing fault diagnosis

InactiveCN110617964AGood ability concentrationAccurate extractionMachine part testingTime markFrequency conversion

The invention discloses a synchronous compression transformation order analysis method for rolling bearing fault diagnosis. According to the method, firstly, SST is utilized to analyze a variable-speed vibration signal of a bearing to obtain time-frequency distribution of the vibration signal; secondly, an instantaneous frequency ridge of frequency conversion is extracted and subjected to high-order polynomial fitting, a fitted instantaneous frequency curve is obtained, and phase discrimination time marks are solved according to the fitted instantaneous frequency curve; thirdly, equal-angle resampling is performed on the original vibration signal to obtain an angular domain signal; and fourthly, Hilbert envelope demodulation is performed on the angular domain signal, an envelope order spectrum of the angular domain signal is solved, whether the rolling bearing has a fault or not and the fault type are judged by analyzing the envelope order spectrum, a diagnosis result is given, maintenance suggestions are proposed, and therefore normal running of a metro vehicle is guaranteed. Through the synchronous compression transformation order analysis method, instantaneous frequency conversion information contained in the vibration signal can be precisely extracted, order tracking is realized, a specific hardware device is not needed, the installing process is greatly simplified, and thefault monitoring cost is lowered.

Owner:中国铁道科学研究院集团有限公司城市轨道交通中心

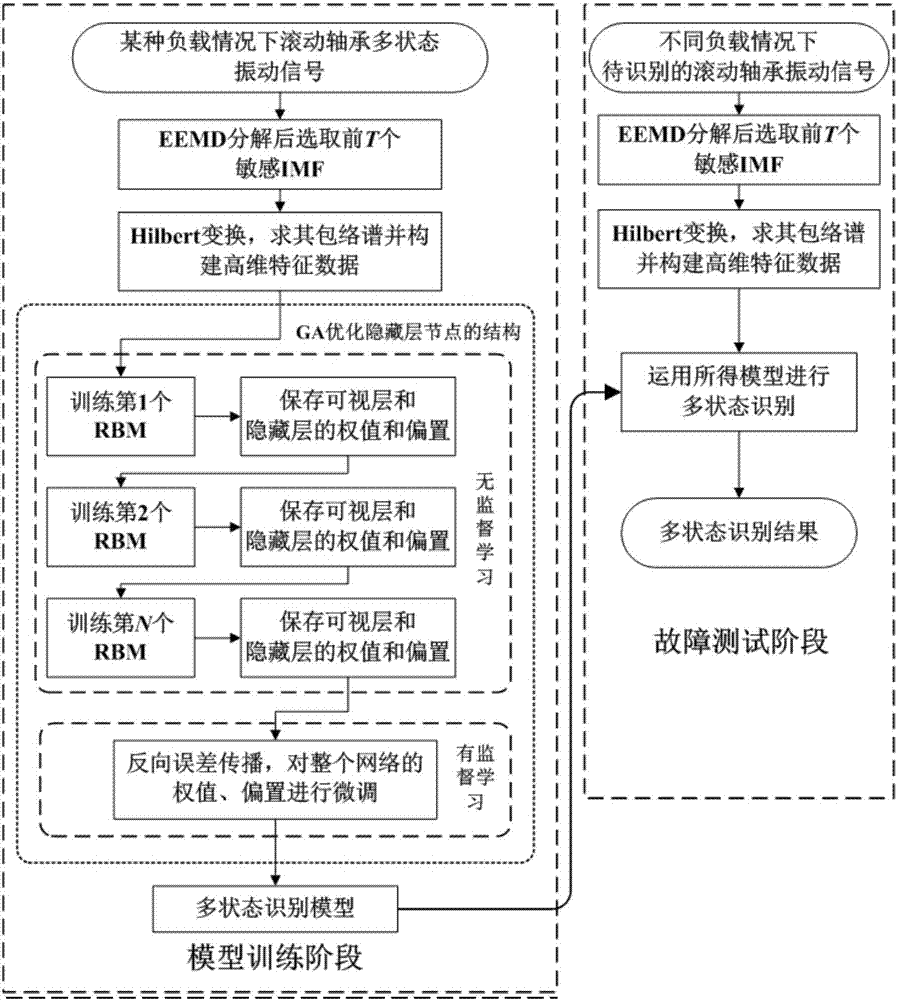

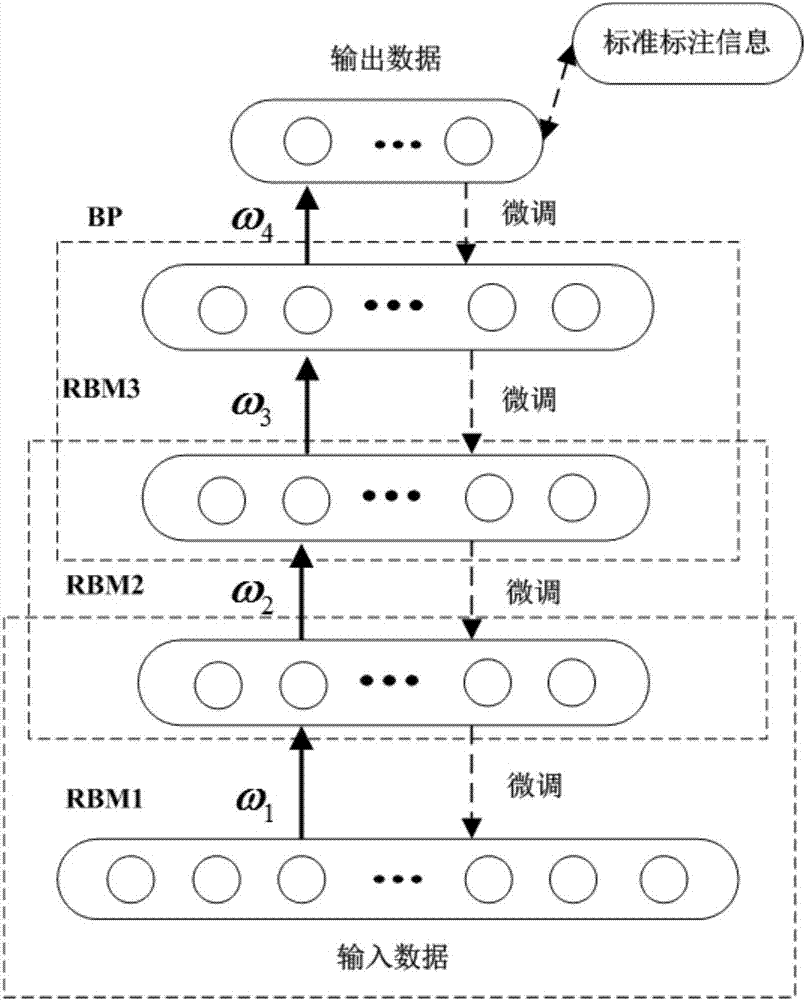

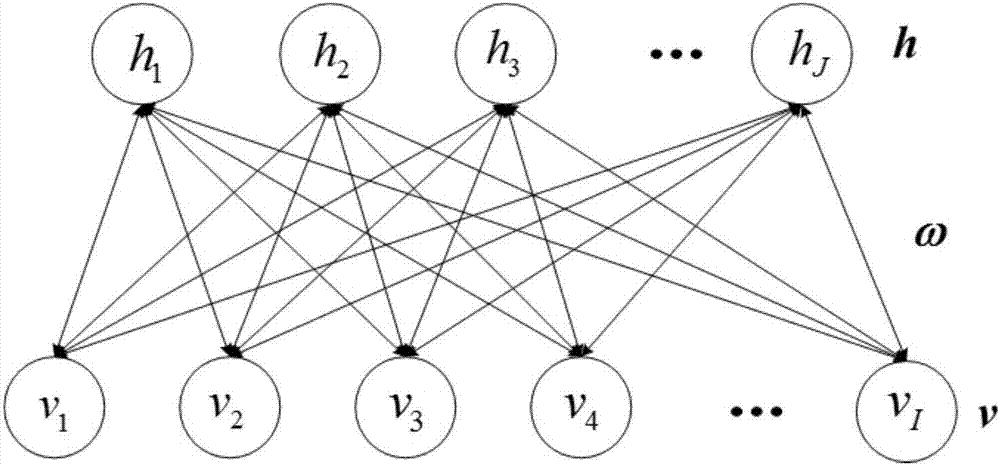

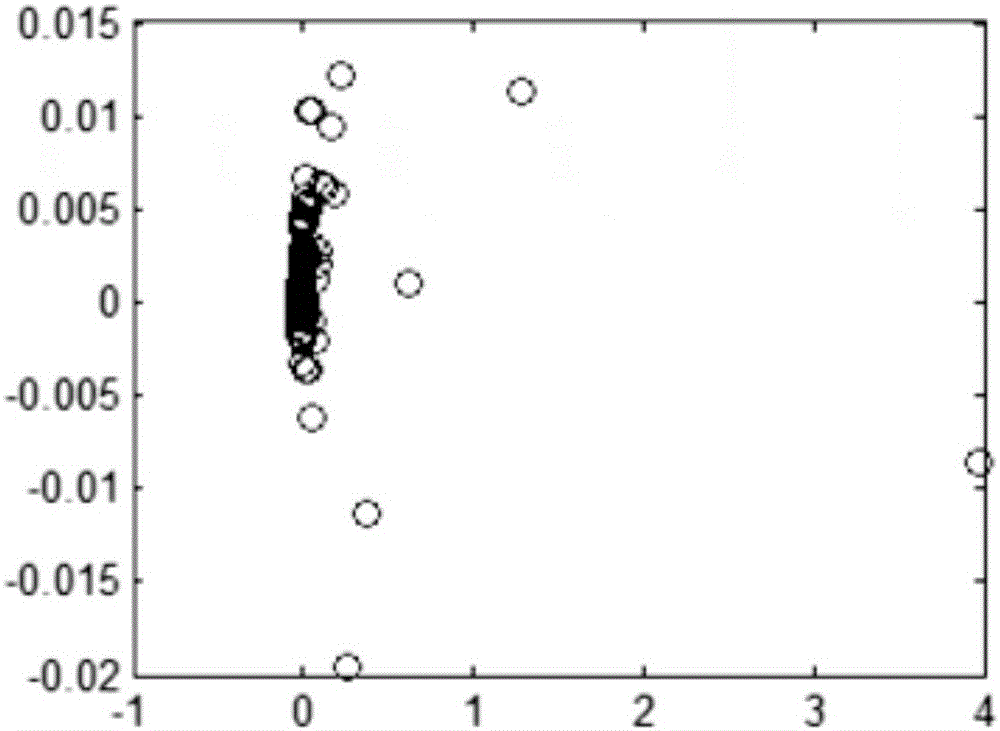

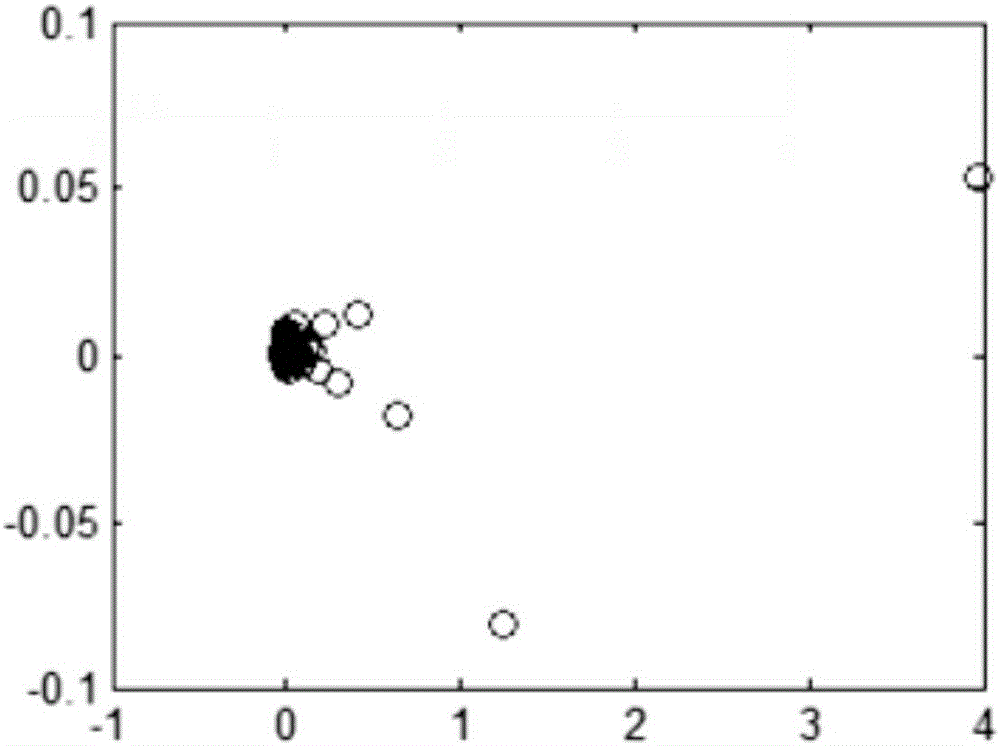

Identification method of rolling bearing state under variable load of EEMD-Hilbert envelope spectrum in combination with DBN

InactiveCN106886660AReduce distractionsMulti-state recognition implementationGeometric CADNeural learning methodsEngineeringHigh dimensional

The invention provides an identification method of rolling bearing state under variable load of EEMD-Hilbert envelope spectrum in combination with DBN, and belongs to the field of rolling bearing fault detection. The aim is to solve the problems that under the circumstance of training data using one load and test data using other loads, the rolling bearing fault state and the fault extent cannot be accurately identified. Firstly EEMD is conducted on the vibration signals of each status of the rolling bearing, then a sensitive eigenmode state function is selected, and Hilbert transformation is conducted to obtain the envelope spectrum. Finally, new high-dimensional data are built according to the order of the IMF envelope spectrum of the vibration signals of each status, then inputted into the DBN of each hidden layer node structure optimized by the genetic algorithm, and the multi-state recognition of rolling bearing under the variable load is achieved. In the process of 10 state recognition of rolling bearing using DBN, under the circumstance of the training data using one load and the test data using other loads, the EEMD-Hilbert envelope spectrum time domain or frequency-domain amplitude spectrum can better reflect the multiple state characteristics of rolling bearing under different loads, and has a higher recognition rate.

Owner:HARBIN UNIV OF SCI & TECH

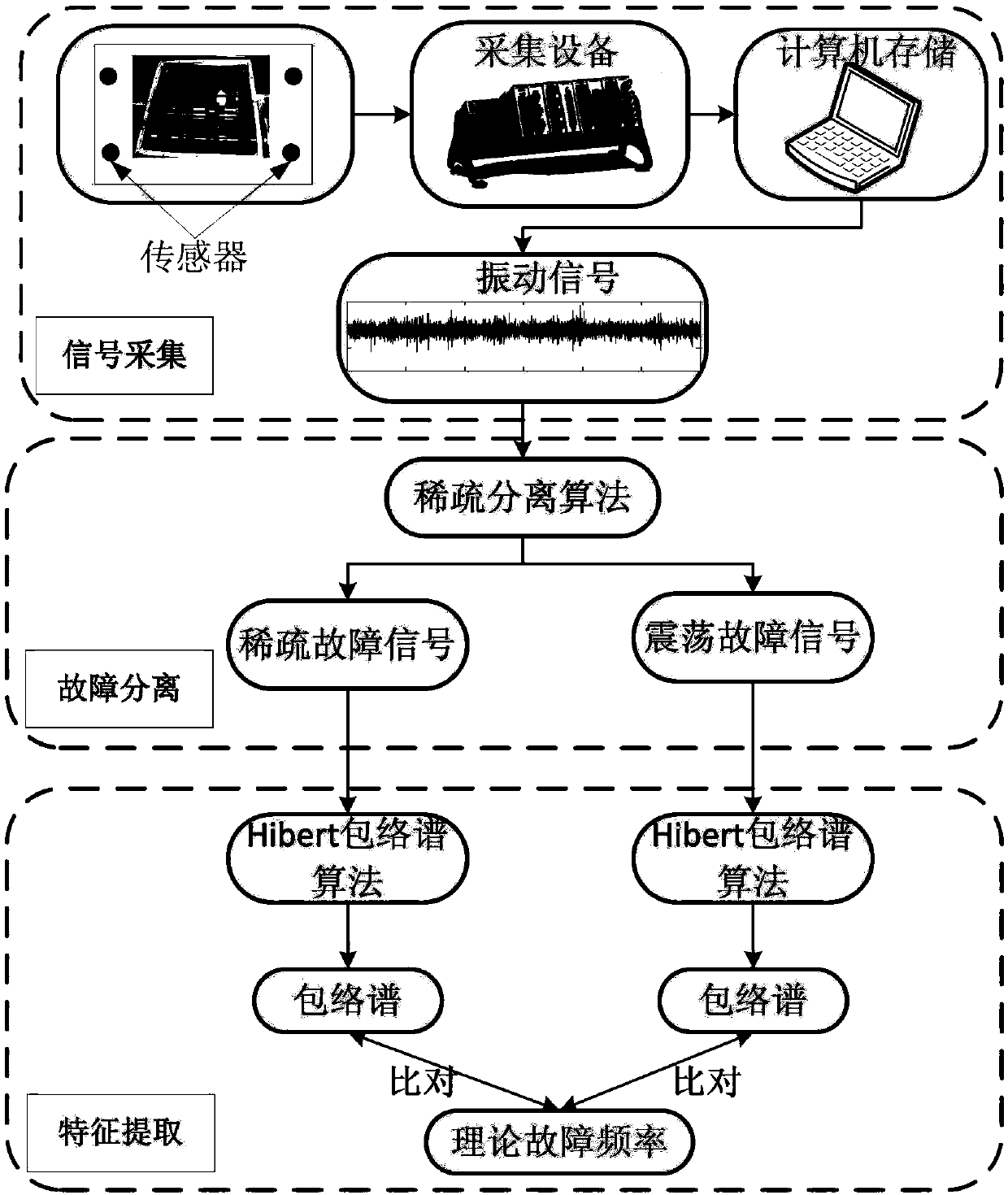

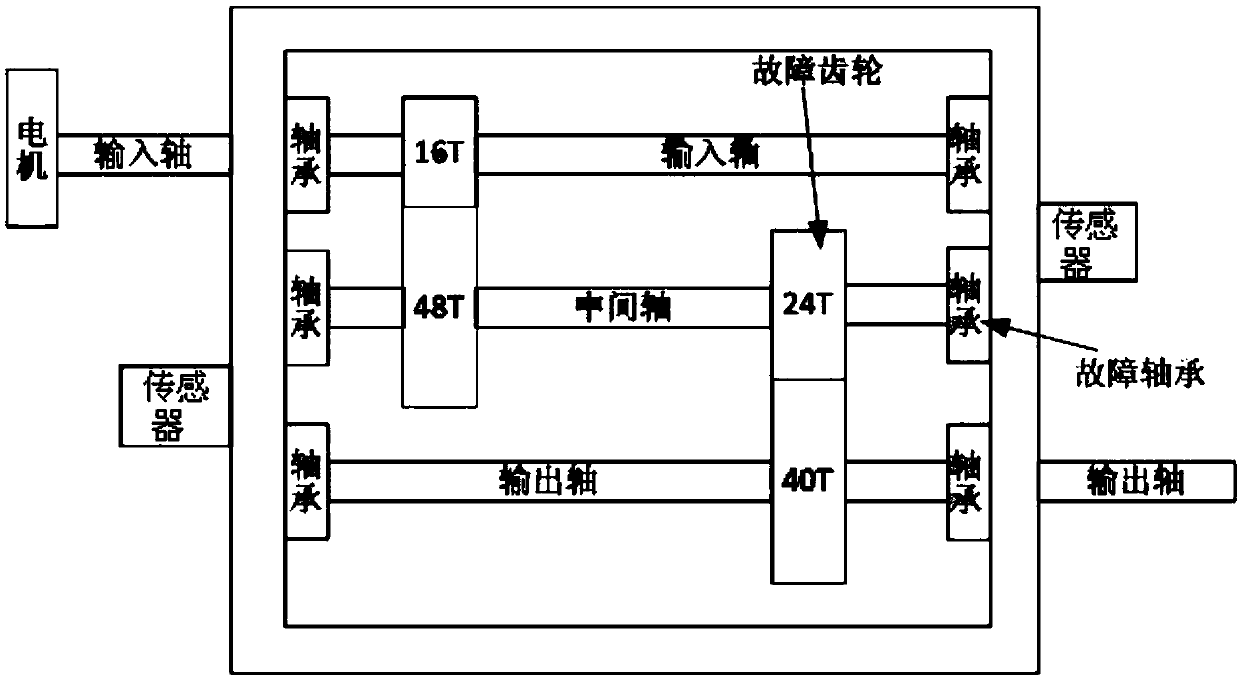

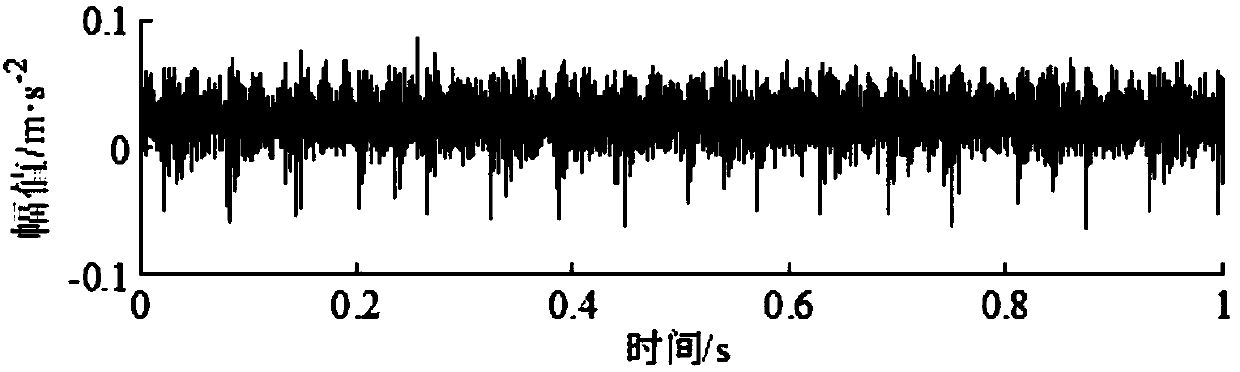

Gear box composite weak fault diagnosis method of sparse separation model

InactiveCN108152033AReduce distractionsReduce computational complexityMachine gearing/transmission testingHarmonicDiagnosis methods

The invention relates to a gear box composite weak fault diagnosis method of a sparse separation model. The method comprises the following steps of picking up a composite fault vibration signal of a gear box through an acceleration sensor; conducting the sparse decomposition on a to-be-analyzed signal by utilizing the sparse separation model algorithm, and extracting a periodic sparse fault signaland an oscillating fault signal; respectively performing envelope demodulation on the sparse fault signal and the low-frequency oscillating signal by utilizing the hilbert envelope demodulation spectrum; extracting the envelope spectrum and all sub-harmonic components of the envelope spectrum; finally comparing obtained values with theoretical calculation values, and positioning to figure out a composite fault type. According to the invention, the method is independent of the structure prior knowledge of vibration signals, and is also free of the construction of a pulse redundant dictionary through collecting a bulk of sample signals. Therefore, the interference of background noises can be well reduced and a relatively weak composite fault can also be extracted. The method is strong in stability and is suitable for the real-time fault inspection and the on-line monitoring of the gear box in the working state so as to avoid the occurrence of sudden accidents.

