Valve assembling production line

A technology for assembly lines and valves, applied in assembly machines, metal processing, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

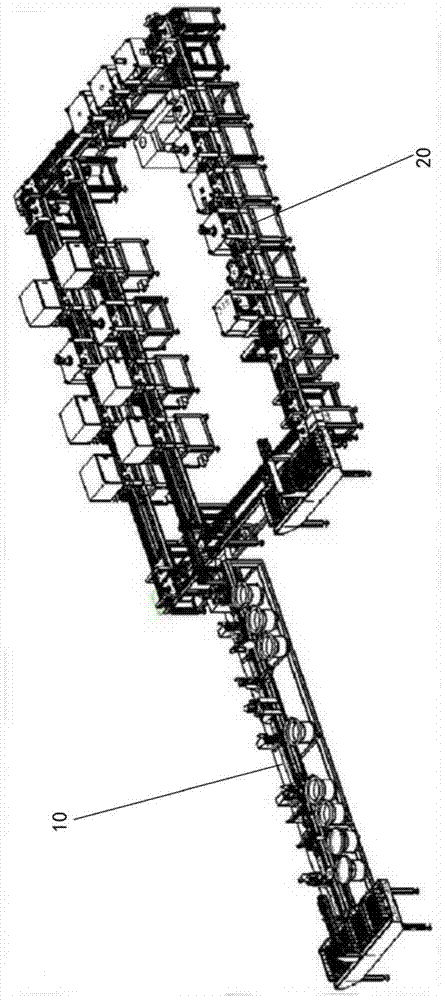

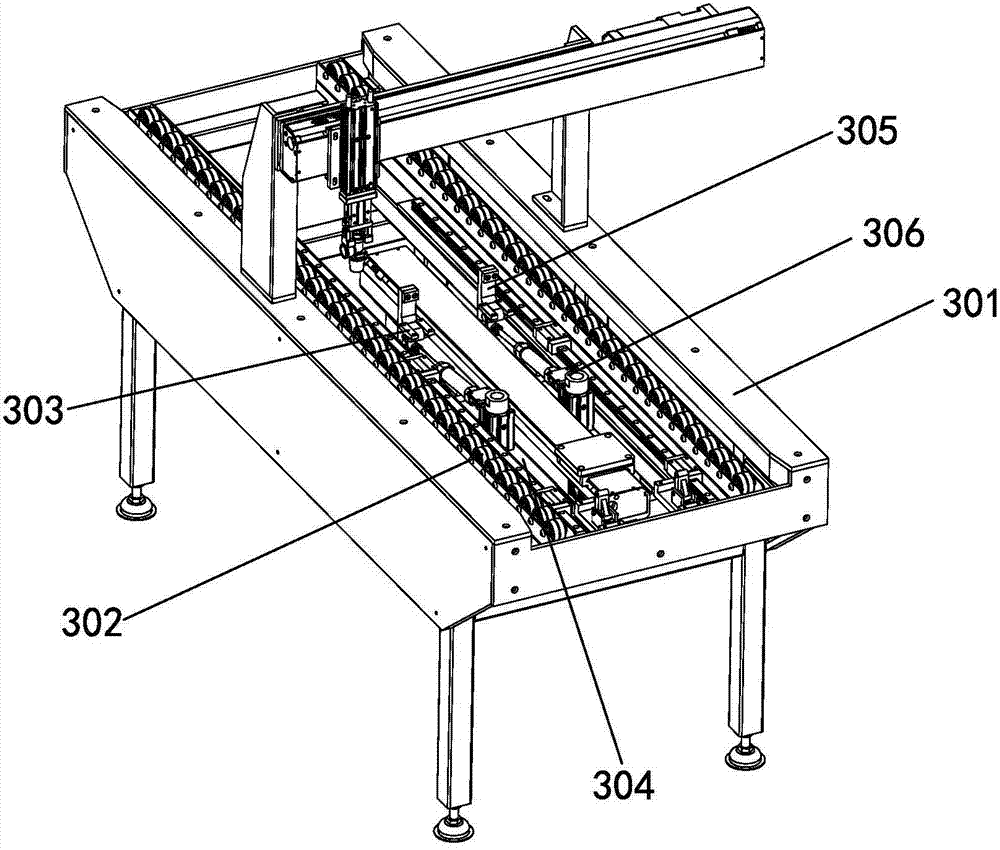

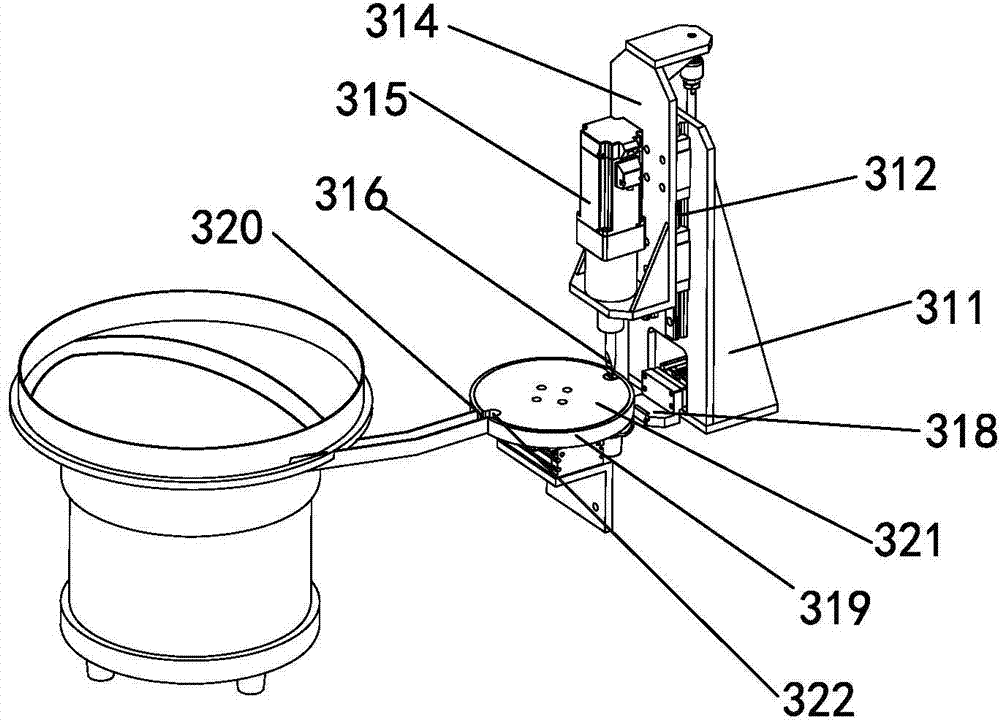

[0096] like Figure 1 to Figure 29 As shown, it is a valve assembly line disclosed by the present invention, which includes an assembly frame 10, and the assembly frame 10 is sequentially provided with a plugging device, a connecting piece device, a valve stem device, a rubber pad device, and a rubber detection device. Gasket sealing performance device, nut mounting device, nut tightening device, gasket mounting device, hand wheel mounting device, spring mounting device and spring nut mounting device, the plug mounting device, connecting piece mounting device, valve stem mounting device, The rubber pad installation device, the rubber pad sealing performance detection device, the nut installation device, the nut tightening device, the gasket installation device, the handwheel installation device, the spring installation device and the spring nut installation device are all connected by the assembly transmission device to the previous device. The completed product is sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com