Airplane engine air compressor stall detection method

An aircraft engine and fault detection technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as inability to accurately detect aircraft engines, time lag, and difficulty in finding engine stall faults in a timely and accurate manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

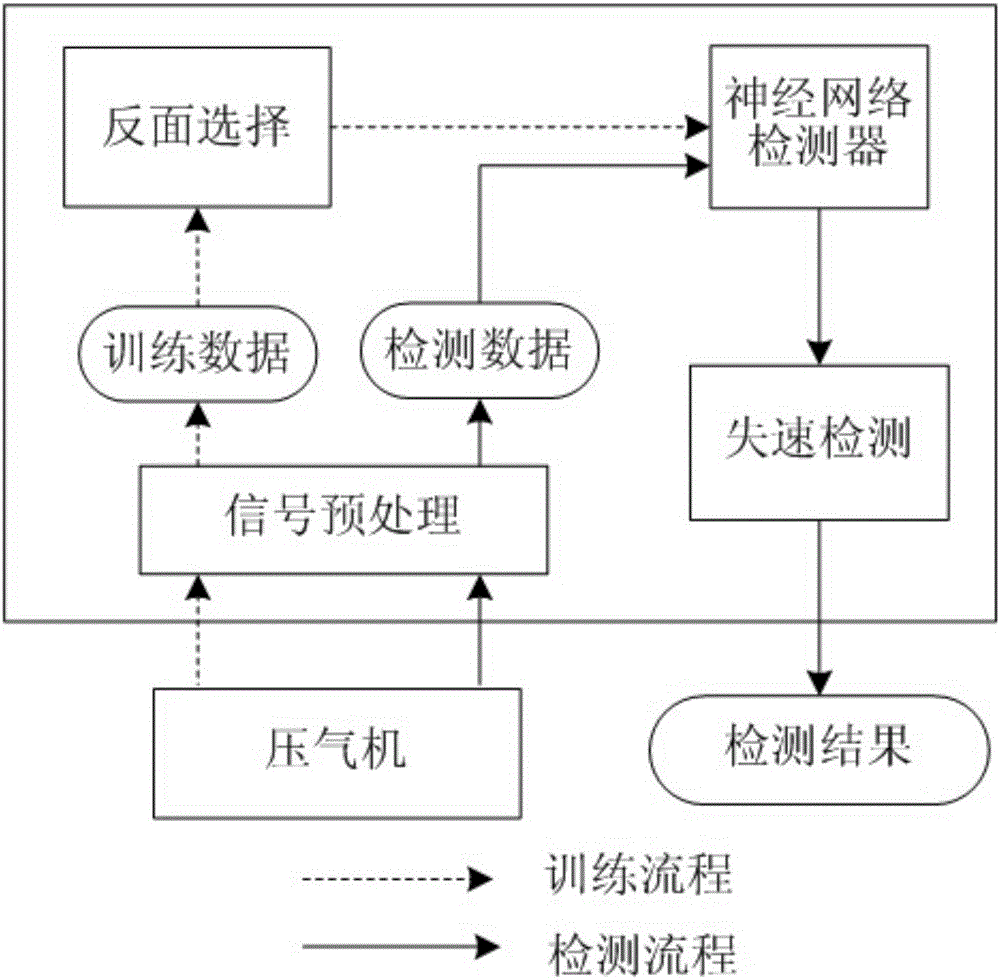

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

[0055]When the high-speed multi-stage axial flow compressor works in a steady state at medium and high speeds, if the intermediate stage stalls, it will directly cause engine surge. Therefore, for most aircraft engines using axial flow compressors, in the steady state of medium and high speeds, the anti-surge system can be instructed to work by detecting the stall signal. It can prevent the large loss of the boost ratio and efficiency of the compressor, and is of great significance for improving the stability of the engine work.