Owner:DONGHUA UNIV

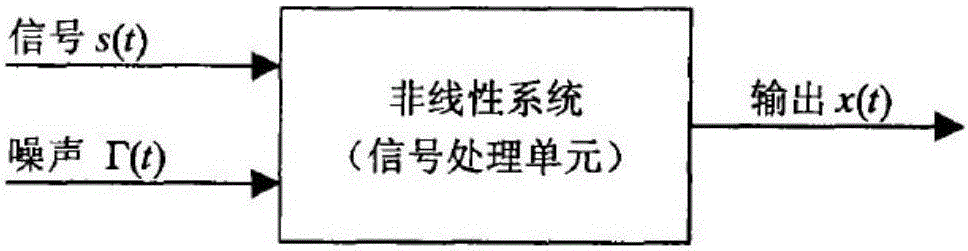

Fault diagnosis method for rolling bearing

InactiveCN105938468AReal-time monitoring of operating conditionsAvoid major accidentsInformaticsComplex mathematical operationsFast Fourier transformFrequency spectrum

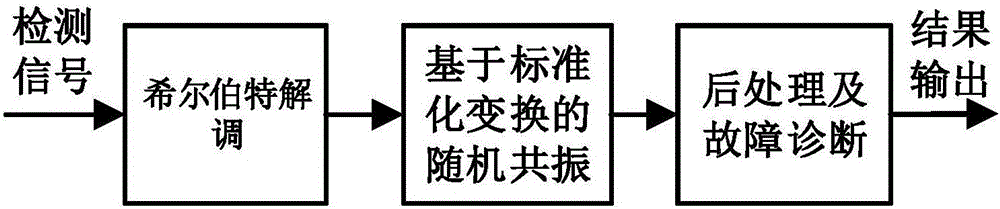

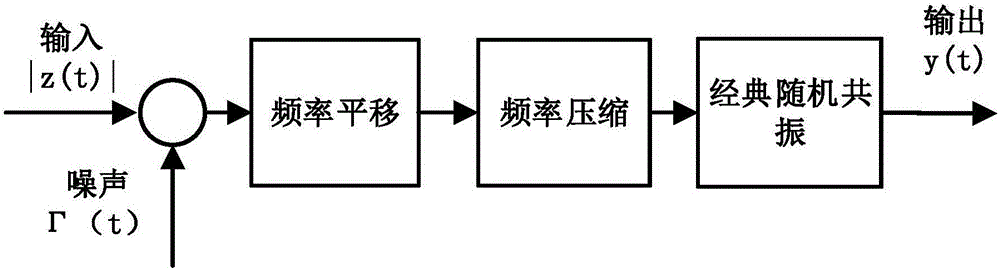

The invention discloses a fault diagnosis method for a rolling bearing. The method comprises the following steps that 1, the fault feature frequency of the rolling bearing is calculated; 2, an acceleration signal, to be detected, of the rolling bearing is obtained; 3, Hilbert transform is carried out on the acceleration signal to be detected, and a Hilbert envelope demodulation signal is calculated; 4, stochastic resonance treatment based on standard transform is carried out on the Hilbert envelope demodulation signal, and a carrier frequency and an output signal are obtained; 5, fast Fourier transform is carried out on the output signal to obtain an output signal frequency spectrum peak value, and the feature frequency of the acceleration signal to be detected is obtained according to the carrier frequency parameter and the output signal frequency spectrum peak value; 6, the feature frequency of the acceleration signal to be detected is compared with the fault feature frequency, and a diagnosis result is obtained. By means of the method, the fault of the rolling bearing can be diagnosed and recognized, and particularly, the early fault of the rolling bearing in the strong-noise background can be diagnosed and recognized.

Owner:BEIJING JIAOTONG UNIV

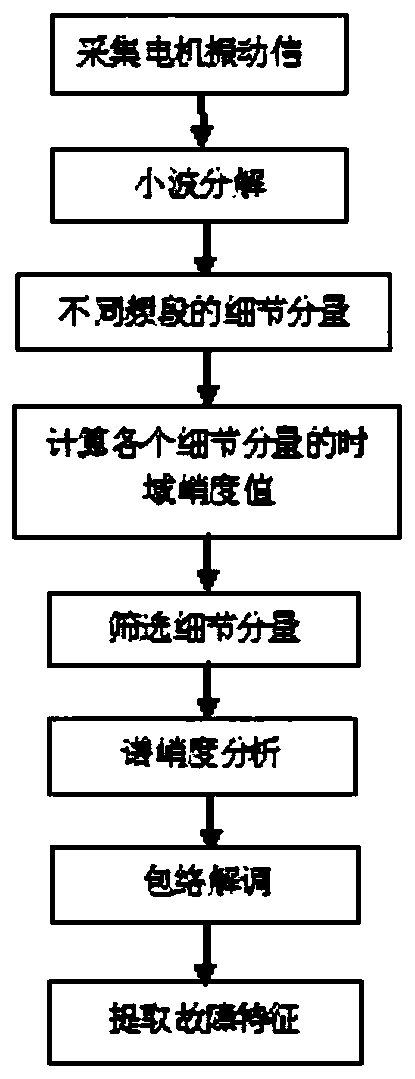

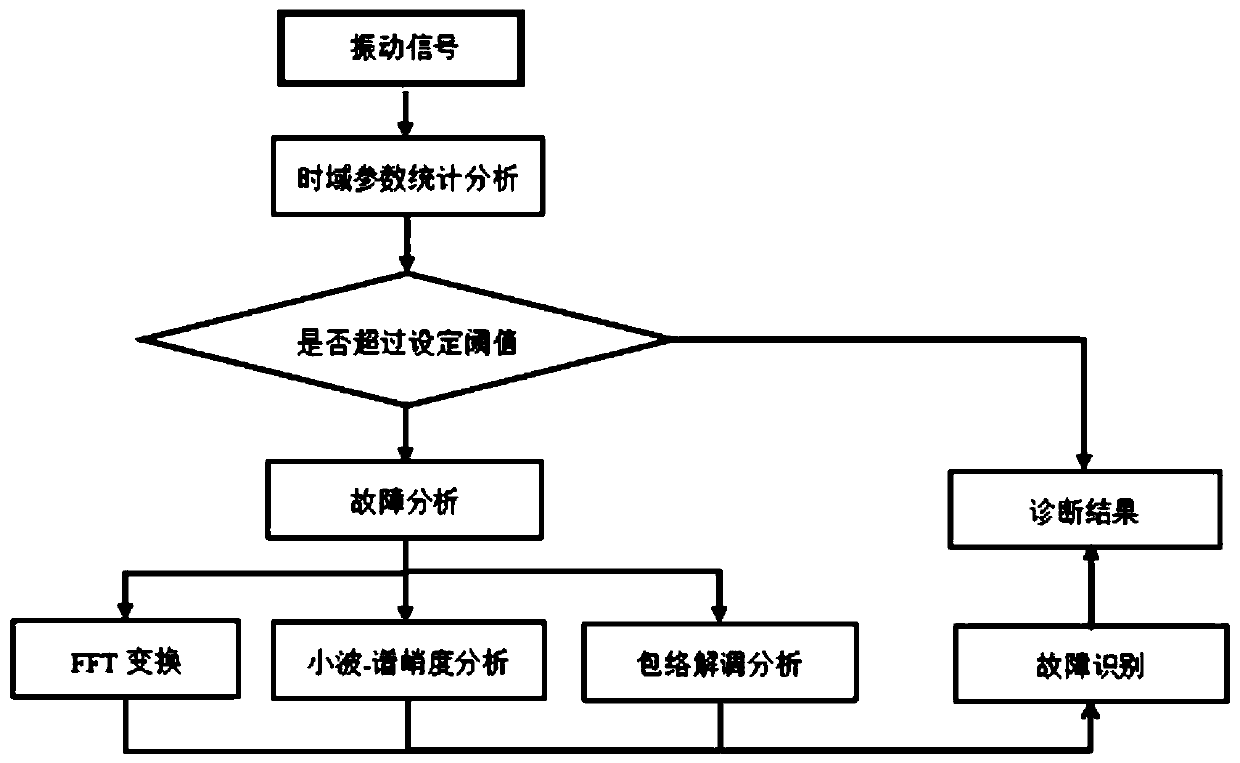

Induction motor bearing fault diagnosis system and diagnosis method based on wavelet-spectral kurtosis

ActiveCN110160791AHigh degree of automationAccurate identificationMachine part testingCharacter and pattern recognitionFrequency spectrumStatistical analysis

The invention discloses an induction motor bearing fault diagnosis system and diagnosis method based on wavelet-spectral kurtosis. The induction motor bearing fault diagnosis system based on the wavelet-spectral kurtosis comprises a wavelet-spectral kurtosis analysis module, a time domain parameter statistical analysis module, an FFT analysis module, a Hilbert envelope demodulation analysis module, a spectral kurtosis analysis module, and the like; the wavelet-spectral kurtosis analysis module includes two data preprocessing methods of wavelet and wavelet packet, which can realize the identification and feature extraction of multiple faults in a motor bearing coupled fault vibration signal; the time domain parameter statistical analysis module monitors whether the motor bearing is abnormalor not by calculating kurtosis values of time domain sensitive parameters; and a spectrum analysis module and the Hilbert envelope demodulation analysis module mainly determine the feature extractionof the single bearing fault of the motor. The induction motor bearing fault diagnosis system based on the wavelet-spectral kurtosis realizes the integrated design of the induction motor bearing faultdiagnosis method, and can quickly and effectively process and analyze the single and composite fault signals of the motor bearing and obtain accurate diagnosis results.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Fault diagnosis method of motor bearing based on time-frequency domain statistical characteristic

ActiveCN109883702ASuppress noiseHighlight fault informationMachine part testingDiagnosis methodsFrequency conversion

The invention discloses a fault diagnosis method of a motor bearing based on a time-frequency domain statistical characteristic. The fault diagnosis method comprises the following steps that: speed pulse signals and vibration signals of the motor bearing in T time interval are collected simultaneously, and a frequency conversion curve f is calculated according to the speed pulse signals; the vibration signals at a stationary speed are intercepted according to the frequency conversion curve and are sectioned; health indicators of the vibration signals in all segments are calculated according toa formula of the health indicators, a fault degree grade of each segment is obtained by comparing the health indicators with a fault threshold table, and the fault grade with the highest fault degreegrades counted is the fault grade of the motor bearing; Hilbert envelope spectrums of the vibration signals in all segments are calculated, effective frequencies of all envelope spectrums are determined according to a calculation method of the effective frequencies, the most frequent occurrence frequency of the effective frequencies counted is a fault frequency, and then a fault position of the bearing is determined. The overall fault degree and the fault position of the motor bearing are accurately obtained by counting the fault grade of the vibration signals and the effective frequencies ofthe envelope spectrums in a plurality of time intervals.

Owner:XI AN JIAOTONG UNIV

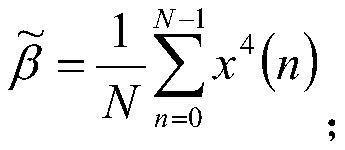

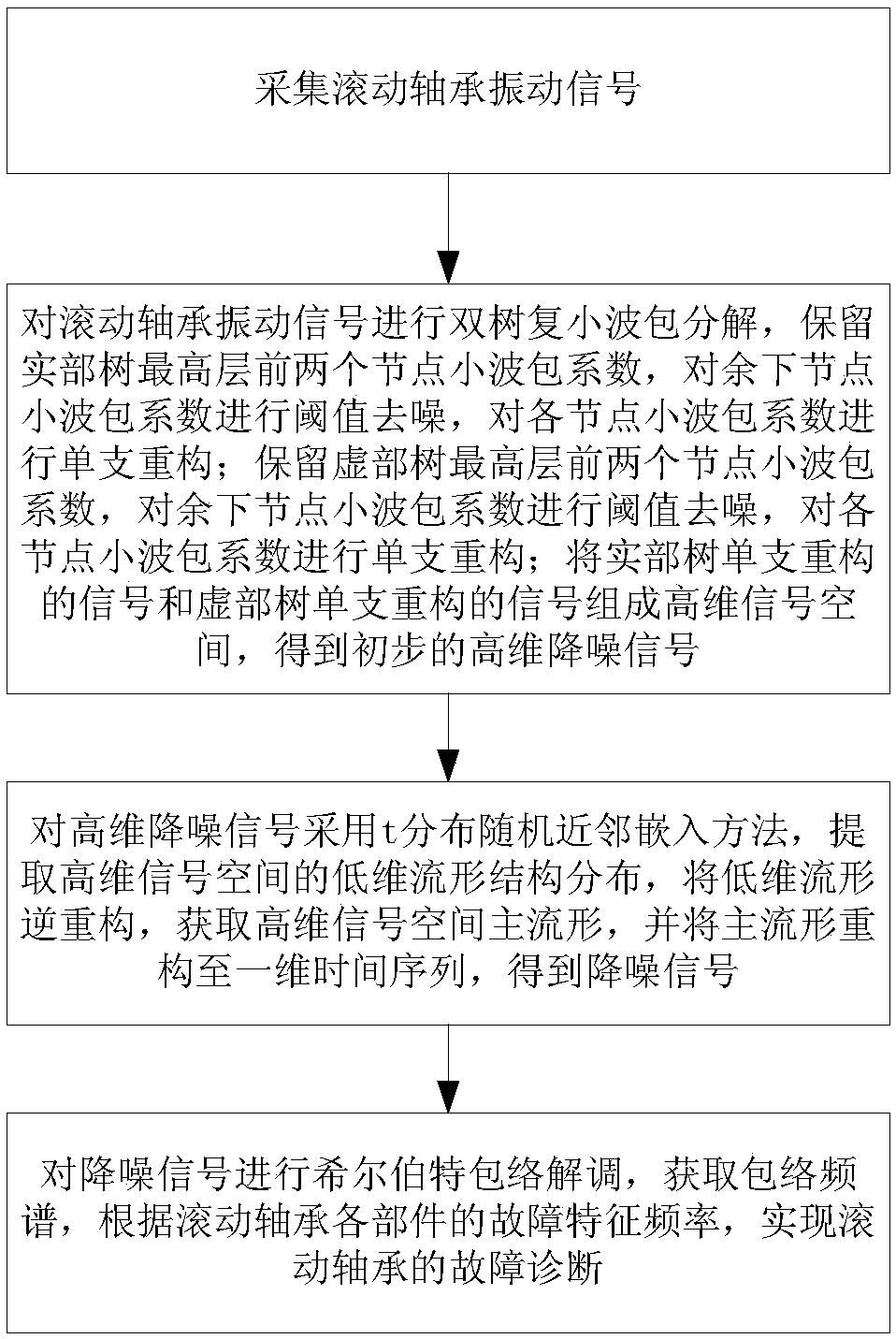

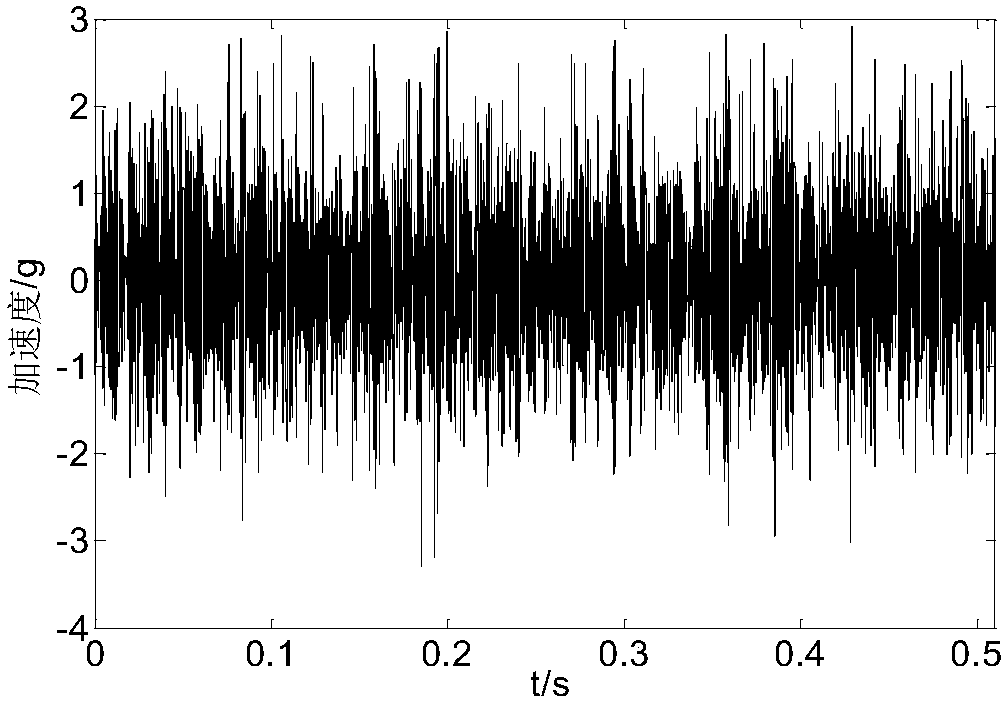

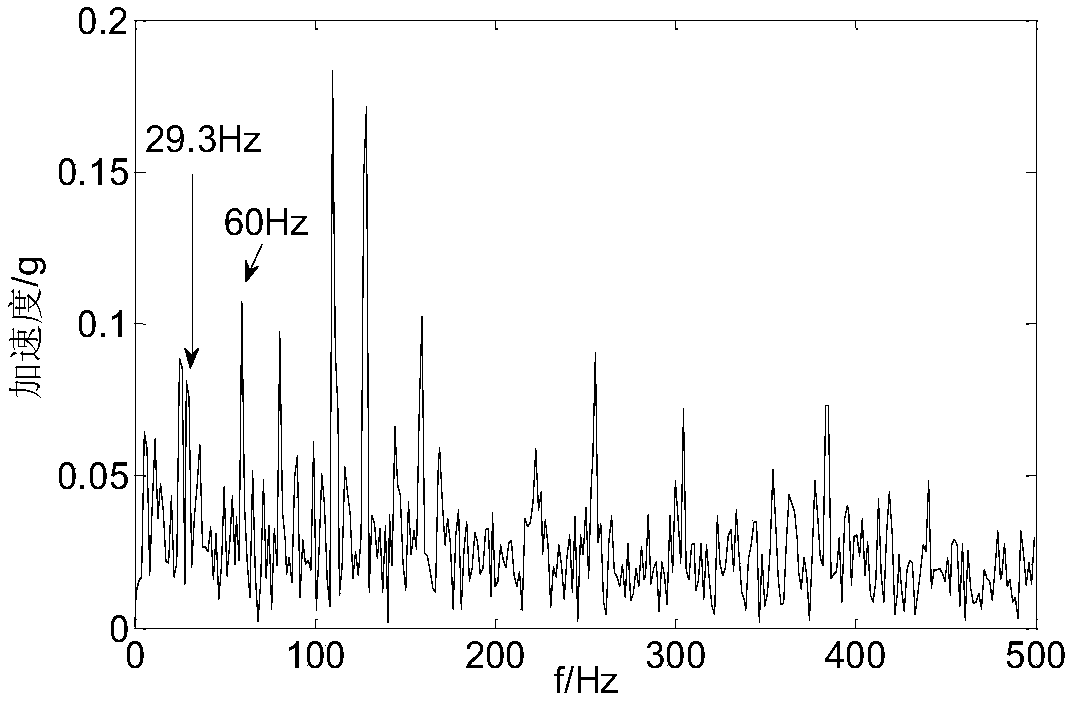

Rolling bearing fault diagnosis method based on dual-tree complex wavelet pack manifold domain noise reduction

ActiveCN107727399AAccurately obtain fault characteristic frequencyImplement fault diagnosisMachine bearings testingComplex mathematical operationsFrequency spectrumDecomposition

The invention relates to a rolling bearing fault diagnosis method based on dual-tree complex wavelet pack manifold domain noise reduction. The rolling bearing fault diagnosis method based on the dual-tree complex wavelet pack manifold domain noise reduction comprises steps of using an accelerated speed sensor to collect a vibration signal of the rolling bearing, performing dual-tree complex wavelet pack decomposition on the vibration signal, maintaining wavelet pack coefficients of first two nodes, performing threshold noise reduction on wavelet coefficients of the rest nodes, performing single branch reconstruction on the wavelet pack coefficient of each node to perform a high dimensional signal space, using a t distribution random neighbor embedding method to extract low a dimensional manifold, performing inverse reconstruction on the low-dimensional manifold to obtain a high-dimensional space main manifold, obtaining a signal after noise reduction, performing Hilbert envelope demodulation on the signal after noise reduction to obtain an envelope frequency spectrum of the vibration signal, and realizing fault diagnosis of the rolling bearing according to an inner ring fault characteristic frequency and an outer ring fault characteristic frequency of the rolling bearing, a rolling body fault characteristic frequency and a retainer fault characteristic frequency.

