Hub bearing fault diagnosis method

A fault diagnosis and wheel bearing technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as difficulty in extracting wheel bearing faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

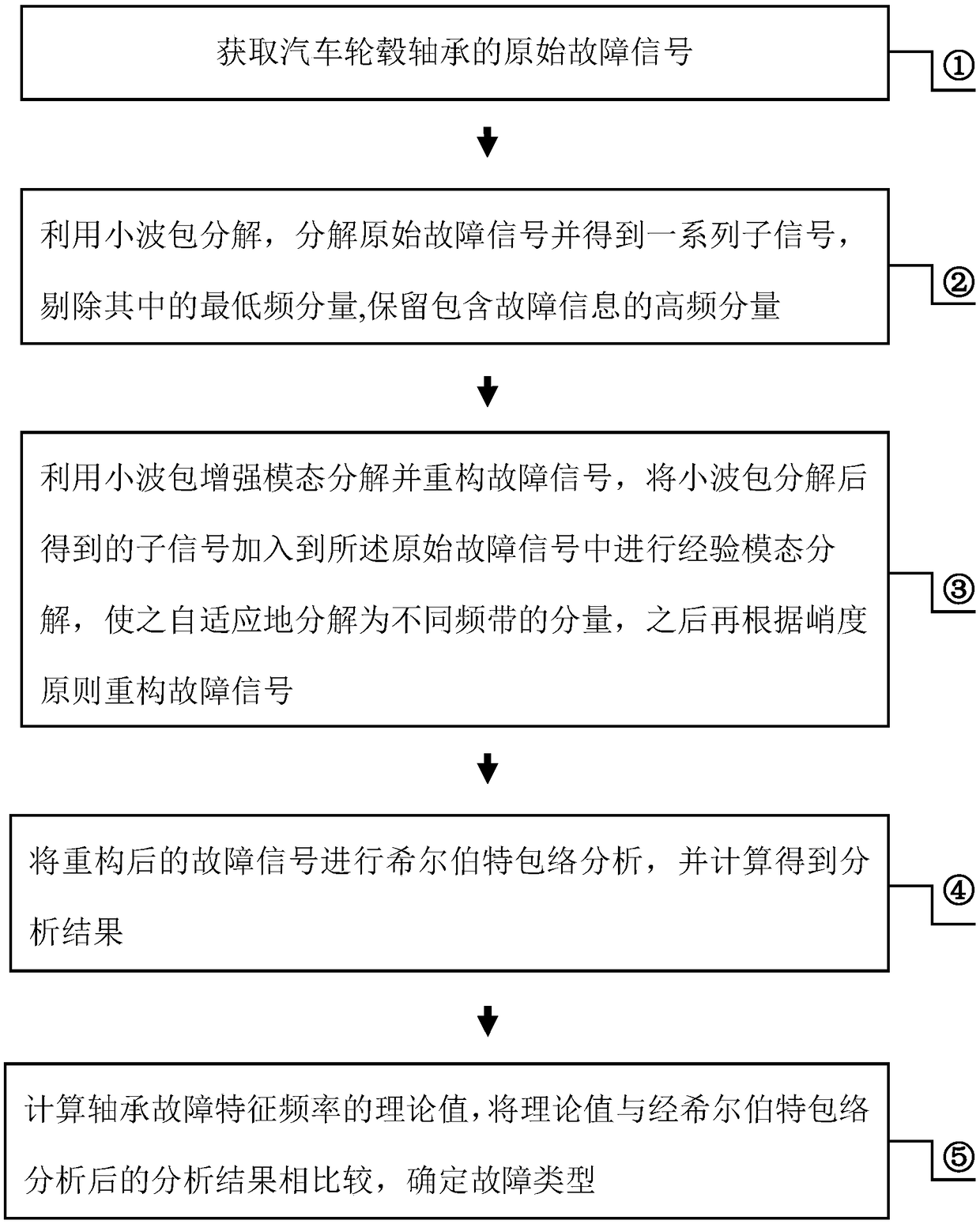

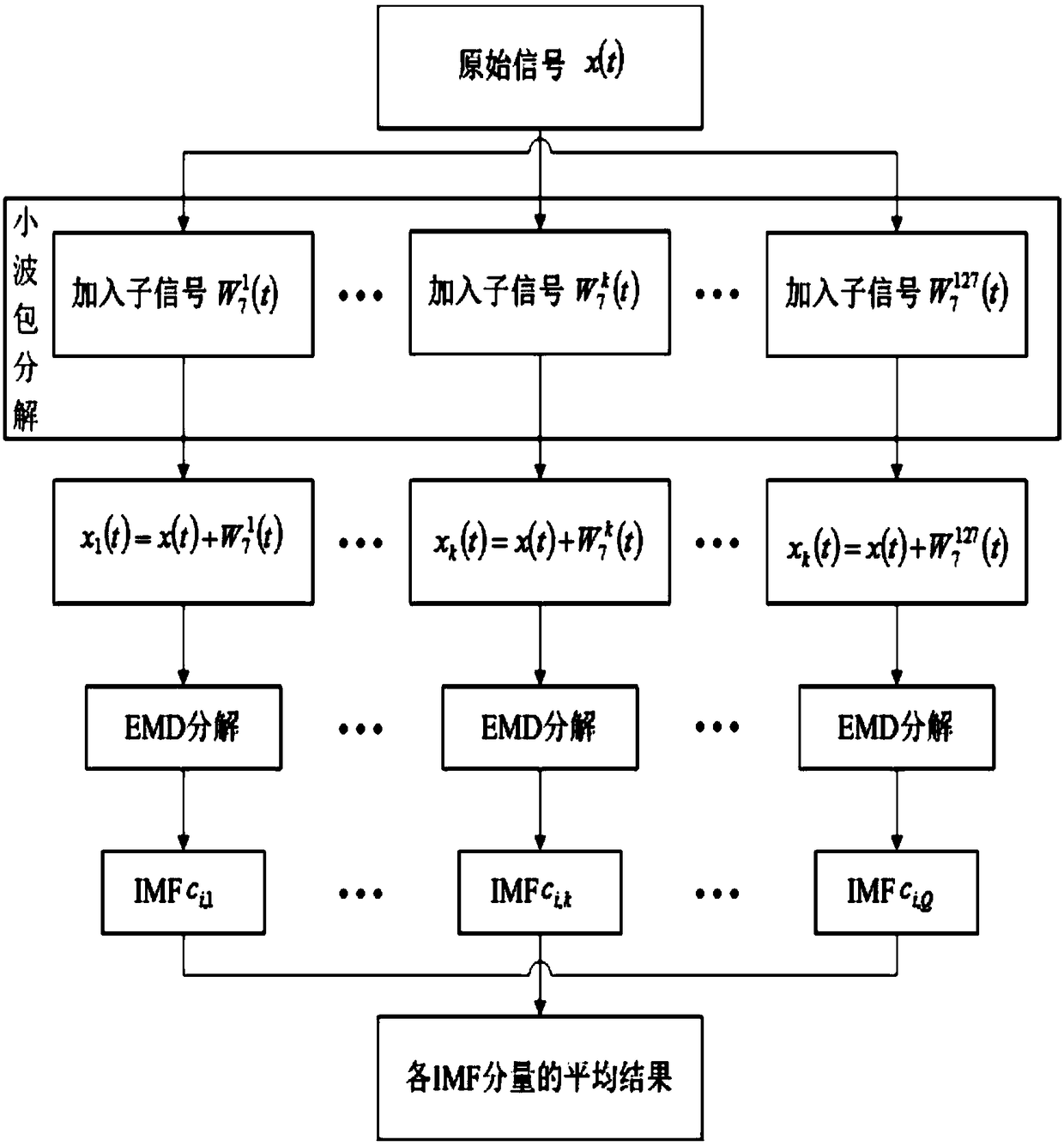

Method used

Image

Examples

Embodiment 1

[0069] Example 1: Fault Diagnosis of Hub Bearing Outer Ring

[0070] Take an automobile hub bearing as SKF7018CD / P4A type, the pitch circle diameter is 115mm, the number of rolling elements is 20, the rolling element diameter is 12.5mm, and the contact angle is 15°. The sampling frequency is 20000Hz, the bearing runs without load, and the speed is 1200r / min. According to the calculation formula of the characteristic frequency of the bearing fault outer ring: The calculated outer ring fault characteristic frequency is 179Hz.