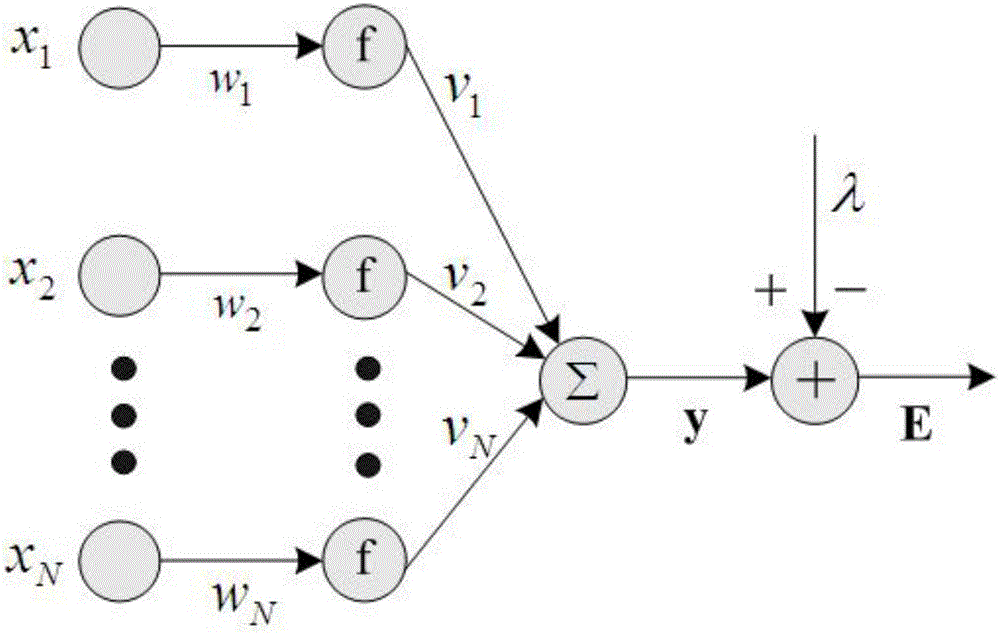

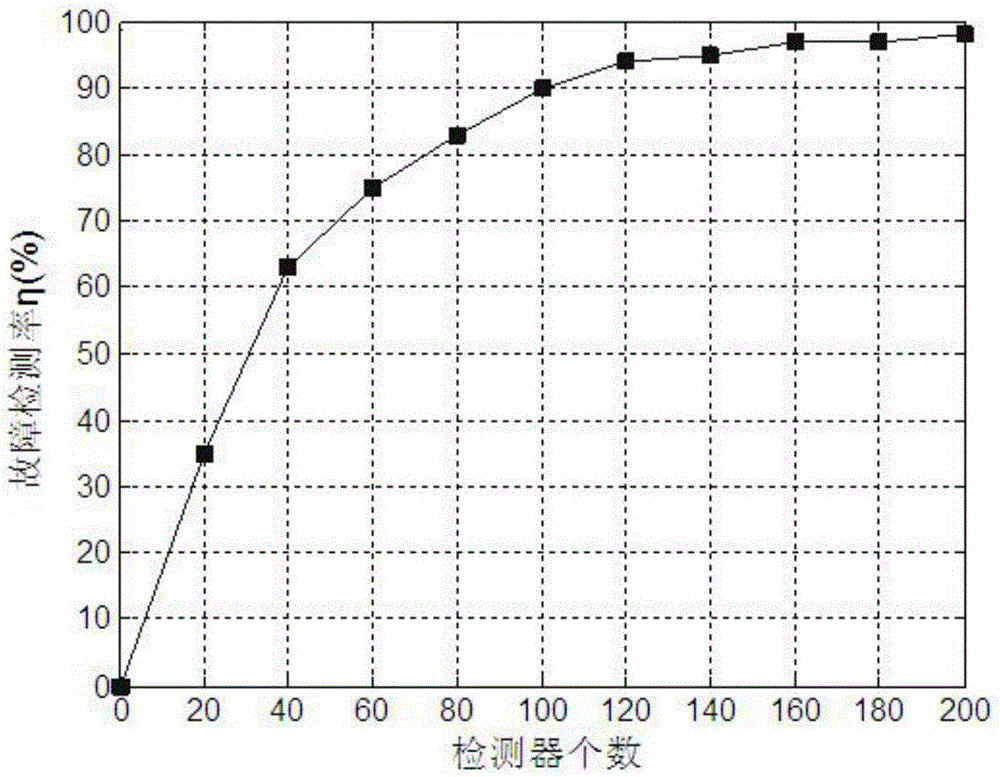

[0056] The detection of aircraft engine compressor stall failure is currently mainly judged by the performance changes of the engine after the stall, which belongs to the post-event detection method, and there is a large time lag. When the compressor stalls, the pressure fluctuation caused by the stalled air mass will change the mode charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com