Owner:NAVAL UNIV OF ENG PLA

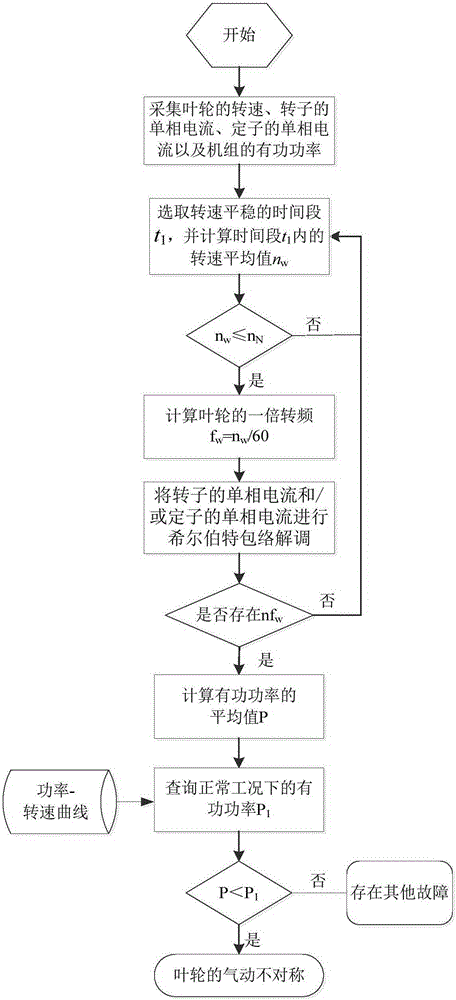

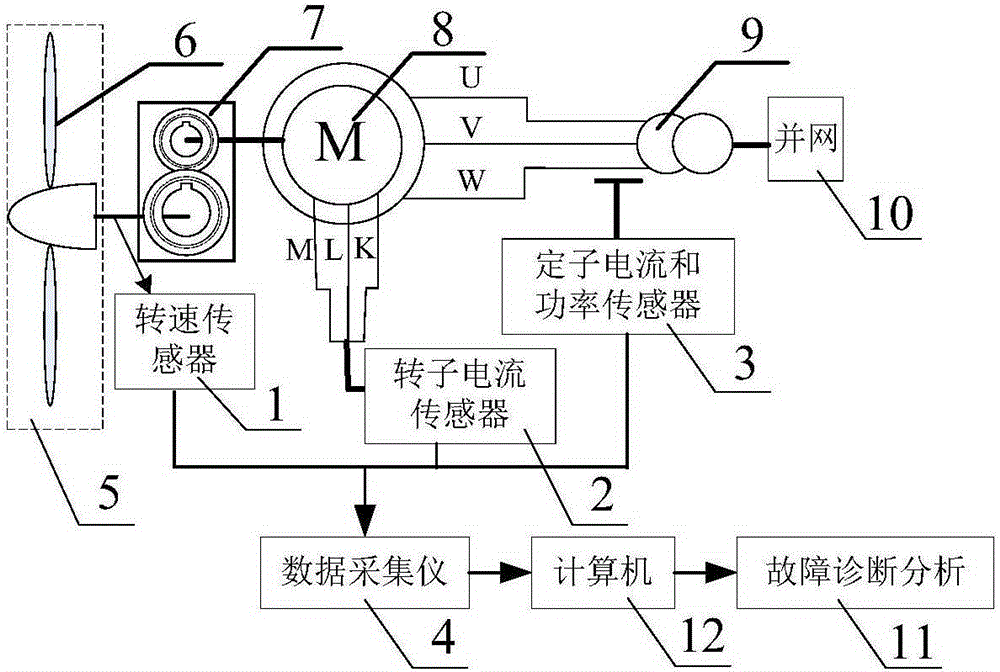

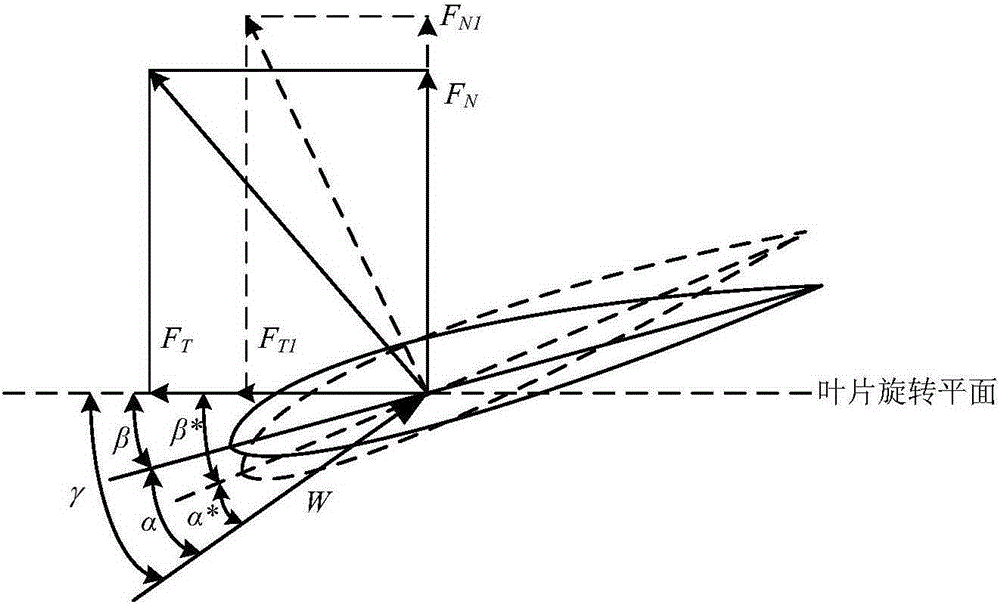

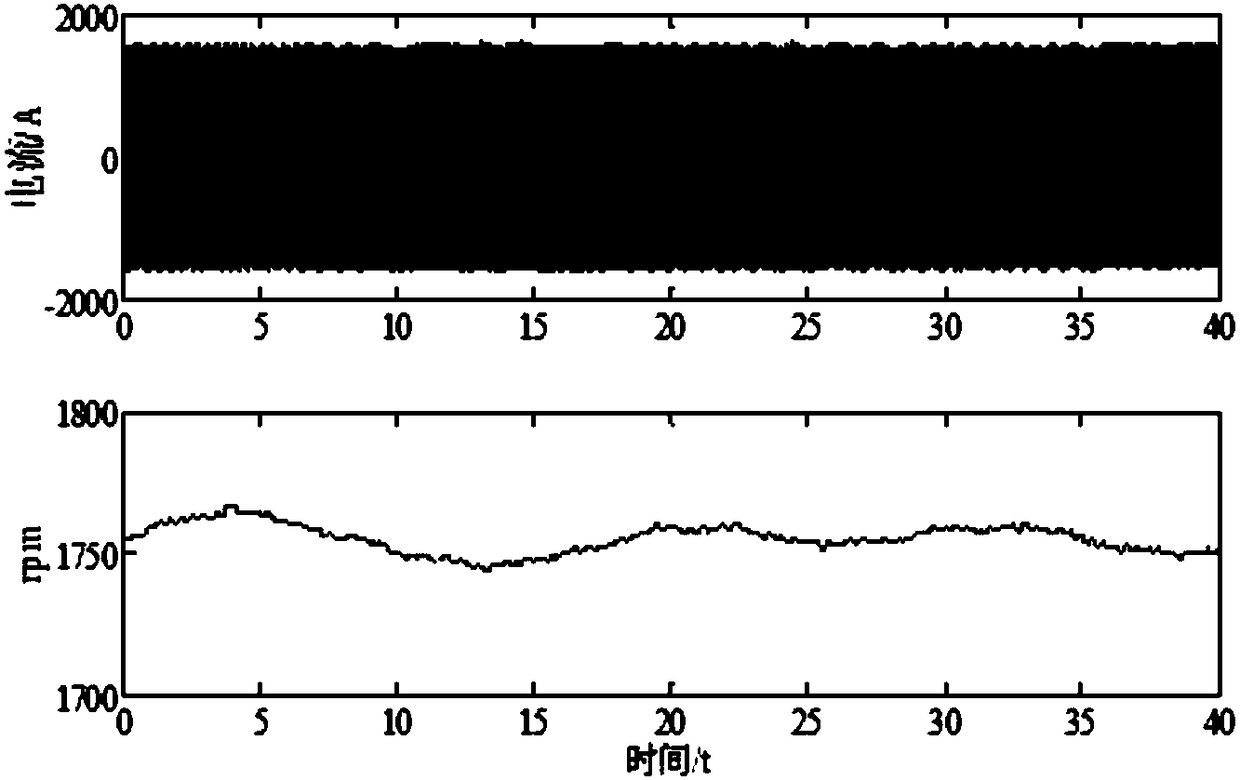

Method for diagnosing pneumatic asymmetric fault of impeller of doubly-fed wind turbine generator system

The invention provides a method for diagnosing a pneumatic asymmetric fault of an impeller of a doubly-fed wind turbine generator system. The method comprises the following steps: synchronously a rotating speed of the impeller, and the single-phase currents and the active powers of a rotor and a stator of a doubly-fed wind power generator within a time period t; selecting a time period t1 when the rotating speed of the impeller is steady and calculating a rotating speed mean value nw of the impeller; judging whether the rotating speed mean value nw is smaller than a rated rotating speed nN of the impeller, and if so, calculating a one-time rotational frequency fw of the impeller; performing Hilbert envelope demodulation on the single-phase current of the rotor and / or the single-phase current of the stator within the time period t1 and determining whether a fault frequency nfw exists in an envelope demodulation frequency spectrogram, and if so, calculating a mean value P of the active power of the doubly-fed wind turbine generator system within the time period t1; and if the mean value P of the active power is smaller than an active power base value P1, judging that the doubly-fed wind turbine generator system has the pneumatic asymmetric fault of the impeller. According to the method, the accuracy of diagnosis is improved.

Owner:温州华电实业有限公司

Fault diagnosis method for inner ring and outer ring of bearing of axial plunger pump

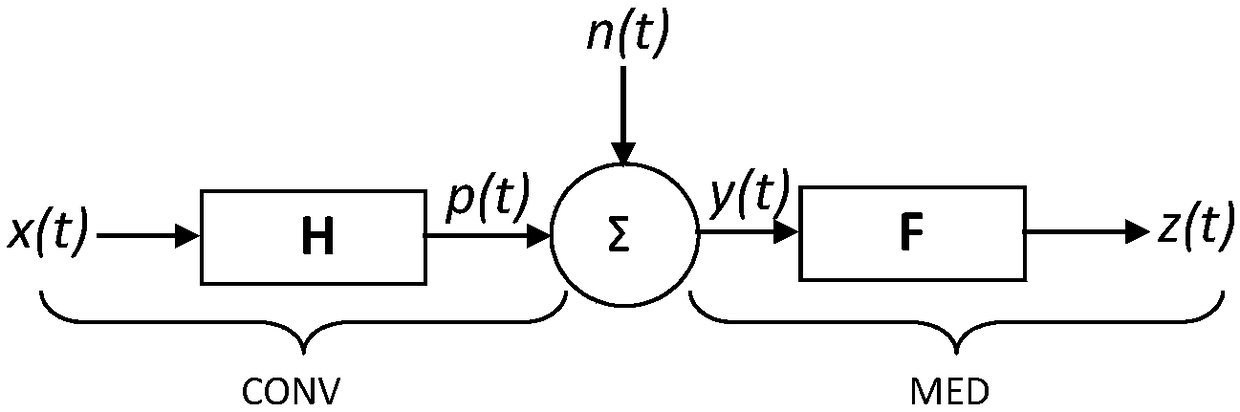

InactiveCN108694298AEnhanced Impact ComponentsReliable detectionGeometric CADMachine bearings testingBandpass filteringElement analysis

The invention relates to a fault diagnosis method for an inner ring and an outer ring of a bearing of an axial plunger pump. According to the method, first, a finite element analysis method is utilized to perform modeling and finite element simulation on the bearing of the plunger pump, inherent frequency of first-order bending vibration of the inner ring and the outer ring of the bearing is obtained through modal analysis to serve as central frequency of a band-pass filter, and filtering is performed at fixed bandwidth 2,000Hz; second, minimum entropy deconvolution is utilized to perform fault feature enhancement on signals obtained after band-pass filtering; and last, fault feature frequency is obtained through Hilbert envelope demodulation. Through the method, on the one hand, modal analysis is utilized to obtain a carrier frequency center of fault feature signals, and the fault feature signals subjected to amplitude modulation nearby the inherent frequency of the first-order bending vibration of the inner ring and the outer ring of the bearing can be effectively captured; and on the other hand, the minimum entropy deconvolution technology is utilized to perform fault impact feature enhancement on the filtered signals, the fault frequency and multiplied frequency of the bearing can be visually demodulated, and therefore a fault type is determined.

Owner:WENZHOU UNIVERSITY

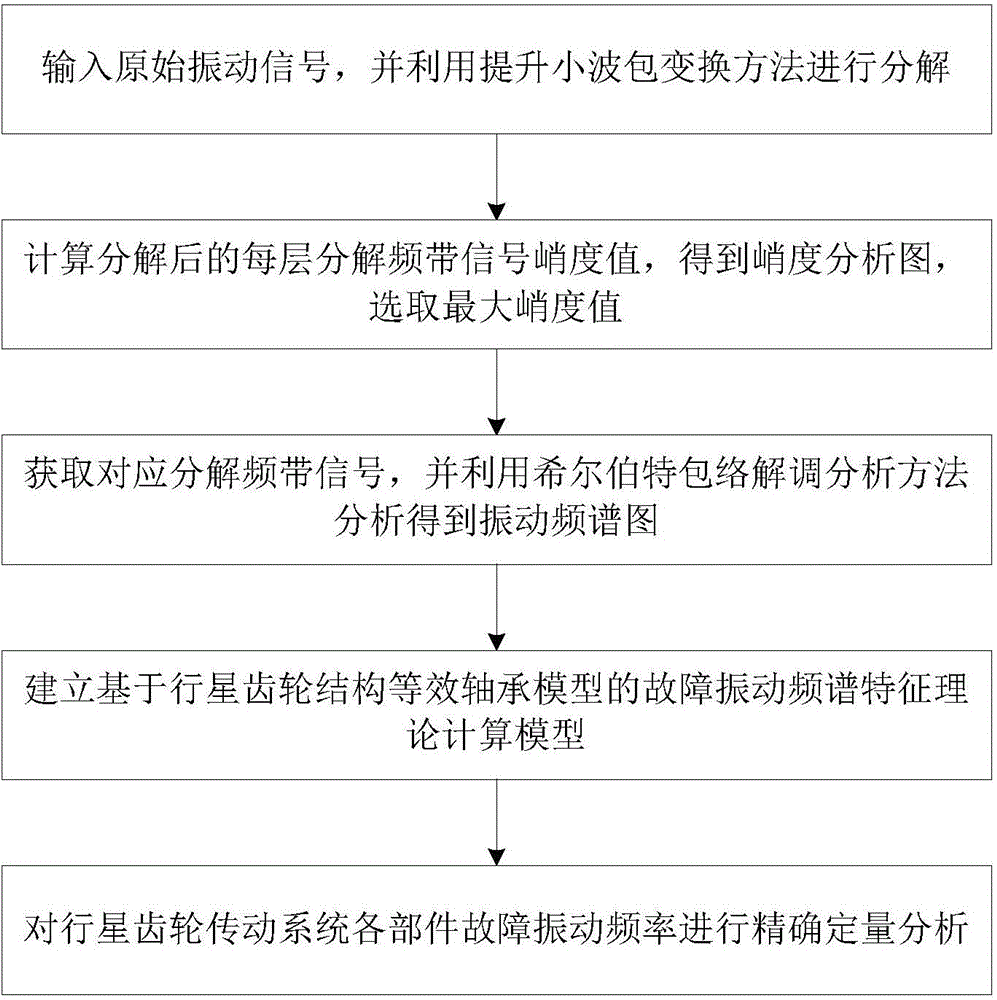

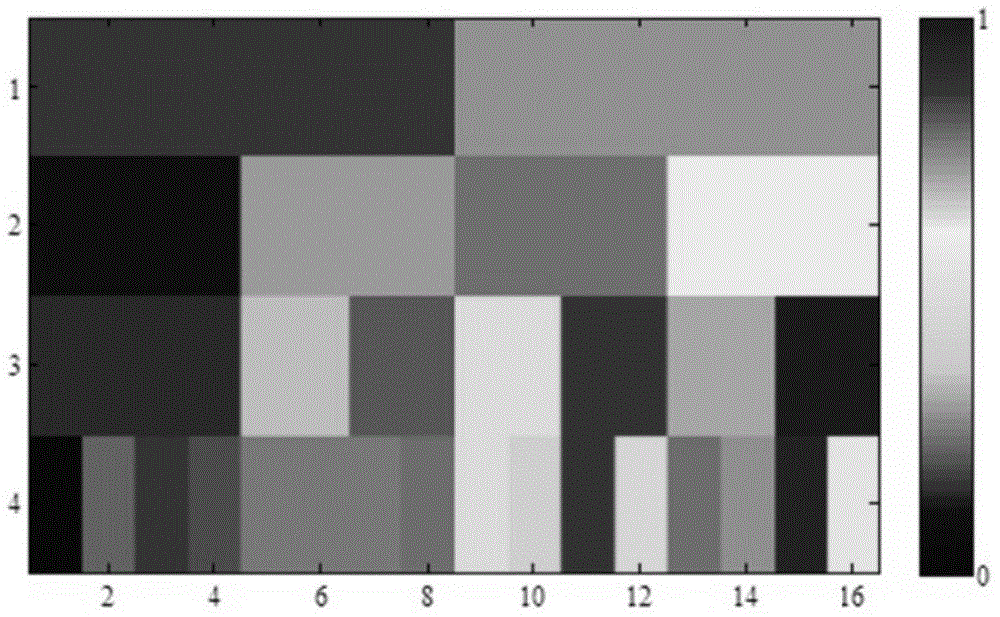

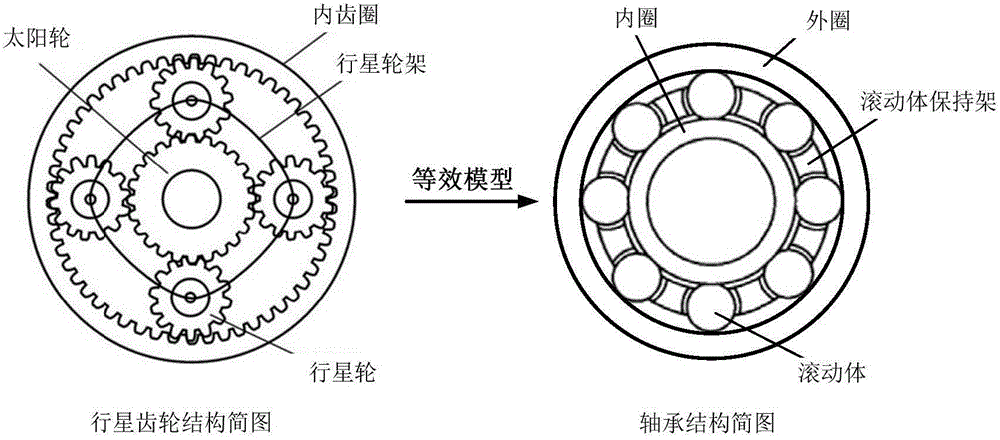

Vibration spectrum feature analysis method based on planetary gear structure equivalent bearing model

InactiveCN104792523APrecise Characterization of Fault Characteristic FrequencyHigh precisionMachine gearing/transmission testingFrequency spectrumDecomposition

The invention discloses a vibration spectrum feature analysis method based on a planetary gear structure equivalent bearing model. The vibration spectrum feature analysis method specifically includes inputting an original vibration signal, decomposing the vibration signal according to a lifting wavelet package transformation method, calculating a kurtosis value of each decomposed frequency band signal acquired by decomposition to acquire a kurtosis analysis chart, selecting the maximum kurtosis value, acquiring a corresponding decomposed frequency band signal, analyzing the frequency band signal according to a Hilbert envelope demodulation analysis method to acquire a vibration spectrogram, creating a vibration spectrum feature theoretical calculation model based on the planetary gear structure equivalent bearing model, and analyzing fault vibration frequency of each component of a planetary gear transmission system accurately and quantitatively. The vibration spectrum feature analysis method has the advantages that the vibration spectrum feature analysis method is high in accuracy, simple and reliable; direct correspondence between theoretically calculated fault frequency peak values and actual fault frequency peak values is achieved, and accordingly, fault feature frequency of each component of the planetary gear transmission system is represented accurately.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

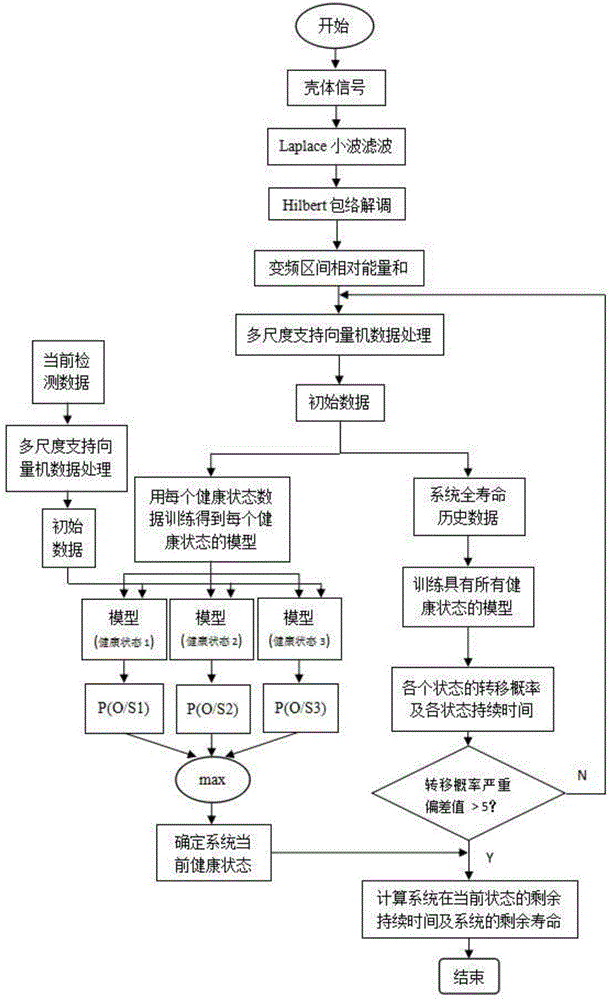

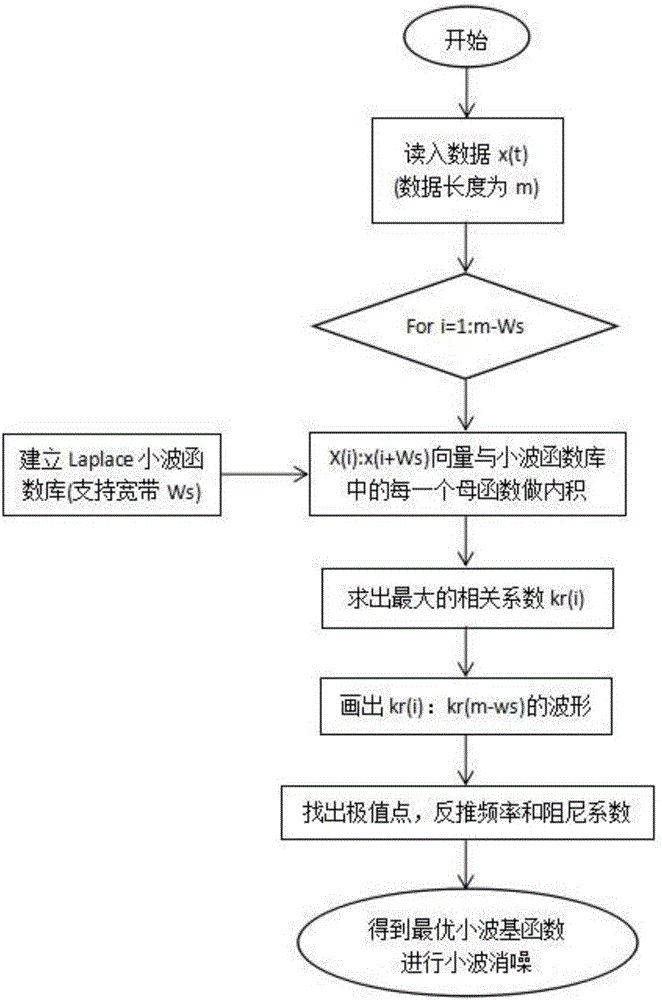

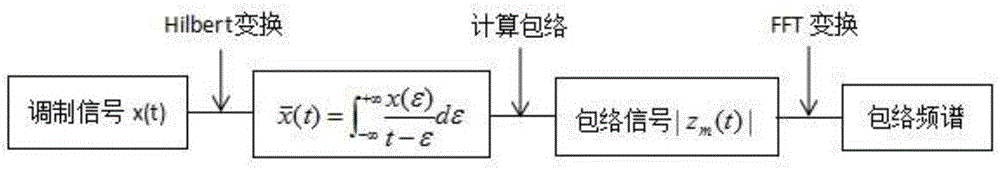

Probability time-varying seawater hydraulic pump fault prediction method

InactiveCN106407998AAccurate extractionHigh precisionCharacter and pattern recognitionOriginal dataHydraulic pump

The invention discloses a probability time-varying seawater hydraulic pump fault prediction method, which belongs to the field of deep sea seawater plunger pump fault prediction research. The probability time-varying seawater hydraulic pump fault prediction method comprises the steps of: selecting working volume efficiency of a deep sea seawater plunger pump as a fault prediction characteristic quantity, and acquiring seawater numerical values sent out by the plunger pump to form a plunger pump fault prediction original data sequence; carrying out Laplace wavelet extraction and then Hilbert envelope demodulation for processing the original data sequence, so as to obtain a new data sequence; conducting reconstruction and recombination based on multi-scale support vector machine data processing, so as to obtain accurate initial data; introducing the processed data into a service life prediction method based on time-varying state transition, and training the data to obtain whole life historical data and health state models of a system; subjecting current monitoring data to multi-scale support vector machine data processing, comparing the processed data with the health state models, recognizing the current health state of the system and calculating a state transition coefficient; and finally calculating remaining duration and remaining life of the system in the current state.

