Long period fiber grating strain gauge for micro strain detection of high-temperature pipes

A fiber grating, long-period technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as long-period fiber grating strain gauges that have not yet been seen, and achieve the effect of simple structure, accurate and effective detection, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

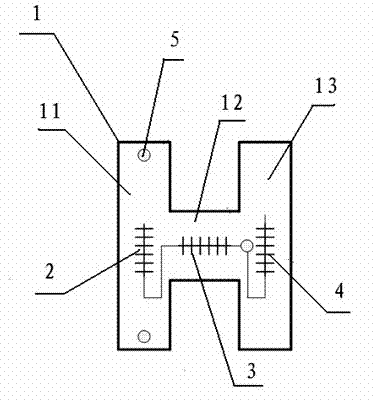

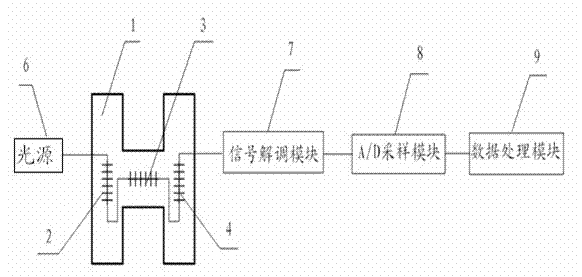

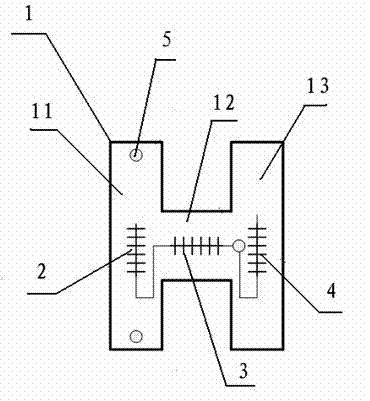

[0021] Attached below figure 1 -2 and the specific embodiment The present invention is described in further detail:

[0022] Long-period fiber grating strain gauges for micro-strain detection in high-temperature pipelines, such as figure 1 As shown, a metal substrate 1 is included, and the metal substrate 1 is H-shaped. The metal substrate 1 includes a first vertical beam 11, a second vertical beam 13, and is connected between the first vertical beam 11 and the second vertical beam 13. Between the beams 12, the first high-temperature long-period fiber grating 2 is longitudinally fixed on the first vertical beam 11, the second high-temperature long-period fiber grating 3 is laterally fixed on the beam 12, and the third high-temperature long-period fiber grating 4 is free at both ends. The ground is longitudinally fixed on the second vertical beam 13, and the first high-temperature long-period fiber grating 2, the second high-temperature long-period fiber grating 3, and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com