Flexible plate assembly axial fatigue test method

A test method and technology of a fatigue testing machine are used in the field of axial fatigue testing of flexible plate assemblies, which can solve problems such as work damage and material plastic deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

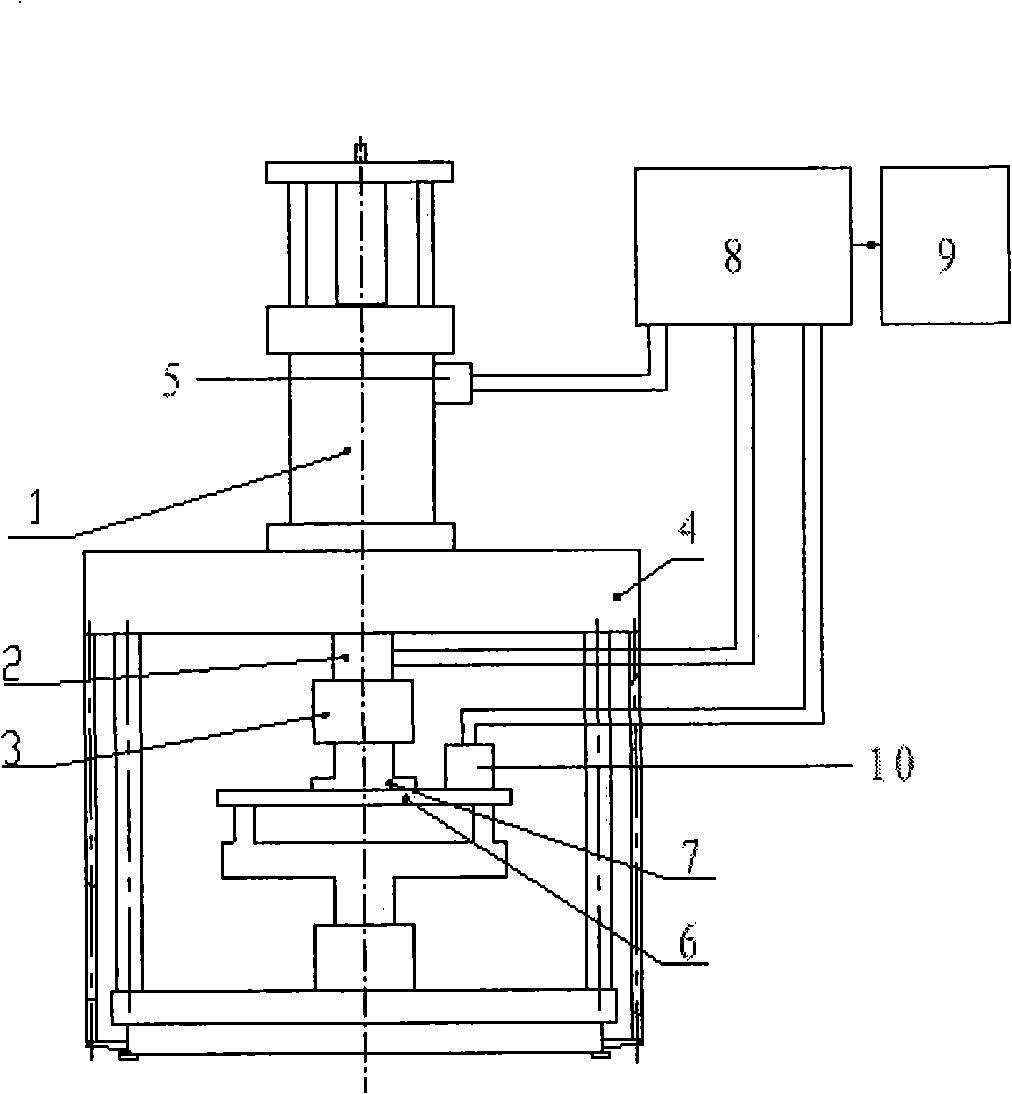

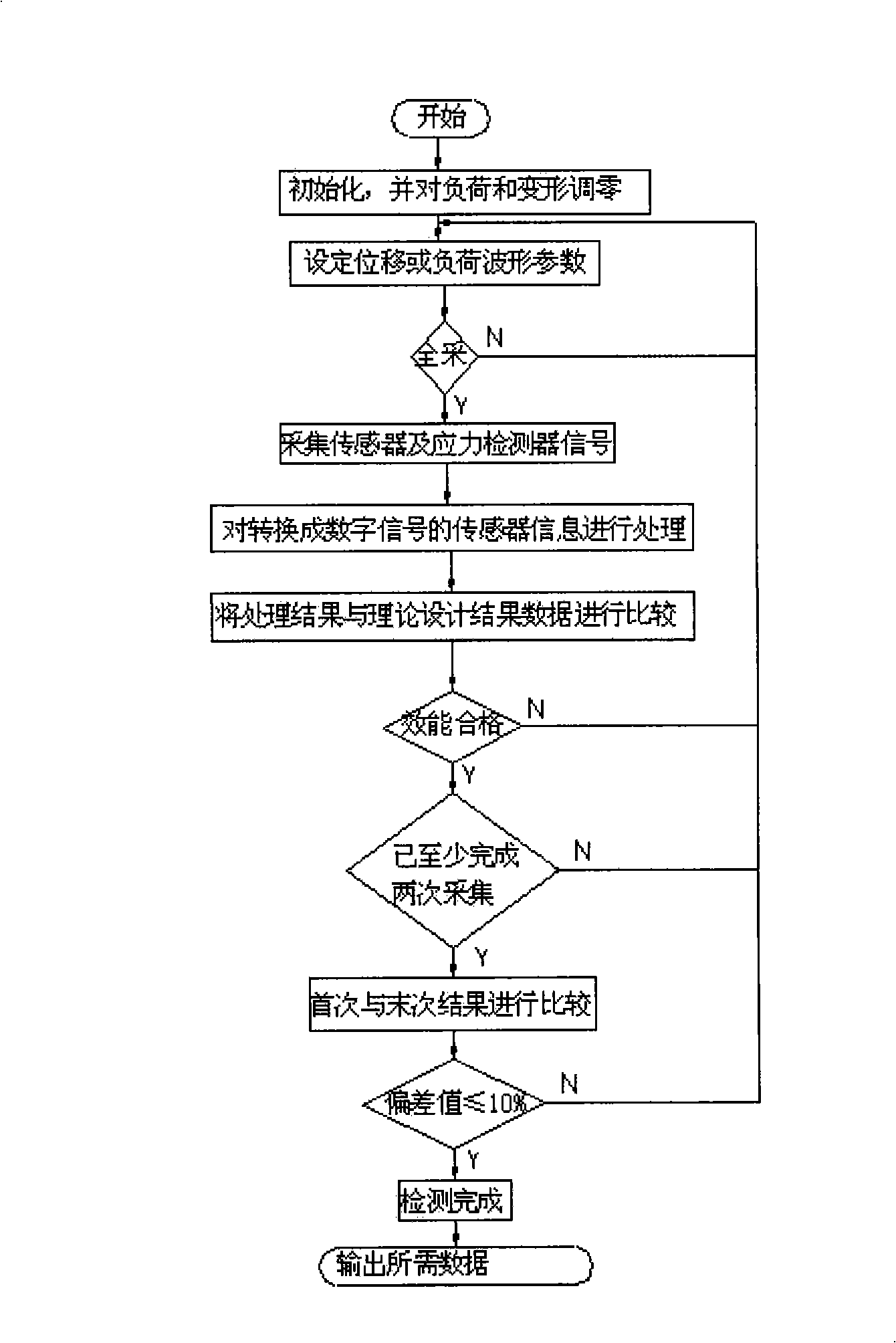

[0013] Such as figure 1 As shown, the test adopts a microcomputer-controlled electro-hydraulic servo fatigue testing machine, and a displacement sensor 5, a load sensor 2 and a stress detector 10 are arranged on the microcomputer-controlled electro-hydraulic servo fatigue testing machine. The load sensor 2 is connected between the beams 4, and the displacement sensor 5 is installed on the actuator 1 of the testing machine. Install the flexible plate assembly 6 on the tooling 7 simulating the crankshaft with bolts, and the testing machine applies a sinusoidal alternating load to the flexible plate assembly, so that the flexible plate assembly performs reciprocating loading motion according to the required displacement.