Owner:BEIJING UNIV OF TECH

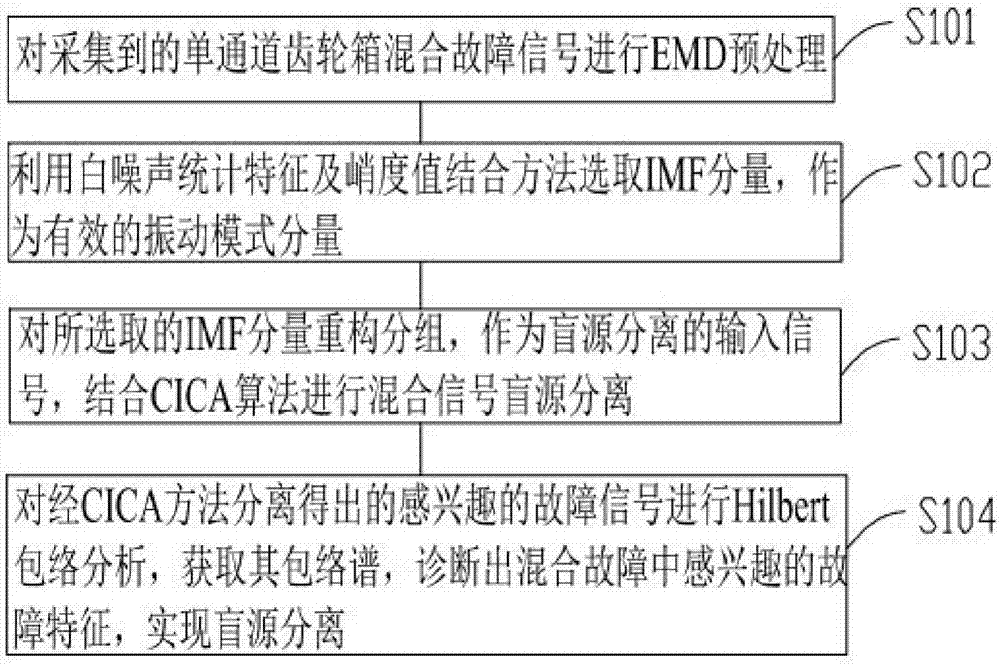

Blind source separation method of hybrid fault signal of gear case

InactiveCN107255563AAccurate extractionImprove targetingMachine gearing/transmission testingWhite noiseHilbert envelope

The invention, which relates to the technical field of the blind source separation diagnosis method for hybrid faults of the gear case, discloses a blind source separation method of a hybrid fault signal of a gear case. The method comprises: carrying out EMD preprocessing on a collected single-channel gear-case hybrid fault signal; on the basis of a method of combination of a white noise statistical feature and a kurtosis value, selecting an IMF component as an effective vibration mode component; carrying out reconstruction and grouping on the selected IMF component to form a blind source separation input signal, carrying out hybrid signal blind source separation by combining a CICA algorithm, and extracting an interested fault signal; and carrying out a Hilbert envelope analysis on the interested fault signal obtained by the CICA method to obtain an envelope spectrum, diagnosing the feature of the interested fault among the hybrid fault to realize blind source separation. With the method provided by the invention, blind source separation single-channel extension is realized and the interested fault signal is extracted.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

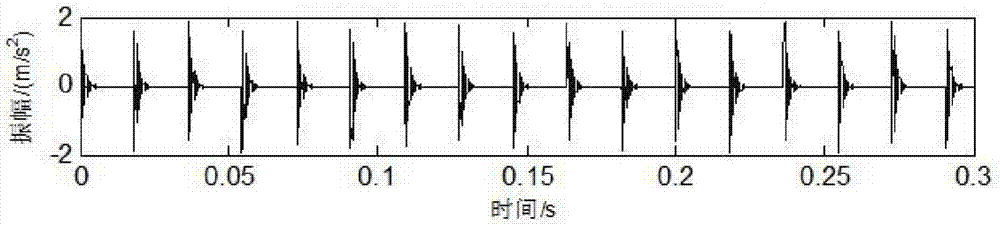

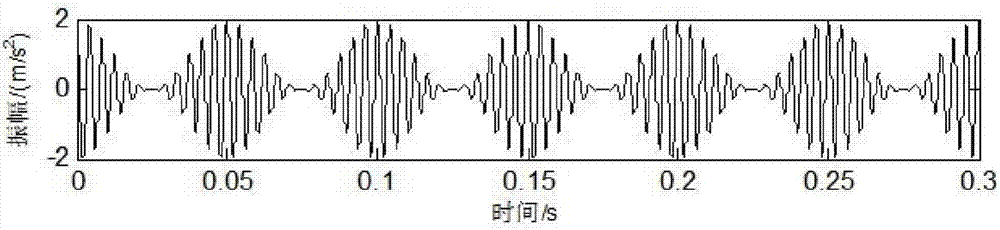

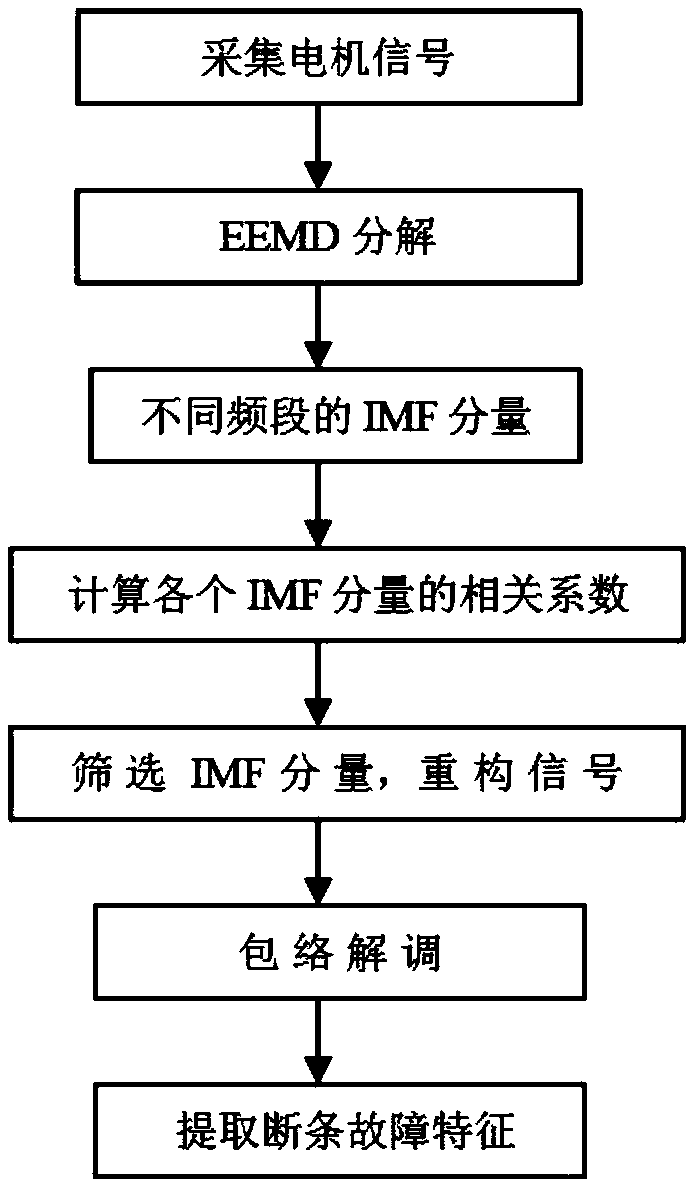

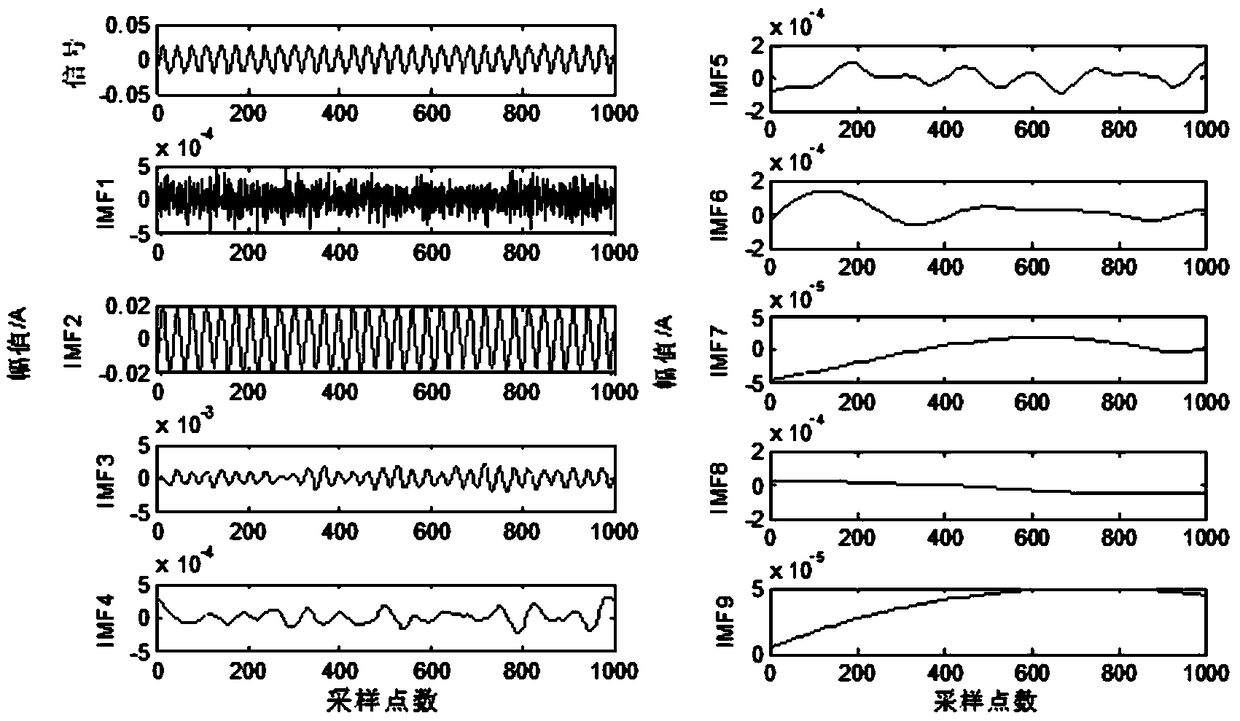

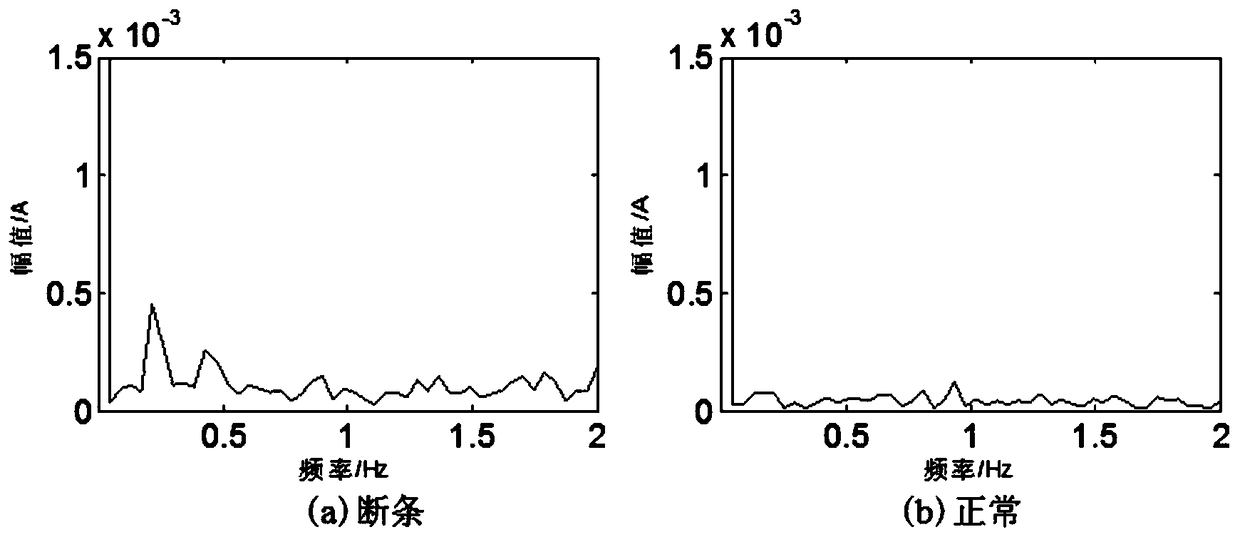

Ensemble empirical mode decomposition current diagnosis method for motor broken bar faults

InactiveCN108761332ASignificant features of broken barsDynamo-electric machine testingCorrelation coefficientSignal-to-noise ratio (imaging)

The invention discloses an ensemble empirical mode decomposition current diagnosis method for motor broken bar faults. According to the characteristics of the motor rotor broken bar faults, the advantages of EEMD decomposition and Hilbert demodulation are combined to adopt the EEMD analysis method with adaptivity and a high signal-to-noise ratio to perform self-adaption decomposition on a motor broken bar current signal in the no-load and load conditions of a motor. The whole frequency band is finely divided, and then an IMF component with a large correlation coefficient with an original signal is selected to reconstruct the signal. Hilbert envelope demodulation is performed on the reconstructed signal to extract fault characteristics related to the faults from the demodulation result of the current signal; and the fault characteristic information is highlighted and separated, so that the characteristics of the motor broken bar faults are more obvious in the current signal. A basis isprovided for current detection and diagnosis of the motor broken bar faults.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

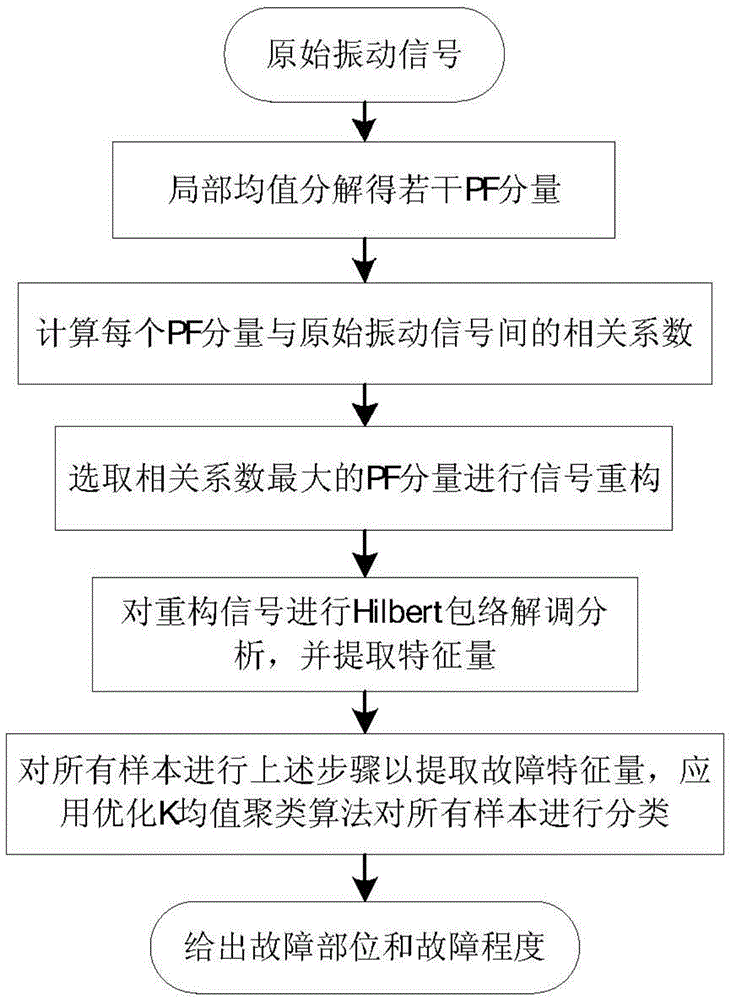

Fault diagnosis method for gear case of wind turbine generator system

InactiveCN104792520ACondition monitoringImprove signal-to-noise ratioMachine gearing/transmission testingCorrelation coefficientCluster algorithm

The invention provides a fault diagnosis method for a gear case of a wind turbine generator system. According to the fault diagnosis method based on LMD (local mean decomposition) and an optimized K mean value clustering algorithm, important factors such as non-stable characteristics, fault degree recognition and fault position diagnosis of vibration signals of the gear case of the wind turbine generator system are considered. The method includes collecting original vibration acceleration signals of measurement points of the gear case of the wind turbine generator system, decomposing the original vibration acceleration signals according to an LMD method into a plurality of PF (product function) components, selecting the PF components according to a principle that correlation coefficients are biggest to perform signal reconstruction, performing Hilbert envelope spectrum analysis on reconstructed signals to further extract fault characteristic quantity, and finally, classifying fault positions and fault degrees by the optimized K mean value clustering algorithm.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

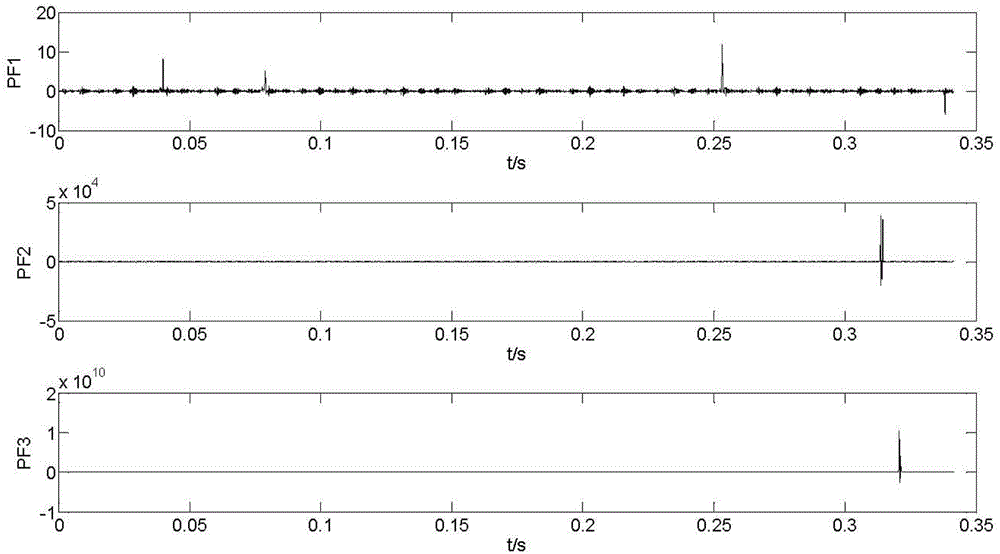

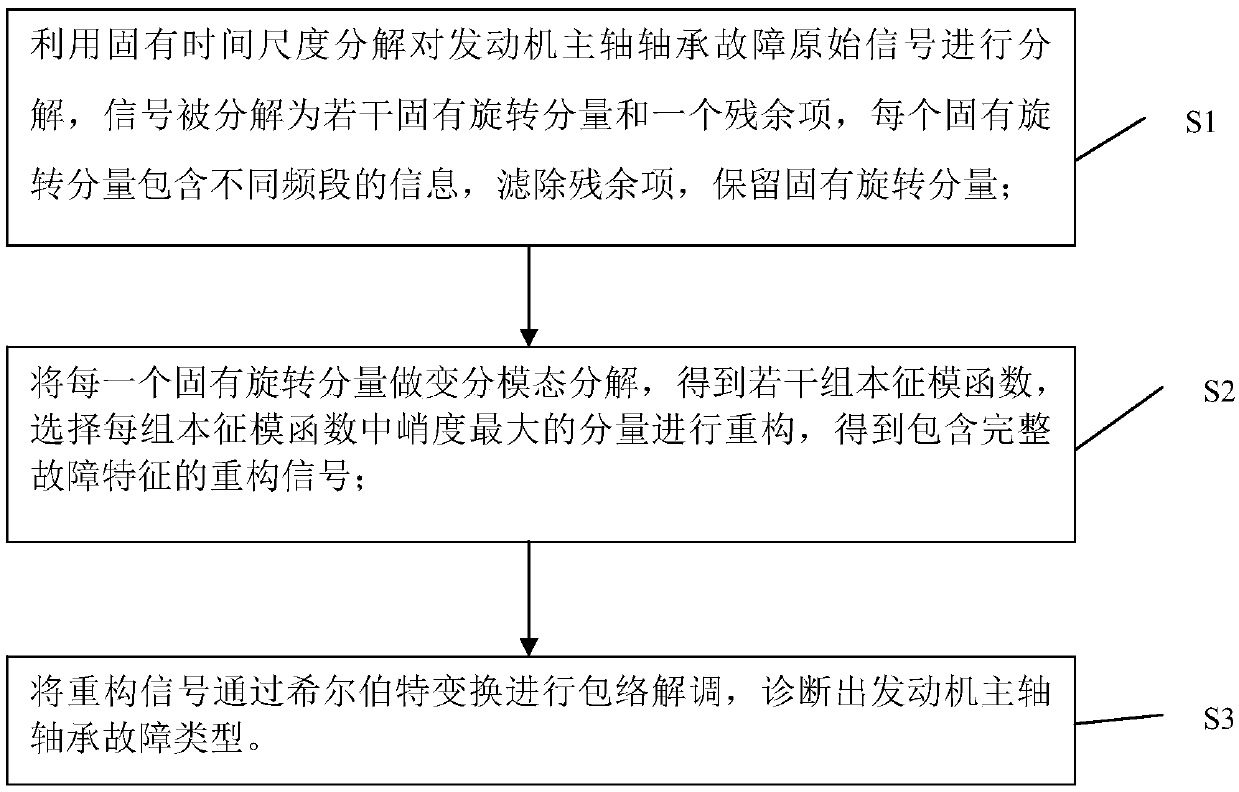

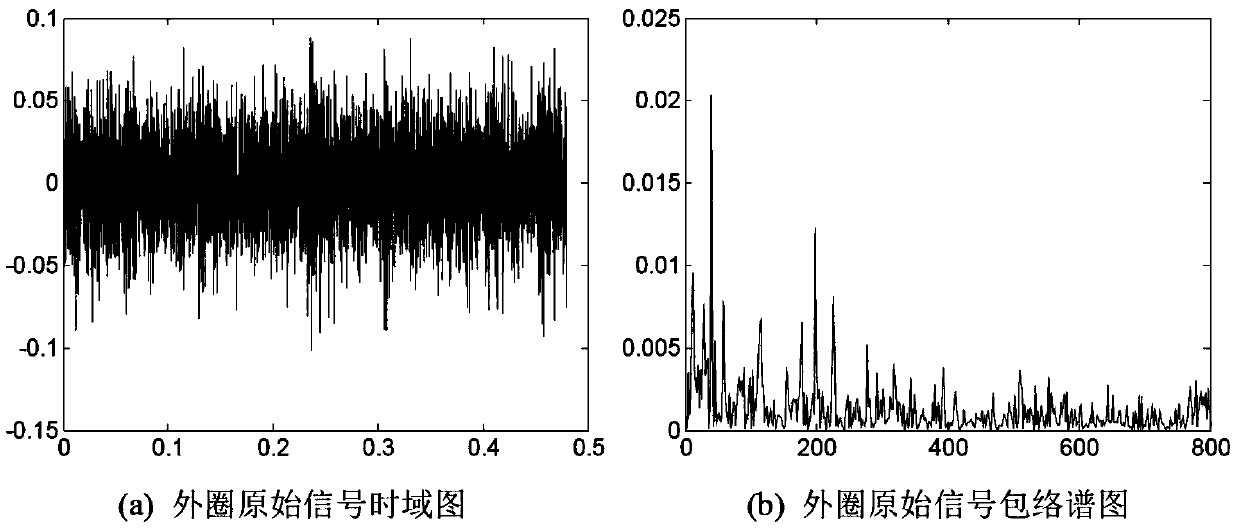

Improved variation mode decomposition diagnosis method for engine main shaft bearing fault diagnosis

InactiveCN109682600AEfficient separationImprove dismantling efficiencyMachine part testingSignal-to-noise ratio (imaging)Decomposition

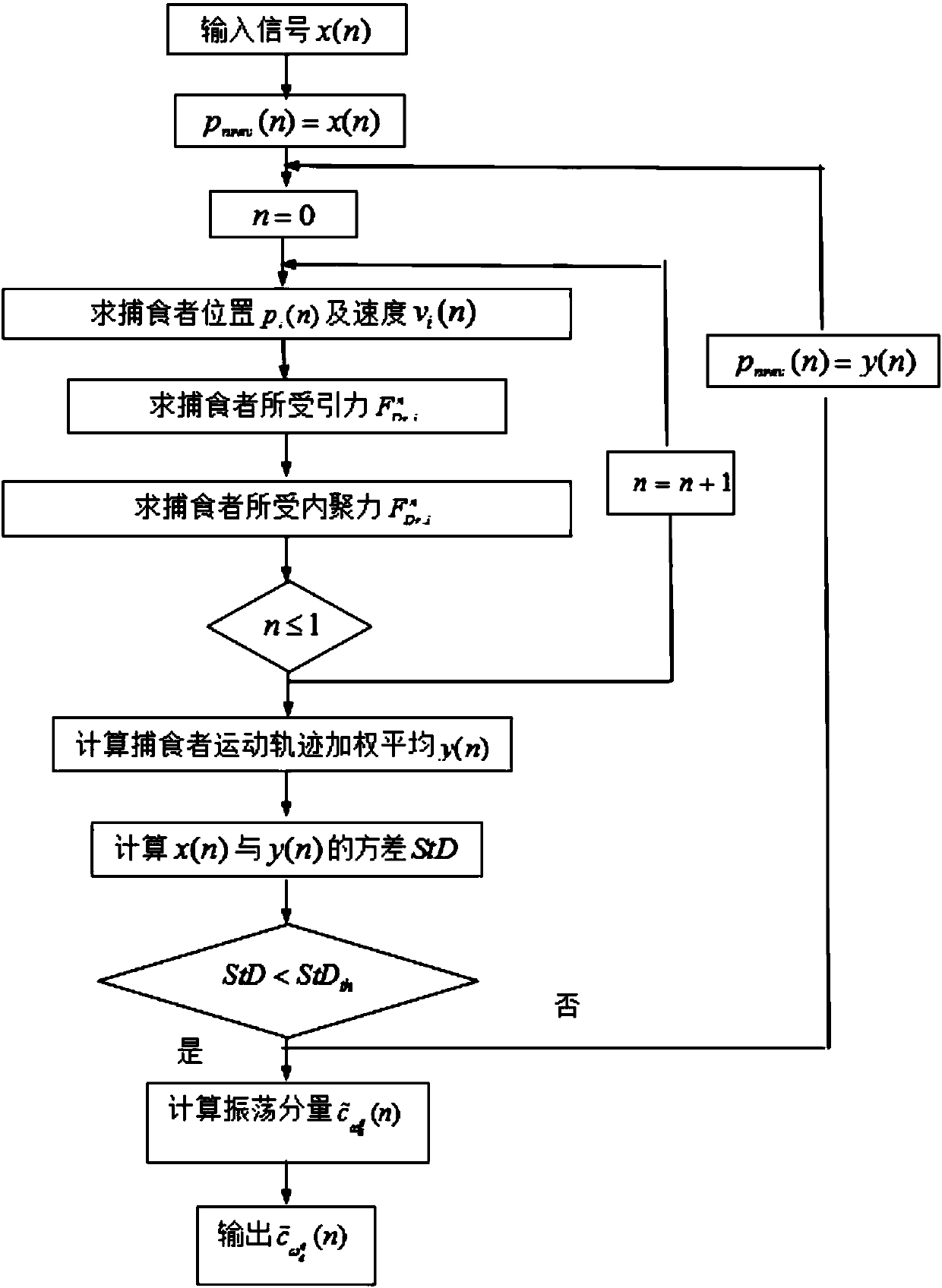

The invention discloses an improved variation mode decomposition diagnosis method for engine main shaft bearing fault diagnosis. Firstly, a fault original signal is input into inherent time scale decomposition, the signal is decomposed into a plurality of inherent rotation components and a residual term, the residual term is filtered out, and key components of the signal are completely retained while the original signal is denoised; secondly, each inherent rotation component is subjected to variation mode decomposition, the optimal component in each group of IMFs is selected according to the kurtosis principle, and the signal is reconstructed; finally, the reconstructed signal is subjected to hilbert envelope transformation to diagnose the fault types of bearings. According to the method,on the one hand, the signal is denoised by means of inherent time scale decomposition, and the signal-to-noise ratio is increased; on the other hand, each inherent rotation component is self-adaptively decomposed to be close to the respective center frequency by means of variable mode decomposition, and the optimal components are selected to reconstruct the signal. The method has good denoising capability, completely retains fault information, and has strong fault diagnosis advantages.