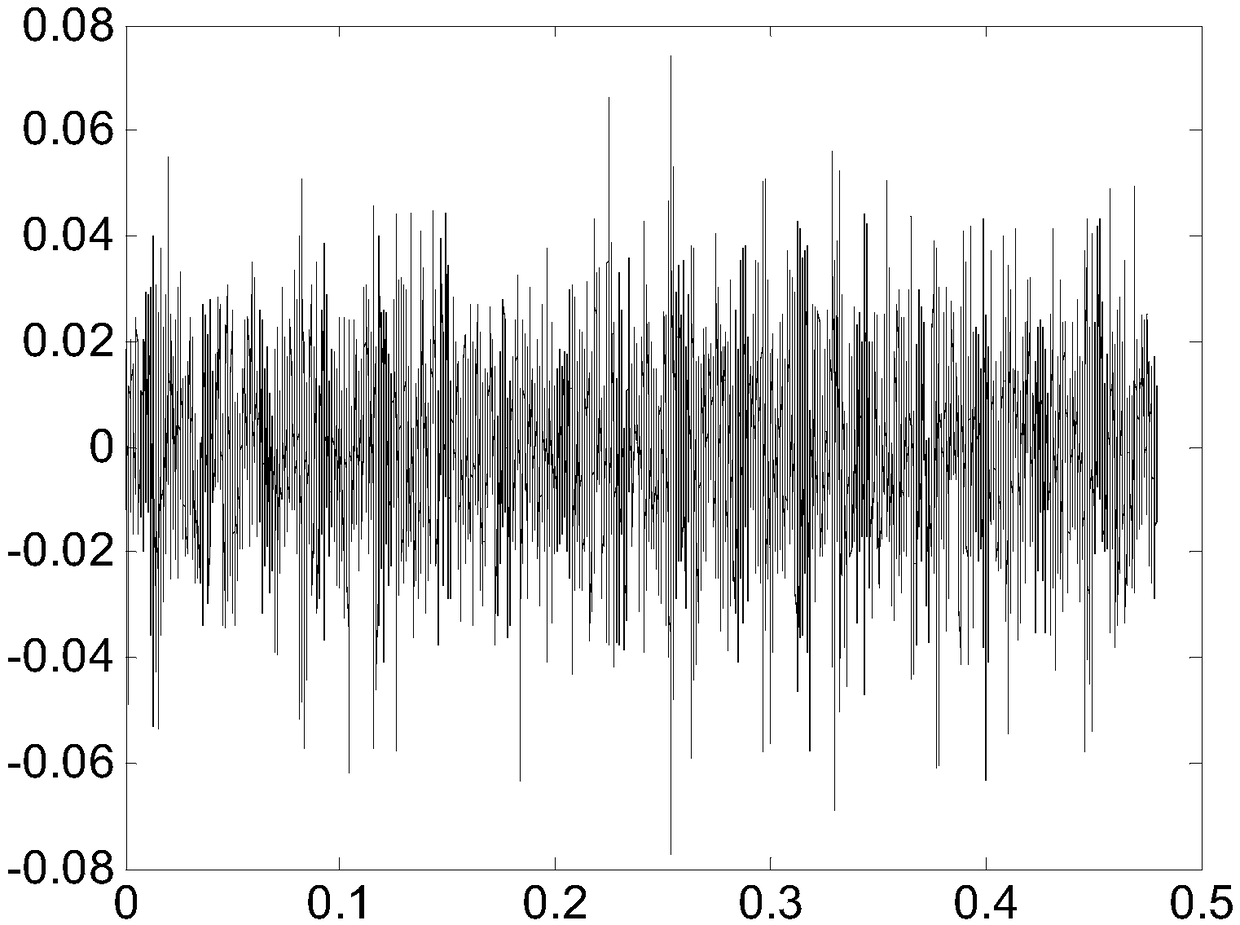

[0071] The time-domain diagram and the Hilbert envelope spectrum diagram of the original signal in the outer ring are as follows image 3 and Figure 4 As shown, due to the interference of strong background noise, Figure 4 The impact that matches the characteristic frequency of the outer ring fault cannot be found in the test, and the fault type cannot be judged. The db1 mother wavelet is used to decompose the original signal into 7 layers of wavel...

Embodiment 2

[0073] Example 2: Fault diagnosis of the inner ring of the hub bearing

[0074] Take an automobile hub bearing as SKF7018CD / P4A type, the pitch circle diameter is 115mm, the number of rolling elements is 20, the rolling element diameter is 12.5mm, and the contact angle is 15°. The sampling frequency is 20000Hz, the bearing runs without load, and the speed is 1200r / min. The formula for calculating the fault characteristic frequency of the bearing inner ring is: The calculated outer ring fault characteristic frequency is 220.9Hz.

[0075] The time-domain diagram and Hilbert envelope spectrum of the original signal in the inner circle are shown as Figure 8 and Figure 9 As shown, due to the interference of strong noise, Figure 9 The impact corresponding to the characteristic frequency of the inner ring fault cannot be found in the data, and the fault type cannot be judged. The db1 mother wavelet is selected to decompose the original signal into 7-layer wavelet packets. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com