Intelligent fault diagnosis method for rotating machine at time-varying rotating speed

A technology for rotating machinery and fault diagnosis, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., and can solve problems such as fault diagnosis that cannot be solved by deep learning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings.

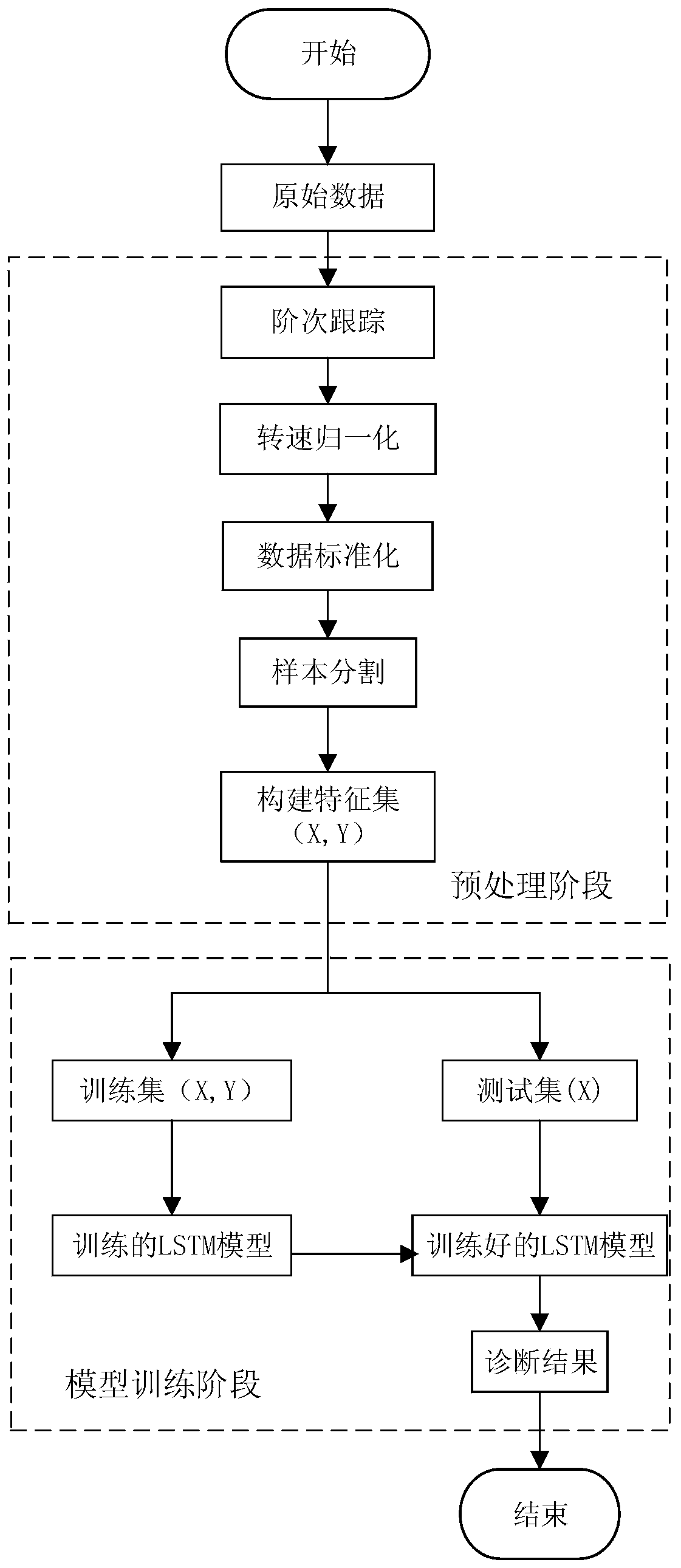

[0077] Such as figure 1 As shown, the intelligent fault diagnosis method for rotating machinery under time-varying speed combines keyless phase order tracking with deep learning methods to realize self-adaptive intelligent fault diagnosis and identification of rotating machinery under variable speed conditions, which specifically includes the following steps:

[0078] Step 1: Use the acceleration sensor to collect the vibration signal of the bearing;