Owner:WENZHOU UNIVERSITY

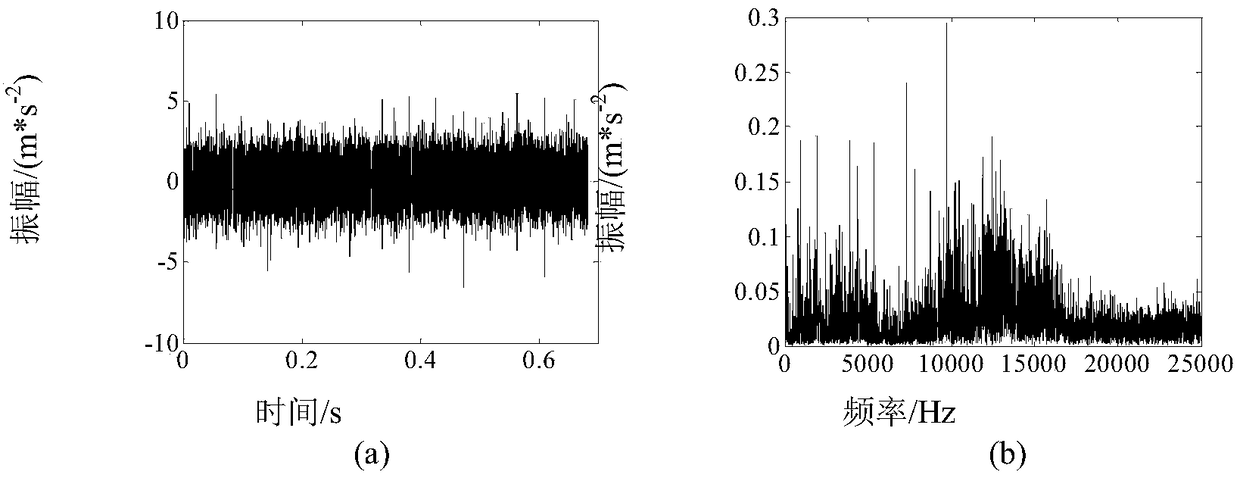

Fault diagnosis method for piston-type air compressor crankcase rolling bearing

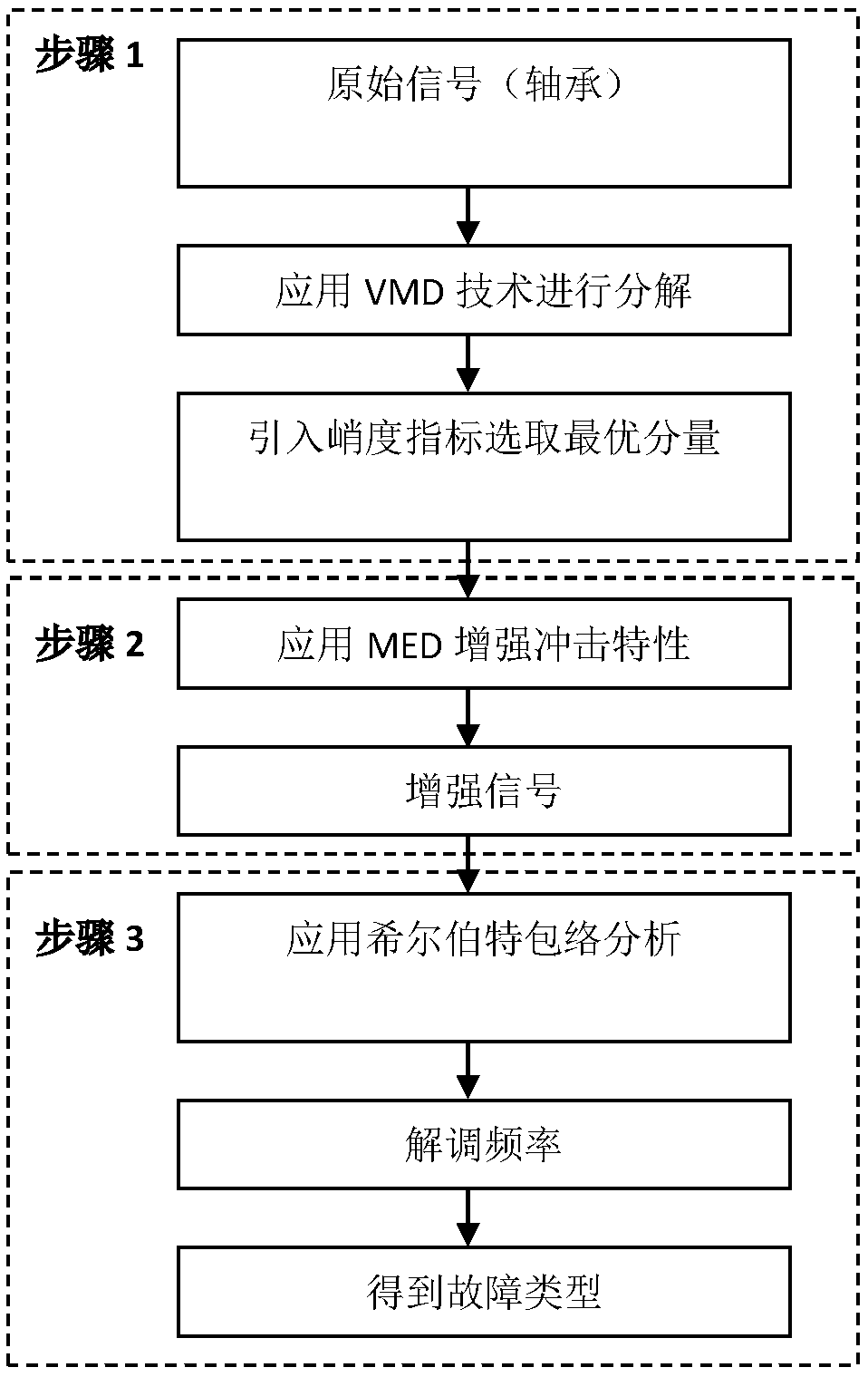

InactiveCN109187024AAccurate identificationImprove reliabilityMachine part testingDiagnosis methodsDecomposition

The invention discloses a fault diagnosis method for a piston-type air compressor crankcase rolling bearing, and belongs to the field of piston-type air compressor maintenance. The fault diagnosis method specifically comprises the steps that firstly, a variational mode decomposition (VMD) technology is adopted to decompose an original vibration signal of the piston-type air compressor rolling bearing, and mode components with the given number are obtained; then Kurtosis index is applied to all the mode components obtained by decomposition, thus respective Kurtosis values are obtained, the modecomponent corresponding to the maximum Kurtosis value is selected as the optimal component, and minimum entropy deconvolution (MED) is applied to the optimal component to enhance the periodic impactcharacteristics of fault excitation; and finally, Hilbert envelope analysis is used for demodulating the fault frequency of the enhanced signal, and a fault diagnosis result is obtained by comparing the fault frequency with a fault theoretical calculation frequency value. According to the fault diagnosis method for the piston-type air compressor crankcase rolling bearing, the fault type of the piston-type air compressor crankcase rolling bearing can be identified quickly and effectively, and the fault diagnosis method has the advantages of high reliability and good engineering feasibility.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

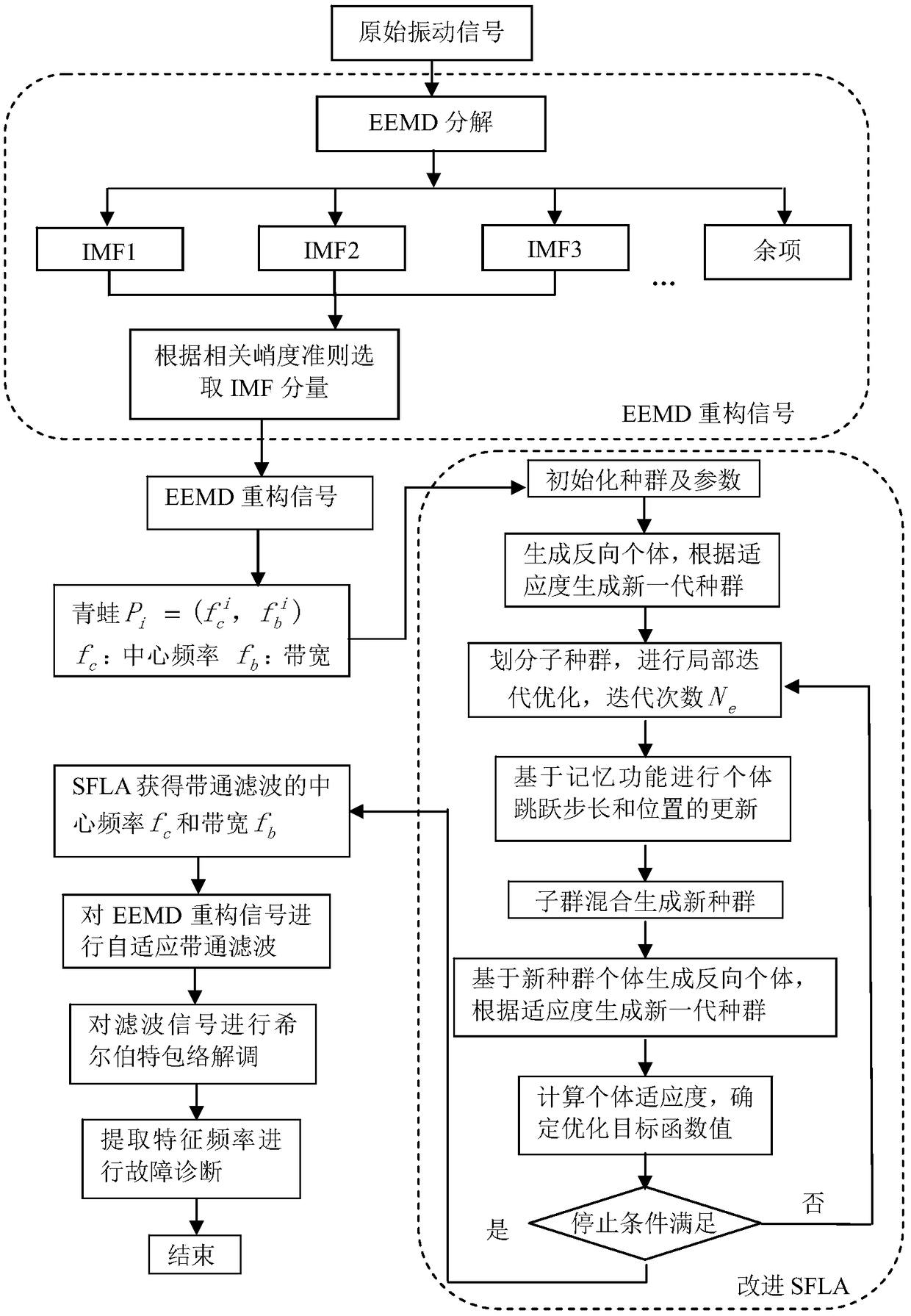

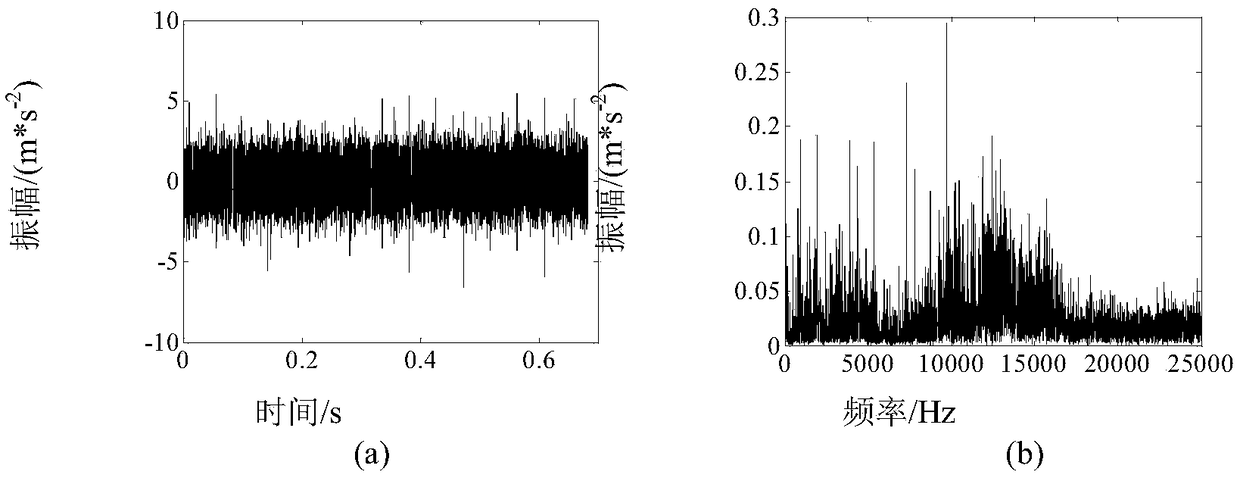

Modified shuffled frog-leaping algorithm enhanced self-adaption band-pass filtering method for fault diagnosis of screw compressor

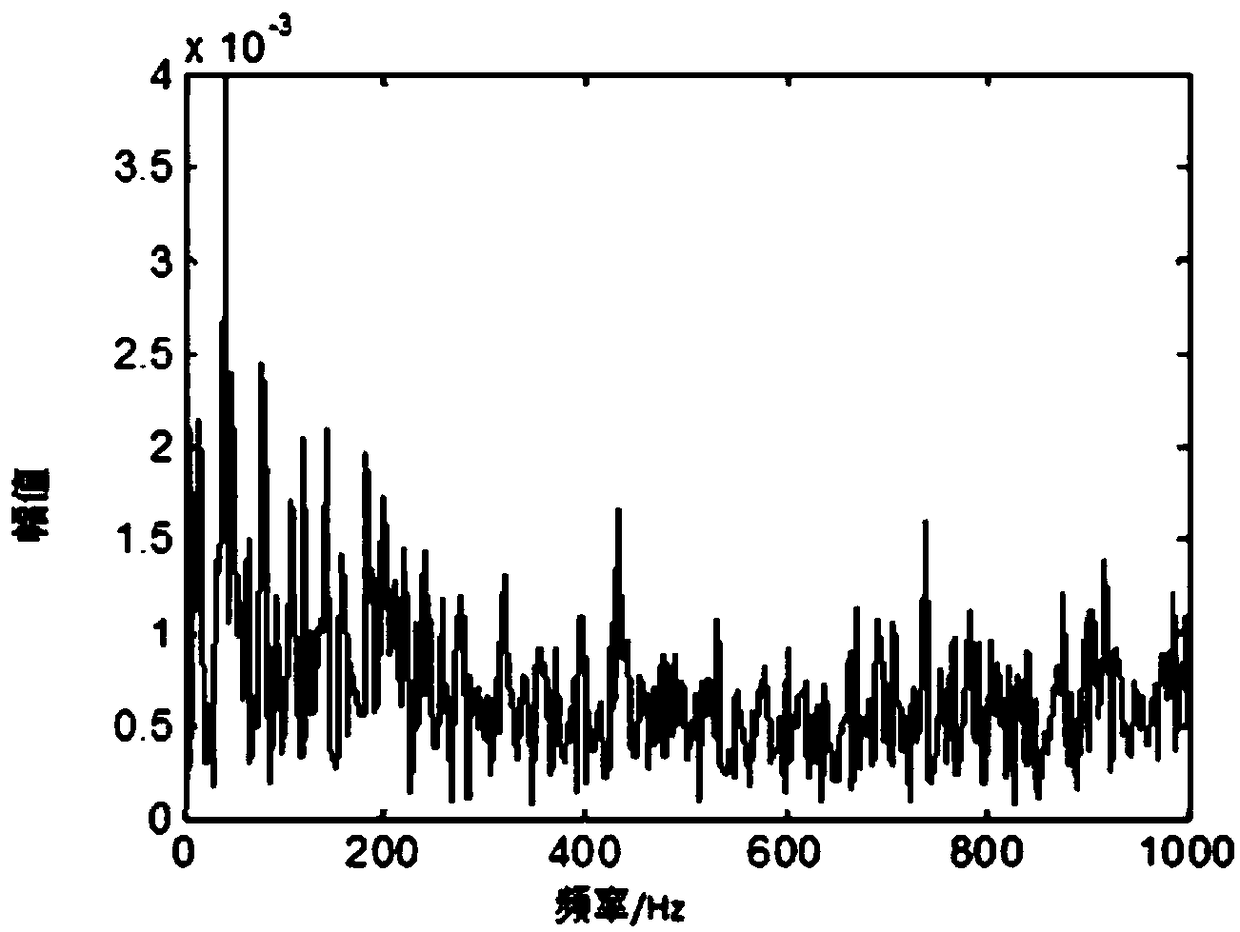

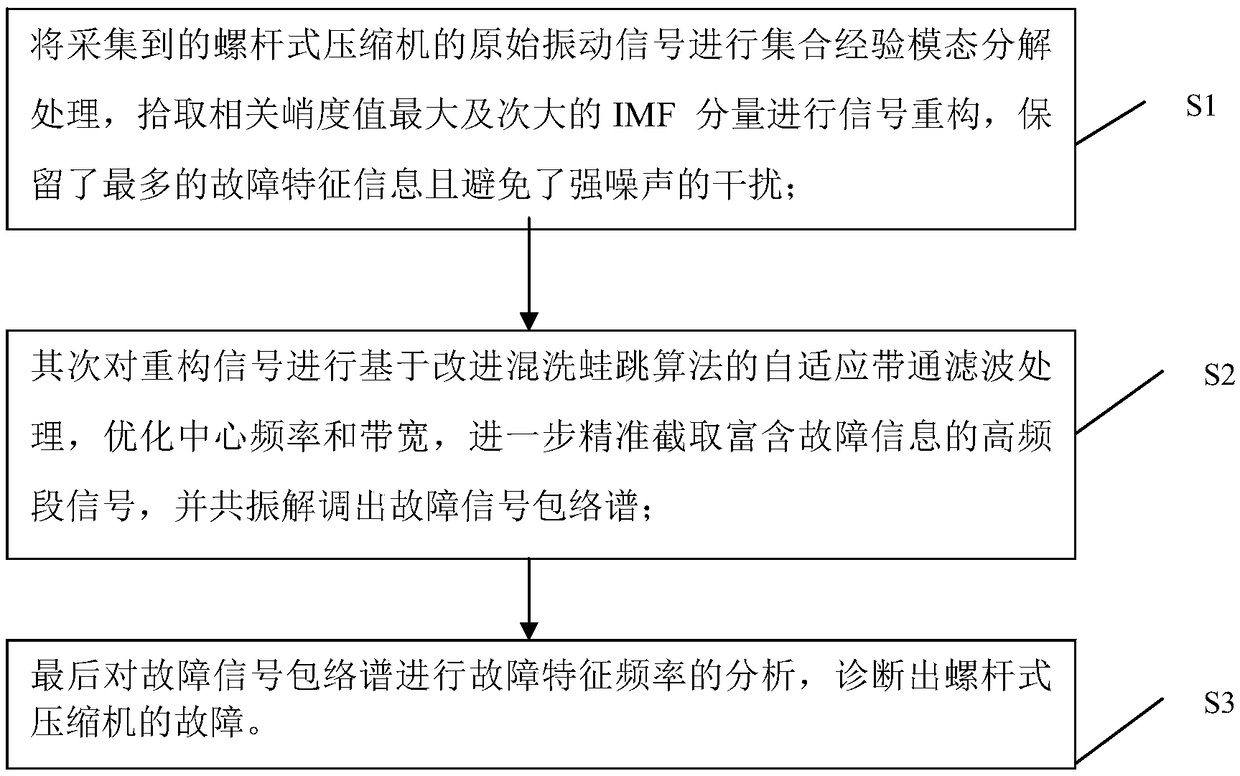

ActiveCN109404285AAvoid interferenceMultiple fault signature informationArtificial lifeMachines/enginesHilbert envelopeShuffled frog leaping algorithm

The invention discloses a modified shuffled frog-leaping algorithm enhanced self-adaption band-pass filtering method for fault diagnosis of a screw compressor. The method includes: 1) performing EEMDprocessing on a collected vibrating signal, calculating the relative kurtosis value of each IMF component, picking the maximum and sub-maximum components of the relative kurtosis value and performingsignal reconstruction; 2) performing modified SFLA-based self-adaption band-pass filtering processing on the reconstructed signal, and precisely cutting-out a high-frequency band signal being rich infault information; 3) performing Hilbert envelope demodulation analysis on the filtered signal, performing spectral analysis on the demodulated signal, and finally diagnosing the fault of the screw compressor. In the invention, firstly, by means of the relative kurtosis value, IMF component reconstruction is carried out to obtain new signals, so that the fault information is maintained as most aspossible and influence on feature extraction due to noise and false component is avoided; secondly, by means of a self-adaption band-pass filter enhanced by the modified SFLA, the reconstructed signalis subjected to the self-adaption band-pass filtering, so that central frequency and bandwidth of band-pass filtering are optimized, and precision of the fault diagnosis is increased.

