Rotary machine composite fault diagnosis method based on group decomposition

A technology for rotating machinery and composite faults, which is applied in the testing of mechanical components, computer components, and pattern recognition in signals. It can solve problems such as inability to decompose, lack of mathematical foundation, and large bandwidth of EMD components, and achieve high frequency resolution. , the effect of high frequency resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to facilitate a better understanding of the method provided by the present invention, the following will be further elaborated in conjunction with specific examples.

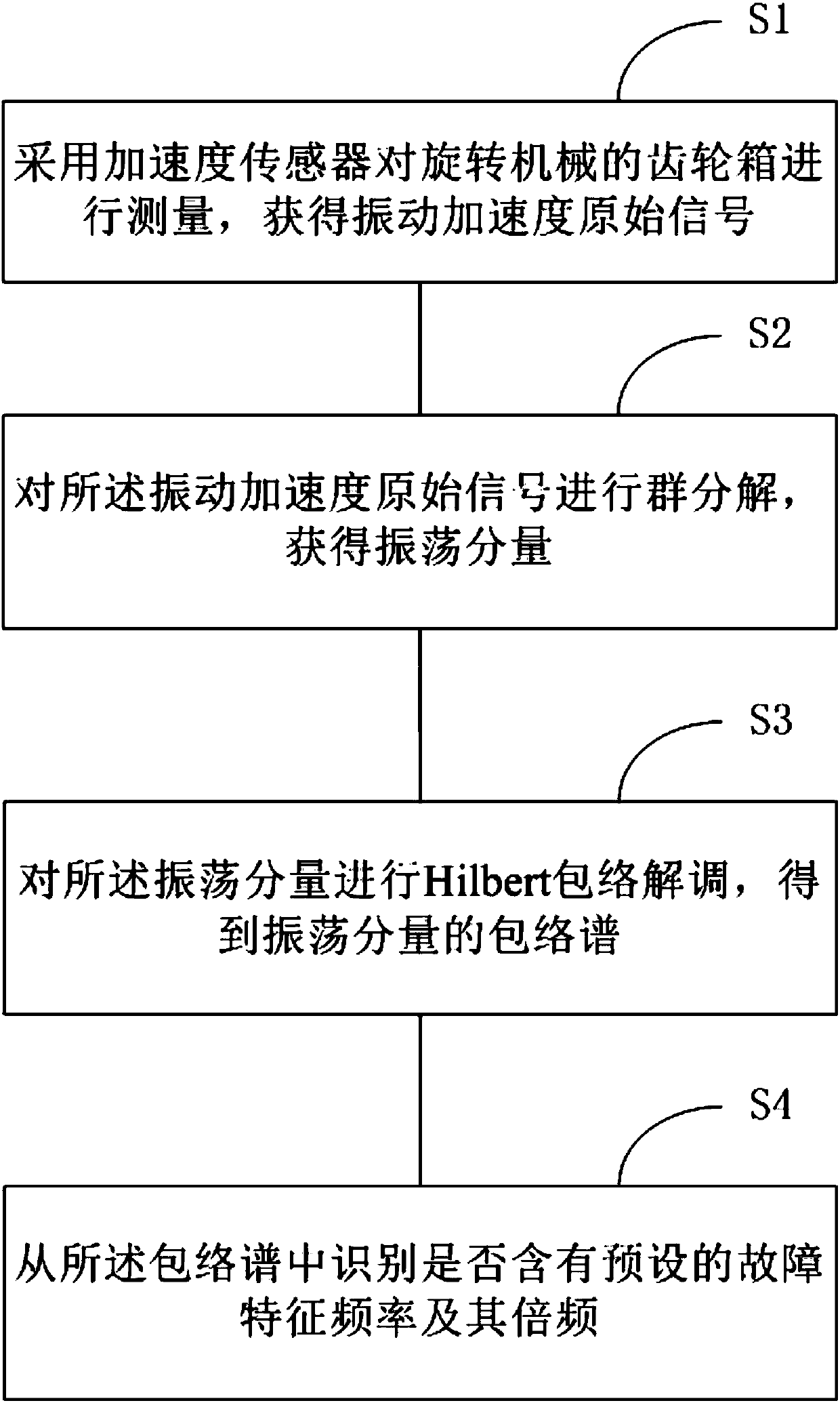

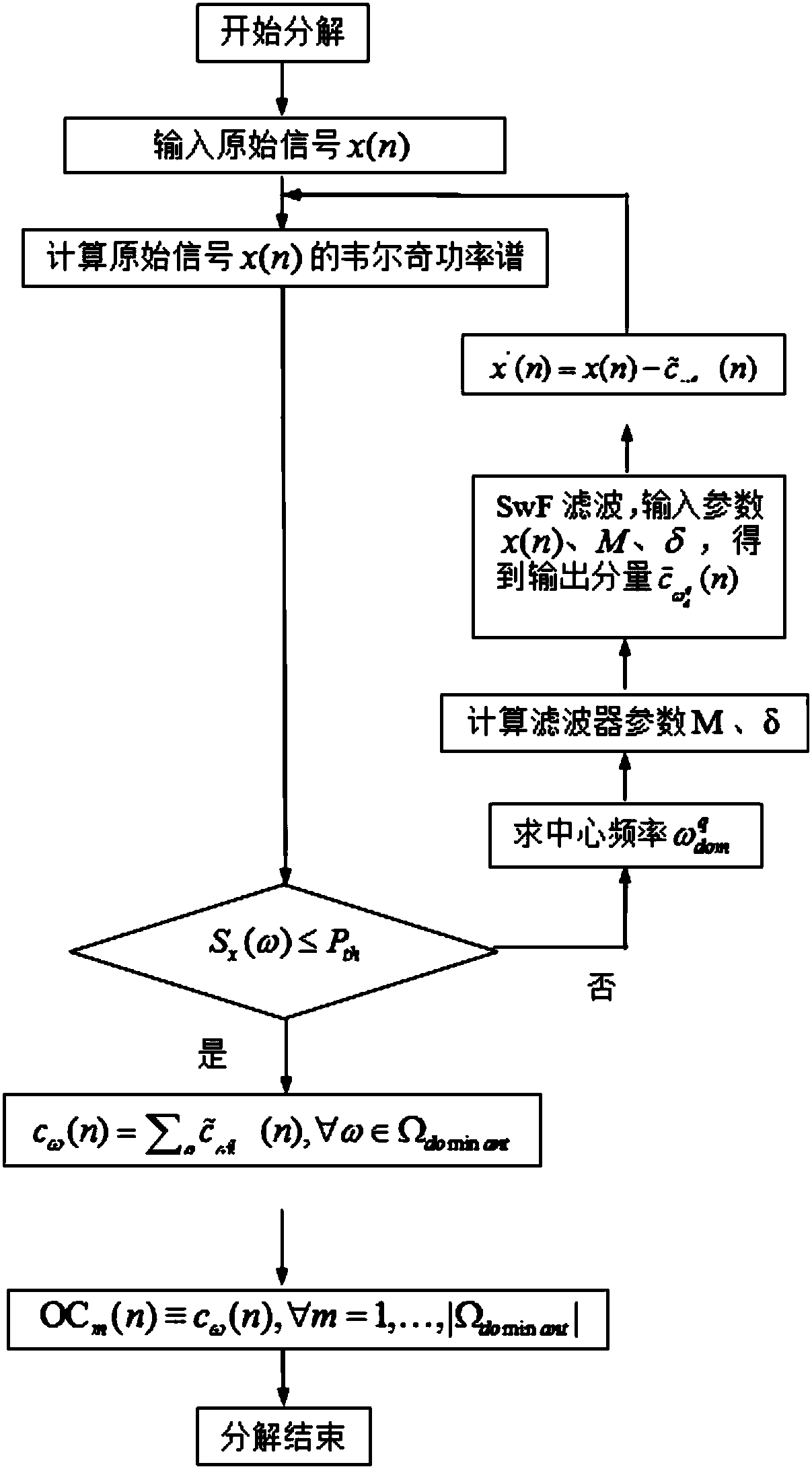

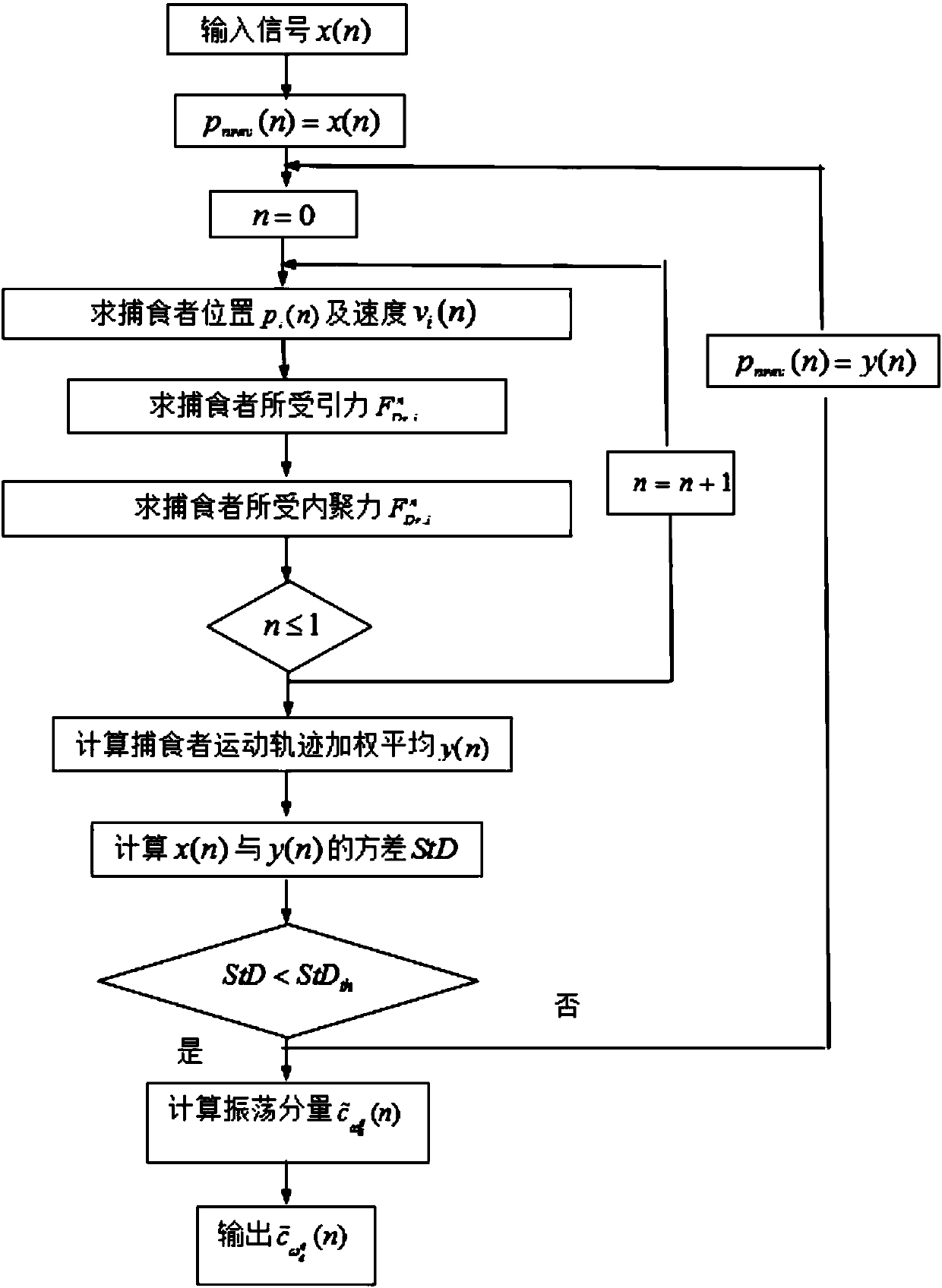

[0076] Such as figure 1 As shown, the present invention provides a method for compound fault diagnosis of rotating machinery based on group decomposition, comprising: step S1: using an acceleration sensor to measure the gearbox of the rotating machinery to obtain the original signal x(n) of vibration acceleration; step S2: Perform group decomposition on the vibration acceleration original signal x(n) to obtain the oscillation component OC m (n); Step S3: for the oscillation component OC m (n) Perform Hilbert envelope demodulation to obtain the envelope spectrum of the oscillation component Step S4: From the envelope spectrum Identify whether it contains the preset fault characteristic frequency and its multiplier: if it contains the fault characteristic frequency and its multiplier, it means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com