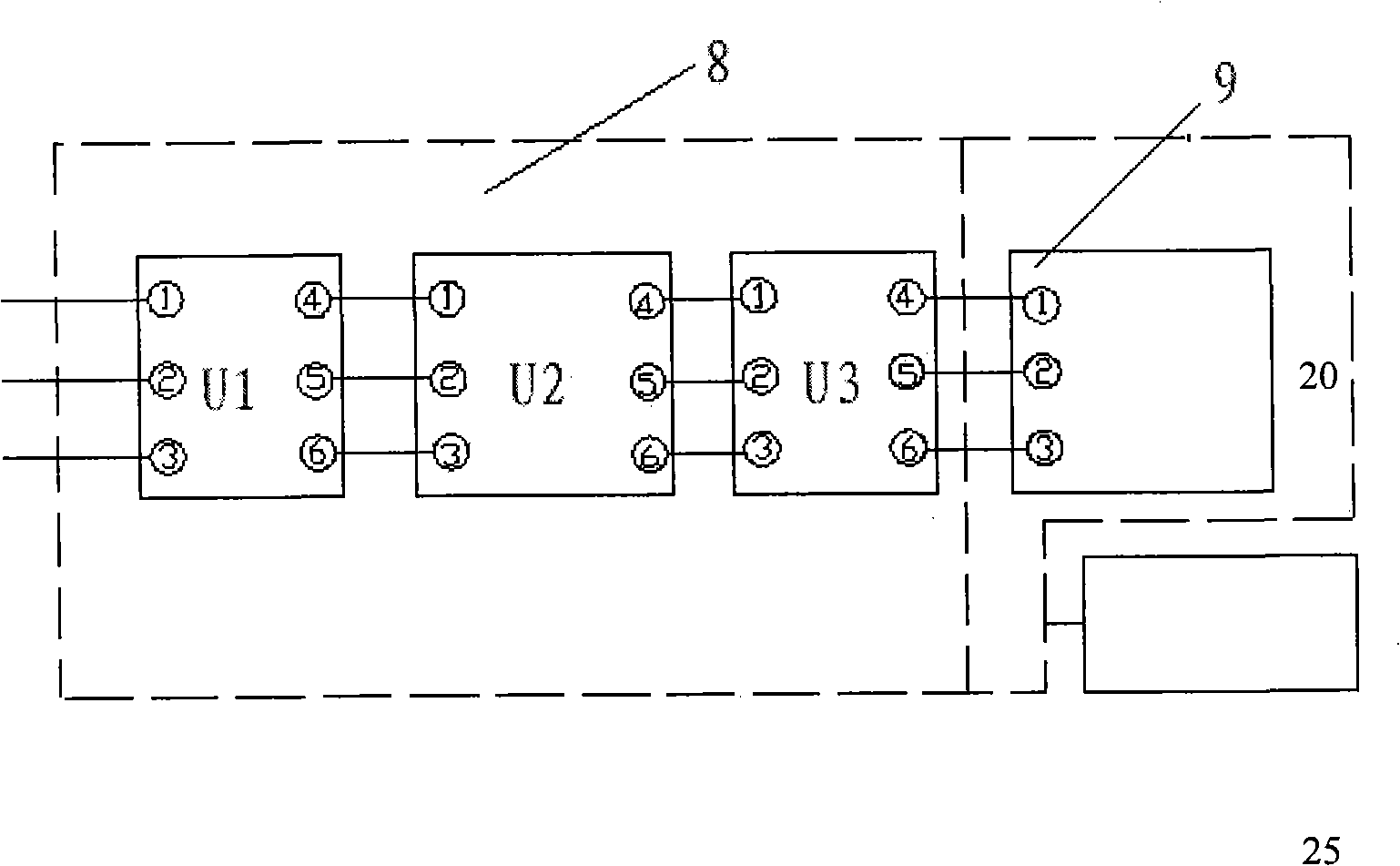

[0014] Such as figure 1 , figure 2 As shown, the signals output by the displacement sensor, the load sensor and the stress detector are transmitted to the single-chip microcomputer U2, and the single-chip microcomputer outputs the signal, so that the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com