Owner:WENZHOU UNIVERSITY

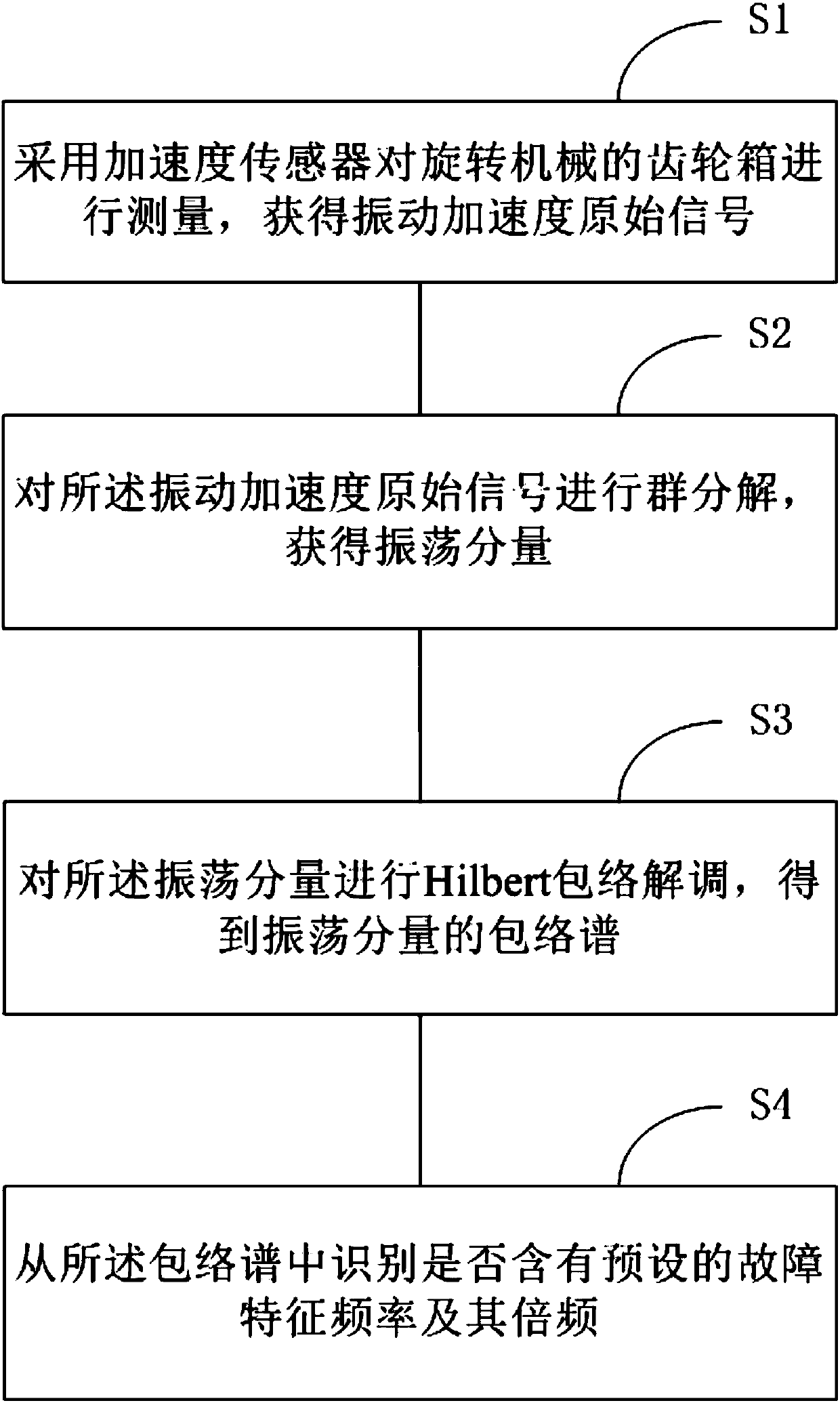

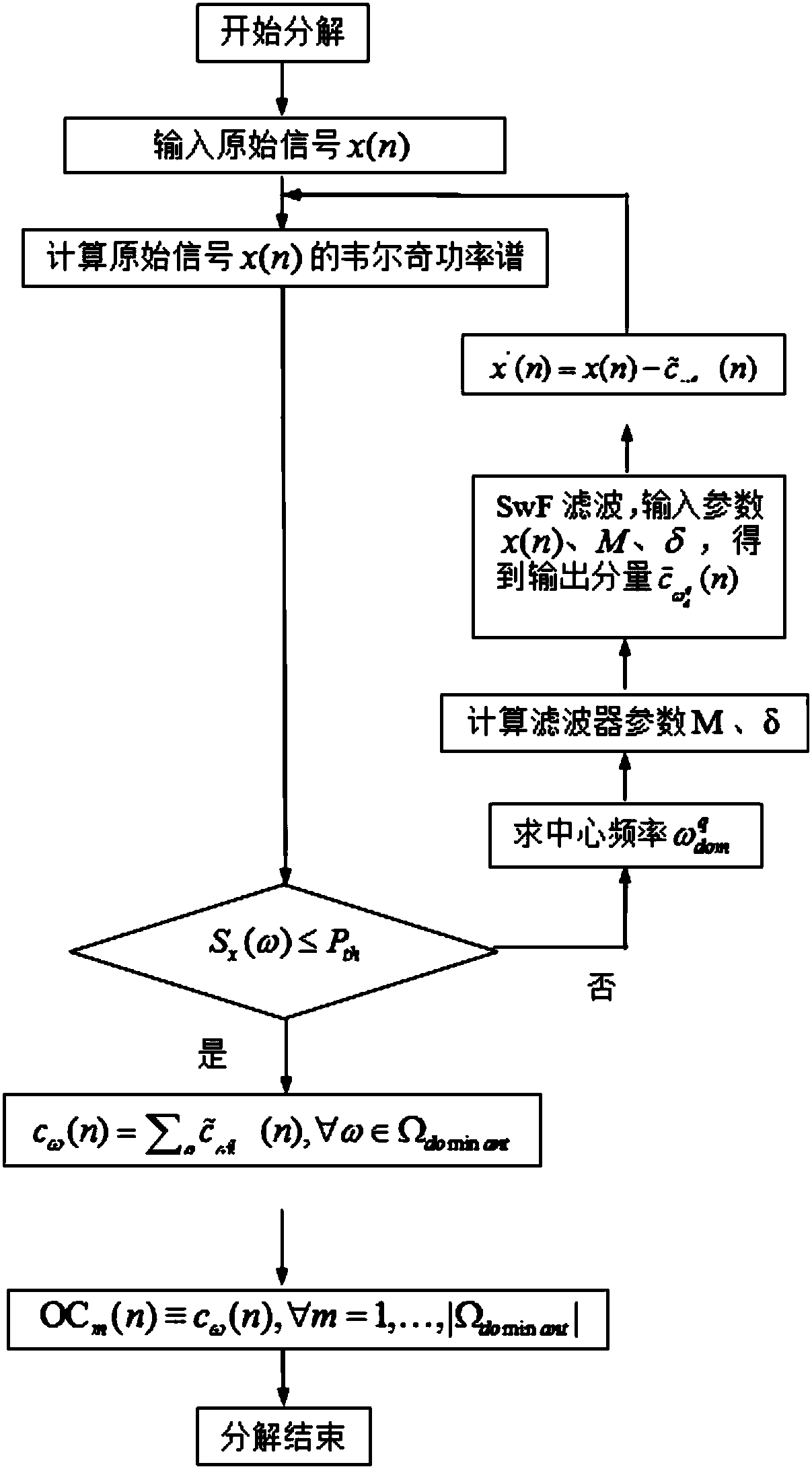

Rotary machine composite fault diagnosis method based on group decomposition

ActiveCN108507783AHigh frequency resolutionMachine gearing/transmission testingCharacter and pattern recognitionVibration accelerationDecomposition

The invention discloses a rotary machine composite fault diagnosis method based on group decomposition, comprising a step S1 of measuring the gear box of a rotary machine by using an acceleration sensor to obtain a vibration acceleration original signal x(n); a step S2 of subjecting the vibration acceleration original signal x(n) to group decomposition to obtain an oscillation component OCm(n); astep S3 of performing Hilbert envelope demodulation on the oscillation component OCm(n) to obtain an envelope spectrum Xocm(f) of the oscillation component Xocm(f); a step S4 of identifying whether apreset fault feature frequency and its multiplied frequency are included in the envelope spectrum Xocm(f). The method decomposes the vibration acceleration signal of the rotary machine by using the group decomposition method, adaptively decomposes a non-stationary multi-component vibration signal into a plurality of single-mode oscillation components with instantaneous frequencies having physicalsignificance, performs envelope demodulation on the oscillation components to obtain the component envelope spectrum, analyzes the envelope spectrum, determines the faulty parts and fault types, and accurately diagnose the faults.

Owner:HUNAN UNIV

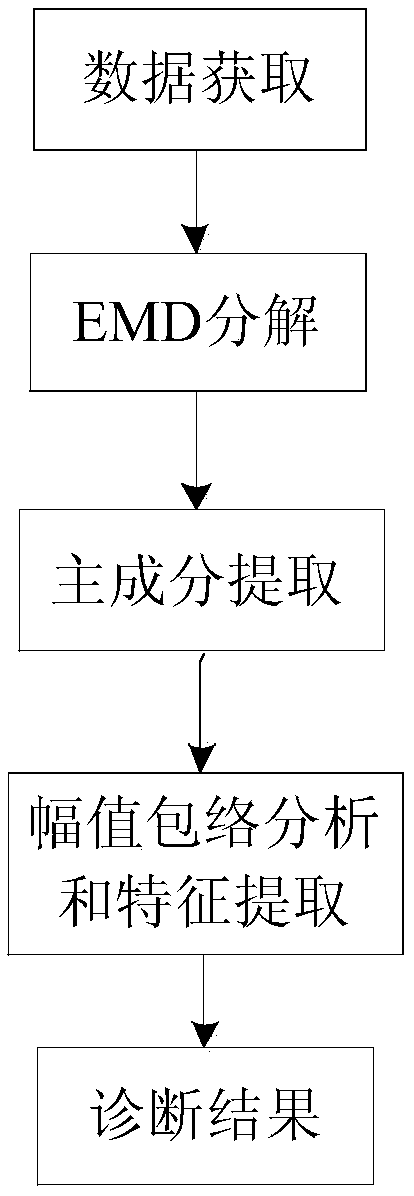

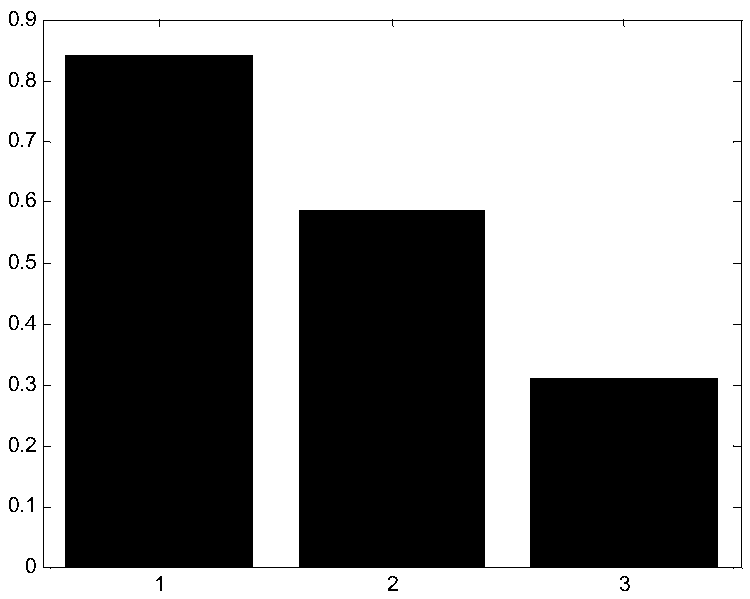

Wind turbine generator impeller imbalance monitoring method based on empirical mode decomposition

The invention discloses a wind turbine generator impeller imbalance monitoring method based on empirical mode decomposition (EMD). The wind turbine generator impeller imbalance monitoring method includes the following steps: 1) during a data collection process, collecting stator phase current iA and revolving speed r of a generator when the wind turbine generator is combined to the grid to generate electricity; 2) conducting EMD on the phase current iA collected and selecting the main component which contains fault features, namely, the first IMF component, which is marked as IMF (1); 3) conducting Hilbert envelope demodulation on the main component IMF (1) for extracting the fault features, and obtaining a spectrum signal if; and 4) extracting amplitude values Q1, Q2, and Q3 at 1, 2 and 3times operating frequencies of the rotating speed of the impeller from if, and if the three amplitude values are all higher than corresponding threshold values, then judging that an imbalance fault exists. According to the wind turbine generator impeller imbalance monitoring method, the degree of monitoring accuracy is improved and certain engineering application value is possessed in blade imbalance detection of double-fed generator units.

Owner:ZHEJIANG WINDEY

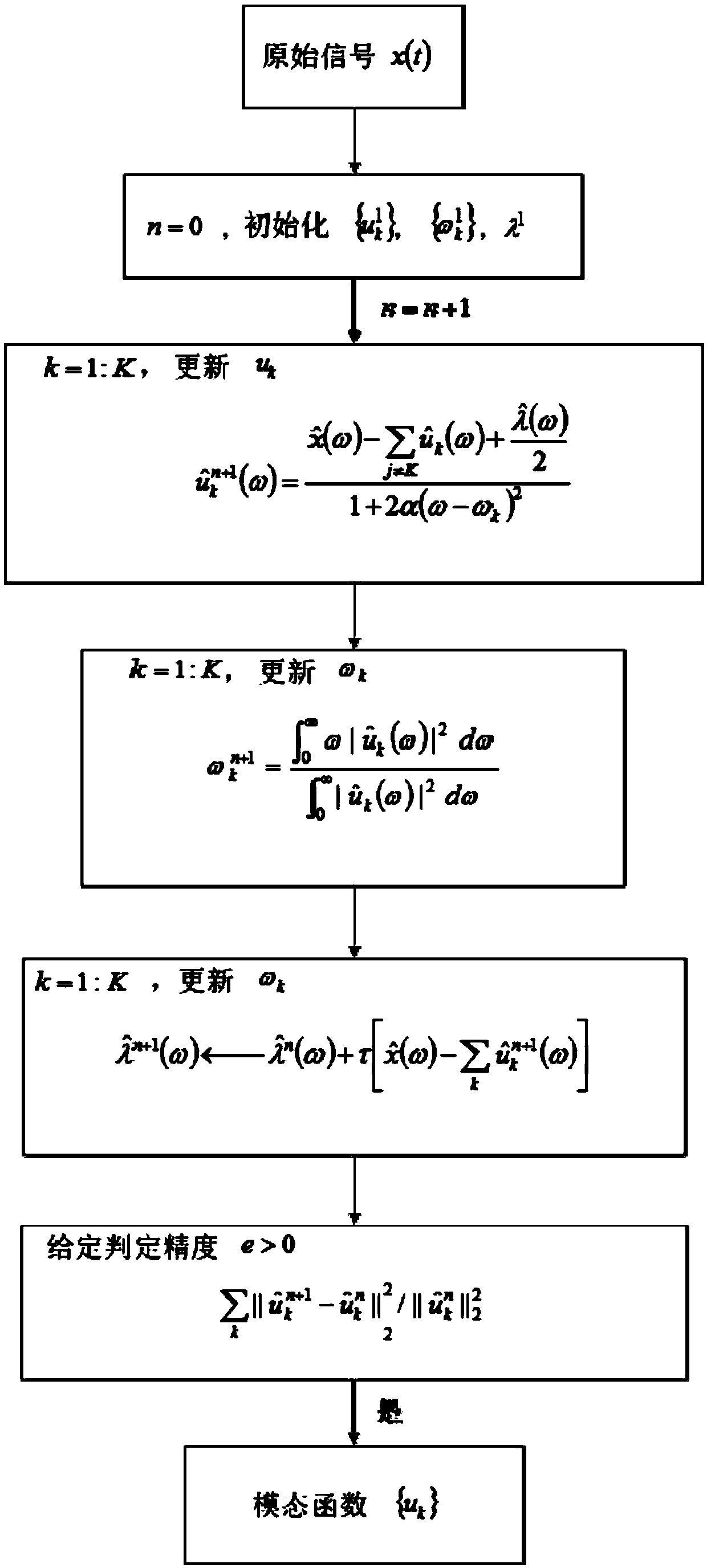

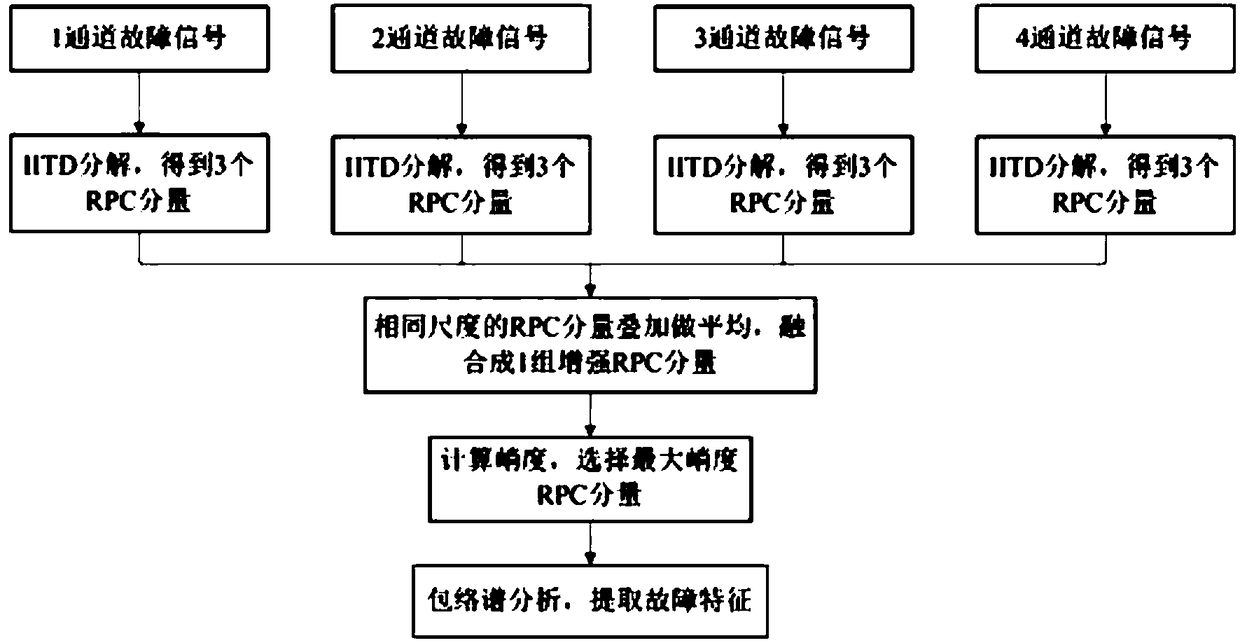

Fault diagnosis method for automobile generator bearing

ActiveCN109187023AFault foundFinding diagnostic faultsMachine part testingSustainable transportationSingular value decompositionEngineering

The invention belongs to the field of automobile maintenance, and relates to a fault diagnosis method for an automobile generator bearing. The fault diagnosis method comprises the steps that firstly,four channels of generator bearing fault signals are collected, and improved intrinsic time-scale decomposition (IITD) is used for decomposing each channel of original signals into proper rotation components (PRC) and a monotonous trend item; the PRCs are reconstructed into one set according to the decomposing scale, autocorrelation coefficients of all the reconstructed PRCs are calculated, the maximum correlation component is selected to construct a Hankel matrix and conduct enhanced multi-resolution singular value decomposition (MRSVD), and a corresponding approximate signal and a corresponding detail signal are obtained; and finally, the optimum precise component is selected to conduct Hilbert envelope transform, and the fault type is determined. On the one hand, by utilizing improved IITD and fusing the multi-channel signals, the signal-to-noise ratio is effectively increased, and noise is inhibited; and on the other hand, the signals are further refined and purified through enhanced MRSVD, accurate fault information is obtained, and the bearing fault type is determined through Hilbert envelope demodulation.