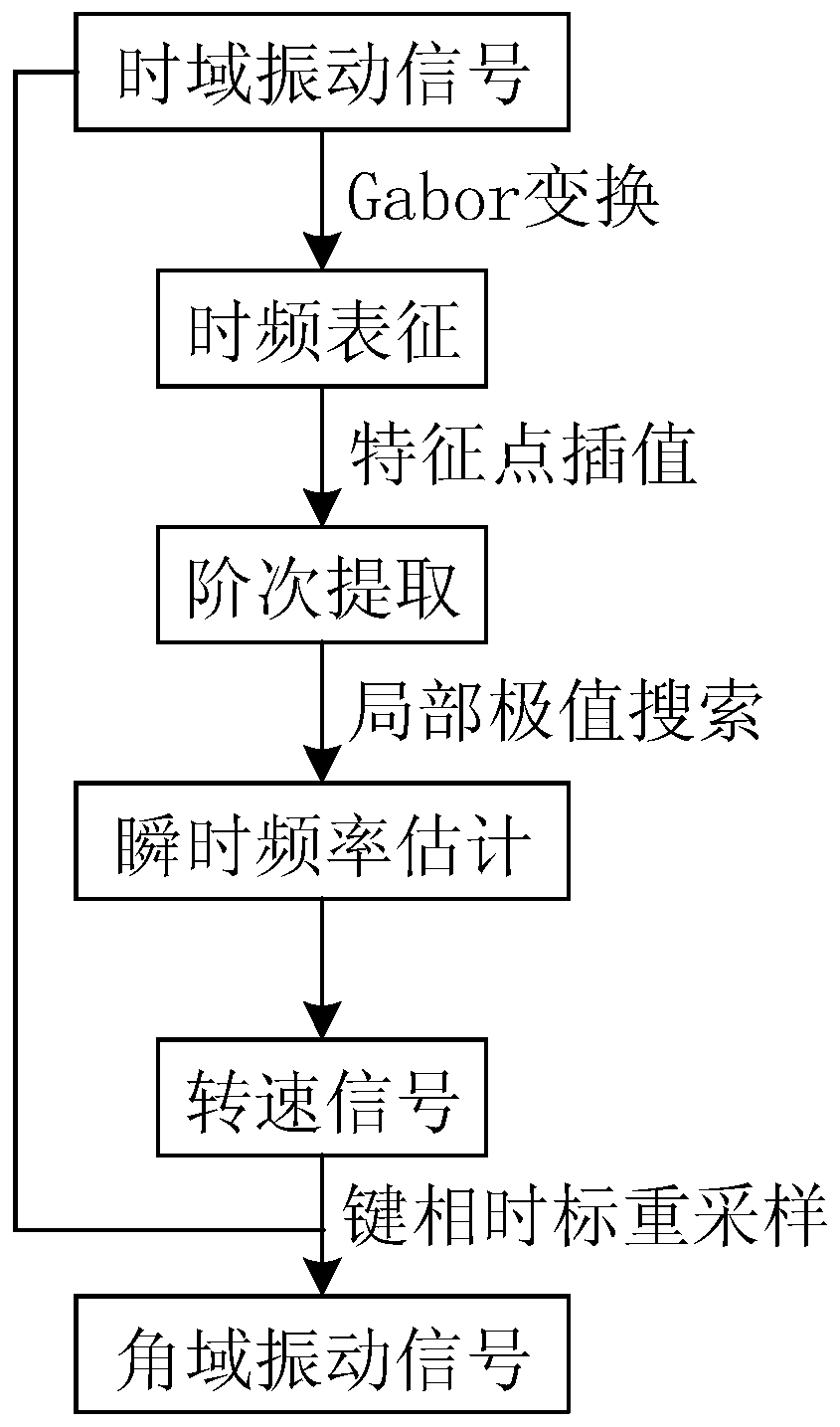

[0079] Step 2: Perform Gabor expansion on the collected signal to obtain a Gabor time-frequency diagram;

[0080] Step 3: Select an obvious order component in the Gabor time-frequency diagram, place control points on its ridge line, connect the control points with a straight line, obtain the filter center frequency line by linear interpolation, and calculate the filter neighborhood;

[0081] Step 4: Obtain the Gabor co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com