Wind turbine generator bearing fault diagnosis method under variable speed

A technology for wind turbines and fault diagnosis, which is used in mechanical bearing testing, mechanical component testing, and machine/structural component testing. and effectiveness, the effect of eliminating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in combination with specific embodiments.

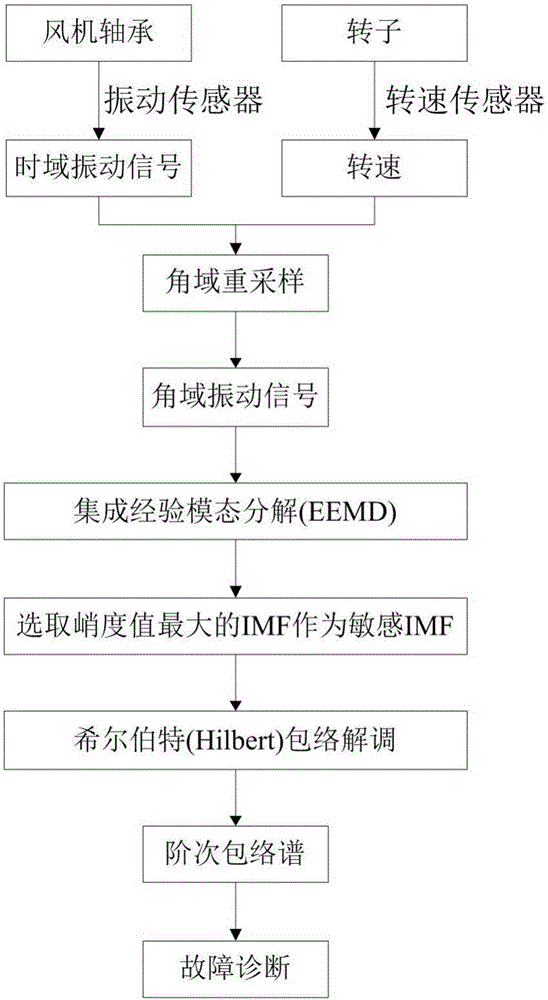

[0045] Such as figure 1 Shown is a schematic flow chart of the wind turbine bearing fault diagnosis method under variable speed in the present invention, and the specific steps are as follows:

[0046] 1. Fault Feature Extraction

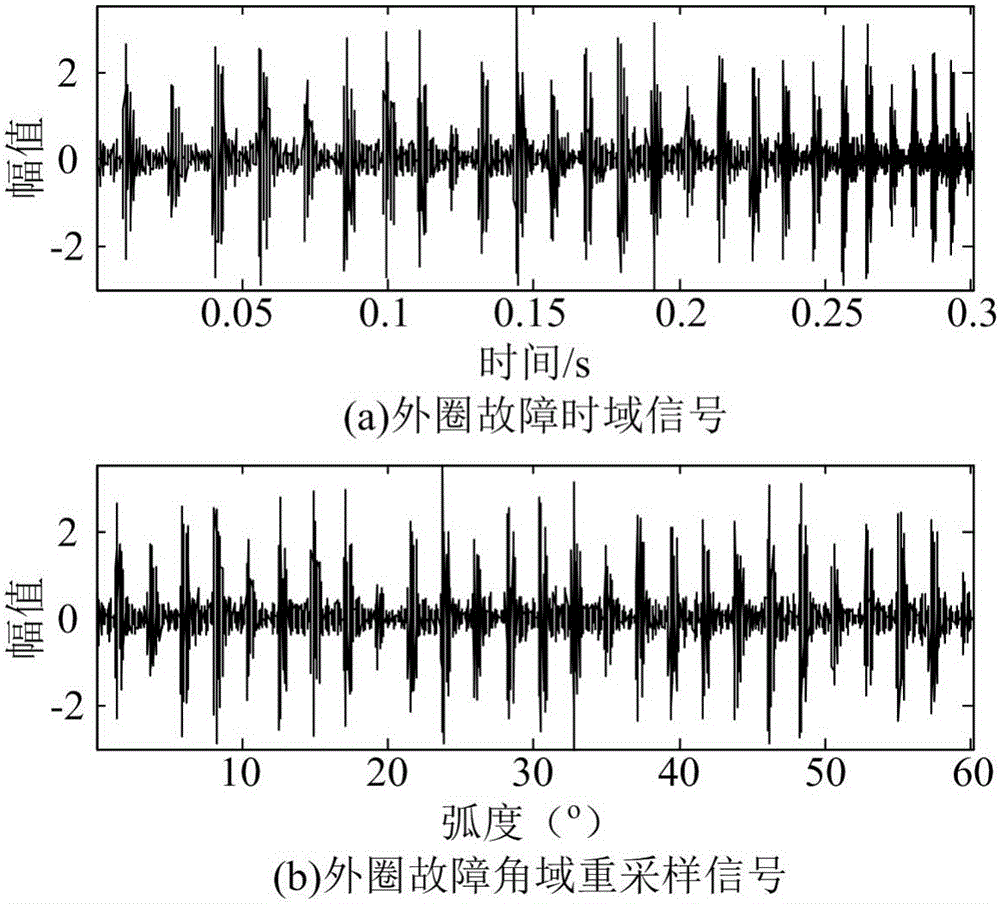

[0047] 1 angle domain resampling

[0048] Step 1: Install an acceleration sensor on the bearing of the wind turbine to collect the vibration signal x(t) of the bearing in real time, and install a speed sensor on the wind turbine to synchronously collect the speed n(t) of the main shaft of the fan.

[0049] Step 2: Use the least squares fitting method to fit the speed n(t) to obtain the speed fitting function n * (t).

[0050] Step 3: Fitting function n to rotational speed * (t) is integrated to obtain the change relationship θ(t) between the spindle rotation angle and time, and draw the rotation angle change curve according to θ(t). The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com