Owner:河南富双实业有限公司

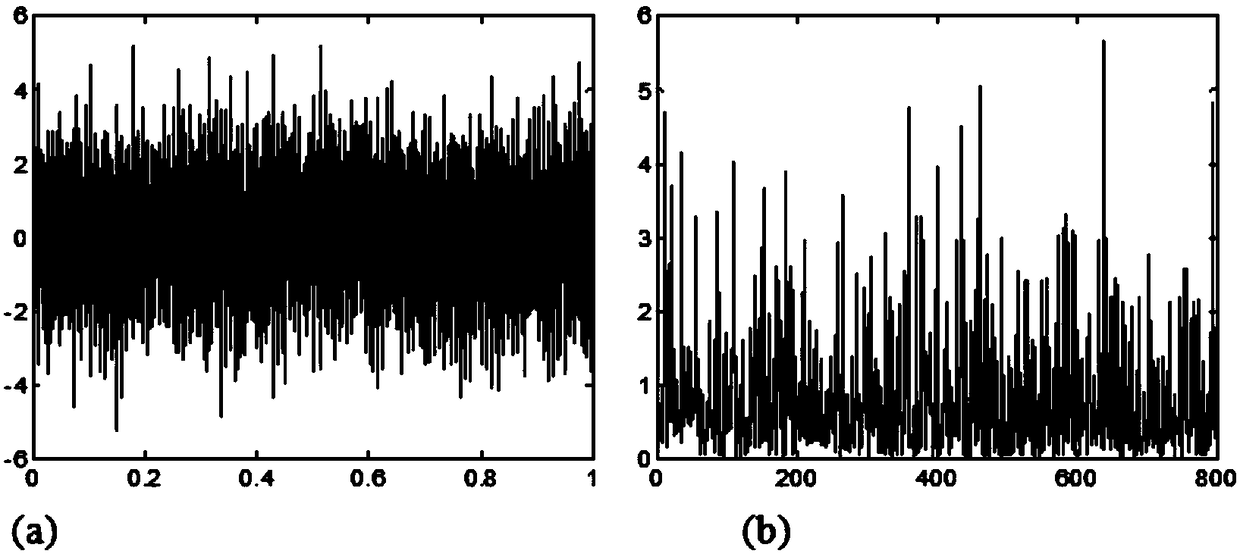

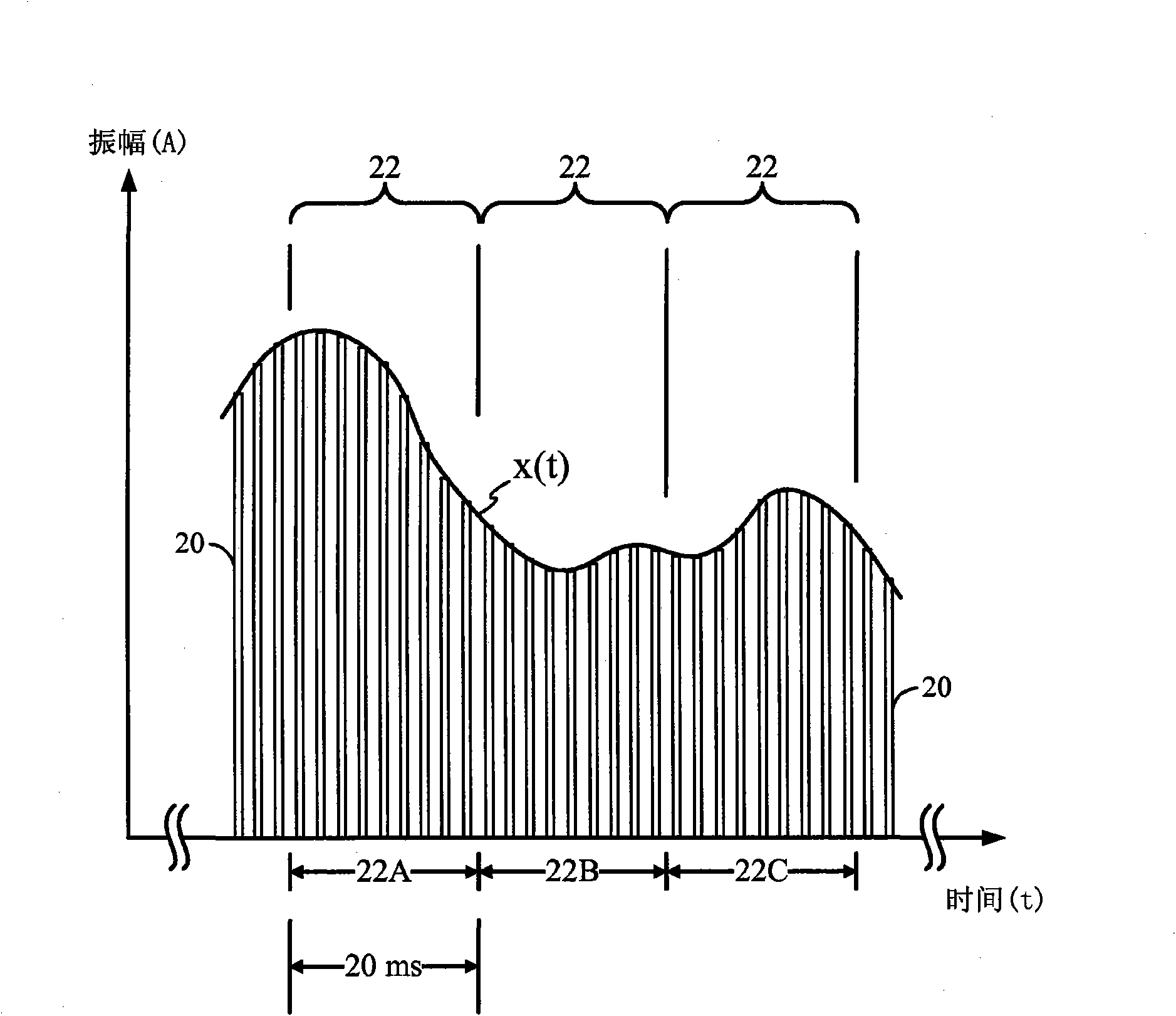

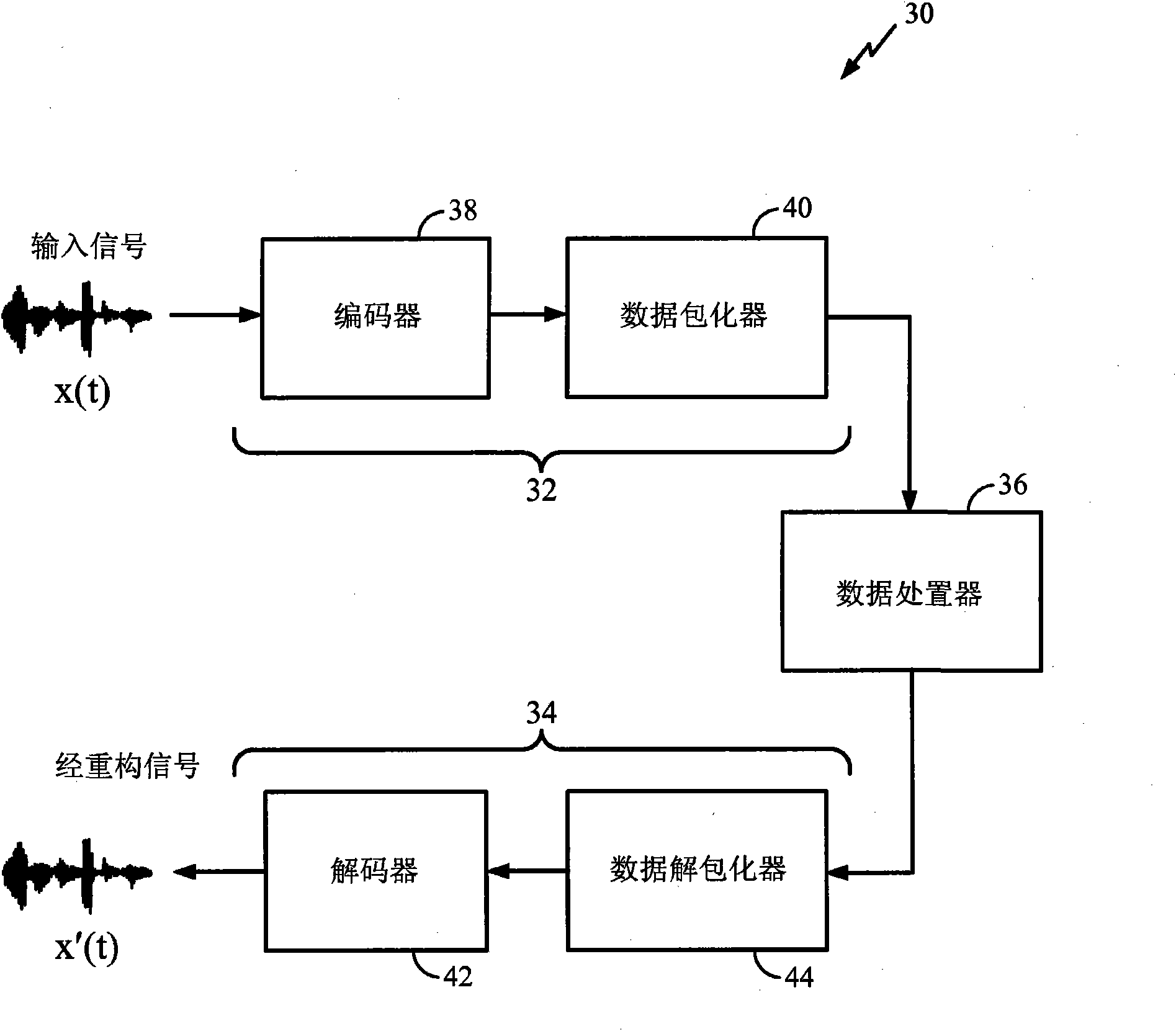

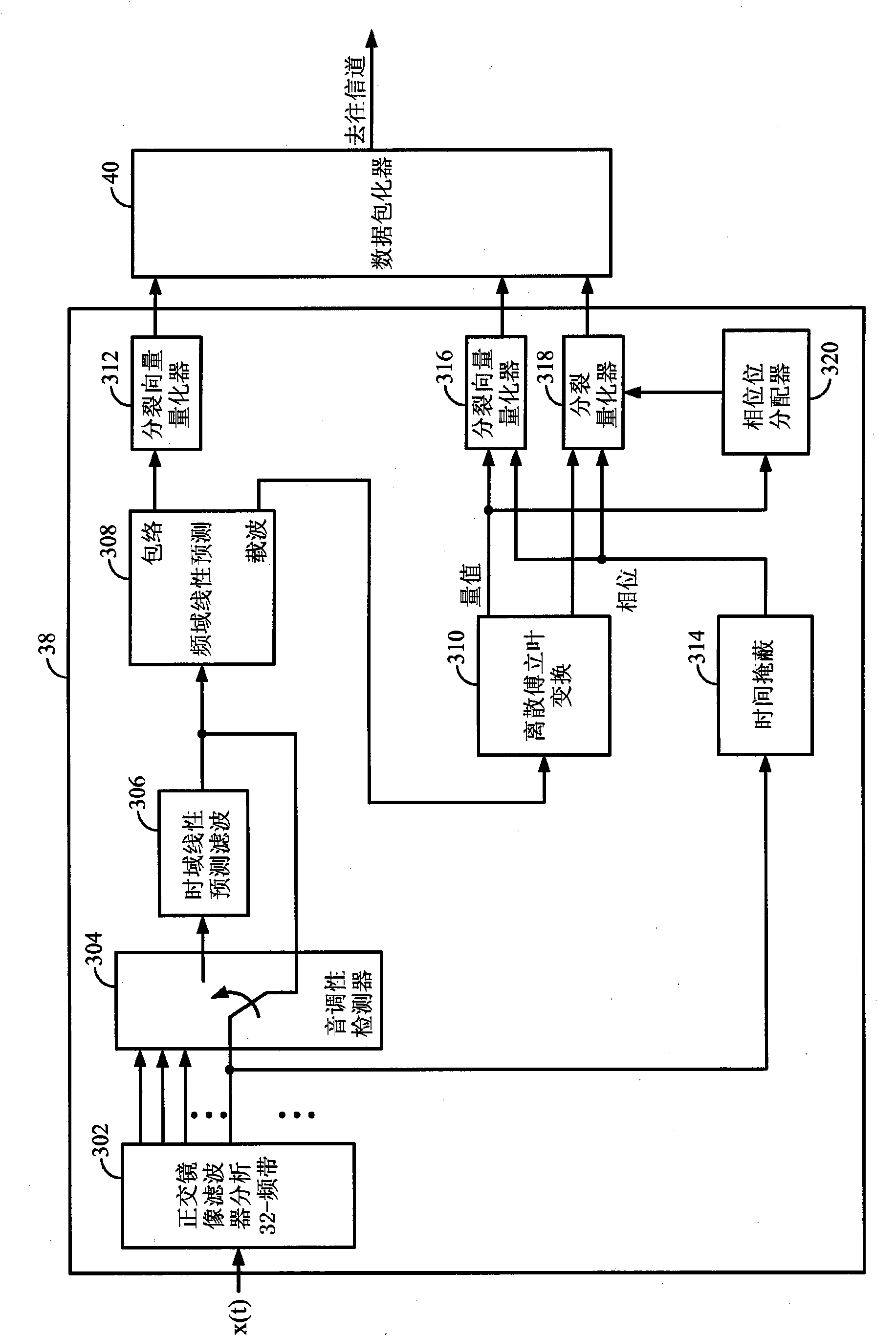

Temporal masking in audio coding based on spectral dynamics in frequency sub-bands

An audio coding technique based on modeling spectral dynamics is disclosed. Frequency decomposition of an input audio signal is performed to obtain multiple frequency sub-bands that closely follow critical bands of human auditory system decomposition. Each sub-band is then frequency transformed and linear prediction is applied. This results in a Hilbert envelope and a Hilbert Carrier for each of the sub-bands. Because of application of linear prediction to frequency components, the technique is called Frequency Domain Linear Prediction (FDLP). The Hilbert envelope and the Hilbert Carrier are analogous to spectral envelope and excitation signals in the Time Domain Linear Prediction (TDLP) techniques. Temporal masking is applied to the FDLP sub-bands to improve the compression efficiency. Specifically, forward masking of the sub-band FDLP carrier signal can be employed to improve compression efficiency of an encoded signal.

Owner:QUALCOMM INC

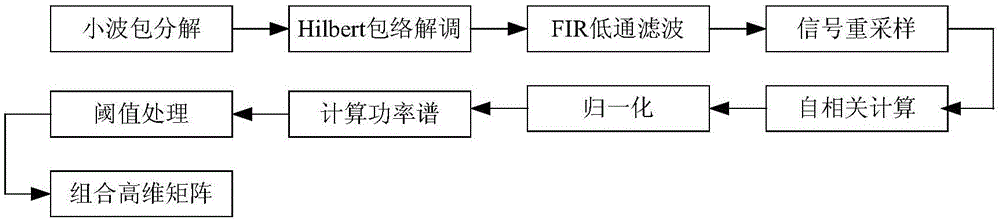

Wavelet packet frequency domain signal manifold studying failure diagnosis method

ActiveCN105973584AShorten the lengthEliminate high frequency noiseMachine part testingCharacter and pattern recognitionTime domainDecomposition

The invention relates to a wavelet packet frequency domain signal manifold studying failure diagnosis method which comprises the steps of acquiring vibration data on rotating mechanical equipment, performing N-layer wavelet packet decomposition on the acquired vibration data for obtaining 2N component time domain signals; performing Hilbert envelope demodulation on each component time domain signal generated through decomposition, and extracting a modulation signal; performing FIR filtering on a demodulation signal; performing resampling on each component time domain signal in a low sampling frequency for reducing data length; performing autocorrelation calculation on the layered resampled data and performing normalization for forming an autocorrelation coefficient; calculating the power spectrum of the autocorrelation coefficient after normalization of each component, performing threshold processing on power spectrum data by means of a preset threshold, forming high-dimension data vector from the power spectrum data after threshold processing; performing dimension reduction on the high-dimension data vector, combining the component power spectrum data for forming an L*2N-dimensional matrix, finally forming a two-dimensional or three-dimensional manifold, and determining the fault state of the rotating mechanical equipment through a manifold result.

Owner:北京科信机电技术研究所有限公司

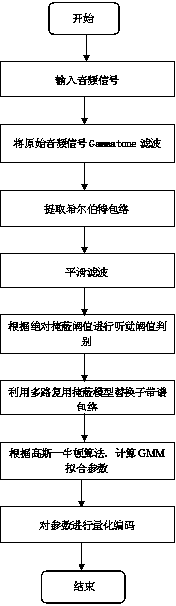

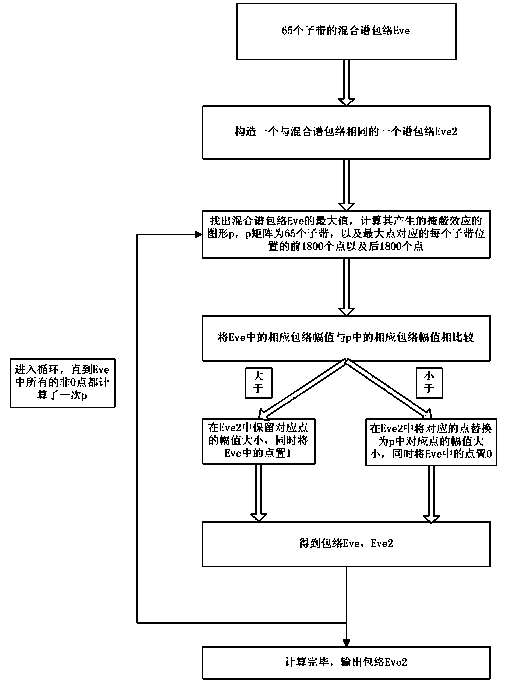

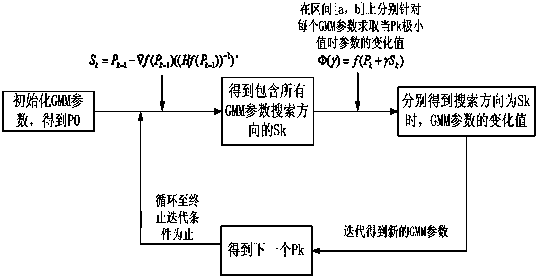

Perception domain audio encoding method and system based on Gaussian mixed model

The invention discloses a perception domain audio encoding method and system based on a Gaussian mixed model. The perception domain audio encoding method includes the steps of (1) filtering an input audio signal through an auditory filter to obtain a sub-band signal, (2) extracting a Hilbert envelope of the sub-band signal, and carrying out smooth filtering on the Hilbert envelope to obtain a sub-band signal spectrum envelope, (3) obtaining an absolute masking threshold of the sub-band signal spectrum envelope through a psychoacoustics model, and carrying out auditory threshold judgment on the sub-band signal spectrum envelope according to the absolute masking threshold, (4) replacing the sub-band signal spectrum envelope with a multiplexing masking model, (5) carrying out Gaussian mixed model parameter fitting on the sub-band signal spectrum envelope through the Gaussian-Newton algorithm, and (6) quantizing and encoding fitted Gaussian mixed model parameters. The perception domain audio encoding method and system can be applied to high-quality medium-low code rate voice encoding, and the encoding rate can be greatly lowered.

Owner:WUHAN UNIV

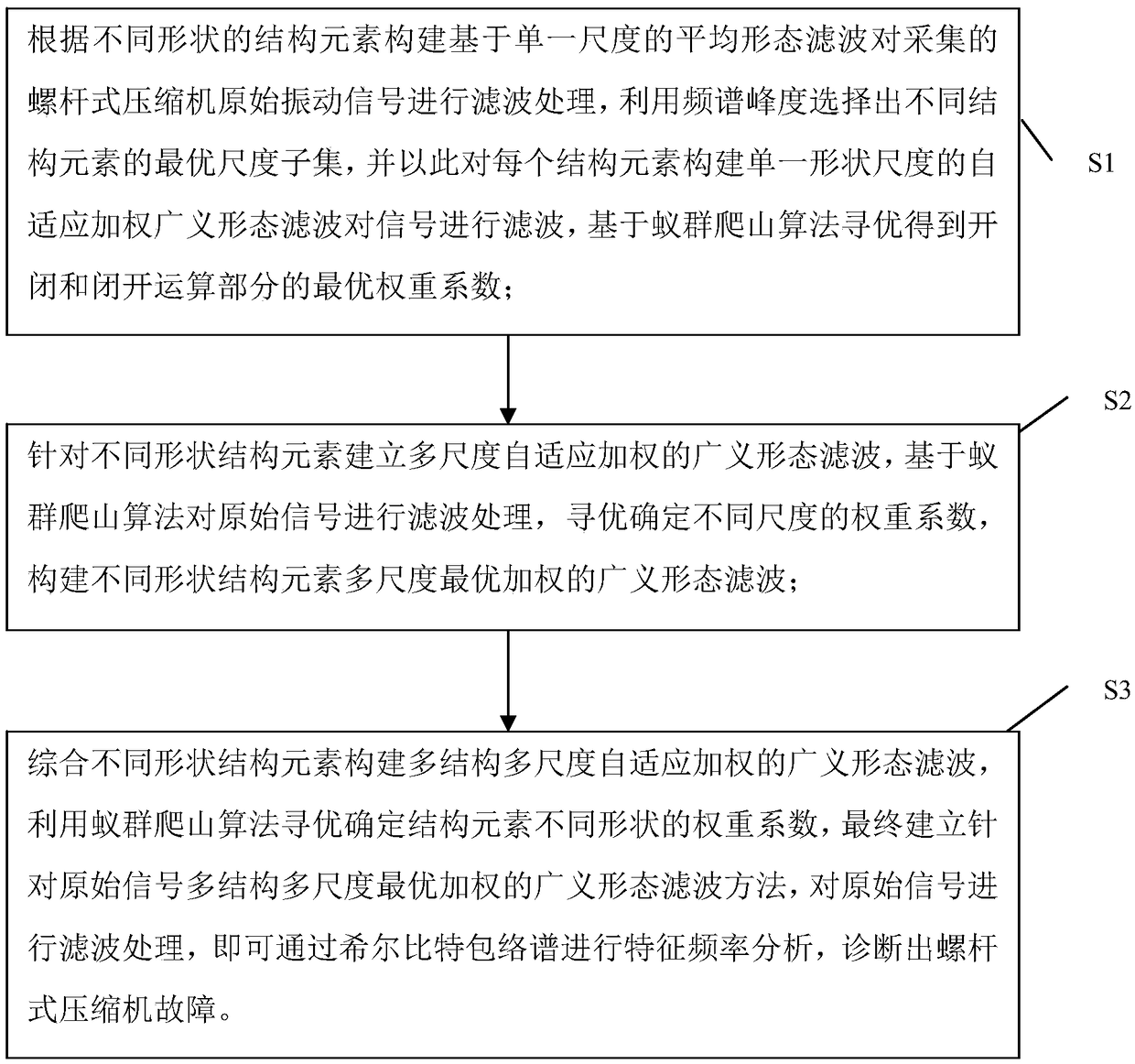

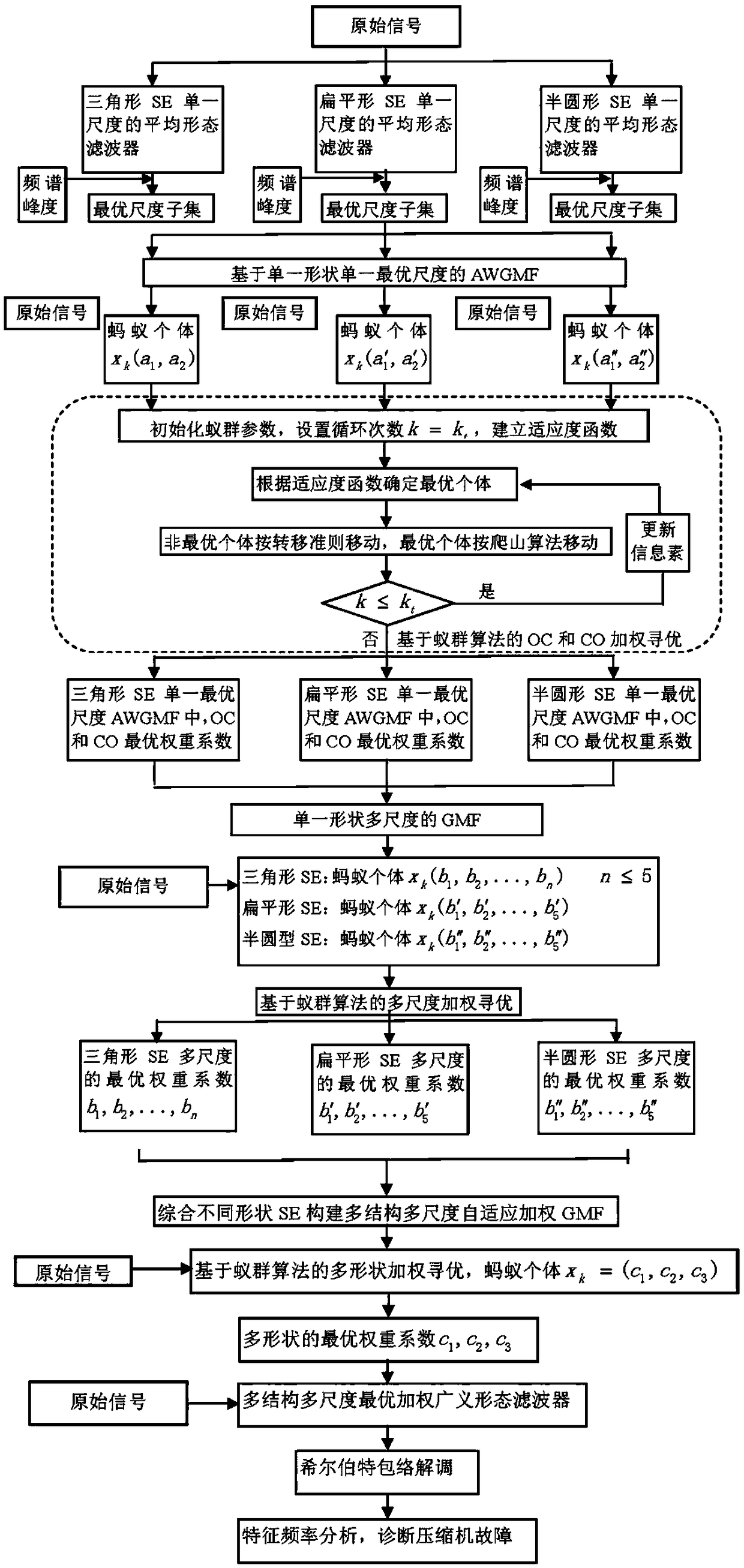

Multi-scale self-adaptive weighted generalized morphological filtering method for screw-type compressor fault diagnosis

ActiveCN109441822ADiagnosisEasy extractionArtificial lifeMachines/enginesPattern recognitionFrequency spectrum

The invention provides a multi-scale self-adaptive weighted generalized morphological filtering method for screw-type compressor fault diagnosis. The technical scheme adopted by the method comprises the following steps that based on morphological filtering processing of a compressor vibration signal, firstly, the optimal scale subset of SEs in different shapes is determined; secondly, self-adaptive weighting is carried out on scale elements basing on the optimal scale subset of the SEs in the different shapes, and an ant colony hill-climbing algorithm is used for determining the optimal weight; then, based on the optimal scale subset and the optimal weight coefficient of the scale elements, the self-adaptive weighting of shapes is carried out through combining the SEs in the different shapes, and the ant colony hill-climbing algorithm is used for determining the optimal weight; finally, based on the optimal weights of the scales and the shapes, the multi-structure and multi-scale optimal weighted morphological filtering processing is carried out on an original signal, the spectral analysis is carried out on the Hilbert envelope demodulation of a filtering signal, and finally the fault of the compressor is diagnosed. According to the method, noise can be effectively eliminated, and fault feature information can be extracted.

Owner:WENZHOU UNIVERSITY

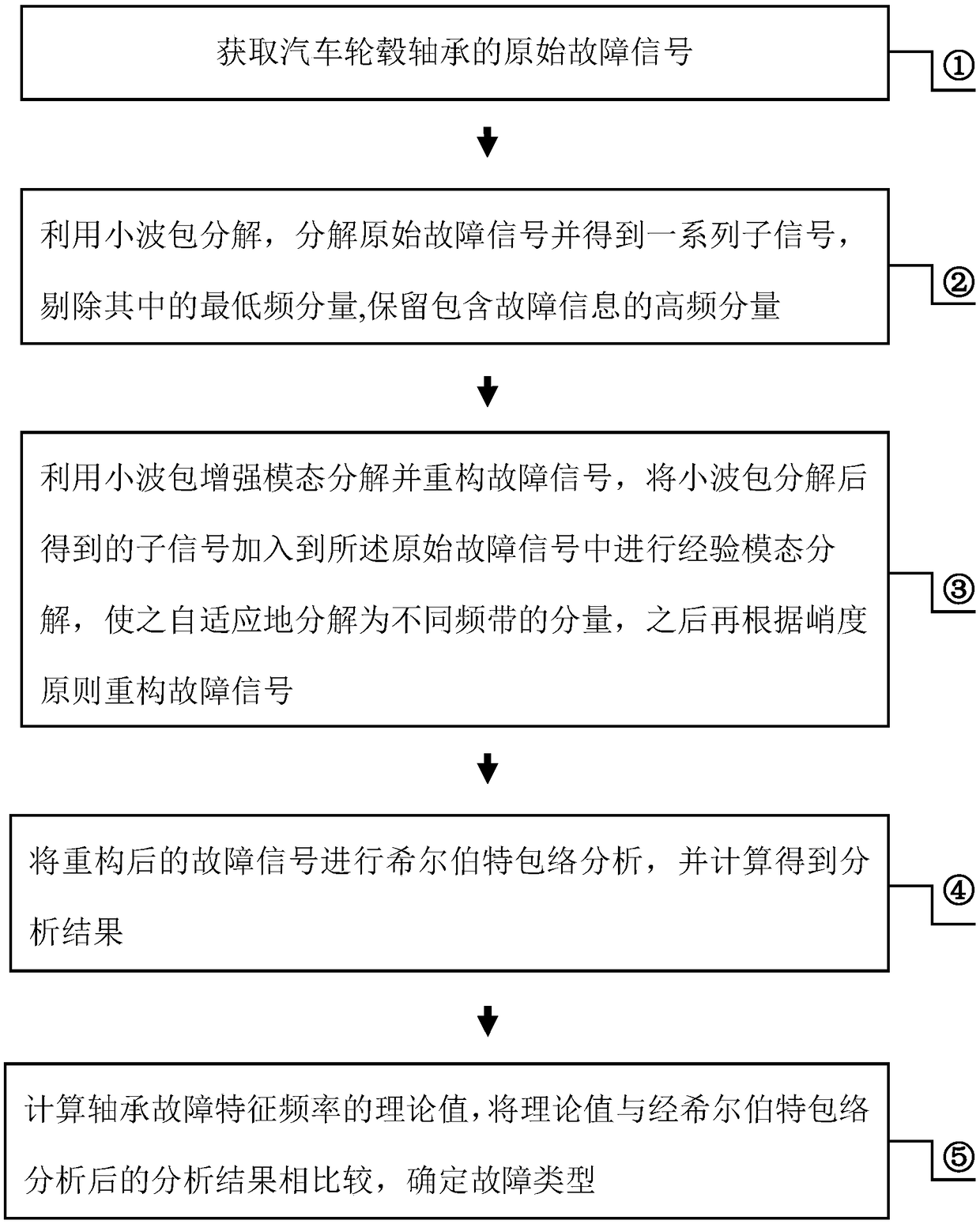

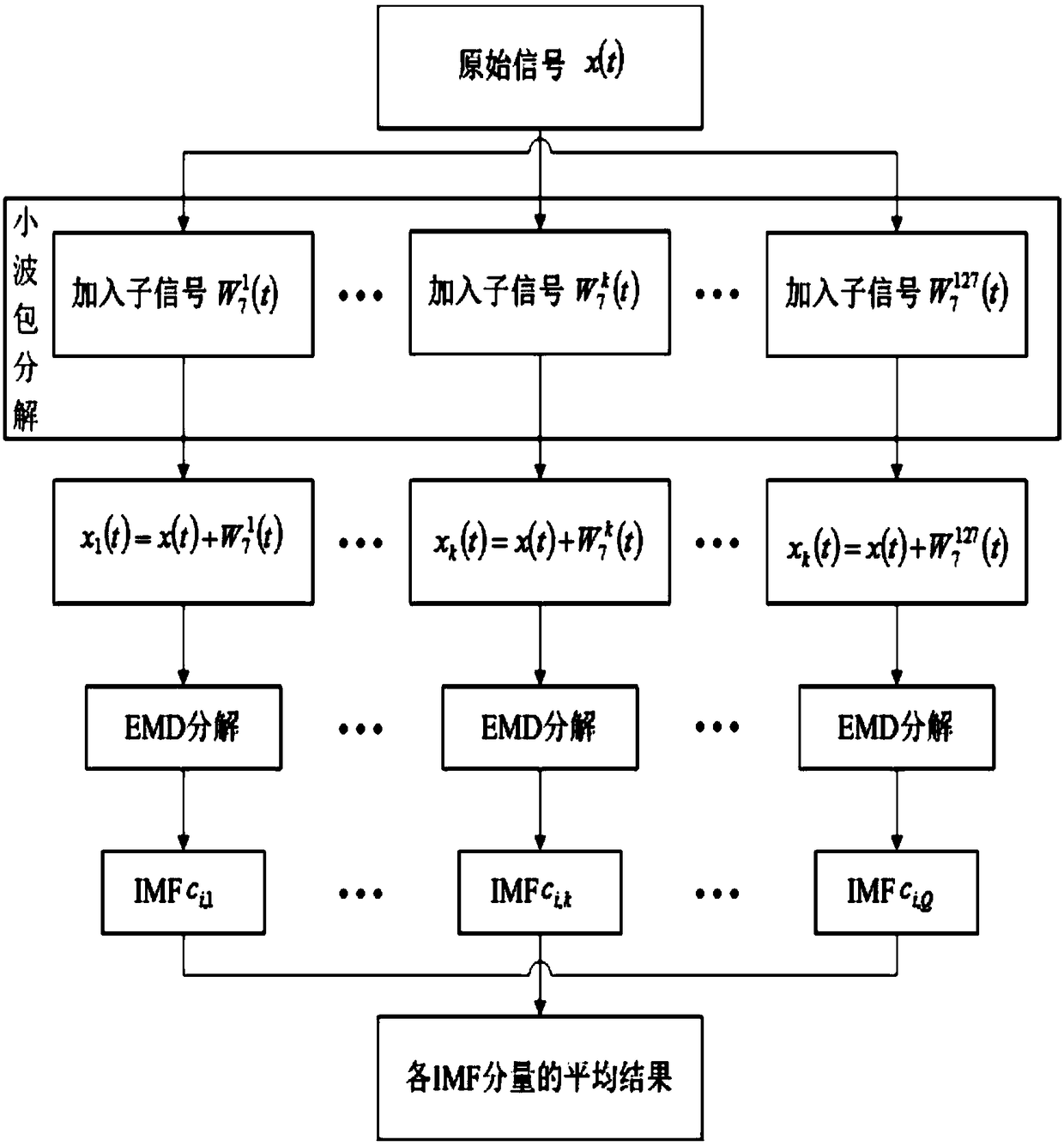

Hub bearing fault diagnosis method

The invention belongs to the field of automobile maintenance and relates to a wavelet packet enhanced EMD (Empirical Mode Decomposition) hub bearing fault diagnosis method. The method comprises the steps of firstly decomposing original signals by using wavelet packet decomposition to obtain sub-signals, and filtering away lowest frequency components in the sub-signals to reserve rest high-frequency components; adding the series of sub-signals to the original signals to enable the sub-signals to be distributed in the whole time-frequency space of the signals uniformly; then further decomposingthe mixed signals into multiple intrinsic mode functions by utilizing wavelet packet enhanced EMD and extracting components including high-fault characteristic information for reconstruction; and finally performing Hilbert envelope analysis on the reconstructed signals and diagnosing the bearing fault type. According to the wavelet packet enhanced EMD hub bearing fault diagnosis method, the original signals are subjected to fine decomposition and noise elimination by utilizing the wavelet packet decomposition and the signal-to-noise ratio is improved efficiently; the signals are further decomposed into local characteristic signals with different time scales by utilizing wavelet packet enhanced EMD, and the bearing fault type can be detected intuitively through envelope demodulation.

Owner:温州大学苍南研究院

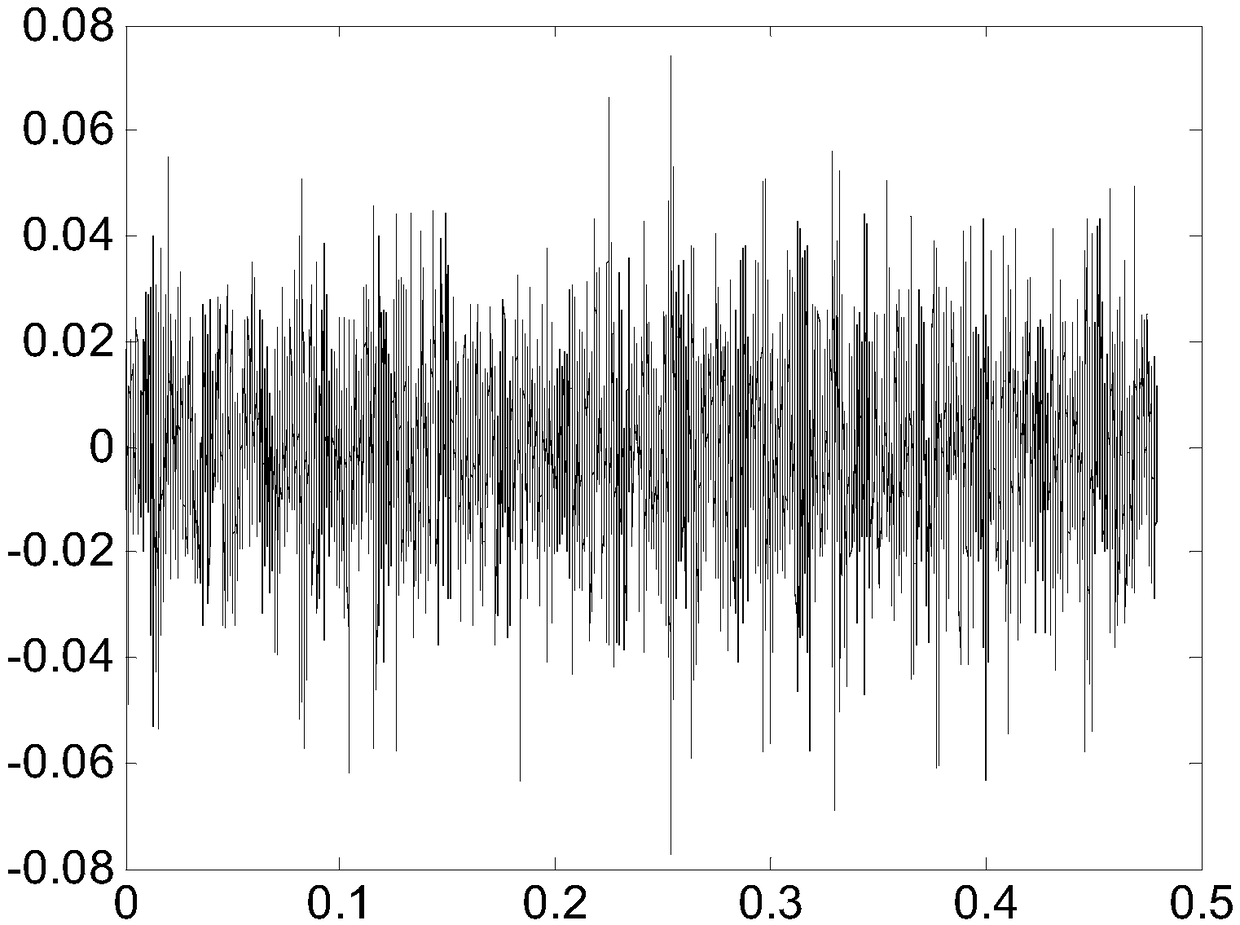

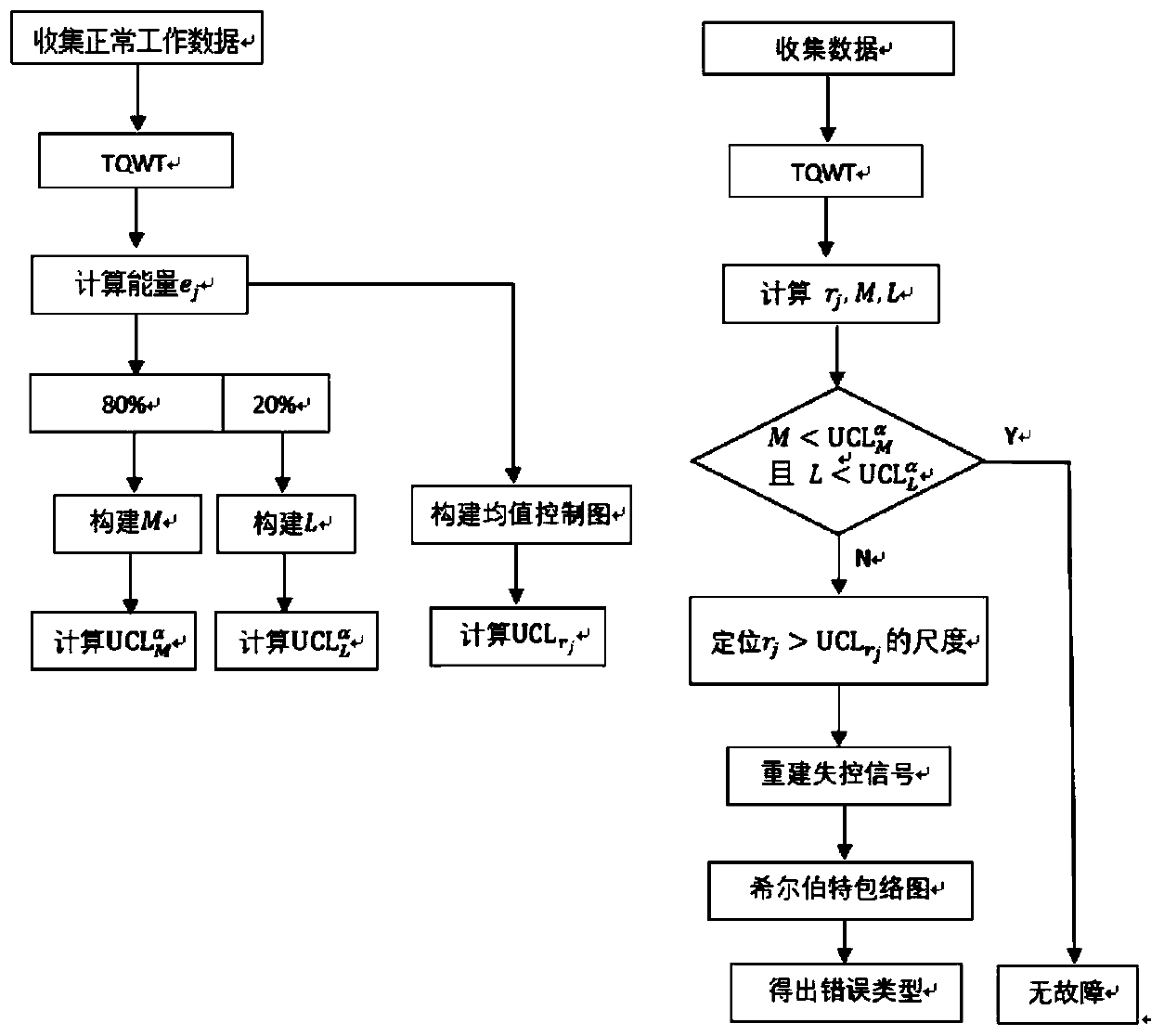

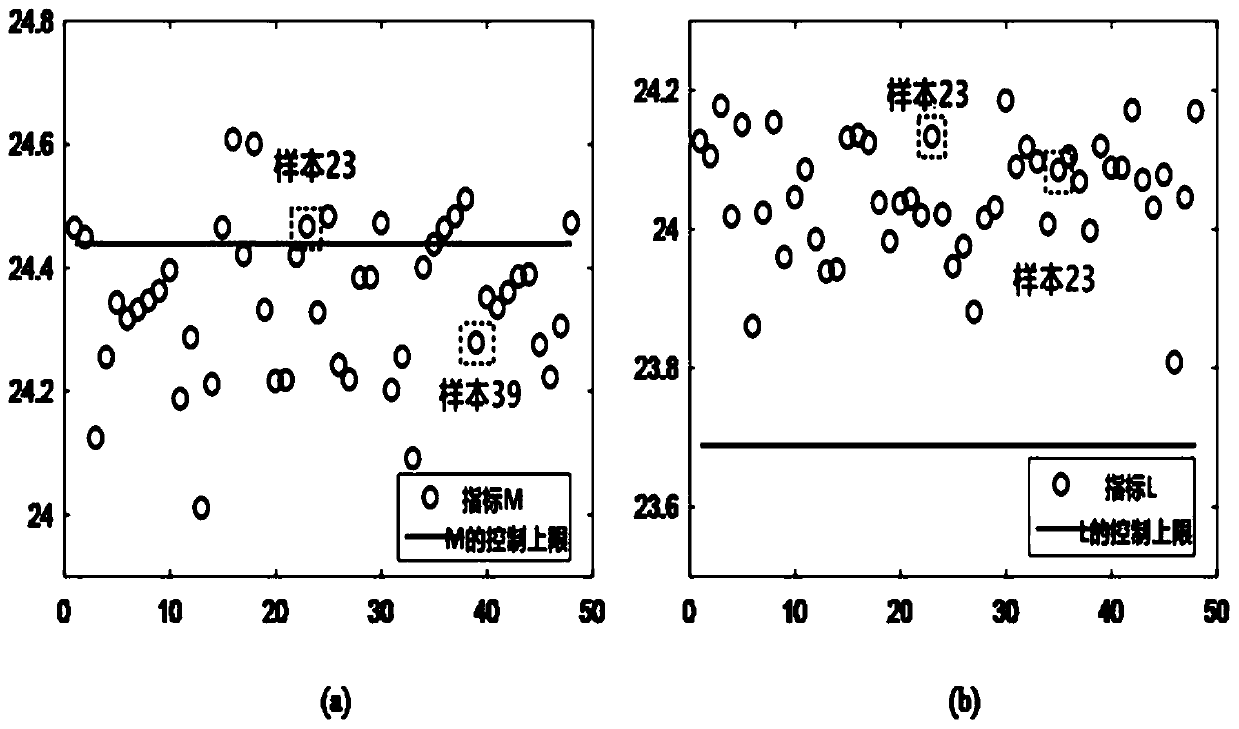

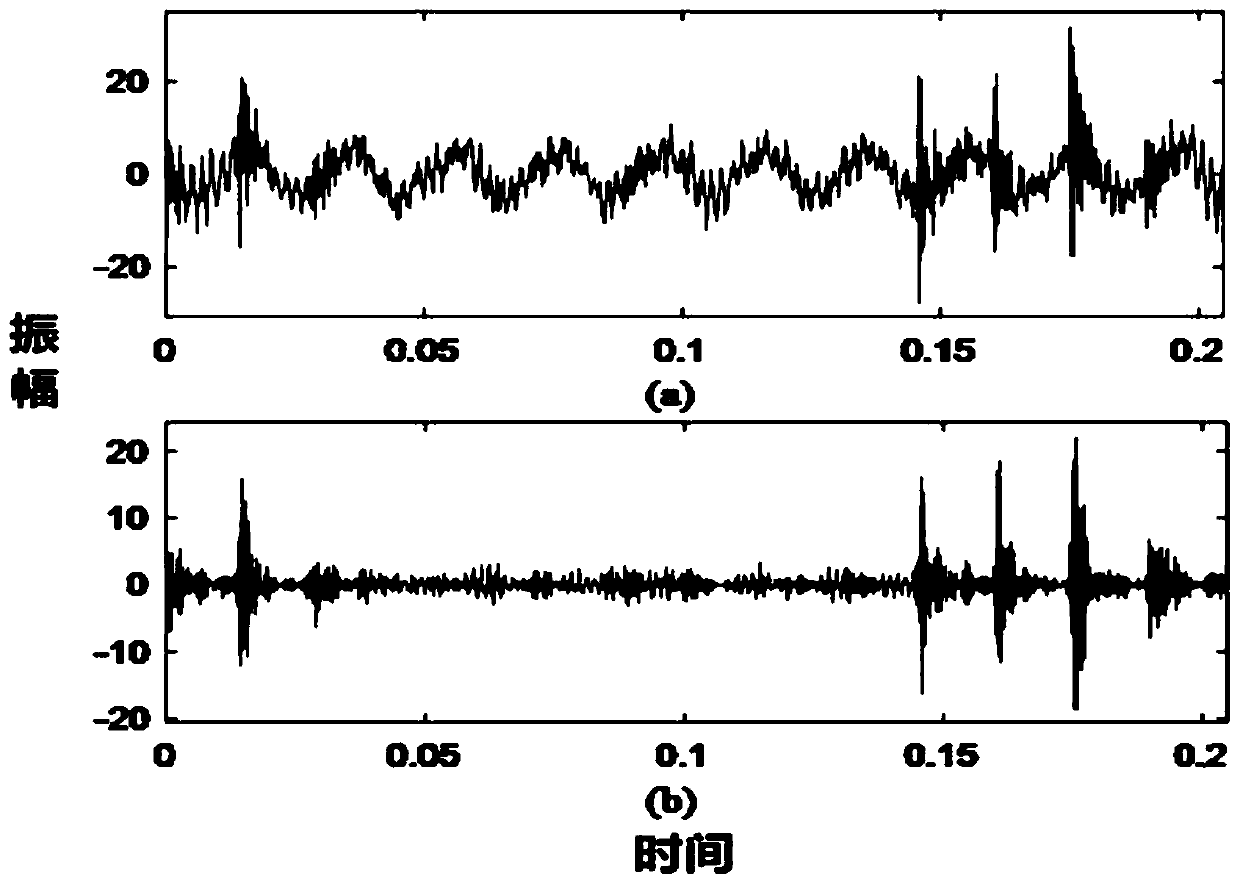

Bearing state monitoring and fault diagnosis method based on TQWT auxiliary SPC

ActiveCN110987431AMonitoring status is goodAvoid lossMachine part testingSafety indexComputer science

The invention provides a bearing state monitoring and fault diagnosis method based on TQWT auxiliary SPC. The core of the method is that TQWT has the capability of extracting bearing fault vibration characteristics. The method comprises the following steps: S1, decomposing vibration data under a normal condition into different wavelet coefficients by utilizing TQWT; S2, determining two safety indexes according to a main wavelet coefficient and a residual coefficient in state monitoring so as to carry out state monitoring; S3, determining a control upper limit through non-parametric statisticsand a unilateral confidence limit of the index; S4, establishing a Schmidt control chart of the multi-scale wavelet coefficients to perform fault diagnosis; and S5, reconstructing the fault signal byusing the inverse TQWT, and improving the detection performance by using the Hilbert envelope spectrum to obtain the fault type. The innovation of the method avoids excessive assumption of data distribution and stability caused by use of Wiener distribution, and meanwhile, the method can also effectively analyze the fault type of the bearing, and is a method which can be applied to industrial application.

Owner:JIANGSU UNIV

Rub-impact fault diagnosis method based on wavelet and harmonic component greedy sparse recognition

ActiveCN110147637AExact translation invariancePrecise Linear Phase CharacteristicsGeometric CADMachine part testingMultiscale decompositionDecomposition

The invention discloses a rub-impact fault diagnosis method based on wavelet and harmonic component greedy sparse recognition, and relates to a mechanical fault diagnosis method. Firstly, redundant second-generation wavelet packet transformation is adopted to carry out multi-scale decomposition on a signal; an amplitude signal is enhanced from the subspace signals of each scale; Hanning window Fourier transform is performed on the selected subspace, and the signal is divided into a plurality of harmonic components according to an energy concentration principle; a greedy sparse recognition algorithm of harmonic parameters is adopted to carry out iterative accurate recognition on amplitude, frequency and phase parameters; a noise reduction signal of the subspace is constructed through the harmonic parameters; through Hilbert envelope demodulation, the instantaneous amplitude and instantaneous frequency information of the subspace can be accurately obtained so as to diagnose the rub-impact fault of the rotor system. And the method has accurate translation invariance and linear phase characteristics. The mode rupture phenomenon in the decomposition process can be avoided, the parameteridentification precision is continuously improved through the iteration method, and the rub-impact fault of the rotor system is diagnosed through periodic abrupt change of the instantaneous amplitudeand the instantaneous frequency.

Owner:XIAMEN UNIV +1

Absolute anti-aliasing multi-scale filtering method for rotary mechanical structure complex harmonic dynamic process

ActiveCN109540560AImprove robustnessEliminate sources of aliasingSubsonic/sonic/ultrasonic wave measurementUsing electrical meansFrequency spectrumAnti-aliasing

The invention provides an absolute anti-aliasing multi-scale filtering method for a rotary mechanical structure complex harmonic dynamic process and relates to a mechanical fault diagnosis method. A non-contact type eddy current sensor is installed on a bearing seat of rotary mechanical equipment running at a constant rotating speed for performing de-averaging processing on the collected vibrationdisplacement signals; the frequency, amplitude and phase information of each high-energy harmonic component in the signal are extracted through a redundant Fourier transform feature; the frequency response of a lifting wavelet packet filter with the decomposition depth being J is obtained through a discrete unit pulse response sequence; weighted filtering is carried out on the extracted harmoniccomponents through a wavelet packet frequency spectrum function; the time domain waveform of a wavelet subspace sequence is observed, Hilbert envelope analysis is carried out, and the loss amplitude and the instantaneous frequency are calculated so as to determine the fault feature.

Owner:XIAMEN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com